Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Meth A Oxides

Caricato da

kcute_khot0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

22 visualizzazioni3 pagineikh

Titolo originale

Meth a Oxides

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoikh

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

22 visualizzazioni3 pagineMeth A Oxides

Caricato da

kcute_khotikh

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

Methaoxides Reaction time 45min

Temp rapture 60C

1.5 Wt %

Yield is more than 98%

Disadvantage in General for Both NaOH and KOH mostly KOH:

Presence of water content generally manifests itself through excessive soap production. Apart

from that, the soaps of saturated fatty acids tend to solidify at ambient temperatures and thus a

reaction mixture with excessive soap may gel-up and form a semi-solid mass which is very

difficult to recover.

Methaoxides:

The formation of methyl esters by transesterfication stoichiometrically requires three moles of

alcohol for every mole of triglyceride However, transesterification is an equilibrium reaction in

which a large excess of the alcohol is required to drive the reaction close to completion.

Fortunately, the equilibrium constant favors the methyl esters such that only a 6:l molar ratio of

methanol: triglyceride is sufficient to cause a 95-98% yield of ester. It might be anticipated that,

in such an equilibrium system, the observed phase separation of the by product, glycerol, would

play a major role in achieving conversions close to 100%. Fuel standards currently developing

for biodiesel methyl esters severely limit the mono-and diglyceride contents. Because of this, and

the high cost of the raw material, very high conversions are important, and if achieved, could

eliminate the necessity for distillation beyond that required for removal of the excess alcohol.

The 6: l methanol: oil ratio, which appears to be that being adopted in commercial processes, was

also used in the kinetic study of 1986.

In this sense, the reactions that used sodium or potassium hydroxide were faster than the

reactions with the sodium or potassium methoxides. Regarding both types, the transesterification

with the sodium catalyst was faster than the reaction with the potassium catalyst. Thus, the near

100% methyl ester concentration was obtained at 30 min with sodium hydroxide, at 45 min when

using sodium methoxide or potassium hydroxide and after 4 h with potassium methoxide.

The preferred catalysts for large continuous-flow production processes are Sodium and

potassium methaoxide which is now commercially available as well. In transesterification, the

effective species of catalysis is the methoxide radicals (CH3O). The activity of a catalyst

depends upon the amount of methoxide radicals available for the reaction (Komers et al., 2001a,

b). For sodium or potassium hydroxide, methoxide ion is prepared in situ by reacting hydroxide

and methanol:

This reaction also yields water that remains in the system. Hydrolysis of triglycerides and alkyl

esters may occur due to the presence of water, which further leads to the formation of free fatty

acids and thus to undesired soap. Saponification will also occur if a strong base, e.g., NaOH or

KOH, is present in the system by reacting with esters and triglycerides directly. On the other

hand, the water problem can be avoided if sodium and potassium methoxide solutions, which can

be prepared water-free, are applied. Additionally, although the use of methoxides cannot avoid

soap formation if the feedstock contains free fatty acids, which is also true for use of KOH or

NaOH, but very little saponification of esters or triglycerides occurs because methoxides behave

as weak Lewis bases.

However all these base reactions differ at different conditions for example at 65 C and molar

ratio 3:1 Sodium methaoxides yields more biodiesel but by increasing the molar ratio and

decreasing temperature Potassium metha oxide will result in higher yield of biodiesel and lower

yield of soap formation:

Optimization in transesterifying methanol and canola oil using four alkaline catalyst

formulations by examining their effects on biodiesel yield and soap formation at different

catalyst molar concentrations, reaction temperatures, and methanol-to-oil molar ratios. Optimum

operating conditions for maximizing biodiesel yield and minimizing soap formation were

determined by statistically analyzing the experimental data using a multiple response

optimization statistical software and further verified through experimentation.

According to Freedman et al. (1986) NaOCH3 is a more effective catalyst formulation than

NaOH and almost equal oil conversion was observed at 6:1 alcohol-to-oil molar ratio for 1%wt

NaOH and 0.5%wt NaOCH3. Vicente et al. (2004) reported higher yields with methoxide

catalysts, but the rate of reaction was highest for NaOH and lowest for KOCH3 at 65C, a

methanol-to-oil ratio of 6:1, and a catalyst concentration of 1%wt. It was observed that

potassium based catalysts gave better yield than sodium-based catalysts and methoxide catalysts

gave higher yields than their corresponding hydroxide catalyst. The trend observed can be

modelled as follows:

KOCH

3

> NaOCH

3

> KOH > NaOH

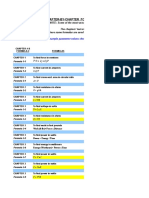

The table below summarizes the results obtained among the four catalyst formulations:

Generally, the catalyst formulation on soap showed that potassium based catalysts resulted in

higher soap formation than the corresponding sodium-based catalysts. Only KOH was found to

have a significantly higher level of soap formation than the other three formulations in terms of

soap formation:

NaOCH

3

> NaOH > KOCH

3

>>KOH

It was observed that methoxide catalysts led to better biodiesel yields than hydroxide catalysts.

The methoxide catalysts not only accelerated the reaction but also elevated the conversion

equilibrium. Based on statistical optimization, the operating conditions for maximizing biodiesel

yield and minimizing soap formation were potassium methoxide as catalyst at a concentration of

0.2 mol/mol (1.59%wt), reaction temperature of 50

o

C, and methanol-to-oil molar ratio of 4.5:1.

This resulted in an optimum yield of 95.8% with a total soap formation of 0.75%.

Refrences :

Gemma Vicente, Mercedes Martinez, Jos Aracil, Integrated biodiesel

production: a comparison of different homogeneous catalysts systems,

Bioresource Technology, Volume 92, Issue 3, May 2004, Pages 297-305, ISSN

0960-8524, http://dx.doi.org/10.1016/j.biortech.2003.08.014.

(http://www.sciencedirect.com/science/article/pii/S096085240300230X)

Man Kee Lam, Keat Teong Lee, Abdul Rahman Mohamed, Homogeneous, heterogeneous

and enzymatic catalysis for transesterification of high free fatty acid oil

(waste cooking oil) to biodiesel: A review, Biotechnology Advances, Volume

28, Issue 4, JulyAugust 2010, Pages 500-518, ISSN 0734-9750,

http://dx.doi.org/10.1016/j.biotechadv.2010.03.002.

(http://www.sciencedirect.com/science/article/pii/S0734975010000388)

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Msds Thinner 21-06Documento8 pagineMsds Thinner 21-06ridhowibiiNessuna valutazione finora

- Astral Column Pipe PricelistDocumento4 pagineAstral Column Pipe PricelistVaishamNessuna valutazione finora

- Abstract Classes and Methods in Object Oriented ProgrammingDocumento13 pagineAbstract Classes and Methods in Object Oriented Programmingkishore1201Nessuna valutazione finora

- Gate Mock Test1Documento17 pagineGate Mock Test1Gopinathan SudheerNessuna valutazione finora

- TCON300Documento722 pagineTCON300DGGNessuna valutazione finora

- TM4C129XNCZAD MicrocontrollerDocumento2.191 pagineTM4C129XNCZAD Microcontrollermamaligosu1Nessuna valutazione finora

- F1FR80 Series Quick-Response SprinklersDocumento6 pagineF1FR80 Series Quick-Response SprinklersAtila AmayaNessuna valutazione finora

- Touch Screen TechnologyDocumento18 pagineTouch Screen TechnologySmîlērNessuna valutazione finora

- Method Statement For Cable & TerminationDocumento6 pagineMethod Statement For Cable & TerminationRajuNessuna valutazione finora

- JEDI Slides Intro1 Chapter 02 Introduction To JavaDocumento17 pagineJEDI Slides Intro1 Chapter 02 Introduction To JavaredbutterflyNessuna valutazione finora

- حل جميع المعادلات الكهربائيةDocumento60 pagineحل جميع المعادلات الكهربائيةGandhi HammoudNessuna valutazione finora

- Chap1-Geometrical Optics - ExercisesDocumento3 pagineChap1-Geometrical Optics - ExercisesReema HlohNessuna valutazione finora

- Hughes Brothers PDFDocumento52 pagineHughes Brothers PDFJavier MaldonadoNessuna valutazione finora

- Counter List HuaweiDocumento14 pagineCounter List Huaweiwedewe02Nessuna valutazione finora

- PDF Saa6d140e 2 Seriespdf CompressDocumento8 paginePDF Saa6d140e 2 Seriespdf CompressNathawatNessuna valutazione finora

- Gpa 2145Documento15 pagineGpa 2145Sergio David Ruiz100% (1)

- Manufacturing Egg Trays from Waste PaperDocumento17 pagineManufacturing Egg Trays from Waste Paperravibarora86% (7)

- ALTERNATOR - ST170741: Parts ListDocumento2 pagineALTERNATOR - ST170741: Parts Listkaswade BrianNessuna valutazione finora

- MC 8051Documento85 pagineMC 8051Sonu SatishNessuna valutazione finora

- bbk-lt2614-lt3214 Service Manual PDFDocumento42 paginebbk-lt2614-lt3214 Service Manual PDFrj arcinasNessuna valutazione finora

- Learning Resource Management Made SimpleDocumento12 pagineLearning Resource Management Made SimpleJosenia ConstantinoNessuna valutazione finora

- 1HD-T - 1 Land Cruiser Engine Service ManualDocumento26 pagine1HD-T - 1 Land Cruiser Engine Service ManualMichael Dzidowski86% (7)

- Fundamentals 2014Documento959 pagineFundamentals 2014Angelo Vittorio VettorazziNessuna valutazione finora

- ISO 128-25 Technical Drawings - General Principles of Presentation - Lines On Shipbuilding Drawings (1999)Documento16 pagineISO 128-25 Technical Drawings - General Principles of Presentation - Lines On Shipbuilding Drawings (1999)SantoshNessuna valutazione finora

- Sample Style GuideDocumento5 pagineSample Style Guideapi-282547722Nessuna valutazione finora

- X-Span & Setting ToolsDocumento18 pagineX-Span & Setting ToolsDenier RubianoNessuna valutazione finora

- Unban FormsDocumento74 pagineUnban FormsNoob ab AbNessuna valutazione finora

- LR Phono PreampsDocumento44 pagineLR Phono PreampsMartin FernandezNessuna valutazione finora

- Zhao PeiDocumento153 pagineZhao PeiMuhammad Haris HamayunNessuna valutazione finora