Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

RCC Beam Design Task-01

Caricato da

Mohamed SaheelDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

RCC Beam Design Task-01

Caricato da

Mohamed SaheelCopyright:

Formati disponibili

REFERENCE

CALCULATION

OUTPUT

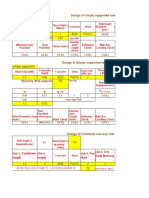

Analysis

Length Width Dead load Imposed load Ultimate Design Load L B g i w 4.2 0.225 13.62 12 38.27 kN/m kN/m kN/m

Single span fixed end condition

BM @ fixed end BM @ mid span SF MA MC V 56.25 28.13 80.36 kN kNm

Design Data

Material Properties Concrete grade Characteristic steel strength Youngs modulus of concrete Youngs modulus of steel Density of concrete Durabilty Requirements Exposure condition - Severe fcu fy EC ES pct 20 460 26000 200000 24 N/mm

2

N/mm2 N/mm2 N/mm2 kN/m

3

Beam

Design of Reinforcement

Sizes Top r/f Bottom r/f Links Cover Width of the beam overall depth of the beam bt hb = 12 = 16 = 6 = 25 = 225 = 350 mm mm mm mm mm mm

Design of Top Reinforcement

Effective depth Design bending moment Cl 3.4.4.4 BS 8110; 1985 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.87 Take Z = 0.83d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 476 Area of steel provided As prov 559 mm2/m mm2/m Z = 270.57 d mm Z= 270.57 mm d M K = 311 = 56.25 = M/[bd2fcu] = 0.103 k= 0.103 mm kNm d= 311 mm

Provide T and T

16 10

2 2

Nos Nos

T T

16 10

2 nos 1 nos

Design of Bottom Reinforcement

Effective depth Design bending moment

d M K

= 311 = 28.13 = M/[bd2fcu] = 0.052

mm kNm

d=

311

mm

k=

0.052

Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.94 Take Z = 0.92d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 220 Area of steel provided As prov 270 mm2/m mm2/m Z = 292.34 d mm Z= 292.34 mm

Provide T and T

12 10

1 2

Nos Nos

T T

12 10

2 nos 0 nos

Ckeck for Shear Resistance

Ultimate shear force at support Shear stress Vu = 80.36 = Vu/[bv*d] = 1.15 Maximum shear 100 As/[bv*d] 400/d c c + 0.4 Since c+0.4 < < max shear, design links to be provided Link size Shear link spacing Max spacing < 0.75d Provide R6 @ 150 mm c/c upto 1.5 m from both ends Middle area spacing shall be 200 mm c/c Sv = 6 < 113.73 < 233.25 mm = 3.6 = 0.80 = 1.29 = 0.62 = 1.02 N/mm

2

kN

= 1.15

N/mm

N/mm2

Deflection Checking

SS condition assumed to check deflection Table 3.10 BS 8110; 1985 Basic Span/Effective depth ratio Service stress in the tension r/f fs = 20 = 5*fy*As req/(8*As prov*b) = 245 Modification factor for tension r/f MF N/mm2

= 0.55+ [477-fs]/[120*(0.9+M/bd2)] = 1.1 ( < 2.0 )

Hence allowable Span/Effective depth ratio

= MF * Basic Span/Eff. Depth = 22

Actual Span/Effective Depth ratio

= 6.225/382 = 14.23

Since [Span/Eff.Depth]actual < [Span/Eff.Depth]allowable deflection is within the limit

Deflection is within the limt

REFERENCE

CALCULATION

OUTPUT

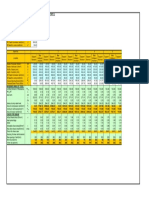

Analysis

Length Width Dead load [slab+finishes+beam] Imposed load Ultimate Design Load L B g i w 6 0.225 15.29 12 40.61 kN/m kN/m kN/m

Single span fixed end condition

BM @ fixed end BM @ mid span SF MA MC V 121.82 60.91 121.82 kN kNm

Design Data

Material Properties Concrete grade Characteristic steel strength Youngs modulus of concrete Youngs modulus of steel Density of concrete Durabilty Requirements Exposure condition - Severe fcu fy EC ES pct 25 460 26000 200000 24 N/mm2 N/mm2 N/mm2 N/mm

2

kN/m3

Beam

Design of Reinforcement

Sizes Top r/f Bottom r/f Links Cover Width of the beam overall depth of the beam bt hb = 20 = 16 = 10 = 25 = 225 = 425 mm mm mm mm mm mm

Design of Top Reinforcement

Effective depth Design bending moment Cl 3.4.4.4 BS 8110; 1985 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.83 Take Z = 0.81d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 747 Area of steel provided As prov 717 mm2/m mm2/m Z = 317.06 d mm Z= 317.06 mm d M K = 382 = 103.55 = M/[bd2fcu] = 0.126 k= 0.126 mm kNm d= 382 mm

Provide T and T

20 16

1 2

Nos Nos

T T

20 16

2 nos 1 nos

Design of Bottom Reinforcement

Effective depth Design bending moment d M K = 382 = 79.18 = M/[bd2fcu] = 0.096 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.88 Take Z = 0.89d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 539 Area of steel provided As prov 629 mm /m mm2/m

2

mm kNm

d=

382

mm

k=

0.096

d mm Z= 336.16 mm

= 336.16

Provide T and T

16 20

0 2

Nos Nos

T T

16 20

0 nos 2 nos

Ckeck for Shear Resistance

Ultimate shear force at support Shear stress Vu = 121.82 = Vu/[bv*d] = 1.42 Maximum shear 100 As/[bv*d] 400/d c c + 0.4 Since c+0.4 < < max shear, design links to be provided Link size Shear link spacing Max spacing < 0.75d Provide R10 @ 150 mm c/c upto 1.5 m from both ends Middle area spacing shall be 200 mm c/c Sv = 10 < 202.83 < 286.5 mm = 4.0 = 0.83 = 1.05 = 0.60 = 1.00 N/mm

2

kN

= 1.42

N/mm

N/mm2

Deflection Checking

SS condition assumed to check deflection Table 3.10 BS 8110; 1985 Basic Span/Effective depth ratio Service stress in the tension r/f fs = 20 = 5*fy*As req/(8*As prov*b) = 300 Modification factor for tension r/f MF N/mm2

= 0.55+ [477-fs]/[120*(0.9+M/bd2)] = 0.91 ( < 2.0 )

Hence allowable Span/Effective depth ratio

= MF * Basic Span/Eff. Depth = 18.2

Actual Span/Effective Depth ratio

= 6.225/382 = 16.30

Since [Span/Eff.Depth]actual < [Span/Eff.Depth]allowable deflection is within the limit

Deflection is within the limt

REFERENCE

CALCULATION

OUTPUT SLAB THICK 150 MM

Analysis

Length Width Dead load [slab+finishes] Imposed load Ultimate Design Load Total Design Load L B g i w F 3 0.225 14.88 12 40.03 120.10

kN/m kN/m kN/m kN

Single span fixed end condition

BM @ C BM @ B SF @ A MC MB V 39.63 32.43 54.04 kN kNm

Design Data

Material Properties Concrete grade Characteristic steel strength Youngs modulus of concrete Youngs modulus of steel Density of concrete Durabilty Requirements Exposure condition - Severe fcu fy EC ES pct 25 460 26000 200000 24 N/mm2 N/mm2 N/mm2 N/mm2 kN/m3

Beam

Design of Reinforcement

Sizes Top r/f Bottom r/f Links Cover Width of the beam overall depth of the beam bt hb = 12 = 12 = 6 = 25 = 225 = 350 mm mm mm mm mm mm

Design of Top Reinforcement @ C

Effective depth Design bending moment Cl 3.4.4.4 BS 8110; 1985 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.91 Take Z = 0.90d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 318 Area of steel provided As prov 339 mm2/m mm2/m Z = 284.83 d mm Z= 284.83 mm d M K = 313 = 39.63 = M/[bd2fcu] = 0.072 k= 0.072 mm kNm d= 313 mm

Provide T

12

Nos

12

2 nos

and T

16

Nos

16

1 nos

Design of Bottom Reinforcement @ B

Effective depth Design bending moment d M K = 313 = 32.43 = M/[bd2fcu] = 0.059 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.93 Take Z = 0.92d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 255 Area of steel provided As prov 339 mm2/m mm2/m Z = 291.09 d mm Z= 291.09 mm k= 0.059 mm kNm d= 313 mm

Provide T and T

12

3 0

Nos Nos

T T

12 0

3 nos 0 nos

Ckeck for Shear Resistance

Ultimate shear force at support Shear stress Vu = 54.04 = Vu/[bv*d] = 0.77 Maximum shear 100 As/[bv*d] 400/d c c + 0.4 Since c+0.4 > > 0.5 c max shear, minimum links required Link size Shear link spacing Max spacing < 0.75d Provide R6 @ 150 mm c/c upto 1.5 m throughout Sv = 6 < 149.29 < 234.75 mm = 4.0 = 0.48 = 1.28 = 0.53 = 0.93 N/mm

2

kN

= 0.77

N/mm

N/mm2

Deflection Checking

SS condition assumed to check deflection Table 3.10 BS 8110; 1985 Basic Span/Effective depth ratio Service stress in the tension r/f fs = 20 = 5*fy*As req/(8*As prov*b) = 270 Modification factor for tension r/f MF N/mm2

= 0.55+ [477-fs]/[120*(0.9+M/bd2)] = 1.28 ( < 2.0 )

Hence allowable Span/Effective depth ratio

= MF * Basic Span/Eff. Depth = 25.6

Actual Span/Effective Depth ratio

= 6.225/382 = 10.30

Since [Span/Eff.Depth]actual < [Span/Eff.Depth]allowable deflection is within the limit

Deflection is within the limt

REFERENCE

CALCULATION

OUTPUT SLAB THICK 150 MM

Analysis

Length Width Dead load [slab+finishes] Imposed load Ultimate Design Load Total Design Load L B g i w F 3 0.225 14.88 12 40.03 120.10

kN/m kN/m kN/m kN

Single span fixed end condition

BM @ E BM @ D SF @ C ME MD V 28.82 25.22 66.05 kNm kNm kN

Design Data

Material Properties Concrete grade Characteristic steel strength Youngs modulus of concrete Youngs modulus of steel Density of concrete Durabilty Requirements Exposure condition - Severe fcu fy EC ES pct 25 460 26000 200000 24 N/mm2 N/mm2 N/mm2 N/mm2 kN/m3

Beam

Design of Reinforcement

Sizes Top r/f Bottom r/f Links Cover Width of the beam overall depth of the beam bt hb = 12 = 12 = 6 = 25 = 225 = 350 mm mm mm mm mm mm

Design of Top Reinforcement @ C

Effective depth Design bending moment Cl 3.4.4.4 BS 8110; 1985 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.94 Take Z = 0.93d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 224 Area of steel provided As prov 339 mm2/m mm2/m Z = 294.22 d mm Z= 294.22 mm d M K = 313 = 28.82 = M/[bd2fcu] = 0.052 k= 0.052 mm kNm d= 313 mm

Provide T

12

Nos

12

2 nos

and T

16

Nos

16

1 nos

Design of Bottom Reinforcement @ B

Effective depth Design bending moment d M K = 313 = 25.22 = M/[bd2fcu] = 0.046 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.95 Take Z = 0.94d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 194 Area of steel provided As prov 226 mm2/m mm2/m Z = 297.35 d mm Z= 297.35 mm k= 0.046 mm kNm d= 313 mm

Provide T and T

12

2 0

Nos Nos

T T

12 0

2 nos 0 nos

Ckeck for Shear Resistance

Ultimate shear force at support Shear stress Vu = 66.05 = Vu/[bv*d] = 0.94 Maximum shear 100 As/[bv*d] 400/d c c + 0.4 Since c+0.4 < < max shear, design links to be provided Link size Shear link spacing Max spacing < 0.75d Provide R6 @ 125 mm c/c upto 1.5 m from support Sv = 6 < 144.91 < 234.75 mm = 4.0 = 0.48 = 1.28 = 0.53 = 0.93 N/mm

2

kN

= 0.94

N/mm

N/mm2

Deflection Checking

SS condition assumed to check deflection Table 3.10 BS 8110; 1985 Basic Span/Effective depth ratio Service stress in the tension r/f fs = 20 = 5*fy*As req/(8*As prov*b) = 190 Modification factor for tension r/f MF N/mm2

= 0.55+ [477-fs]/[120*(0.9+M/bd2)] = 1.72 ( < 2.0 )

Hence allowable Span/Effective depth ratio

= MF * Basic Span/Eff. Depth = 34.4

Actual Span/Effective Depth ratio

= 6.225/382 = 10.30

Since [Span/Eff.Depth]actual < [Span/Eff.Depth]allowable deflection is within the limit

Deflection is within the limt

REFERENCE

CALCULATION

OUTPUT SLAB THICK 125 MM

Analysis

Length Width Dead load Imposed load Ultimate Design Load L B g i w 3 1 4.6 4 12.84

kN/m kN/m kN/m

Single span fixed end condition

BM @ fixed end BM @ mid span SF MA MC V 10.60 8.70 19.26 kNm kNm kN

Design Data

Material Properties Concrete grade Characteristic steel strength Youngs modulus of concrete Youngs modulus of steel Density of concrete Durabilty Requirements Exposure condition - Severe fcu fy EC ES pct 25 460 26000 200000 24 N/mm2 N/mm2 N/mm2 N/mm2 kN/m3

Beam

Design of Reinforcement

Sizes Top r/f Bottom r/f Links Cover Width of the strip overall depth of the slab bt hb = 0 = 10 = = 25 = 1000 = 125 mm mm mm mm mm mm

Design of Top Reinforcement

Effective depth Design bending moment Cl 3.4.4.4 BS 8110; 1985 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.94 Take Z = 0.83d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 272 Area of steel provided As prov 314 mm2/m mm2/m Z = 89.3 d mm Z= 89.3 mm d M K = 95 = 10.60 = M/[bd2fcu] = 0.047 k= 0.047 mm kNm d= 95 mm

Provide T and T T10 @ 250 mm spacing

10 10

4 0

Nos Nos

T T

10 10

5 nos

Design of Bottom Reinforcement

Effective depth Design bending moment d M K = 95 = 8.70 = M/[bd2fcu] = 0.039 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.95 Take Z = 0.92d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 221 Area of steel provided As prov 314 mm2/m mm2/m Z = 90.25 d mm Z= 90.25 mm k= 0.039 mm kNm d= 95 mm

Provide T T10 @ 250 mm spacing

10

Nos

10

5 nos

Ckeck for Shear Resistance

Ultimate shear force at support Shear stress Vu = 19.26 = Vu/[bv*d] = 0.2 Maximum shear 100 As/[bv*d] 400/d c c + 0.4 Since < 0.5 c = 4.0 = 0.33 = 4.21 = 0.63 = 1.03 N/mm2 N/mm

2

kN

= 0.2

N/mm2

Deflection Checking

Continous condition assumed to check deflection Table 3.10 BS 8110; 1985 Basic Span/Effective depth ratio Service stress in the tension r/f fs = 27 = 5*fy*As req/(8*As prov*b) = 202 Modification factor for tension r/f MF N/mm2

= 0.55+ [477-fs]/[120*(0.9+M/bd2)] = 1.78 ( < 2.0 )

Hence allowable Span/Effective depth ratio

= MF * Basic Span/Eff. Depth = 48.06

Actual Span/Effective Depth ratio

= 3000/85 = 31.58

Since [Span/Eff.Depth]actual < [Span/Eff.Depth]allowable deflection is within the limit

Deflection is within the limt

REFERENCE

CALCULATION

OUTPUT SLAB THICK 125 MM

Analysis

Length Width Dead load Imposed load Ultimate Design Load L B g i w 6 1 4.6 4 12.84

kN/m kN/m kN/m

Single span fixed end condition

BM @ fixed end BM @ mid span SF MA MC V 3.46 4.76 38.52 kNm kNm kN

Design Data

Material Properties Concrete grade Characteristic steel strength Youngs modulus of concrete Youngs modulus of steel Density of concrete Durabilty Requirements Exposure condition - Severe fcu fy EC ES pct 25 460 26000 200000 24 N/mm2 N/mm2 N/mm2 N/mm

2

kN/m3

Beam

Design of Reinforcement

Sizes Top r/f Bottom r/f Links Cover Width of the strip overall depth of the slab bt hb = 0 = 10 = 10 = 25 = 1000 = 125 mm mm mm mm mm mm

Design of Top Reinforcement

Effective depth Design bending moment Cl 3.4.4.4 BS 8110; 1985 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.98 Take Z = 0.83d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 98 Area of steel provided As prov 314 mm2/m mm2/m Z = 80.75 d mm Z= 80.75 mm d M K = 85 = 3.46 = M/[bd2fcu] = 0.019 k= 0.019 mm kNm d= 85 mm

Provide T

10

Nos

10

2 nos

Design of Bottom Reinforcement

Effective depth Design bending moment d M K = 85 = 4.76 = M/[bd2fcu] = 0.026 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.97 Take Z = 0.92d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 132 Area of steel provided As prov 314 mm2/m mm /m

2

mm kNm

d=

85

mm

k=

0.026

d mm Z= 82.45 mm

= 82.45

Provide T T10 @ 250 mm spacing

10

Nos

10

5 nos

Ckeck for Shear Resistance

Ultimate shear force at support Shear stress Vu = 38.52 = Vu/[bv*d] = 0.45 Maximum shear 100 As/[bv*d] 400/d c c + 0.4 Since < 0.5 c = 4.0 = 0.37 = 4.71 = 0.67 = 1.07 N/mm

2

kN

= 0.45

N/mm

N/mm2

Deflection Checking [Not necessary in long span direction]

SS condition assumed to check deflection Table 3.10 BS 8110; 1985 Basic Span/Effective depth ratio Service stress in the tension r/f fs = 20 = 5*fy*As req/(8*As prov*b) = 121 Modification factor for tension r/f MF N/mm

2

= 0.55+ [477-fs]/[120*(0.9+M/bd2)] = 2.45 ( < 2.0 )

Hence allowable Span/Effective depth ratio

= MF * Basic Span/Eff. Depth = 49

Actual Span/Effective Depth ratio

= 3000/120 = 35.29

Since [Span/Eff.Depth]actual < [Span/Eff.Depth]allowable deflection is within the limit

Deflection is within the limt

REFERENCE

CALCULATION

OUTPUT SLAB THICK 150 MM

Analysis

Length Width Dead load [slab+finishes] Imposed load Ultimate Design Load L B g i w 7 0.225 15.42 12 40.79

kN/m kN/m kN/m

Single span fixed end condition

BM @ fixed end BM @ mid span SF MA MC V 166.55 83.28 142.76 kN kNm

Design Data

Material Properties Concrete grade Characteristic steel strength Youngs modulus of concrete Youngs modulus of steel Density of concrete Durabilty Requirements Exposure condition - Severe fcu fy EC ES pct 25 460 26000 200000 24 N/mm2 N/mm2 N/mm2 N/mm

2

kN/m3

Beam

Design of Reinforcement

Sizes Top r/f Bottom r/f Links Cover Width of the beam overall depth of the beam bt hb = 20 = 16 = 10 = 25 = 225 = 475 mm mm mm mm mm mm

Design of Top Reinforcement

Effective depth Design bending moment Cl 3.4.4.4 BS 8110; 1985 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.8 Take Z = 0.81d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 993 Area of steel provided As prov 943 mm2/m mm2/m Z = 345.6 d mm Z= 345.6 mm d M K = 432 = 149.90 = M/[bd2fcu] = 0.143 k= 0.143 mm kNm d= 432 mm

Provide T and T

20 16

3 0

Nos Nos

T T

20 16

2 nos 2 nos

Design of Bottom Reinforcement

Effective depth Design bending moment d M K = 432 = 104.09 = M/[bd2fcu] = 0.099 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.87 Take Z = 0.89d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 634 Area of steel provided As prov 742 mm /m mm2/m

2

mm kNm

d=

432

mm

k=

0.099

d mm Z= 375.84 mm

= 375.84

Provide T and T

12 20

1 2

Nos Nos

T T

12 20

0 nos 2 nos

Ckeck for Shear Resistance

Ultimate shear force at support Shear stress Vu = 142.76 = Vu/[bv*d] = 1.47 Maximum shear 100 As/[bv*d] 400/d c c + 0.4 Since c+0.4 < < max shear, design links to be provided Link size Shear link spacing Max spacing < 0.75d Provide R10 @ 150 mm c/c upto 1.5 m from both ends Middle area spacing shall be 200 mm c/c Sv = 10 < 193.73 < 324 mm = 4.0 = 0.97 = 0.93 = 0.61 = 1.01 N/mm

2

kN

= 1.47

N/mm

N/mm2

Deflection Checking

SS condition assumed to check deflection Table 3.10 BS 8110; 1985 Basic Span/Effective depth ratio Service stress in the tension r/f fs = 20 = 5*fy*As req/(8*As prov*b) = 303 Modification factor for tension r/f MF N/mm2

= 0.55+ [477-fs]/[120*(0.9+M/bd2)] = 0.87 ( < 2.0 )

Hence allowable Span/Effective depth ratio

= MF * Basic Span/Eff. Depth = 17.4

Actual Span/Effective Depth ratio

= 6.225/382 = 16.72

Since [Span/Eff.Depth]actual < [Span/Eff.Depth]allowable deflection is within the limit

Deflection is within the limt

REFERENCE

CALCULATION

OUTPUT SLAB THICK 150 MM

Analysis

Length Width Dead load [slab+finishes] Imposed load Ultimate Design Load Total Design Load L B g i w F 3 0.225 17.18 14 46.45 139.36

kN/m kN/m kN/m kN

Single span fixed end condition

BM @ C BM @ B SF @ A MC MB V 45.99 37.63 62.71 kN kNm

Design Data

Material Properties Concrete grade Characteristic steel strength Youngs modulus of concrete Youngs modulus of steel Density of concrete Durabilty Requirements Exposure condition - Severe fcu fy EC ES pct 25 460 26000 200000 24 N/mm2 N/mm2 N/mm2 N/mm2 kN/m3

Beam

Design of Reinforcement

Sizes Top r/f Bottom r/f Links Cover Width of the beam overall depth of the beam bt hb = 12 = 12 = 6 = 25 = 225 = 350 mm mm mm mm mm mm

Design of Top Reinforcement @ C

Effective depth Design bending moment Cl 3.4.4.4 BS 8110; 1985 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.9 Take Z = 0.90d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 374 Area of steel provided As prov 402 mm2/m mm2/m Z = 281.7 d mm Z= 281.7 mm d M K = 313 = 45.99 = M/[bd2fcu] = 0.083 k= 0.083 mm kNm d= 313 mm

Provide T

12

Nos

12

and T

16

Nos

16

2 nos

Design of Bottom Reinforcement @ B

Effective depth Design bending moment d M K = 313 = 37.63 = M/[bd2fcu] = 0.068 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.92 Take Z = 0.92d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 299 Area of steel provided As prov 339 mm2/m mm2/m Z = 287.96 d mm Z= 287.96 mm k= 0.068 mm kNm d= 313 mm

Provide T and T

12

3 0

Nos Nos

T T

12 0

3 nos 0 nos

Ckeck for Shear Resistance

Ultimate shear force at support Shear stress Vu = 62.71 = Vu/[bv*d] = 0.89 Maximum shear 100 As/[bv*d] 400/d c c + 0.4 Since c+0.4 > > 0.5 c max shear, minimum links required Link size Shear link spacing Max spacing < 0.75d Provide R6 @ 150 mm c/c upto 1.5 m throughout Sv = 6 < 149.29 < 234.75 mm = 4.0 = 0.57 = 1.28 = 0.56 = 0.96 N/mm

2

kN

= 0.89

N/mm

N/mm2

Deflection Checking

SS condition assumed to check deflection Table 3.10 BS 8110; 1985 Basic Span/Effective depth ratio Service stress in the tension r/f fs = 20 = 5*fy*As req/(8*As prov*b) = 267 Modification factor for tension r/f MF N/mm2

= 0.55+ [477-fs]/[120*(0.9+M/bd2)] = 1.22 ( < 2.0 )

Hence allowable Span/Effective depth ratio

= MF * Basic Span/Eff. Depth = 24.4

Actual Span/Effective Depth ratio

= 6.225/382 = 10.30

Since [Span/Eff.Depth]actual < [Span/Eff.Depth]allowable deflection is within the limit

Deflection is within the limt

REFERENCE

CALCULATION

OUTPUT SLAB THICK 150 MM

Analysis

Length Width Dead load [slab+finishes] Imposed load Ultimate Design Load Total Design Load L B g i w F 3 0.225 17.18 14 46.45 139.36

kN/m kN/m kN/m kN

Single span fixed end condition

BM @ E BM @ D SF @ C ME MD V 33.45 29.26 76.65 kNm kNm kN

Design Data

Material Properties Concrete grade Characteristic steel strength Youngs modulus of concrete Youngs modulus of steel Density of concrete Durabilty Requirements Exposure condition - Severe fcu fy EC ES pct 25 460 26000 200000 24 N/mm2 N/mm2 N/mm2 N/mm2 kN/m3

Beam

Design of Reinforcement

Sizes Top r/f Bottom r/f Links Cover Width of the beam overall depth of the beam bt hb = 12 = 12 = 6 = 25 = 225 = 350 mm mm mm mm mm mm

Design of Top Reinforcement @ C

Effective depth Design bending moment Cl 3.4.4.4 BS 8110; 1985 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.93 Take Z = 0.93d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 263 Area of steel provided As prov 339 mm2/m mm2/m Z = 291.09 d mm Z= 291.09 mm d M K = 313 = 33.45 = M/[bd2fcu] = 0.061 k= 0.061 mm kNm d= 313 mm

Provide T

12

Nos

12

2 nos

and T

16

Nos

16

1 nos

Design of Bottom Reinforcement @ B

Effective depth Design bending moment d M K = 313 = 29.26 = M/[bd2fcu] = 0.053 Since K < 0.156 no compresiion r/f required Z = [0.5+(0.25-K/0.9)0.5] * d = 0.94 Take Z = 0.94d Required area of steel to carry ultimate BM As req,M = M/[0.95*fy*Z] = 228 Area of steel provided As prov 226 mm2/m mm2/m Z = 294.22 d mm Z= 294.22 mm k= 0.053 mm kNm d= 313 mm

Provide T and T

12

2 0

Nos Nos

T T

12 0

2 nos 0 nos

Ckeck for Shear Resistance

Ultimate shear force at support Shear stress Vu = 76.65 = Vu/[bv*d] = 1.09 Maximum shear 100 As/[bv*d] 400/d c c + 0.4 Since c+0.4 < < max shear, design links to be provided Link size Shear link spacing Max spacing < 0.75d Provide R6 @ 125 mm c/c upto 1.5 m from support Sv = 6 < 106.24 < 234.75 mm = 4.0 = 0.48 = 1.28 = 0.53 = 0.93 N/mm

2

kN

= 1.09

N/mm

N/mm2

Deflection Checking

SS condition assumed to check deflection Table 3.10 BS 8110; 1985 Basic Span/Effective depth ratio Service stress in the tension r/f fs = 20 = 5*fy*As req/(8*As prov*b) = 223 Modification factor for tension r/f MF N/mm2

= 0.55+ [477-fs]/[120*(0.9+M/bd2)] = 1.5 ( < 2.0 )

Hence allowable Span/Effective depth ratio

= MF * Basic Span/Eff. Depth = 30

Actual Span/Effective Depth ratio

= 6.225/382 = 10.30

Since [Span/Eff.Depth]actual < [Span/Eff.Depth]allowable deflection is within the limit

Deflection is within the limt

Design of Pad Footing F2 - 600mm x 300mm plate resting on footing Load F Weight of footing Service load Pser Ultimate load Pult Bearing capacity of soil Footing area Say, Length Width Actual area Overall depth "h" 193 18.432 211.432 317.148 125 1.69 1.6 1.6 2.56 300

TO BE EDITED

kN/m

> mm >

1.69 178.09

m2 mm

Design for Bending Ultimate bearing pressure 123.89 < 125.00 kN/m2

Critical BM at colum face BM

41.873

kNm

Bar diameter assumed Cover Effective depth Average depth

12 50 232 238

mm mm

M/bd2 100As/bd Reinforcement required As

0.486 0.1 371.2 mm2

Minimum r/f required

624

mm

Provide T12 @ 300 c/c

r/f provided

678.24

mm2

>

624.00

mm2

Check for Punching Shear Max shear v 1.110 N/mm

2

<

4.00

N/mm

Critical perimeter Area outside the perimeter Punching shear V Stress v Shear r/f not required

4056 1.532 189.77 0.197

mm m

2

kN N/mm

2

<

4.00

N/mm

Detail Foundation depth (to bottom of footing) : 1200 mm Size : 1600 x 1600 mm Footing thickness : 300 mm Reinforcement : T12 @ 300 c/c both direction

Potrebbero piacerti anche

- Slab DesignDocumento28 pagineSlab DesignUlasi IfeanyiNessuna valutazione finora

- Slab Design FFDocumento17 pagineSlab Design FFSivaAgathamudiNessuna valutazione finora

- DESIGN CalculationDocumento47 pagineDESIGN CalculationZayyan Romjon100% (2)

- 7 Slab Design 1503Documento32 pagine7 Slab Design 1503Er Mohd NoshadNessuna valutazione finora

- Design ProjectDocumento36 pagineDesign Projectveenabalu20Nessuna valutazione finora

- Design Detail For RCC One Way SlabDocumento18 pagineDesign Detail For RCC One Way SlabWanda BeasleyNessuna valutazione finora

- Design of T-BeamDocumento6 pagineDesign of T-BeamDineshNessuna valutazione finora

- Slab Design Full Report: Material and Design DataDocumento22 pagineSlab Design Full Report: Material and Design DataazwanNessuna valutazione finora

- Design of Beam BS 8110 (May 2019)Documento3 pagineDesign of Beam BS 8110 (May 2019)thanigai veluNessuna valutazione finora

- Typical Retaining Wall 213Documento19 pagineTypical Retaining Wall 213Vidya ShankarNessuna valutazione finora

- Slab DesignDocumento25 pagineSlab DesignSabin Leroy HmgnNessuna valutazione finora

- Plinth Beams DesignDocumento24 paginePlinth Beams DesignRathinavel VenkateshwaranNessuna valutazione finora

- Engg/10/s4 Reinforced Concrete Design To Bs 8110: Contract RefDocumento3 pagineEngg/10/s4 Reinforced Concrete Design To Bs 8110: Contract RefGodfrey James MachotaNessuna valutazione finora

- Beam Design With RCCDocumento24 pagineBeam Design With RCCOsarieme Osakue100% (1)

- Slab Design SpreadsheetDocumento16 pagineSlab Design SpreadsheetmuraliNessuna valutazione finora

- 6.3 Staircase Waist SlabDocumento2 pagine6.3 Staircase Waist SlabEr Mohd NoshadNessuna valutazione finora

- Combine Footing FinallDocumento227 pagineCombine Footing FinallKhalid BanafaNessuna valutazione finora

- Design of STRIP FoundationDocumento21 pagineDesign of STRIP FoundationPremasiri Karunarathna100% (5)

- Combined Foundation Design - : Gross Bearing Cpacity 156 KN /MDocumento5 pagineCombined Foundation Design - : Gross Bearing Cpacity 156 KN /MvipinNessuna valutazione finora

- RCCe11 Element DesignDocumento8 pagineRCCe11 Element DesignZayyan RomjonNessuna valutazione finora

- RCC51 Column Load Take-Down & DesignDocumento8 pagineRCC51 Column Load Take-Down & DesignirrezaNessuna valutazione finora

- Sloped FootingDocumento19 pagineSloped FootingBala ChandarNessuna valutazione finora

- SlabDocumento6 pagineSlabBishal ShresthaNessuna valutazione finora

- Column Biaxial ProblemsDocumento25 pagineColumn Biaxial ProblemsRajanvmNessuna valutazione finora

- Wing WallDocumento4 pagineWing WallFaizal AryanovNessuna valutazione finora

- Flat Slab DesignDocumento6 pagineFlat Slab DesignforbeskaNessuna valutazione finora

- Design of Stair CaseDocumento2 pagineDesign of Stair Casepathan is khanNessuna valutazione finora

- PAB 831 Industrial Concrete Products: Perunding BaktiDocumento1 paginaPAB 831 Industrial Concrete Products: Perunding Baktitini871100% (1)

- Isolated Footing Design Example and Excel SheetDocumento8 pagineIsolated Footing Design Example and Excel Sheetosama prog100% (1)

- Beam Design: 101 30 M ('M' For Moderate, "S" For Severe, "VS" For Very Severe, "E" For Extreme) 415 40 40 456 SpanDocumento11 pagineBeam Design: 101 30 M ('M' For Moderate, "S" For Severe, "VS" For Very Severe, "E" For Extreme) 415 40 40 456 SpannytenNessuna valutazione finora

- Staircase Isolated Tread TypeDocumento9 pagineStaircase Isolated Tread TypeNishan GajurelNessuna valutazione finora

- Slab Deflection CalculationDocumento2 pagineSlab Deflection CalculationAHMED SOHELNessuna valutazione finora

- Made Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: RiyadhDocumento6 pagineMade Date Sheet AR 17-Jul-11 1 Check Date Rev. MKI 17-Jul-11 0 PROJECT TITLE: Minhal Crowne Plaza Location: Riyadhsidiq7Nessuna valutazione finora

- Continuous Slab Design ProgrammeDocumento31 pagineContinuous Slab Design ProgrammeNikhilNessuna valutazione finora

- Design of Rectangular Water TankDocumento197 pagineDesign of Rectangular Water TankNguyễn Quốc PhượngNessuna valutazione finora

- FOOTING Excel SheetDocumento2 pagineFOOTING Excel SheetAbdul KabasyNessuna valutazione finora

- Design of ColumnDocumento46 pagineDesign of ColumnAnissah ManialaNessuna valutazione finora

- Sample Calulation BeamDocumento9 pagineSample Calulation Beamche azimNessuna valutazione finora

- Purlin DesignDocumento6 paginePurlin DesignAnonymous mcHqIfbnV1Nessuna valutazione finora

- Slab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)Documento12 pagineSlab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)shiv kumarNessuna valutazione finora

- Wall Description: Calculation of Supporting Wall FootingDocumento24 pagineWall Description: Calculation of Supporting Wall FootingPrakash Singh RawalNessuna valutazione finora

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Documento2 pagineAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Md Nadeem Akhtar100% (1)

- Design of Wall Like ColumnDocumento4 pagineDesign of Wall Like Columnvishnumani3011Nessuna valutazione finora

- 2010 7.0 DESIGN OF SLAB and BEAMsDocumento71 pagine2010 7.0 DESIGN OF SLAB and BEAMsJoseph Tan LantoNessuna valutazione finora

- Doubly Reinforced BeamDocumento10 pagineDoubly Reinforced Beamkalpanaadhi50% (2)

- Design of Simply Supported One Way SlabDocumento15 pagineDesign of Simply Supported One Way SlabNikhil100% (2)

- Splice Check - 07282020 PDFDocumento3 pagineSplice Check - 07282020 PDFAngelo MoralNessuna valutazione finora

- Combined Footing Edge-Edge ColumnDocumento34 pagineCombined Footing Edge-Edge ColumnJohnMiguelMolinaNessuna valutazione finora

- Column Reinforcement Design: Uex UeyDocumento15 pagineColumn Reinforcement Design: Uex Ueyswargadwari consultancyNessuna valutazione finora

- Column DesignDocumento2 pagineColumn DesignVinayak PotdarNessuna valutazione finora

- Trial ExcelDocumento15 pagineTrial ExcelCyndrille John BragatNessuna valutazione finora

- Strap FootingDocumento30 pagineStrap Footinganon_140586866Nessuna valutazione finora

- Beam Design With Deflection CheckDocumento2 pagineBeam Design With Deflection ChecksandeepNessuna valutazione finora

- Design of Footing For Corner ColumnDocumento4 pagineDesign of Footing For Corner ColumnMegatech Engineering ConsultantsNessuna valutazione finora

- FCK Fy B H D D': Grade of Concrete (N/MM) Grade of Reinf Steel (N/MM)Documento1 paginaFCK Fy B H D D': Grade of Concrete (N/MM) Grade of Reinf Steel (N/MM)Manoj Kumar PalNessuna valutazione finora

- Design of Isolated FootingDocumento28 pagineDesign of Isolated FootingmeenuNessuna valutazione finora

- Beam-Design-R CDocumento123 pagineBeam-Design-R CMarkNessuna valutazione finora

- Structure of RCC Beam Design Task 01Documento29 pagineStructure of RCC Beam Design Task 01George GeorgianNessuna valutazione finora

- Beam DesignsDocumento123 pagineBeam DesignssitehabNessuna valutazione finora

- Manual Beam DesignDocumento14 pagineManual Beam DesignRonald Kaaku50% (2)

- Imanin UnmayaiNee Arivaya - Final - 09 08 2012Documento304 pagineImanin UnmayaiNee Arivaya - Final - 09 08 2012Mohamed SaheelNessuna valutazione finora

- By Road LevelsDocumento1 paginaBy Road LevelsMohamed SaheelNessuna valutazione finora

- BSR 1999 ColomboDocumento487 pagineBSR 1999 ColomboMohamed Saheel100% (1)

- P6 Schedule and BOQ ChallengesDocumento6 pagineP6 Schedule and BOQ ChallengesMohamed SaheelNessuna valutazione finora

- 01 - Demolisher (2005)Documento13 pagine01 - Demolisher (2005)Mohamed SaheelNessuna valutazione finora

- Windows Embedded CE 6.0 R3 LicenseDocumento5 pagineWindows Embedded CE 6.0 R3 LicenseMohamed SaheelNessuna valutazione finora

- Colourcon HRMDocumento8 pagineColourcon HRMMohamed SaheelNessuna valutazione finora

- Contract Administration in Project Management - ConceptsDocumento5 pagineContract Administration in Project Management - ConceptsMohamed SaheelNessuna valutazione finora

- Baba Fakrudhin Tamil HistoryDocumento105 pagineBaba Fakrudhin Tamil HistoryMohamed SaheelNessuna valutazione finora

- Present GlobalcommentstowebDocumento8 paginePresent GlobalcommentstowebMohamed SaheelNessuna valutazione finora

- Operations ManagementDocumento290 pagineOperations Managementrockon60594% (104)

- Falcon 4 CLHS Cameras: True High-Performance: High-Speed Global Shutter CMOS CamerasDocumento4 pagineFalcon 4 CLHS Cameras: True High-Performance: High-Speed Global Shutter CMOS CamerasEkpetorson ChinweikeNessuna valutazione finora

- Water Level Sensor (Submersible)Documento4 pagineWater Level Sensor (Submersible)anon_975837510Nessuna valutazione finora

- Condensation and BoilingDocumento14 pagineCondensation and BoilingCrislyn Akilit Bayawa100% (1)

- Band Gaps and Electronics Structure of PerovskitesDocumento12 pagineBand Gaps and Electronics Structure of PerovskitesThanh Long TaNessuna valutazione finora

- Oracle Database 11g Transparent Data EncryptionDocumento40 pagineOracle Database 11g Transparent Data EncryptionYelena BytenskayaNessuna valutazione finora

- ISG Services OverviewDocumento12 pagineISG Services OverviewsdonNessuna valutazione finora

- EWAD-CF EEDEN15-435 Data Books EnglishDocumento42 pagineEWAD-CF EEDEN15-435 Data Books EnglishrpufitaNessuna valutazione finora

- API-650 Design Procedure ExampleDocumento21 pagineAPI-650 Design Procedure Examplegdwvcd93% (14)

- Simulation of Congestion Control Algorithm AimDocumento4 pagineSimulation of Congestion Control Algorithm AimHaru HarshuNessuna valutazione finora

- Maharashtra State Board of Technical Education (Autonomous) (ISO/IEC - 27001 - 2005 Certified) Winter - 2022 Examination Model Answer Subject: 22619Documento22 pagineMaharashtra State Board of Technical Education (Autonomous) (ISO/IEC - 27001 - 2005 Certified) Winter - 2022 Examination Model Answer Subject: 22619Pratiksha JadhavNessuna valutazione finora

- S ParametersDocumento29 pagineS ParameterseloiseNessuna valutazione finora

- BIBLIOMETRICDocumento30 pagineBIBLIOMETRICkalaranishanmuganathNessuna valutazione finora

- Rsa Netwitness Logs and Packets: Server, Dac and San HW SpecificationsDocumento10 pagineRsa Netwitness Logs and Packets: Server, Dac and San HW SpecificationsfunyiroemberNessuna valutazione finora

- Wood Conserving StovesDocumento117 pagineWood Conserving Stovesalitoparana100% (1)

- Pediatric Appendicitis ScoreDocumento6 paginePediatric Appendicitis ScorePinandhito LatukolanNessuna valutazione finora

- National Telecommunication Corporation (NTC)Documento40 pagineNational Telecommunication Corporation (NTC)Faheem Sajid100% (1)

- HR Wallingford-009 - Wave - GaugeDocumento2 pagineHR Wallingford-009 - Wave - GaugeSutanto HadiNessuna valutazione finora

- Study of Educational Aspiration and Socio-Economic Status of Secondary School StudentsDocumento11 pagineStudy of Educational Aspiration and Socio-Economic Status of Secondary School StudentsvivekNessuna valutazione finora

- 3questions Measurements and UncertaintyDocumento2 pagine3questions Measurements and UncertaintyLeanne DerigeNessuna valutazione finora

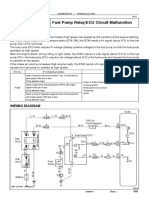

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDocumento4 pagineDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealNessuna valutazione finora

- 1 - Classful Ip AddressingDocumento6 pagine1 - Classful Ip AddressingBiruk Tesfaye Legesse100% (1)

- Bouveault-Blanc Ester ReductionDocumento3 pagineBouveault-Blanc Ester ReductionAriel GarciaNessuna valutazione finora

- Computer Networks: Introduction (Chapter 1)Documento92 pagineComputer Networks: Introduction (Chapter 1)Speed PianoNessuna valutazione finora

- An Isogeometric Analysis Approach For The Study of Structural VibrationsDocumento59 pagineAn Isogeometric Analysis Approach For The Study of Structural VibrationsBharti SinghNessuna valutazione finora

- Detailedlessonplanintrigonometry 130303203030 Phpapp01Documento4 pagineDetailedlessonplanintrigonometry 130303203030 Phpapp01Hazel Clemente CarreonNessuna valutazione finora

- Tugas HKSA Deskriptor (Fitriani Choerunnisa (11171013) 3FA1)Documento4 pagineTugas HKSA Deskriptor (Fitriani Choerunnisa (11171013) 3FA1)fitriani choerunnisaNessuna valutazione finora

- Mac Keyboard ShortcutsDocumento16 pagineMac Keyboard ShortcutsSaira FazalNessuna valutazione finora

- E-Studio 205L, 255, 305, 355, 455 MFP Service HandbookDocumento732 pagineE-Studio 205L, 255, 305, 355, 455 MFP Service HandbookAnonymous gn8qxx66% (35)

- 3 Statement Model: Strictly ConfidentialDocumento13 pagine3 Statement Model: Strictly ConfidentialLalit mohan PradhanNessuna valutazione finora

- Introduction To Chaos: The Damped, Driven, Nonlinear PendulumDocumento14 pagineIntroduction To Chaos: The Damped, Driven, Nonlinear PendulumKikkuNessuna valutazione finora