Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Acid Dealumination of EM-5

Caricato da

JOSEPH HERBERT MABELCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Acid Dealumination of EM-5

Caricato da

JOSEPH HERBERT MABELCopyright:

Formati disponibili

ELSEVIER

Acid dealumination

of EM-5

of Technology,

P.J. Kooyman, P. van der Waal, and H. van Bekkum Laboratory of Organic Chemistry and Catalysis, Delji University Julianalaan 136, 2628 BL Del& The Netherlands

The acid dealumination of various samples of ZSM-5 is studied using mineral acids as the dealuminating agent. Apart from the synthesis method of the ZSM-5, the acid concentration, the temperature, and the duration of the acid treatment are varied. The results are evaluated using elemental analysis and 27AI MAS n.m.r. A comparison with literature data is presented. It seems 0 Elsevier Science that the dealumination of MFI is not as straightforward as is often assumed. Inc. 1997

Keywords: MFI zeolite; dealumination; aluminum; mineral acid treatment

INTRODUCTION

Generally, the less framework aluminum acidic sites a unit cell of a zeolite possesses, the stronger the acidity per site is. Thus, by controlling the Si/Al ratio of the zeolite framework, the acidic catalytic properties of the zeolite can be influenced. However, many types of zeolites (e.g., MOR and zeolite Y (FAU)) cannot be synthesized directly in a high-silica form. These zeolites have to be dealuminated using a postsynthesis treatment. Although it is well known that most zeolites can be dealuminated without seriously affecting the crystal structure of the materials, not many types of zeolites have been studied systematically for their behavior under acid dealumination conditions. The most commonly used dealumination methods are the so-called steaming treatment (in which the zeolite is heated to high temperatures, e.g., 5OOC, in a flow of steam) and treatment with gaseous SiCl,, also at elevated temperatures. Many papers have been published on the behavior of zeolite Y (FAU) under these treatments, mainly because the resulting material, USY, shows improved catalytic cracking properties, which is of great interest to the petroleum industry. Using either of the aforementioned treatments, zeolites are obtained that contain less framework Al species than the parent materials, but few framework vacancies (silanol nests). This is due to direct substitution of Si for Al in the SiCl, treatment, and to the T-jump mechanism in steaming. Because of the latter mechanism, mesopores are also created during the migration of SiO, under the action of heat and steam. Less frequently used dealumination techniques include reaction with chelating agents like EDTA and oxalic acid, reaction with aqueous (NH,)$iF,, and reaction with F, gas. The creation of framework vacancies upon dealumination can be desirable when another transition metal (e.g., Ti, Fe, B, Ga, V) has to be incorporated into the

Address Received reprint requests to Dr. P.J. Kooyman. 10 January 1994; accepted 4 August

zeolite framework, leading to suitable catalysts for various processes. However, as the direct incorporation of some transition metals (e.g., I?) into the MFI framework is not straightforward,3 it can be beneficial to follow a secondary synthesis route, in which Al-containing MFI is first dealuminated via acid treatment to create silanol nests. Subsequently the desired transition metal is inserted into or attached to the silanol nests, creating transition-metal-containing MFI. Literature data on the acid dealumination of Alcontaining MFI show a great variety of results. Although hydrochloric acid treatment is often used to dealuminate MFI, several authors use hydrochloric acid ion exchange as a means to convert MFI to the H-form.4 Although treatment conditions are similar, it is then assumed that only ion exchange occurs; the possibility of dealumination is not even taken into account. From a comparison of literature data concerning hydrochloric acid treatment of ZSM-5,5-12 the question arises whether the synthesis method of ZSM5 is important in the resistance of the material to acid dealumination. Thus, we have synthesized various samples of ZSM-5 according to different synthesis methods, and we have studied the results of treating these samples of ZSM-5 with varying concentrations of different mineral acids and of changing the temperature of the acid treatment.

EXPERIMENTAL Materials: synthesis of ZSM-5

1996

Samples denoted as ARGN were synthesized according to the original patent method, described by Argaucr and Landolt,s Nindicating the Si/Al ratio of the resulting material. Typical features of this synthesis method are the high TPA/Si (TPA = tetrapropylammonium cation) and H,O/Si ratios employed. Thus, a solution A was prepared by dissolving 40.1 g of Aerosil 200 (Degussa) in 209.5 g of 40% TPAOH in water (CFZ Zaltbommel). To obtain a solution, it is necessary to

Zeolites 18:50-53, 1997 0 Elsevier Science Inc. 1997 655 Avenue of the Americas,

New York, NY 10010

0144-2449/97/$17.00 PII SO144-2449(96)00106-6

MFI dealumination:

P. J. Kooyman

et al.

heat the mixture to about 100C under stirring. Solution B was obtained by dissolving the appropriate amount of NaAlO, (ICN Pharmaceuticals) in 72.3 g of water and was stirred into solution A. The resulting gel was autoclaved at 150C for 6 days. Sample SSG40 (Si/Al = 40) was synthesized according to a method described by Sand and Ghamami.i4 105 g of Ludox AS-40 (Du Pont) , 127 g of 25% NH, in water, 16 g TPABr (CFZ Zaltbommel), and 2.86 g of aluminum isopropoxide (Janssen Chimica) were mixed to a homogeneous gel, which was autoclaved at 180C for 2 weeks. Sample (HA-15 (Si/Al = 15) was synthesized according to a method described by Change et all5 by making a solution A of 150 g of Ludox HS-40 and 100 g of 1.3% TPABr in water, and a solution B by dissolving 8.65 g of NaOH in 11 g of H,O and subsequently slowly adding 6 g of sodium aluminate. Then solution B was stirred into solution A, and the resulting gel was autoclaved for 3 days at 175C. Sample RR-38 (Si/Al = 38) was synthesized according to the method used by Rraushaar and van Hooffs by first making three solutions: solution A by dissolving 12 g of NaOH and 30 g of Cab-0-Sil (the Cabot Company) in 90 g of water; solution B by dissolving 3.4 g of Al,(SO,), . 18H,O and 24.0 g of TPABr in 74.3 g of 4 N H,SO,; solution C by dissolving 14.7 g of NaCl in 45.3 g of water. Then, starting with solution C, solution B and about 3/4of the total amount of solution A were added simultaneously under vigorous stirring. The pH was set at 3 by adding a little bit more of solution A, and the mixture was stirred for 2 h. The pH was then set at 9 by adding the remaining part of solution A and a small amount of NaOH while stirring, and the mixture was autoclaved at 160C for 3 days. All MFI samples synthesized were identified as pure MFI by X-ray diffraction and i.r. spectroscopy. Before the dealumination experiments, all samples were calcined in air in a muffle furnace at at least 500C overnight, to remove occluded TPA. The samples are expected to be mainly in the protonic form. The Si/Al ratios were determined by ICP analysis of the samples dissolved in diluted HF/H,SO,/H,BO,.

glass vessel; at temperatures higher than 100C a Teflon-lined stainless steel autoclave (not stirred) was used.

Al MAS n.m.r.

Solid-state *Al n.m.r. spect r a were recorded on a Varian VXR-400 S spectrometer, using magic angle spinning and a Doty probe. I M aqueous Al(NOs)s was used as an external chemical shift reference (8 = 0). Acquisition time was 0.3 s with an acquisition delay of 0.3 s. The number of datapoints was 16,000, and the pulse width was 1.5 ps, to correspond to a flip angle <15.16 Spinning rates were between 3,500 and 5.500 Hz.

RESULTS AND DISCUSSION

The treatment of sample ARL44 with 1 N H,SO, and 1 N HBr at 80C does not give dealumination at all, whereas treatment with 1 N HCl at 80C leads to only slight dealumination. Aqueous HF was not used as the dealuminating agent, because it is well known that even diluted HF not only dissolves aluminum from a zeolite framework, but that silicon is also dissolved, creating mesopores. Threefold 0.5-h treatment with 1 N HCl at 80C of various samples of ARL with different Si/Al ratios does not result in substantial dealumination, although Si/Al ratios show a slight increase. Apparently, hardly any dealumination is achieved in these experiments. However, we have to take into account that any dealumination procedure comprises two stages. In the first stage, aluminum is removed from its tetrahedral framework position and becomes octahedrally coordinated inside the zeolitic pore structure. Thus, after this first stage the bulk Si/Al ratio does not change, even though the framework Si/Al ratio can change significantly. In the second stage (which can occur almost simultaneously with the first stage and does not require different reagents), the octahedrally coordinated Al (H,O) r species diffuses out of the zeolitic pore system and into the surrounding solution. During this second stage the bulk Si/Al ratio decreases, whereas the framework Si/ Al ratio does not change. Possibly after 0.5 h at 80C aluminum has indeed been extracted from the framework but is still present inside the pores of the zeolite. If this is the case, a decrease of the bulk Si/Al ratio would be expected upon prolonged acid treatment or upon increasing the temperature of the acid treatment, as in both cases the total diffusion of the extraframework aluminum species is expected to be more complete. However, prolonging the 1 N HCl treatment at 80C from 3 * 0.5 h to 3 * 24 h does not lead to a significantly higher degree of dealumination. Using higher reaction temperatures up to 160C does not lead to a significantly higher degree of dealumination either. Although the experiments at 125C and 160C were performed without stirring, and thus the material may have been dealuminated a little bit less than it would have been with stirring, these results show that even at 160C dealumination is not significant.

Acid treatment

The samples of ZSM-5 were treated with different mineral acids at different temperatures to study aluminum removal from the framework. Threefold treatment with 100 ml of 1 N aqueous acid per gram of zeolite, for at least half an hour, was applied. The zeolite was placed in the reaction vessel with the acid solution and was heated to the desired temperature, which was maintained for the amount of time indicated, after which the source of heat was removed and the suspension was left to settle. The acid solution was decanted, fresh acid solution was added, and the whole procedure was repeated. After the third heating period, the suspension was filtrated, and the zeolite was washed thoroughly with water. Samples were dried overnight at 120C in air. Up to 100C the dealumination experiments were performed in a stirred round-bottomed

Zeolites

l&50-53,

1997

51

MFI dealumination:

P. J. Kooyman

et a/.

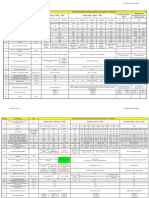

Figure I shows the *Al MAS n.m.r. spectra of the sample ARL22 before and after 3fold treatment with 1 N HCl for 1 and 24 h at 80C. From these spectra it is clear that the starting material contains only tetrahedrally coordinated aluminum (signal at 54 ppm), whereas a small part of the aluminum is coordinated octahedrally in the acid-treated samples (signal at 0 ppm) . Both acid-treated samples contain approximately the same ratio of tetrahedrally to octahedrally coordinated aluminum. From these n.m.r. spectra we can conclude that although some aluminum is extracted from the framework upon acid treatment, dealumination is not very efficient, and dealumination efficiency does not increase upon prolonging the acid treatment from 3 * 1 h to 3 * 24 h. We can also conclude that the removal of octahedral aluminum is incomplete. As none of the samples obtained using the AFU synthesis method showed significant dealumination, samples of ZSM-5 obtained using different synthesis methods were treated with 1 N aqueous HCl. However, sample CHA-15 is not easily dealuminated. The Al MAS n.m.r. spectra of sample SSG-40 after 3-fold 2-h treatment with 1 N HCl shows only a very small signal at 0 ppm, indicating that practically no aluminum is removed from the framework. Kraushaar and van Hooffs are the only authors to report almost 100% dealumination upon treating ZSM5 with 1 N HCl. Our sample KR-38 was prepared according to the synthesis method these authors use.6 The *Al MAS n.m.r. spectra of this material before and after 1 N HCI treatment (3 * 1 h at 80C) show that our material KR-38 is very resistant to acid treatment (the signal for octahedrally coordinated aluminum is very

small after acid treatment). After completion of this study, Prof. van Hooff informed us that their dealumination results are difficult to reproduce.6 Subtle differences in the synthesis conditions might play an important role in determining the stability of the material obtained. Kornatowski et al.,* reported reasonable dealumination using Mostowicz synthesis method and subjecting this sample of ZSM-5 to boiling 1.25 N HCl. Moreover, in that case the degree of dealumination increases with increasing acid treatment period.** However, the majority of the literature data as well as the data of the present work show that the acid dealumination of ZSM-5 is not as feasible as one would be inclined to think. It seems that most ZSM-5 synthesis methods provide samples that are very resistant to acid dealumination. This stability might be because of the virtual al, sence of structural defects. One would expect that samples of ZSM-5 obtained via a very fast synthesis method will possibly contain intrinsic structural defects and may be more susceptible to acid dealumination. This fast crystallization might be achieved by adding seeds to the synthesis gel or by applying microwave heating s* during the synthesis. CONCLUSIONS The acid dealumination of zeolite ZSM-5 is not as straightforward as it seems to be. Apparently no dealumination is found when using aqueous HBr or H,SO,, and hardly any dealumination is found when using aqueous HCl. For the samples studied, the temperature or the period of time of the acid treatment do not influence the extent of dealumination, nor do the Si/ Al ratio of the samples or the synthesis method according to which the samples were obtained. ACKNOWLEDGMENTS Thanks are due to Dr. J.A. Peters and Mr. A. van Estrik, who recorded the Al MAS n.m.r. spectra. Mr. J. Padmos performed the elemental analyses. Dr. A. Sinnema is acknowledged for valuable discussions regrateful1 garding r7 Al MAS n.m.r.

40

0 wm

-40

Figure 1 AI

rial; (b) after treatment.

MAS n.m.r. spectra of ARL-22: (a) starting mate3 * l-h acid treatment; and (c) after 3 * 24-h acid

Sie, ST. in AdvancedZeolite Science and Applications (Eds. J.C. Jansen, M. St8cker, H.G. Karge and J. Weitkamp), Stud. Surf. Sci. Catal. 1994, Vol. 85, p. 587 lone, K.G., Vostrikova, L.A. and Mastikhin, V.M. J. Molec. Catal. 1985, 31, 355 Kraushaar-Czarnetzki, B. and von Hooff, J.H.C. Catal. Lett. 1989,2,43 Wang, D.Z., Lu, X.D., Dou, X.Y., Li, W.B. and Yang, C.H. Appl. Catal. 1990, 59, 75 Kraushaar, B and van Hooff, J.H.C. Catal. Lett. 1988, 1, 81 van Hooff, J.H.C. private communication Kornatowski, J., Rozwadowski, M., Gutze, A. and Wisniewski, K.E. in Zeolites as Catalysts, Sorbents and Detergent Builders (Eds. H.G. Karger and J. Weitkamp) Stud. Surf. Sci. Catal. 1989, Vol. 46, p. 567 Kornatowski, J., Baur, W.H., Pieper, G., Rozwadowski, M., Schmitt W. and Cichowlas. A. J, Chem. Sot. Farad. Trans. 1992,88,275

52

Zeolites

18:50-53.

1997

MFI dealumination: 9 10 Debra% G.. Gourgue, A.. Nagy, J.B. and de Clippeleir, G. Zeolites 1986, 6, 241 Skeels, G.W. and Flank, W.H. in lntrazeolite Chemistry, ACS Symp. Ser. 218, (Eds. G.D. Stuck and F.G. Dwyer) Hon. Chem. Sot., Washington, DC, 1983, p. 369 Dwyer, J., Fitch, F.R., Qin G. and Vickerman, J.C. J. fhys. Chem. 1982,86,4574 Sayed, M.B. Thermochimica Acta 1988, 126,325 Argauer, R.J. and Landolt, G.R. US Pat. 3,702,886 (1972) Ghamami, M. and Sand, L.B. Zeolites 1983, 3, 155 15 16 17

t? J. Kooyman

et a/.

11 12 13 14

18

Chang, C.G., Waters, S.M. and Sanchez, M.G. Eur. Pat. 173,895 (1986) Man, P.P. and Klinowski, J. J. Chem. Sac., Chem. Commun. 1988, 1291 Jansen, J.C., Arafat, A., Barakat, A.K. and van Bekkum, H. in Molecular Sieves, Synthesis of Microporous Materials, Vol. 1, (Eds. M.L. Occelli and H.E. Robson) Van Nostrand Reinhold, New York, 1992, p. 507 Arafat, A., Jansen, J.C., Ebaid, A.R. and van Bekkum, H. Zeolites 1993, 13, 162

Zeolites

18:50-53,

1997

53

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Steel Metallurgy For The Non-Metallurgist: January 2007Documento11 pagineSteel Metallurgy For The Non-Metallurgist: January 2007Anurag RamdasNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Guide To Expansion Joints (Choosing and Maintenance)Documento16 pagineGuide To Expansion Joints (Choosing and Maintenance)stevebeanNessuna valutazione finora

- Distillation Column PipingDocumento57 pagineDistillation Column PipingKaran Singh92% (13)

- EIFS performance standardsDocumento40 pagineEIFS performance standardsRyan ClarkeNessuna valutazione finora

- 1300 Math Formulas - Alex SvirinDocumento338 pagine1300 Math Formulas - Alex SvirinMirnesNessuna valutazione finora

- Going Green With ZeolitesDocumento7 pagineGoing Green With ZeolitesJOSEPH HERBERT MABELNessuna valutazione finora

- KinecticsDocumento8 pagineKinecticsJOSEPH HERBERT MABELNessuna valutazione finora

- Assessment of Practical Skill in Science-XDocumento59 pagineAssessment of Practical Skill in Science-XSamehaIrum100% (1)

- 1634Documento2 pagine1634JOSEPH HERBERT MABELNessuna valutazione finora

- Shiftting TelephoneDocumento2 pagineShiftting TelephoneAbhishek DasNessuna valutazione finora

- Singer Instruction Manual 8280 PDFDocumento50 pagineSinger Instruction Manual 8280 PDFJOSEPH HERBERT MABELNessuna valutazione finora

- Copenhagen Draft Agreement 2009Documento13 pagineCopenhagen Draft Agreement 2009JOSEPH HERBERT MABELNessuna valutazione finora

- The Bhopal Gas TragedyDocumento16 pagineThe Bhopal Gas TragedyGrapes als PriyaNessuna valutazione finora

- GoldDocumento2 pagineGoldJOSEPH HERBERT MABELNessuna valutazione finora

- Mathematics FormulaDocumento34 pagineMathematics FormulaJOSEPH HERBERT MABEL100% (1)

- Scholarly PublishingDocumento1 paginaScholarly PublishingJOSEPH HERBERT MABELNessuna valutazione finora

- Shiftting TelephoneDocumento2 pagineShiftting TelephoneAbhishek DasNessuna valutazione finora

- Journal of Molecular Liquids: M. Asha Jhonsi, A. KathiravanDocumento5 pagineJournal of Molecular Liquids: M. Asha Jhonsi, A. KathiravanJOSEPH HERBERT MABELNessuna valutazione finora

- AnticancerDocumento11 pagineAnticancerJOSEPH HERBERT MABELNessuna valutazione finora

- Nuclear BasicsDocumento5 pagineNuclear BasicsJOSEPH HERBERT MABELNessuna valutazione finora

- Clay and heteropoly acid catalysts for green processesDocumento21 pagineClay and heteropoly acid catalysts for green processesJOSEPH HERBERT MABELNessuna valutazione finora

- Iop PDFDocumento173 pagineIop PDFJOSEPH HERBERT MABELNessuna valutazione finora

- Alkylation of Catechol With T-Butyl Alcohol Over Acidic ZeolitesDocumento8 pagineAlkylation of Catechol With T-Butyl Alcohol Over Acidic ZeolitesJOSEPH HERBERT MABELNessuna valutazione finora

- Physicochemical and Catalytic Properties of HZSM-5 Zeolites Dealuminated by TheDocumento6 paginePhysicochemical and Catalytic Properties of HZSM-5 Zeolites Dealuminated by TheJOSEPH HERBERT MABELNessuna valutazione finora

- The Twelve Principles of Green Chemistry1Documento2 pagineThe Twelve Principles of Green Chemistry1JOSEPH HERBERT MABELNessuna valutazione finora

- Heteropolyacids. Versatile Green Catalysts Usable in A Variety of Reaction MediaDocumento7 pagineHeteropolyacids. Versatile Green Catalysts Usable in A Variety of Reaction MediaJOSEPH HERBERT MABELNessuna valutazione finora

- Influence of Mild Dealumination On Physicochemical, Acidic and Catalytic Properties of H-ZSM-5Documento6 pagineInfluence of Mild Dealumination On Physicochemical, Acidic and Catalytic Properties of H-ZSM-5JOSEPH HERBERT MABELNessuna valutazione finora

- Steam and Acid Dealumination of Mordenite Characterization and Influence On The Catalytic Performance in Linear Alkylbenzene SynthesisDocumento9 pagineSteam and Acid Dealumination of Mordenite Characterization and Influence On The Catalytic Performance in Linear Alkylbenzene SynthesisJOSEPH HERBERT MABELNessuna valutazione finora

- Solid Acids For Green ChemistryDocumento7 pagineSolid Acids For Green ChemistryJOSEPH HERBERT MABELNessuna valutazione finora

- Catalysis and Sustainable (Green) ChemistryDocumento11 pagineCatalysis and Sustainable (Green) ChemistryJOSEPH HERBERT MABELNessuna valutazione finora

- Physicochemical and Catalytic Properties of HZSM-5 Zeolites Dealuminated by TheDocumento6 paginePhysicochemical and Catalytic Properties of HZSM-5 Zeolites Dealuminated by TheJOSEPH HERBERT MABELNessuna valutazione finora

- Effect of The Degree and Type of The Dealumination Method On The Structural, Compositional and Acidic Characteristics of H-ZSM5 ZeolitesDocumento20 pagineEffect of The Degree and Type of The Dealumination Method On The Structural, Compositional and Acidic Characteristics of H-ZSM5 ZeolitesJOSEPH HERBERT MABELNessuna valutazione finora

- Microporous Characteristics of HY, HZSM-5 and H-Mordenite Dealumination by Calcination - HONG - 1995Documento12 pagineMicroporous Characteristics of HY, HZSM-5 and H-Mordenite Dealumination by Calcination - HONG - 1995JOSEPH HERBERT MABELNessuna valutazione finora

- Effect of Hydrothermal Dealumination of A Synthetic Faujasite by IR SpectrosDocumento4 pagineEffect of Hydrothermal Dealumination of A Synthetic Faujasite by IR SpectrosJOSEPH HERBERT MABELNessuna valutazione finora

- Coomassie Blue Staining for Protein DetectionDocumento3 pagineCoomassie Blue Staining for Protein DetectionYvy Villafani BNessuna valutazione finora

- Timber: Civil Engineering MaterialDocumento47 pagineTimber: Civil Engineering MaterialSamirsinh ParmarNessuna valutazione finora

- VIESSMANN DHW Calculation VitocellTechnicalGuideDocumento52 pagineVIESSMANN DHW Calculation VitocellTechnicalGuideaakoglanisNessuna valutazione finora

- FAME - Automated Fatty Acid Derivatization & GC - MS AnalysisDocumento3 pagineFAME - Automated Fatty Acid Derivatization & GC - MS AnalysisHushla ShudriNessuna valutazione finora

- ProjectDocumento7 pagineProjectaarav singhNessuna valutazione finora

- Admixtures and Shotcrete DurabilityDocumento7 pagineAdmixtures and Shotcrete DurabilityMulyawan WIdiasmanNessuna valutazione finora

- Fat Digestion and Metabolism in RuminantsDocumento23 pagineFat Digestion and Metabolism in Ruminantsshahbaz zafarNessuna valutazione finora

- Mathematical Heat Transfer Model Research For The Improve-Ment of Continuous Casting Slab TemperatureDocumento6 pagineMathematical Heat Transfer Model Research For The Improve-Ment of Continuous Casting Slab TemperatureSanjeev SahuNessuna valutazione finora

- s4 Chemistry Paper 1 Set 1 Marking GuideDocumento11 pagines4 Chemistry Paper 1 Set 1 Marking GuideNamuli MercyNessuna valutazione finora

- Manufacturing porcelain figures using binder jetting 3D printingDocumento8 pagineManufacturing porcelain figures using binder jetting 3D printingcesarNessuna valutazione finora

- LSP For Carbon Fiber AircraftDocumento12 pagineLSP For Carbon Fiber AircraftDavid GoldNessuna valutazione finora

- Nama: Rodiatul Jannah No Absen: 28 Kelas: Xi-Mipa 3 Guru Mapel: Widisuwita Sumadia, M.PDDocumento10 pagineNama: Rodiatul Jannah No Absen: 28 Kelas: Xi-Mipa 3 Guru Mapel: Widisuwita Sumadia, M.PDrodiatul jannahNessuna valutazione finora

- WPS MCC 001 PDFDocumento1 paginaWPS MCC 001 PDFNuwan RanaweeraNessuna valutazione finora

- Internship Format1Documento44 pagineInternship Format1Prajwal ChavanNessuna valutazione finora

- Protons, Neutrons, and Electrons Practice WorksheetDocumento2 pagineProtons, Neutrons, and Electrons Practice WorksheetRedHoeBeerNessuna valutazione finora

- Analysis QBDocumento167 pagineAnalysis QBChethan PrabhuNessuna valutazione finora

- Morbido Af-99100 v12 Msds enDocumento14 pagineMorbido Af-99100 v12 Msds enjanNessuna valutazione finora

- PV Module IonDocumento4 paginePV Module IonrmalewarNessuna valutazione finora

- Pamphlet 001 Chlorine BasicsDocumento61 paginePamphlet 001 Chlorine Basicsthorem100% (1)

- Usp42-Nf37 202Documento4 pagineUsp42-Nf37 202Mohamed Hassan100% (1)

- CVDocumento2 pagineCVyadse100% (1)

- J Parenter Enteral Nutr - 2015 - Frank - Thiamin in Clinical PracticeDocumento18 pagineJ Parenter Enteral Nutr - 2015 - Frank - Thiamin in Clinical Practicejuhh tavaresNessuna valutazione finora

- Compressed Air SystemDocumento29 pagineCompressed Air Systemsk sajidNessuna valutazione finora

- Edicto - Thermodynamics Lab - Heat FusionDocumento2 pagineEdicto - Thermodynamics Lab - Heat FusionEdicto, Beatrice CarolineNessuna valutazione finora

- F&C Safety Data Sheet Catalog No.: 315407 Product Name: Ammonia Solution 25%Documento7 pagineF&C Safety Data Sheet Catalog No.: 315407 Product Name: Ammonia Solution 25%Rizky AriansyahNessuna valutazione finora

- 9h47.02 CD Emerald LyseDocumento9 pagine9h47.02 CD Emerald LyseanggitasaputriNessuna valutazione finora