Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tower Cranes Commisioning

Caricato da

pammu18Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tower Cranes Commisioning

Caricato da

pammu18Copyright:

Formati disponibili

16.

Inspecting, testing, maintaining and repairing tower cranes

16.1 'Competent person' for inspecting tower cranes 16.2 Requirements for non-destructive testing 16.3 Pre-erection inspections and tests (on ground inspection) 16. Commissioning inspections and tests 16.! Pre-operationa" inspection 16.6 Routine inspection and maintenance 16.# $nnua" inspections 16.% 1&-'ear ma(or inspection 16.) Records of inspections and maintenance 16.1& *ower crane maintenance 16.11 *ower crane repair 16.12 +econd-,and imported tower cranes -ai"ure to carr' out appropriate p"anned inspections. tests and preventative maintenance programs ma' "ead to decreased safet' and efficienc' in t,e operation of t,e tower crane. /nspection and appropriate testing must 0e carried out at sufficient"' frequent interva"s to ensure1 a. t,e parts of t,e crane su0(ect to deterioration t,roug, corrosion. damage. wear and a0rasion are rep"aced 0efore t,e' 0ecome unservicea0"e2 and 0. t,e crane is maintained in a safe and servicea0"e condition. *,e inspection and testing regime for tower cranes consists of t,e fo""owing1 a. 0. c. d. e. f. pre-erection inspection and tests2 commissioning inspection and tests2 pre-operationa" inspection2 routine inspection and maintenance2 annua" inspection2 and 1&-'ear ma(or inspection.

16.1 'Competent person' for inspecting tower cranes

*,e Workplace Health and Safety Act 1995 (P3-. #66 45) inc"udes o0"igations for persons conducting a 0usiness or underta6ing. owners and supp"iers of p"ant. $n o0"igation ,o"der w,o owns a crane ma' engage a competent person to inspect t,e crane to determine w,et,er t,e condition of t,e crane poses a ris6 to safet'. $ competent person can 0e1 a. t,e owner of t,e crane2 0. a person emp"o'ed 0' t,e owner of t,e crane (i.e. w,ere t,e owner is a"so an emp"o'er)2 or c. an independent consu"tant or t,ird part'. 16.1.1 Inspecting specific parts of a crane

$ competent person w,o ,as 0een engaged to inspect a specific part of a crane s,ou"d ,ave suita0"e e7perience and 6now"edge in t,e inspection of t,at part of t,e crane. *,is person ma' not necessari"' need e7perience in inspecting t,e comp"ete crane. -or e7amp"e1

a.

$ competent person inspecting we"ding on a crane s,ou"d ,ave suita0"e 6now"edge and e7perience in t,e inspection and testing of we"ds. inc"uding 6now"edge of non-destructive testing met,ods. and $+89:+ 1!! 1 Structural steel welding (non-;ueens"and <overnment "in6). 0. $ competent person inspecting ,'drau"ic s'stems and circuitr' on t,e crane s,ou"d ,ave suita0"e 6now"edge and e7perience in t,e inspection and testing of ,'drau"ic s'stems. c. $ competent person inspecting e"ectrica" s'stems on t,e crane s,ou"d ,ave suita0"e 6now"edge and e7perience in e"ectrica" s'stems. inc"uding t,e a0i"it' to read circuit diagrams and understand re"evant tec,nica" standards. *,is person must 0e a qua"ified and "icensed e"ectrician w,ere t,e vo"tage of t,e e"ectrica" s'stem is greater t,an !& vo"ts a"ternating current or 11! vo"ts direct current. d. $ competent person carr'ing out non-destructive testing on tower crane components s,ou"d ,ave suita0"e 6now"edge and e7perience in non-destructive testing met,ods. *,is person must 0e accredited 0' t,e 9ationa" $ssociation of *esting $ut,orities (9$*$). /n t,ese instances. t,e competent person wou"d ma6e a statement t,at t,e particu"ar part of t,e crane (e.g. t,e we"ding. ,'drau"ic s'stem or e"ectrica" s'stem) comp"ies wit, t,e re"evant tec,nica" standards. /t wou"d not 0e appropriate for t,is person to state t,at t,e comp"ete crane comp"ies wit, a re"evant tec,nica" standard or is in a safe condition. 16.1.2 Inspecting a complete crane $ competent person w,o ,as 0een engaged to inspect t,e comp"ete crane s,ou"d ,ave suita0"e 6now"edge of and e7perience in t,e inspection of cranes. $"t,oug, t,is person wou"d not necessari"' need to 0e an engineer for inspections ot,er t,an t,e 1&-'ear ma(or inspection. it is advisa0"e t,at t,e person ,ave a qua"ification in a mec,anica""' associated trade. *,is person s,ou"d 0e a0"e to ma6e a (udgement a0out t,e ma7imum a""owa0"e amount of wear and deformation in mec,anica" and structura" components. and t,e associated pass8fai" criteria. *,e person s,ou"d a"so 0e a0"e to demonstrate e7perience in t,e inspection of t,e specific crane t'pe. *,e decisions of t,e competent person s,ou"d 0e 0ased on information contained in t,e manufacturer's instructions. re"evant tec,nica" standards. sound engineering princip"es or a com0ination of a"" t,ese. =,ere a 1&-'ear ma(or inspection is to 0e carried out. t,e competent person certif'ing t,e inspection must 0e an engineer. /n forming t,eir opinion. engineers ma' use t,e advice of ot,er competent persons invo"ved in t,e crane inspection w,o are not engineers. 16.1.3 Altering a crane

=,ere an a"teration ,as 0een made to t,e design of a crane. t,e competent person must 0e an engineer wit, suita0"e 6now"edge and e7perience. /t is "i6e"' t,at t,e competent person wi"" need to perform engineering ca"cu"ations on t,e crane design to determine t,at it comp"ies wit, re"evant tec,nica" standards.

16.2 Requirements for non-destructi e testing

9on-destructive testing (93*) is t,e testing of materia"s to detect interna". surface and concea"ed defects or discontinuities. using met,ods w,ic, do not damage or destro' t,e materia" under test. 93* of specific tower crane components must ta6e p"ace at set interva"s (e.g. pre-erection tests and ma(or inspection). *a0"e 1 specifies t,e minimum frequenc' of 93* for particu"ar crane components. $"" 93* must 0e carried out 0' a competent person w,o ,as 0een accredited 0' t,e 9$*$. *,e resu"ts of 93* must 0e avai"a0"e at t,e wor6p"ace w,ere t,e crane is erected. =,en using 93* for t,e detection of crac6s in meta"s. t,e paint must 0e removed from t,e meta" surface.

Component tested 5oom c"evises Counterweig,t s,eave 0rac6et we"ds - moving counterweig,ts on"' Cruciform we"ds ("uffing cranes on"') 5utt ,ea" 0osses ("uffing cranes on"') 5and 0ra6e we"ds

!"# description Crac6 test Crac6 test

!"# frequenc$ Pre-erection Pre-erection

Crac6 test

Pre-erection

Crac6 test

Pre-erection

Crac6 test

Pre-erection Pre-erection

+"ew ring 0o"ts (w,ere s"ew Crac6 test minimum ring ,as to 0e sp"it at 1& > 0o"ts disassem0"') *ower 0o"ts Crac6 test minimum 1& > 0o"ts

Pre-erection

$"uminium s,eaves +"ew ring 0o"ts (a"" s"ew rings) 5oom c,ord t,ic6ness

Crac6 test Crac6 test a"" 0o"ts

Pre-erection ! 'ears

?ateria" t,ic6ness testing Crac6 test Crac6 test

1& 'ears

+"ew ring @'drau"ic "uffing c'"inder g"and nut @'drau"ic "uffing c'"inder and ram (rod ends and caps) 5oom "acing we"ds

1& 'ears 1& 'ears

Crac6 test

1& 'ears

Crac6 test minimum 1&> Crac6 test

1& 'ears

$-frame (a"" connector we"ds on primar' c,ords) $-frame "acing we"ds

1& 'ears

Crac6 test minimum 1&> Crac6 test Crac6 test

1& 'ears

@oo6 =e"ds on ,oo6 tro""e'

1& 'ears 1& 'ears

*a0"e 11 -requenc' of 93* testing for specific tower crane components 16.2.1 Crac% testing of &ooms and counterweig't s'ea e &rac%et welds 5ooms on non-se"f-erecting tower cranes are connected 0' pins t,at pass t,roug, ma"e and fema"e c"evises on t,e ends of eac, 0oom section. $"" we"ds on ma"e and fema"e c"evises on t,e ends of ever' 0oom section s,ou"d undergo 93* prior to eac, crane erection for non-se"f-erecting cranes. ?agnetic partic"e testing is t,e usua" met,od used for performing t,ese tests.

/n addition to carr'ing out crac6 testing of connection c"evises. "uffing crane 0ooms ,ave a ,istor' of crac6ing in t,e fo""owing areas1 a. counterweig,t s,eave 0rac6et we"ds2 0. we"ds in cruciform area2 and c. 0utt ,ea" 0osses. *,ese areas s,ou"d a"so 0e crac6 tested 0' 93* prior to eac, crane erection. 16.2.2 Crac% testing of &and &ra%es A"der designed -avco tower cranes are provided wit, 0and 0ra6es. An some of t,ese cranes. t,e stee" 0and is we"ded to an end fitting t,at ,as a pin passing t,roug, it. *,ese we"ds ,ave 0een 6nown to crac6. $"" -avco tower cranes fitted wit, 0and 0ra6es must ,ave t,e we"d 0etween t,e 0and and t,e end fitting crac6 tested 0' 93* prior to eac, erection. 9ote t,at t,ere ma' not 0e a we"d on some 0ra6e 0ands. 16.2.3 Crac% testing of slew ring &olts *,e integrit' of s"ew ring 0o"ts is critica" for ensuring 0ot, t,e mac,ine dec6 and 0oom remain attac,ed to t,e tower. +"ew ring 0o"ts ma' 0ecome damaged. and t,eir effective "ife reduced if 0o"ts are eit,er under or over-torqued. -or tower cranes w,ere t,e s"ew ring must 0e sp"it eac, time t,e crane is moved (e.g. -avco 1!&&). 1&> of s"ew ring 0o"ts must undergo 93*. 5o"ts to 0e tested are to 0e se"ected from t,e s"ew ring 0' a competent person. /f an' crac6s are detected. a"" 0o"ts must 0e tested. $"" s"ew ring 0o"ts on tower cranes. inc"uding se"f-erecting tower cranes. must undergo 93* at "east ever' five 'ears. *,e preferred s'stem of testing is to comp"ete"' remove t,e 0o"ts from t,e s"ew ring and e7amine t,em 0' magnetic partic"e testing. 16.2.( Crac% testing of tower &olts *ower 0o"ts are a critica" part of t,e crane. and permit t,e effective transfer of "oad from t,e crane 0oom to t,e crane 0ase. *ower 0o"ts ma' 0ecome damaged from (o0 to (o0. *,eir effective "ife ma' a"so 0e reduced if t,e 0o"ts are eit,er under or over-torqued. =,i"e a"" tower 0o"ts are ,ig, tensi"e 0o"ts. some are made from e7treme"' ,ig, grade stee" and ma' 0e more suscepti0"e to crac6ing. $ minimum of 1&> of tower 0o"ts must 0e crac6 tested 0' 93* prior to eac, crane erection. /f an' crac6s are found. a"" tower 0o"ts must 0e crac6 tested. $ s'stem t,at ensures a"" tower 0o"ts are tested over time is preferred. ,owever a random s'stem of testing ma' a"so 0e used. $ crane owner ma' decide to test more t,an 1&> of 0o"ts w,ere deemed necessar' (e.g. due to a ,istor' of crac6ing). *,e tested 0o"ts s,ou"d 0e identified 0' a met,od t,at does not damage t,e 0o"t. 16.2.) C'ord t'ic%ness testing

Battice-t'pe tower crane 0ooms are constructed from stee". *,e components of t,ese ma' 0e prone to interna" and e7terna" corrosion affecting t,e t,ic6ness of t,e 0oom. *,e t,ic6ness of t,e c,ord wa"" ma' a"so 0e reduced t,roug, a0rasive 0"asting of t,e 0oom. $"" main c,ord sections on tower crane 0ooms s,ou"d undergo t,ic6ness testing at interva"s not e7ceeding ten 'ears. C"trasonic t,ic6ness testing is one met,od of verif'ing w,et,er t,ere is adequate strengt, in t,e c,ords of t,e 0oom. C,ord sections must 0e reviewed for structura" adequac' w,en t,e t,ic6ness is s,own 0' testing to 0e )&> or "ess t,an )&> of t,e origina" t,ic6ness.

16.3 *re-erection inspections and tests +on ground inspection,

*ower crane components must 0e inspected and tested 0' a competent person prior to 0eing de"ivered to t,e wor6p"ace. =,ere a tower crane owner is aware a crane wi"" 0e erected w,en t,e sc,edu"ed annua" inspection is due (refer to section 16.# of t,is code). t,en t,e owner ma' consider carr'ing out an annua" inspection during t,e pre-erection inspection. *,ese inspections and tests must inc"ude t,e fo""owing1 a. 93* of we"ds on vita" components. suc, as 0oom c"evises. 0utt ,ea" 0osses. counterweig,t rope s,eave 0rac6ets2 0. 93* of tower crane 0o"ts2 c. 93* of s"ew ring 0o"ts2 d. 93* of a"uminium s,eaves2 e. t,e condition of t,e power supp"' ca0"e w,ere used2 f. t,e condition of motor 0ra6es2 g. t,e condition of t,e s"ew ring gear and pinions2 ,. air contro"s and associated va"ves2 i. t,e condition of ropes and s,eaves (e.g. erection. ,oisting. counterweig,t and tro""e') and correct rope trac6ing2 (. t,e condition of "imit switc,es and "imiting devices2 6. t,e condition of counterweig,ts2 ". t,e condition and fitment of mac,iner' guarding2 m. 0ra6e s'stems. w,ic, must 0e dismant"ed and inspected for wear and damage according to t,e fo""owing criteria1 i. dr' 0ra6esDprior to eac, erection or more frequent"' if directed 0' t,e manufacturer2 ii. wet 0ra6esDprior to eac, erection. after ! &&& ,ours of crane operation or as directed 0' t,e manufacturer2 n. a"" norma" service items. inc"uding items supp"ied 0' t,e crane manufacturer (e.g. temperature contro" units and adequate seating) 0eing maintained in a servicea0"e condition according to t,e crane manufacturer's instructions2 and o. ot,er tests specified 0' t,e manufacturer. Ance t,e tower crane components ,ave 0een de"ivered to t,e wor6p"ace. t,e' must 0e inspected for an' possi0"e damage and wear during transport. /nspections must a"so 0e made of1 a. t,e crane 0ase design and engineer's report2

0. crane ties and structure to support t,em w,ere used2 and c. t,e power supp"' and eart,ing. Crane owners s,ou"d deve"op t,eir own pre-erection inspection and test report t,at satisfies t,e requirements of t,is code and re"evant $ustra"ian +tandards. /t s,ou"d a"so ref"ect t,e specific t'pe and mode" of crane and reference a"" re"evant design drawings and test certificates.

16.( Commissioning inspections and tests

Commissioning inspections and tests must 0e carried out 0' a competent person once t,e crane ,as 0een erected and 0efore it is put into service. Ance t,e performance of t,e crane ,as 0een satisfactori"' verified 0' t,e commissioning inspections and tests. t,e crane ma' 0e p"aced into service. Commissioning inspections and tests must inc"ude1 a. 0. c. d. e. f. g. ,. i. (. 6. ". m. crane e"ectricit' supp"' w,ere used2 crane 0ase weig,ts or 0a""ast w,ere used2 tower section identification and access2 tower 0o"ts to correct tension2 c"im0ing frame and connection2 (i0 connection pins and retainers2 $-frame connections and retainers2 (i0 and dec6 pendant pins and retainers w,ere used2 mac,iner' guarding2 "ea6age in "ines. tan6s. va"ves. pumps. and ot,er parts of air or ,'drau"ic s'stems2 t,e condition of t,e ropes and s,eaves (e.g. erection. ,oisting. tro""e' and counterweig,t) and correct rope trac6ing2 iso"ating switc,es2 t,e condition and p,ase of t,e power supp"' ca0"e2 verification t,at t,e crane wiring comp"ies wit, $+89:+ 3&&& Electrical installations (known as the Australian/New ealand Wiring !ules" (non;ueens"and <overnment "in6)2 effective operation of contro"s inc"uding inter"oc6s2 effective operation of indicating devices2 effective operation of trave" dece"eration switc,es2 effective operation of ,oist upper and "ower (w,ere required) wor6ing "imit switc,es2 effective operation of warning devices2 effective operation of t,e ,oist and trave" 0ra6es w,en t,e crane is "aden to t,e ma7imum rated capacit'2 effective operation of t,e rescue contro""ed descent device2 and ot,er tests specified 0' t,e crane manufacturer.

n.

o. p. q. r. s. t. u. v.

16.(.1 Commissioning report Crane owners s,ou"d deve"op t,eir own commissioning report t,at satisfies t,e requirements of t,is code and re"evant $ustra"ian +tandards. /t s,ou"d ref"ect t,e specific t'pe and mode" of crane. and reference a"" re"evant design drawings and test certificates.

16.) *re-operational inspection

$ visua" inspection and functiona" test of t,e crane must 0e carried out 0' t,e crane operator 0efore t,e commencement of eac, wor6 s,ift. *,is s,ou"d inc"ude inspection and testing of t,e fo""owing1 a. 0. c. d. e. f. a"" re"evant items indicated in t,e operations manua"2 operating and emergenc' contro"s2 0ra6es2 safet' switc,es and inter"oc6s. inc"uding "imiting and indicating devices2 visua" inspection of t,e structure2 wire ropes to ensure t,e' are on t,e drum and correct"' reeved on t,e s,eave2 and g. wire ropes for o0vious damage. *,e resu"ts of t,e inspection must 0e entered into a "og0oo6 and 6ept wit, t,e crane. $"" persona" protective equipment s,ou"d 0e inspected to ensure it is functioning correct"'. $"" safet'-re"ated pro0"ems s,ou"d 0e recorded and rectified prior to crane use.

16.6 Routine inspection and maintenance

$ program of routine inspection and maintenance s,ou"d 0e carried out 0' a competent person in accordance wit, t,e crane manufacturer's instructions. /t s,ou"d inc"ude a visua" inspection of t,ose re"evant items t,at can 0e safe"' done w,i"e t,e crane is erected. Routine inspection and maintenance s,ou"d inc"ude t,e fo""owing1 a. a"" functions and t,eir contro"s for speed. smoot,ness of operation and "imits of motion2 0. a"" emergenc' and safet' switc,es and inter"oc6s. inc"uding "imiting and indicating devices2 c. "u0rication of a"" moving parts and inspection of fi"ter e"ements and f"uid "eve"s2 d. visua" inspection and measurements as necessar' of structura" mem0ers and ot,er critica" components suc, as 0ra6es. gears. fasteners. pins. s,afts. wire ropes. s,eaves. "oc6ing devices and e"ectrica" contactors2 e. signage. inc"uding warning signs and contro" mar6ings2 f. wear on w,ee"s and rai"s2 and g. additiona" items nominated in t,e crane manufacturer's instructions. $"" rep"acement parts and components must 0e identica" or equiva"ent to t,e origina" parts or components. $ written report must 0e provided upon comp"etion of t,e inspection.

16.- Annual inspections

$n annua" inspection 0' a competent person is required as part of re-registration requirements of t,e crane. Refer to section 6.3 of t,is code for furt,er detai". =,ere a tower crane owner is aware a crane wi"" 0e erected w,en t,e sc,edu"ed annua" inspection fa""s due. t,e owner ma' consider carr'ing out an annua" inspection prior to crane erection or during t,e pre-erection inspection (refer to section 16.3 of t,is code).

$n annua" inspection s,ou"d inc"ude a"" items specified 0' t,e crane manufacturer for annua" inspection. as we"" as re"evant items inc"uded in t,e routine inspection and maintenance programs. $nnua" inspections inc"ude1 a. a"" re"evant items in t,e pre-erection inspection and tests t,at can 0e safe"' comp"eted w,i"e t,e crane is erected2 0. t,e effective functioning and ca"i0ration of a"" "imiting and indicating devices2 c. detai"ed visua" inspection and to"erance c,ec6ing of a"" critica" structura" and wear components2 d. c,ec6ing of to"erances for wear "imit2 e. a detai"ed visua" c,ec6 for corrosion2 and f. a detai"ed visua" e7amination of critica" areas for evidence of crac6ing. $ written report must 0e provided upon comp"etion of t,e inspection. $n e7amp"e of an $nnua" crane safet' certificate is provided in appendi7 . *,is document ma' 0e used as evidence t,at t,e crane ,as received an annua" safet' inspection 0' a competent person.

16.. 1/-$ear ma0or inspection

AS #55$%& ' (ranes) hoists and winches * Safe use * +ower cranes (non,-ueensland .o/ern0ent link" specifies t,at tower cranes are to undergo a ma(or inspection 0' a competent person to assess t,eir suita0i"it' for continued operation. $ competent person carr'ing out a ma(or inspection s,ou"d 0e supervised 0' an engineer. *ower cranes must undergo a ma(or inspection ever' 1& 'ears. Cnder t,is code. t,e 1&'ear ma(or inspection must inc"ude inspection of t,e structure as we"" as mec,anica" components. $ separate inspection of t,e structure ma' not 0e required at 2! 'ears. *,e parameters of t,e 1&-'ear ma(or inspection s,ou"d 0e considera0"' more compre,ensive t,an t,e 'ear"' inspection. due to t,e amount and severit' of operation t,at a tower crane wi"" 0e e7posed to after 1& 'ears. Even if t,e crane ,as not 0een e7posed to regu"ar operation during t,e 1&-'ear period. t,e crane ma' ,ave deteriorated due to t,e wa' it ,as 0een stored or t,e environment in w,ic, it ,as operated in (e.g. dirt' or corrosive environments). *,e 1&-'ear ma(or inspection must 0e certified 0' an engineer w,o ,as e7perience in t,e inspection of tower cranes. *,e engineer ma' use t,e advice of ot,er competent persons w,en preparing t,e inspection report. $n e7amp"e of a Crane safet' certificate for a 1&-'ear ma(or inspection is provided in appendi7 !. *,is document ma' 0e used as evidence t,at t,e crane ,as received its 1&'ear ma(or inspection 0' an engineer. $ 1&-'ear ma(or inspection invo"ves t,e e7amination (usua""' stripping down un"ess ot,erwise determined 0' an engineer) of a"" wor6ing components of t,e crane. $"" covers and c"adding must 0e removed w,ere necessar' to ena0"e t,e ma(or inspection to 0e carried out. $ 1&-'ear ma(or inspection requires particu"ar attention to 0e given to t,e fo""owing1 a. structura". mec,anica". e"ectrica". instrumentation. contro" and operationa" anoma"ies2

0. c. d. e. f. g.

non-destructive testing e7amination to an appropriate standard2 contro"s and emergenc' stop2 0ra6ing s'stems2 manufacturer's safet' upgrades2 adequac' of safet' instructions and manua"s2 and t,e capacit' and via0i"it' of upgrading t,e crane to t,e requirements of t,e "atest re"evant tec,nica" standard.

16...1 1e$ inspection items for a 1/-$ear ma0or inspection *,e fo""owing items. w,ere appropriate. must 0e inc"uded in a 1&-'ear ma(or inspection for tower cranes1 a. 0. c. d. e. f. g. ,. i. (. 6. ". m. n. o. p. q. r. s"ew ring2 ,'drau"ic motors2 ,'drau"ic pumps2 va"ve 0"oc6s (0odies)2 ,oist and "uff drums2 0ra6ing s'stems2 rope s,eaves2 ,'drau"ic "uffing c'"inder2 gear 0o7es and drive s,afts2 0oom2 $-frame2 pins wit, moving parts (e.g. 0oom ,ee" pins. ram pins)2 static pins2 stee" wire ropes2 e"ectrica" s'stems2 contro" s'stems2 e"ectric motors2 ,oo6 tro""e' (non-"uffing cranes)2 and ,oo6 assem0"'.

s.

9ote t,at t,is "ist on"' specifies some of t,e generic items requiring inspection. +ome of t,e items ma' not 0e app"ica0"e to some t'pes of tower cranes 0ecause t,e feature wi"" not e7ist on t,e crane. *,e fu"" "ist of items to 0e inspected must 0e determined 0' t,e competent person. /t must not 0e assumed t,at t,e items inc"uded in t,e "ist on"' require inspection at 1&'ear"' interva"s. $"" items wi"" require some t'pe of inspection and maintenance at more frequent interva"s (i.e. at annua" and ot,er inspection interva"s) in accordance wit, t,e crane manufacturer's instructions. +ection 16.2.3 a"so requires s"ew ring 0o"ts to 0e crac6 tested 0' 93*. or rep"aced 0' new 0o"ts. ever' five 'ears. =,ere t,ere is documented evidence t,at t,e appropriate inspecting and testing ,as 0een carried out on a certain item wit,in t,e preceding two 'ears. t,is item does not ,ave to 0e stripped down in t,e 1&-'ear ma(or inspection. @owever. t,e competent person must sti"" inspect t,e safe operation of t,e item to certif' t,at it is operating safe"'. *,is requirement app"ies to t,e fo""owing items1 a. 0. c. d. s"ew ring2 ,'drau"ic motors2 ,'drau"ic pumps2 va"ve 0"oc6s2

e. ,oist and "uff drums2 and f. pins wit, moving parts. 2lew Ring a. 0. c. d. e. f. Remove t,e s"ew ring 0o"ts and sp"it t,e s"ew ring. ?easure t,e wear in t,e s"ew ring. Rep"ace worn 0earings and spacers. Carr' out 93* and repair of 0earing race. ?easure t,e 0ac6"as, and teet, widt, in t,e pinion drives and ring drive to ensure t,e' are wit,in t,e manufacturer's specifications. Ensure a"" s"ew ring 0o"ts are crac6 tested 0' 93*. or rep"aced wit, new 0o"ts.

3$draulic motors a. Remove. strip down and inspect a"" ,'drau"ic motors. 0. Rep"ace a"" worn va"ves and ot,er components. c. Ensure to"erances comp"' wit, manufacturer's specifications prior to reassem0"'. d. Ensure motors are pressure and performance tested prior to re-entering service. 3$draulic pumps a. Remove. strip down and inspect a"" ,'drau"ic pumps. 0. Rep"ace a"" worn va"ves and ot,er components. c. Ensure to"erances comp"' wit, manufacturer's specifications prior to reassem0"'. d. Ensure pumps are pressure and performance tested prior to re-entering service. 4al e a. 0. c. &loc%s +&odies, Remove. strip down and inspect a"" va"ve 0"oc6s. Rep"ace a"" worn va"ves and ot,er components. Ensure to"erances comp"' wit, crane manufacturer's specifications prior to reassem0"'. d. Ensure va"ves are pressure and performance tested prior to re-entering service. and luff drums Remove "uff drums and rep"ace drive s,aft 0earings as required. /nspect grooves on t,e "uff drum. /nspect t,e drive pinions for wear and correct a""owa0"e 0ac6"as,. Rep"ace drive pinions if t,e to"erances are outside of t,e manufacturer's specifications. e. /nspect rope anc,or points to ensure t,e' are correct for rope dimensions.

3oist a. 0. c. d.

5ra%ing s$stems a. Remove and dismant"e a"" 0ra6es from t,e crane. 0. C,ec6 pins. springs and 0us,es for correct to"erance. c. Rep"ace ru00er sea"s. d. C,ec6 pistons for correct operation. e. Ensure we"ds in 0ra6ing s'stems are crac6 tested 0' 93*. f. /nspect ,'drau"ic s'stems for "ea6s prior to reassem0"' on t,e crane. g. /nspect wear "imits on 0ra6e "inings. Rope s'ea es a. Remove a"" rope s,eaves and rep"ace 0earings as necessar'. 0. C,ec6 s,eave groove siFe and rep"ace t,e s,eave if it is outside of t,e manufacturer's specifications. c. /nspect s,eaves for crac6ing. a"ignment and damage.

d. Rep"ace s'nt,etic s,eaves if recommended to do so 0' t,e s,eave manufacturer. 3$draulic luffing c$linder a. Remove c'"inder and ram from t,e crane and strip t,e c'"inder and va"ve 0"oc6s. 0. Ensure g"and nuts are crac6 tested and t,reads are c,ec6ed for wear. c. Rep"ace sea"s and re-c,rome ram w,ere necessar'. d. Ensure t,e reassem0"ed c'"inder is pressure tested and c,ec6ed for operation and "ea6s. e. Ensure we"ds on rod ends and caps are crac6 tested 0' 93*. 6ear &o7es and dri e s'afts a. Remove and dismant"e gear 0o7es. drive s,afts and f"e7i0"e coup"ings to t,e e7tent t,at a t,oroug, inspection is possi0"e. 0. Rep"ace worn and damaged 0earings and gears. 5oom a. Ensure a"" 93* on 0oom components required in t,e pre-erection tests is carried out. 0. Ensure u"trasonic c,ord t,ic6ness of 0oom is performed. c. Ensure a minimum of 1&> of "acing we"ds on eac, 0oom section are crac6 tested 0' 93*. /f an' crac6s are found. ensure a"" "acing we"ds on t,e 0oom section are tested. A-frame a. Remove a"" pins. 0. Ensure 93* is carried out on a"" connector we"ds on primar' c,ords. c. Ensure a minimum of 1&> of "acing we"ds are crac6 tested 0' 93*. *ins wit' mo ing parts +e.g. &oom 'eel pins, ram pins, a. Remove and inspect a"" pins wit, moving parts. 0. ?easure t,e diameter of t,e pin and 0us, to ensure it is wit,in t,e manufacturer's to"erance. /f not. t,e pin must 0e remac,ined or rep"aced and t,e 0us, rep"aced. c. /nspect restraint s'stems (i.e. c,ee6 p"ates) and grease nipp"es. 2tatic pins a. Remove and inspect a"" static pins. 0. Repair pins if necessar'. 2teel wire ropes a. /nspect a"" ropes for wear. inc"uding ,oist. "uff. pendant. tro""e' and counterweig,t ropes. to ensure t,e' do not e7ceed t,e discard criteria specified in $+ 2#!) ' Steel wire rope * Application guide (non-;ueens"and <overnment "in6). /f t,e competent person considers t,at t,e rope wi"" require rep"acing wit,in t,e ne7t t,ree mont,s. rep"ace t,e rope wit, one t,at passes t,e inspection criteria of $+ 2#!) ' Steel wire rope * Application guide (non-;ueens"and <overnment "in6). 0. Ensure ropes are on"' rep"aced wit, t,e t'pe of rope specified 0' t,e crane manufacturer un"ess a professiona" engineer specifies ot,erwise. c. /nspect pins and terminations on pendant ropes. 8lectrical s$stems +'a9ardous oltage, a. Ensure a qua"ified and "icensed e"ectrician inspects switc,0oards. wiring. motors and ot,er e"ectrica" components in accordance wit, t,e app"ica0"e parts of $+ 6&2& .1 1 Safety of 0achines * Electrical e1uip0ent of 0achines (non-

;ueens"and <overnment "in6) and $+89:+ 3&&& Electrical installations (known as the Australian/New ealand Wiring !ules" (non-;ueens"and <overnment "in6). 0. Rep"ace damaged or worn components. c. Ensure sign-off is provided 0' t,e e"ectrician. Control s$stems +non-'a9ardous oltage, a. Ensure e"ectrica" contro" s'stems and components are inspected 0' a competent person. 0. Rep"ace damaged or worn components. c. Ensure sign-off is provided 0' t,e competent person. 8lectric motors a. Remove and dismant"e e"ectric motors from t,e crane. 0. /nspect 0rus,es. 0earings. switc,es and motor wiring for damage and wear. c. /nspect sp"ines and s,aft 6e'wa's for wear and crac6s. d. Ensure sign-off is provided 0' t,e competent person. 3oo% a. 0. c. trolle$ +non-luffing cranes, /nspect ,oo6 tro""e' w,ee"s for damage and wear. Rep"ace ,oo6 tro""e' w,ee"s if necessar'. Ensure we"ds on t,e tro""e' are crac6 tested 0' 93*.

3oo% assem&l$ a. 3ismant"e and dimensiona""' inspect t,e ,oo6 assem0"' to ensure it is wit,in t,e manufacturer's specifications. 0. Ensure t,e ,oo6 is crac6 tested 0' 93*. 16...2 Action following a 1/-$ear ma0or inspection -o""owing a 1&-'ear ma(or inspection. t,e crane must 0e upgraded to comp"' wit,1

a. b.

t,e current version of $+ 1 1%. 1 (ranes) hoists and winches * +ower cranes (non-;ueens"and <overnment "in6) or ot,er re"evant tec,nica" standards2 or t,e recommendations of t,e competent person w,o ,as assessed t,e crane and determined w,at needs to 0e done to provide a "eve" of safet' equiva"ent to t,at w,ic, wou"d 0e ac,ieved 0' $+ 1 1%. 1 (ranes) hoists and winches * +ower cranes (non-;ueens"and <overnment "in6) or ot,er re"evant tec,nica" standards.

$ written report detai"ing t,e resu"t of t,e 1&-'ear ma(or inspection must 0e provided to t,e crane owner.

16.: Records of inspections and maintenance

$ crane service record. suc, as a maintenance "og0oo6. of t,e significant events concerning t,e safet' and operation of t,e crane must 0e 6ept and readi"' avai"a0"e. *,e records must 0e easi"' understood. and written in p"ain Eng"is,. Records ma' 0e 6ept in an' suita0"e format. and must 0e transferred wit, owners,ip of t,e crane. $"" entries in t,e maintenance "og0oo6 are to1 a. 0. c. d. c"ear"' descri0e t,e wor6 underta6en and parts rep"aced2 0e dated2 note t,e name of t,e person carr'ing out t,e wor62 and 0e signed 0' t,e person carr'ing out t,e wor6.

3ocumentation stating t,at t,e crane ,as 0een inspected 0' a competent person. and is in a safe and satisfactor' condition. s,ou"d 0e readi"' avai"a0"e. *,e c,ec6s. ad(ustments. rep"acement of parts. repairs and inspections performed. and a"" irregu"arities or damage concerning t,e unit's safe use. must 0e recorded. /n addition. a"" comp"ete routine. annua" inspection and 1& 'ear ma(or inspection reports must 0e maintained and made avai"a0"e for e7amination as required.

16.1/ #ower crane maintenance

$ tower crane preventative maintenance program s,ou"d 0e esta0"is,ed 0ased on t,e wor6ing environment and t,e frequenc' and severit' of use of t,e crane. *,e fo""owing items s,ou"d form part of an effective maintenance program1 a. rep"acement parts and components s,ou"d 0e identica" or equiva"ent to t,e origina" equipment parts and components2 0. a specific rectification program s,ou"d 0e carried out w,ere past e7perience ,as s,own particu"ar pro0"ems wit, a crane2 and c. a"" safet'-re"ated ma"functions and pro0"ems s,ou"d 0e corrected 0efore t,e crane is returned to service. *,e owner of t,e tower crane must ensure t,at1 a. t,e necessar' faci"ities and s'stems of wor6 are provided and maintained so as to minimise t,e ris6s to ,ea"t, and safet' of persons maintaining. inspecting. repairing or c"eaning t,e crane2 0. inspections. maintenance and c"eaning are carried out ,aving regard to procedures recommended 0' t,e crane designer and manufacturer. or t,e re"evant $ustra"ian +tandard. or as deve"oped 0' a competent person2 c. repair. inspection and. w,ere necessar'. testing is carried out 0' a competent person2 d. a"" safet' features and warning devices of t,e crane are maintained and tested2 e. w,en t,e crane ,as 0een damaged to t,e e7tent t,at its function or condition is impaired. resu"ting in increased ris6 to ,ea"t, or safet'. a competent person assesses t,e damage and advises t,e owner of1 i. t,e nature of t,e damage2 and ii. w,et,er t,e crane is a0"e to 0e repaired. and if so. w,at repairs must 0e carried out to minimise ris6s to ,ea"t, and safet'2 f. repairs to t,e crane are carried out so as to retain t,e crane wit,in its design "imits2 and g. annua" maintenance. repair and inspection records are 6ept for t,e crane.

16.11 #ower crane repair

$"" worn or damaged parts of a crane t,at constitute a ,aFard. impair t,e operation of t,e crane. or ma' constitute a ,aFard 0efore t,e ne7t routine inspection. are to 0e repaired or rep"aced. $"" repaired or new parts must comp"' wit, t,e crane manufacturer's recommendations or specifications. =,ere t,ese are not avai"a0"e. t,e repaired or new parts must comp"' wit, t,e recommendations of a competent person. ta6ing into account t,e design requirements of $+ 1 1%. 1 (ranes) hoists and winches * +ower cranes (non;ueens"and <overnment "in6) or an' ot,er re"evant tec,nica" standard.

16.12 2econd-'and imported tower cranes

*,e importance of t,e maintenance ,istor' of second-,and imported tower cranes from overseas cannot 0e underestimated. 5efore a second-,and imported tower crane can 0e operated for t,e first time. t,e owner of t,e crane must ensure t,e crane is su0(ect to an annua" inspection. or a 1&-'ear ma(or inspection if t,e crane is at "east 1& 'ears o"d.

Potrebbero piacerti anche

- California Motorcycle Cheat Sheet, CA DMVDocumento31 pagineCalifornia Motorcycle Cheat Sheet, CA DMVerick gordonNessuna valutazione finora

- Hino Tipper Risk AssesmentDocumento9 pagineHino Tipper Risk AssesmentGnamaSayaNessuna valutazione finora

- Crane Inspection ChecklistDocumento1 paginaCrane Inspection Checklistrig4Nessuna valutazione finora

- Suspended personnel platform checklistDocumento1 paginaSuspended personnel platform checklistmark lester caluzaNessuna valutazione finora

- Webbing Sling Safety Inspection Checklist Report PilotDocumento1 paginaWebbing Sling Safety Inspection Checklist Report PilotThirumaran MuthusamyNessuna valutazione finora

- Shackle Checklist FormDocumento1 paginaShackle Checklist FormРашад ИбрагимовNessuna valutazione finora

- Pre-use crane inspection checklistDocumento2 paginePre-use crane inspection checklistBeyar. Sh100% (2)

- SWP-06 Lifting Operation DaimanDocumento4 pagineSWP-06 Lifting Operation DaimanHassan AbdullahNessuna valutazione finora

- Hand and Power Tool SafetyDocumento50 pagineHand and Power Tool SafetyAntonio Jose De JesusNessuna valutazione finora

- Hand and Power Tool SafetyDocumento50 pagineHand and Power Tool SafetyAntonio Jose De JesusNessuna valutazione finora

- Hot Works SafetyDocumento33 pagineHot Works Safetypammu18Nessuna valutazione finora

- Rigging & Lifting Safety EssentialsDocumento70 pagineRigging & Lifting Safety Essentialspammu1886% (14)

- Hand and Power Tool SafetyDocumento50 pagineHand and Power Tool SafetyAntonio Jose De JesusNessuna valutazione finora

- Checklist Inspection For CraneDocumento1 paginaChecklist Inspection For CraneMohammed Rashid Al-kalbaniNessuna valutazione finora

- IR-II U&O DBN PRE-LIFT CHECKLISTDocumento1 paginaIR-II U&O DBN PRE-LIFT CHECKLISTmiaicarbaNessuna valutazione finora

- Luffing Tower Crane Preshift InspectionDocumento1 paginaLuffing Tower Crane Preshift InspectionEdmond KeraNessuna valutazione finora

- NO. Activity Reference Document Verified Document Document ReviewDocumento6 pagineNO. Activity Reference Document Verified Document Document ReviewHandoko ArimurtiNessuna valutazione finora

- Crawler Crane Checklist Rev 0Documento2 pagineCrawler Crane Checklist Rev 0Maizatul Akmar Manshor100% (2)

- Egyptian Drilling Company Non-Routine Lift ChecklistDocumento2 pagineEgyptian Drilling Company Non-Routine Lift Checklistmohamed atef0% (1)

- Truck Crane Inspection FormDocumento3 pagineTruck Crane Inspection FormAdhy Darmawan100% (1)

- Tower Crane Inspection ChecklistDocumento4 pagineTower Crane Inspection Checklistmailme_viju100% (1)

- Monthly Crane Inspection ChecklistDocumento2 pagineMonthly Crane Inspection Checklistslamet4riadiNessuna valutazione finora

- 2014 Hoisting Rigging Plan 10-6-14 Final Posted To WebsiteDocumento23 pagine2014 Hoisting Rigging Plan 10-6-14 Final Posted To WebsiteSudiatmoko Supangkat100% (1)

- Vehicle Crane Inspection ChecklistDocumento2 pagineVehicle Crane Inspection ChecklistSn Ahsan100% (1)

- Checklist For Equipment Inspection BOOM PLACERDocumento2 pagineChecklist For Equipment Inspection BOOM PLACERIdada Ezekiel100% (1)

- Tower Crane ChecklistDocumento1 paginaTower Crane ChecklistbeshoyNessuna valutazione finora

- New Mobile Crawler Crane ChecklistDocumento2 pagineNew Mobile Crawler Crane ChecklistsunilNessuna valutazione finora

- Crane Mounted On Truck Inspection Report MH 12 FC8311Documento12 pagineCrane Mounted On Truck Inspection Report MH 12 FC8311Safety DeptNessuna valutazione finora

- Manlift Inspection Checklist Pre-Shift Inspection: Inspection Explanation Basic Inspection (From Ground)Documento1 paginaManlift Inspection Checklist Pre-Shift Inspection: Inspection Explanation Basic Inspection (From Ground)Rocky BisNessuna valutazione finora

- Boom Placer Inspection ChecklistDocumento1 paginaBoom Placer Inspection ChecklistMyo LwinNessuna valutazione finora

- Crane Jib Check ListDocumento1 paginaCrane Jib Check ListsawkariqbalNessuna valutazione finora

- Tower Crane Test ReportDocumento10 pagineTower Crane Test Reportguthale100% (2)

- SWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanDocumento2 pagineSWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanHassan AbdullahNessuna valutazione finora

- HSE Inspection and ReportsDocumento4 pagineHSE Inspection and ReportsOmerfAtaNessuna valutazione finora

- Gotcha BrochureDocumento6 pagineGotcha BrochureNurfirman HNessuna valutazione finora

- 3-Pre-Lift Checklist Rev A 06302015Documento2 pagine3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- EOHSMS-02-C22 LOA Lifting SupervisorDocumento3 pagineEOHSMS-02-C22 LOA Lifting SupervisorHassan Abdullah100% (1)

- Scissor Lift ChecklistDocumento1 paginaScissor Lift ChecklistDIBNESH PANDITA100% (1)

- Chain Pulley Block or Chain Hoist Safety Dos and Don'tsDocumento5 pagineChain Pulley Block or Chain Hoist Safety Dos and Don'tsAkram BadranNessuna valutazione finora

- SOP SOP0007 Hitachi Electric Jack HammerDocumento3 pagineSOP SOP0007 Hitachi Electric Jack HammerWidya BungaNessuna valutazione finora

- MCM Lifting Operation ChecklistDocumento8 pagineMCM Lifting Operation ChecklistHein SiNessuna valutazione finora

- February 2012 Wire Rope ExchangeDocumento80 pagineFebruary 2012 Wire Rope ExchangeWire Rope ExchangeNessuna valutazione finora

- Sop LiftingDocumento5 pagineSop LiftingShaiful AnnuarNessuna valutazione finora

- Qcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of CranDocumento26 pagineQcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of Cranbryanpastor106100% (7)

- Load ChartDocumento1 paginaLoad Chartdavid chusnul100% (1)

- Tandem Lifting Container SWGDocumento1 paginaTandem Lifting Container SWGarifNessuna valutazione finora

- Crane Assembling Check ListDocumento2 pagineCrane Assembling Check ListBaldev SinghNessuna valutazione finora

- OSHA Man Basket User ManualDocumento9 pagineOSHA Man Basket User Manualwalid EttihNessuna valutazione finora

- Crawler Crane Annual InspectionDocumento3 pagineCrawler Crane Annual InspectionMark SolmundsonNessuna valutazione finora

- Topic For TBMDocumento19 pagineTopic For TBMdauxomNessuna valutazione finora

- Mobile Crane Inspection ChecklistDocumento1 paginaMobile Crane Inspection ChecklistSaumya Siddhantha Choudhury100% (1)

- 007 Mobile Crane ChecklistDocumento2 pagine007 Mobile Crane Checklistchandral86Nessuna valutazione finora

- Consolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.31 DateDocumento1 paginaConsolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.31 DateradhouaneNessuna valutazione finora

- Daily Safety ChecklistDocumento4 pagineDaily Safety ChecklistKalyan ReddyNessuna valutazione finora

- DAILY CHECK LIST Tyre Mounted CraneDocumento1 paginaDAILY CHECK LIST Tyre Mounted CraneAditya Enterprise100% (1)

- 007 Mobile Crane ChecklistDocumento2 pagine007 Mobile Crane ChecklistJoshua ThomasNessuna valutazione finora

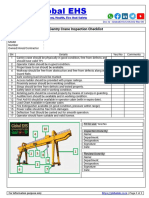

- Gantry Crane Safety Inspection Checklist Global EHSDocumento1 paginaGantry Crane Safety Inspection Checklist Global EHSloganathanNessuna valutazione finora

- Job Safety Analysis FormDocumento2 pagineJob Safety Analysis FormAbhaySngh100% (1)

- Rigging Up Checklist: Rig ModelDocumento2 pagineRigging Up Checklist: Rig Model89simbuNessuna valutazione finora

- Lifting Plan V - 409 18ins Con ValDocumento9 pagineLifting Plan V - 409 18ins Con ValAhmed Butt100% (1)

- Eot Crane ChecklistDocumento1 paginaEot Crane ChecklistMohammad Abubakar Siddiq75% (8)

- Crane Training Handbook With GPR 8719.1B UpdateDocumento558 pagineCrane Training Handbook With GPR 8719.1B Updatemhd abdou100% (3)

- Crane Tech Working Group ReportDocumento59 pagineCrane Tech Working Group ReportOmar El SayedNessuna valutazione finora

- Man Riding Hoist ChecklistDocumento5 pagineMan Riding Hoist ChecklistLeonte LeonNessuna valutazione finora

- Substation Construction and CommissioningDocumento83 pagineSubstation Construction and CommissioningShung Tak ChanNessuna valutazione finora

- Hoist Inspection StandardDocumento7 pagineHoist Inspection StandardhbookNessuna valutazione finora

- IOSH MS V3.1 Part 2Documento1 paginaIOSH MS V3.1 Part 2pammu18100% (1)

- Work tasks, responsibilities and workplace descriptionDocumento1 paginaWork tasks, responsibilities and workplace descriptionpammu18Nessuna valutazione finora

- Project IoshDocumento12 pagineProject IoshOmar MohammedNessuna valutazione finora

- 5 construction risks and how to control themDocumento2 pagine5 construction risks and how to control themMojtaba Andalib AzarNessuna valutazione finora

- Personal Protective Equipment PresentationDocumento29 paginePersonal Protective Equipment Presentationpammu18100% (2)

- Personal Protective Equipment PresentationDocumento29 paginePersonal Protective Equipment Presentationpammu18100% (2)

- Computer safety tipsDocumento27 pagineComputer safety tipsDheen MeeranNessuna valutazione finora

- FORMULAS For CALCULATING RATES PDFDocumento4 pagineFORMULAS For CALCULATING RATES PDFĐào Hùng0% (1)

- PiyushDocumento65 paginePiyushGovind MeenaNessuna valutazione finora

- Airport ATC SyllabusDocumento4 pagineAirport ATC SyllabussinovantonyNessuna valutazione finora

- Car Parking NotesDocumento9 pagineCar Parking NotesVijay KumarNessuna valutazione finora

- A Comparison On Transportation-Related Projects of The Philippine Presidents (Transportation Engineering)Documento13 pagineA Comparison On Transportation-Related Projects of The Philippine Presidents (Transportation Engineering)Emmerson NavarroNessuna valutazione finora

- Case Study PatnaDocumento25 pagineCase Study PatnaMonali LalNessuna valutazione finora

- Local Road Network Ledger CardDocumento5 pagineLocal Road Network Ledger CardMun. Engineer's Office Lakewood ZDSNessuna valutazione finora

- 5a. Method Statement For DBM - RevisedDocumento6 pagine5a. Method Statement For DBM - RevisedRabnawaz ImamNessuna valutazione finora

- MRLMDocumento2 pagineMRLMByron BolañosNessuna valutazione finora

- Design Criteria and AssumptionsDocumento74 pagineDesign Criteria and AssumptionsMarko AdamovićNessuna valutazione finora

- Prel Design Concepts For BRDocumento22 paginePrel Design Concepts For BRAbdo AboretaNessuna valutazione finora

- FINAL Tulay-1Documento10 pagineFINAL Tulay-1Jayson BacaniNessuna valutazione finora

- Cross Harbour Traffic NeedsDocumento63 pagineCross Harbour Traffic NeedsGlobal Halifax100% (2)

- JeppsenDocumento79 pagineJeppsennimeshNessuna valutazione finora

- Bridges: Prof. Anthony Cioffi, P.E. Professor/Chairman New York City College of Technology/CUNYDocumento30 pagineBridges: Prof. Anthony Cioffi, P.E. Professor/Chairman New York City College of Technology/CUNYJulius BaniquedNessuna valutazione finora

- Transportation Engineering-Ii: Elements of Road Cross SectionDocumento31 pagineTransportation Engineering-Ii: Elements of Road Cross SectionUsman HaiderNessuna valutazione finora

- Chapter 1 - Introduction To Highway EngineeringDocumento63 pagineChapter 1 - Introduction To Highway EngineeringSAYA HENSEM100% (1)

- VicRoads Supplement To AGRD Part 4C InterchangesDocumento69 pagineVicRoads Supplement To AGRD Part 4C InterchangesZaidi MohamadNessuna valutazione finora

- TSC BOP and Subsea Tree Handling EquipmentDocumento1 paginaTSC BOP and Subsea Tree Handling Equipmento_tostaNessuna valutazione finora

- Identification of Accident Black Spots and CountermeasuresDocumento32 pagineIdentification of Accident Black Spots and CountermeasuresNiju AzhakesanNessuna valutazione finora

- Documento PDF 9fcf46416ce2 1Documento3 pagineDocumento PDF 9fcf46416ce2 1CristinaNessuna valutazione finora

- Sections A To H Combined Copttm 4th Ed July2015Documento538 pagineSections A To H Combined Copttm 4th Ed July2015Suresh Sampath KumarNessuna valutazione finora

- NYSDOT-Safety Information Management System: Average Accident Costs/Severity Distribution State Highways 2018Documento4 pagineNYSDOT-Safety Information Management System: Average Accident Costs/Severity Distribution State Highways 2018jamcoso3240Nessuna valutazione finora

- AnnexureDocumento5 pagineAnnexurevijay mouryaNessuna valutazione finora

- Equipment For Loading Rail-Carrying Trains: Loading and Unloading Long-Welded Rails Quick, Economical, SafeDocumento4 pagineEquipment For Loading Rail-Carrying Trains: Loading and Unloading Long-Welded Rails Quick, Economical, SafeRohit Bali100% (1)

- I-10 Removal and Claiborne Alternatives - New OrleansDocumento60 pagineI-10 Removal and Claiborne Alternatives - New OrleansnextSTL.comNessuna valutazione finora

- 8005 Michigan Pedestrian Laws Guide for the PublicDocumento2 pagine8005 Michigan Pedestrian Laws Guide for the PublicsabastialtxiNessuna valutazione finora

- RIDOT Highway Design ManualDocumento104 pagineRIDOT Highway Design ManualEnd EndNessuna valutazione finora

- 4.chain Rope Inspection ReportDocumento8 pagine4.chain Rope Inspection ReportrukmalNessuna valutazione finora

- Highway Rates SummaryDocumento39 pagineHighway Rates SummaryR A P RathnaseeliNessuna valutazione finora