Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Project For Gearbox Design

Caricato da

Chandra SekarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Project For Gearbox Design

Caricato da

Chandra SekarCopyright:

Formati disponibili

EASTERN MEDITERRANEAN UNIVERSITY

FACULTY OF ENGINEERING

DEPARTMENT OF MECHANICAL ENGINEERING

ME 376 MACHINE ELEMENTS II

GEARBOX DESIGN PROJECT ASSIGNMENT

DUE DATE: TO BE SUBMITTED DURING OR BEFORE THE FINAL EXAM.

OBJECTIVES:

The ME 376 Design Project is intended to achieve the following aims and objectives:

1. To apply the knowledge acquired and principles learned in the course to a specific, real and

practical design problem.

2. To help students gain an understanding of design approaches and to apply the principles of

strength of materials, material selection, and manufacturing processes.

3. To help students see and understand the interrelationship among individual machine elements,

which are put together to fulfill a certain specified function.

4. To complete a design task, by starting with concepts and making the necessary decision

analysis at every stage of the design, which include the detection of the critical elements and

sections of these parts and the application of the principles of functionality, cost and safety.

5. To gain an experience of working in teams.

PROJECT DESCRIPTION:

You are the designer and you have been asked to design a speed reducer that will take power from the

shaft of an electric motor rotating at 1200 rpm and deliver it to a machine that is to operate at

approximately at 155 rpm. Assume that you have decided to use helical gears to transmit the power

[A power equal to the last two digits of your student number in kilowatts, e.g. H = 67 kW for a

student # 092767.] and you are proposing to use a double-reduction speed reducer like the one shown

in the sample figure attached.

The input shaft (shaft-a) is coupled to the motor shaft. The first gear of the gear train is mounted on

this shaft and rotates at the same speed as the motor (n in = na = 1200 rpm.) Gear-2 drives the mating

gear (gear-3) which is larger, causing the speed of rotation of shaft-bc to be slower than shaft-a. It is

noted that the speed is not yet down to 155 rpm as desired. [That helps explain the need for a doublereduction train set. This is because a compact gearbox is needed!]

The next step is to mount a third gear (gear-4) on shaft-bc and mate it with gear-5 mounted on the

output shaft (shaft-d), which is inline with the input shaft-a. With proper sizing of all four gears, you

should be able to obtain an output speed equal or quite close to the desired speed [n out = ~155 rpm.]

Each of the shafts are supported by two ball or roller bearings that need to be specified by you [there

are six bearings to be selected by the designer!] An overall reliability of 95 %, and a design life of

20.000 h are desired.

The hand of gears #3 and #4 on shaft-bc to be adjusted such that the thrust loads on shaft-bc oppose

each other and thus the resultant axial load on the shaft is to be kept at a minimum level!

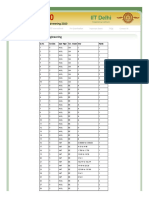

The following list gives some of the important parameters for each gear:

The number of teeth, N (such as: N2, N3, N4, and N5.)

The form of the teeth (involute tooth profile).

The size of the teeth as indicated by the module, m [mm.] (Note that the module m23 of

gear pair-23 may be different from the module m45 of gear pair-45.)

The face width of the teeth, F [mm.] (F23 is not necessarily equal to F45!)

The pitch diameter (dp)for each of the gears, [mm.]

The means of attaching the gear to its shaft (such as: keys and keyways)

EASTERN MEDITERRANEAN UNIVERSITY

FACULTY OF ENGINEERING

DEPARTMENT OF MECHANICAL ENGINEERING

ME 376 MACHINE ELEMENTS II

The means of locating the gear axially on the shaft (collars, retaining rings etc.)

The degree of precision of the gear teeth (You will need to decide on Q V based on the

pitch line velocity V of the pair (Noting that V23 V45)).

Other geometry related to helical gears (e.g. normal and transverse pressure angles ( n,

t) and the helix angle .)

SOME MAJOR TASKS EXPECTED FROM YOU AS A DESIGNER:

1. Determining the number of teeth for each gear: Knowledge of kinematic analysis of geared

mechanisms is required. You will refer to your Class-Notes and Chapter 13 of your text, and

understand the concept of velocity ratio and learn the techniques of designing doublereduction gear trains.

2. Analyzing the forces on gears and shafts: Force analyses are to be made based on the power

transmitted by the gear system. You will need to determine the loads acting on the teeth of

each gear pair, i.e. the transmitted load W t, the axial (thrust) load Wa and the radial load Wr

need to be determined for each gear pair. For example, for gear pair 23, (Wt)23, (Wr)23, and

(Wa)23; and for the pair formed by gears 4 and 5, (Wt)45, (Wr)45, and (Wa)45 must be calculated

and shown on their respective shafts. (You may start with taking n = 200, and = 150.)

3. Determining the stress acting on the gear teeth and selection of material to withstand these

stresses safely are other important tasks. You may take a factor of safety of 2 for this purpose.

These will require the determination of face width F and the module m for each pair. This may

require a trial-and-error approach. (recall that pitch diameter of a gear is: d = m N)

4. You must also be able to draw the shear and bending moment diagrams, as well as drawing

the free-body diagrams and calculating the reactions at the supports (Statics). A good

understanding of the subject matter covered in Chapters 7 and 13, as well as within your classnotes. Since the shafts must be able to accommodate all the elements within the range of the

supports, you must assign proper length dimensions for each of the shafts, considering the

arrangement of the elements and allowing space for the width of each bearing. (This is

important and should be checked later, as the width of the items will finally be decided.)

5. Based on the given data and the reactions found, you will select bearings for each of the

supports. You will need to choose an appropriate load application factor, AF, from Table 11-5.

In this selection, the design life, the design speed, and reliability requirements should all be

considered. Note that the speeds of the shafts are not the same.

6. From the bending moment diagrams obtained in task # 4, and after calculating the torque

transmitted by each one of the shafts, you will select materials for the shafts and design the

shafts. A factor of safety of 2.0 seems to be appropriate. [See Equation 7-11 and 7-12, on

pp.357 of Shigley.] Note that the diameter of the shaft will not be constant. There will be

some keyways and/or shoulders on each of the shaft creating stress concentration, which need

to be considered. Trial and error approaches, therefore, may need to be followed.

7. You are to size the keys and keyways for the application, which also requires selection of

materials for the intended application. [Refer to Section 7 of Chapter 7 in your textbook.]

8. A scaled drawing of the entire system will have to show all elements of the gearbox including

its housing. [See the sample figure supplied.]

9. Make a tabular summary of your results.

10. Give the name and student #s of your team members together with your own.

EASTERN MEDITERRANEAN UNIVERSITY

FACULTY OF ENGINEERING

DEPARTMENT OF MECHANICAL ENGINEERING

ME 376 MACHINE ELEMENTS II

11. A good presentation will earn extra bonus points! Note that stepwise solutions and

explanatory remarks will help improve your style.

Sample Drawing:

Note: Each student must file his/her own project report.

Do provide the dimensional units whenever appropriate.

Be careful with the margins!

For your report A4-Plain papers are recommended.

Your findings must be justifiable and should be based on sound

engineering judgment.

Potrebbero piacerti anche

- Gear Project DesignDocumento21 pagineGear Project Designjimx_101100% (1)

- Gearbox DesignDocumento94 pagineGearbox DesignHema KumarNessuna valutazione finora

- Gear Box Design Project Two: Faculity of Mechanical and Industrial EngineeringDocumento131 pagineGear Box Design Project Two: Faculity of Mechanical and Industrial Engineeringnigusu sisayNessuna valutazione finora

- Gearbox Project ReportDocumento15 pagineGearbox Project ReportPARTHA PRATIM PURKAIT100% (1)

- Gearbox Design Project ReportDocumento2 pagineGearbox Design Project ReportAnonymous dWtqWj4qjNessuna valutazione finora

- CH 13Documento27 pagineCH 13Sanjay KumarNessuna valutazione finora

- Design and Analysis of GearDocumento35 pagineDesign and Analysis of GearABnB InnovationsNessuna valutazione finora

- Design Project - 1 (Autosaved) FinalDocumento45 pagineDesign Project - 1 (Autosaved) FinalMilion dugumaNessuna valutazione finora

- Types of GearsDocumento22 pagineTypes of GearsAnonymous 2RbW9dNessuna valutazione finora

- Ministry of Education: Test Blueprint For Ethiopian Higher Education Institutions' Exit Examination Band-1 ProgramDocumento15 pagineMinistry of Education: Test Blueprint For Ethiopian Higher Education Institutions' Exit Examination Band-1 ProgramŤêk Mãñ JôśÿNessuna valutazione finora

- Material Handling Equipment - Dr. Eng. Daniel KitawDocumento313 pagineMaterial Handling Equipment - Dr. Eng. Daniel KitawBîñïåm ËñdàlåmàwNessuna valutazione finora

- Pressure Vessel Air by TesfahunDocumento49 paginePressure Vessel Air by TesfahunNebyou DanielNessuna valutazione finora

- Gear DesignDocumento22 pagineGear DesignKhalil Raza100% (4)

- 3-d Modelling and Finite Element Analysis of Eot CraneDocumento4 pagine3-d Modelling and Finite Element Analysis of Eot CraneGogyNessuna valutazione finora

- Road Performance PDFDocumento8 pagineRoad Performance PDFwanawNessuna valutazione finora

- Gear TrainDocumento26 pagineGear TraingowthamarajNessuna valutazione finora

- Unit 6 - Design of GearsDocumento22 pagineUnit 6 - Design of GearsKunal AhiwaleNessuna valutazione finora

- Unit 6 - Design of Antifriction BearingsDocumento19 pagineUnit 6 - Design of Antifriction BearingsKunal Ahiwale100% (1)

- ClutchesDocumento12 pagineClutchesAbebaw AyeleNessuna valutazione finora

- Design of ShaftDocumento32 pagineDesign of ShaftaliNessuna valutazione finora

- Design of ShaftDocumento5 pagineDesign of Shaftmanmohansinghlotey100% (1)

- Gear Drawing PDFDocumento12 pagineGear Drawing PDFpradeep315Nessuna valutazione finora

- Thick Thin Cylinders Pressure Vessel. PPT in PDFDocumento5 pagineThick Thin Cylinders Pressure Vessel. PPT in PDFlram70Nessuna valutazione finora

- Design and Fabrication of Bolts (Full)Documento26 pagineDesign and Fabrication of Bolts (Full)subinNessuna valutazione finora

- BISRAT GIRMA Gearbox DesignDocumento92 pagineBISRAT GIRMA Gearbox DesignŠmřű Žăm Ğ Bøýž0% (1)

- Gearbox Project ReportDocumento11 pagineGearbox Project Reportalexpatow50% (2)

- Final Corrected Report, EndalkachewDocumento63 pagineFinal Corrected Report, EndalkachewKalid AbebeNessuna valutazione finora

- Gear Design 2Documento15 pagineGear Design 2cracking khalifNessuna valutazione finora

- Rack and Pinion Gears InformationDocumento6 pagineRack and Pinion Gears InformationifyNessuna valutazione finora

- Abrasive Jet MachiningDocumento6 pagineAbrasive Jet Machiningpatel ketan71% (7)

- Design of Gear Box Prepared By: Yaried Worku Muket AGMASDocumento34 pagineDesign of Gear Box Prepared By: Yaried Worku Muket AGMASyared sitotaw100% (1)

- Design of Machine ElementsDocumento83 pagineDesign of Machine ElementsAyush Bhardwaj100% (1)

- Lecture 16 - Worm Gears Worked Out ProblemsDocumento19 pagineLecture 16 - Worm Gears Worked Out ProblemsApurba haldar50% (2)

- Introduction To GearsDocumento28 pagineIntroduction To Gearssandeep_gaikwad2100% (4)

- Sliding Contact and Rolling Contact BearingDocumento45 pagineSliding Contact and Rolling Contact BearingorgasandreyNessuna valutazione finora

- Design of Shafts CouplingsDocumento45 pagineDesign of Shafts CouplingsRavi Teja100% (2)

- Shafts and BearingsDocumento43 pagineShafts and BearingsMario AndrewNessuna valutazione finora

- Gear Box Design ReportDocumento12 pagineGear Box Design ReportKhalil Raza93% (29)

- Design of IC Engine CylinderDocumento2 pagineDesign of IC Engine CylinderSushil Kumar Singh80% (5)

- Dry Sand MouldingDocumento3 pagineDry Sand Mouldingরিপন মন্ডলNessuna valutazione finora

- Spur Gears: Are Used in Transmitting Torque Between Parallel ShaftsDocumento31 pagineSpur Gears: Are Used in Transmitting Torque Between Parallel ShaftsDipakNessuna valutazione finora

- Master PPT DesignDocumento15 pagineMaster PPT DesignUsama Epn Abdelmksoud AhmedNessuna valutazione finora

- Gear Box Design Assignment S2 2012Documento10 pagineGear Box Design Assignment S2 2012Nang TruongNessuna valutazione finora

- Report On GearDocumento18 pagineReport On GearShubham KhannaNessuna valutazione finora

- Roller Chains Design GuidelinesDocumento6 pagineRoller Chains Design GuidelinesDrew TwitchNessuna valutazione finora

- Gear Box DesignDocumento74 pagineGear Box DesignRanjib BiswasNessuna valutazione finora

- Machine Design Mini Project, Sem I 2018 2019Documento2 pagineMachine Design Mini Project, Sem I 2018 2019lucasNessuna valutazione finora

- Ijmet 07 04 023 PDFDocumento6 pagineIjmet 07 04 023 PDFtienphongbkNessuna valutazione finora

- Small Wind Turbine DesignDocumento19 pagineSmall Wind Turbine DesignIqbal MeskinzadaNessuna valutazione finora

- Machine Tool Design Lab ManualDocumento40 pagineMachine Tool Design Lab ManualRohitGupta100% (2)

- Machine Tool Design Lab ManualDocumento40 pagineMachine Tool Design Lab ManualRohitGupta100% (1)

- Finite Element Method: Project ReportDocumento15 pagineFinite Element Method: Project ReportAtikant BaliNessuna valutazione finora

- MECH3403 Assignment 1 Report FINALDocumento16 pagineMECH3403 Assignment 1 Report FINALCong Thanh LeNessuna valutazione finora

- INME 4011 Term Project Guideline: D&T OnlineDocumento9 pagineINME 4011 Term Project Guideline: D&T OnlineAnkur MenonNessuna valutazione finora

- Design and Development of Fixture For Eccentric ShaftDocumento6 pagineDesign and Development of Fixture For Eccentric ShafttuongnvNessuna valutazione finora

- Axial Turbine FEADocumento8 pagineAxial Turbine FEAcena3135Nessuna valutazione finora

- Notes ProjectDocumento3 pagineNotes Projectsaif aymanNessuna valutazione finora

- He So Nen UonDocumento7 pagineHe So Nen UonTran Van DaiNessuna valutazione finora

- International Journal of Engineering Research and DevelopmentDocumento8 pagineInternational Journal of Engineering Research and DevelopmentIJERDNessuna valutazione finora

- S221 Transmission System Project ME3145Documento20 pagineS221 Transmission System Project ME3145VIỆT LÊ BÁ QUỐCNessuna valutazione finora

- ShankarDocumento1 paginaShankarChandra SekarNessuna valutazione finora

- Ravishankar PackersDocumento1 paginaRavishankar PackersChandra SekarNessuna valutazione finora

- Selvam Packers & Movers: 130, Narayanan Nagar, Salem - 636008Documento1 paginaSelvam Packers & Movers: 130, Narayanan Nagar, Salem - 636008Chandra SekarNessuna valutazione finora

- Log in SheetDocumento2 pagineLog in SheetChandra SekarNessuna valutazione finora

- Ramani Packers & Movers: 4 Roads, Omalur Main Road, Salem - 636007Documento2 pagineRamani Packers & Movers: 4 Roads, Omalur Main Road, Salem - 636007Chandra SekarNessuna valutazione finora

- Played For Namakkal District As A Volley Ball Player HobbiesDocumento2 paginePlayed For Namakkal District As A Volley Ball Player HobbiesChandra SekarNessuna valutazione finora

- VasuDocumento1 paginaVasuChandra SekarNessuna valutazione finora

- Accident AlertDocumento35 pagineAccident AlertChandra SekarNessuna valutazione finora

- Paramveer Polytechnic College Pauparapatti: PROJECT REPORT 2014-2015Documento3 pagineParamveer Polytechnic College Pauparapatti: PROJECT REPORT 2014-2015Chandra SekarNessuna valutazione finora

- Synopsis Introduction To Press Tools and Power Press Pneumatic SystemsDocumento1 paginaSynopsis Introduction To Press Tools and Power Press Pneumatic SystemsChandra SekarNessuna valutazione finora

- S.N O. Material Price/Ton in Rs. First Look: Propriet orDocumento2 pagineS.N O. Material Price/Ton in Rs. First Look: Propriet orChandra SekarNessuna valutazione finora

- A5.hydraulic TrolleyDocumento2 pagineA5.hydraulic TrolleyChandra SekarNessuna valutazione finora

- A2.Shock Power Gensynopsis - 2Documento1 paginaA2.Shock Power Gensynopsis - 2Chandra SekarNessuna valutazione finora

- A14. Air Assisted ClutchDocumento2 pagineA14. Air Assisted ClutchChandra SekarNessuna valutazione finora

- B.E. Civil Engineering Project ProposalDocumento10 pagineB.E. Civil Engineering Project Proposalmahipal287Nessuna valutazione finora

- Curs Ing Ec - An I - Sem I - 2010Documento76 pagineCurs Ing Ec - An I - Sem I - 2010Cosmin Burcea-BlendeaNessuna valutazione finora

- Autodesk® Robot™ Structural Analysis Professional 2011Documento12 pagineAutodesk® Robot™ Structural Analysis Professional 2011Moraru GabrielNessuna valutazione finora

- AACE Journal - Cost Engineering Mar - Apr 2023Documento43 pagineAACE Journal - Cost Engineering Mar - Apr 2023sengoNessuna valutazione finora

- Iso 2857-1973 A2-1986Documento2 pagineIso 2857-1973 A2-1986azitaggNessuna valutazione finora

- Pricelist Reilee Group of Services Rizal Bookhouse 1Documento8 paginePricelist Reilee Group of Services Rizal Bookhouse 1HarveyNessuna valutazione finora

- 04d Process Map Templates-V2.0 (PowerPiont)Documento17 pagine04d Process Map Templates-V2.0 (PowerPiont)EnzoSuazoNessuna valutazione finora

- Gate Iitd Ac in EEKey PHPDocumento2 pagineGate Iitd Ac in EEKey PHPshagun gargNessuna valutazione finora

- New Groutec Datasheet 2018 PDFDocumento24 pagineNew Groutec Datasheet 2018 PDFBadin MallquiNessuna valutazione finora

- Vivek Rajendra Dusane: ObjectiveDocumento4 pagineVivek Rajendra Dusane: ObjectivebhavikaNessuna valutazione finora

- PCI Design Example (Unlocked by WWW - Freemypdf.com)Documento49 paginePCI Design Example (Unlocked by WWW - Freemypdf.com)chuchocivil100% (1)

- Integral As1000Documento365 pagineIntegral As10000501196605285100% (3)

- Suggested Procedure For Earthquake AnalysisDocumento4 pagineSuggested Procedure For Earthquake AnalysisThomas John Doblas AgrabioNessuna valutazione finora

- S.No CLO Statement Domain Learning Level PLODocumento7 pagineS.No CLO Statement Domain Learning Level PLOabdul hameed khanNessuna valutazione finora

- CVEN214 - Lecture 4 Axial Loads - Dr. Wael AlnahhalDocumento33 pagineCVEN214 - Lecture 4 Axial Loads - Dr. Wael AlnahhalNadeenMohamedNessuna valutazione finora

- 1 00112634 SCC-Industrial-Cables-Catalogue Newstyle v11c Aw-2 PDFDocumento94 pagine1 00112634 SCC-Industrial-Cables-Catalogue Newstyle v11c Aw-2 PDFroyclhor0% (1)

- Data Collection TechniquesDocumento31 pagineData Collection Techniqueschamow0% (1)

- Profile of Dr. Premanand ShenoyDocumento1 paginaProfile of Dr. Premanand ShenoyPremanand ShenoyNessuna valutazione finora

- Standards ListDocumento39 pagineStandards ListKlaas Krona100% (1)

- Value Management in Nigerian ConstructionDocumento95 pagineValue Management in Nigerian ConstructionIgwe Isuanaoma100% (2)

- Optimizing A Beverage Can Production Line by MaterDocumento7 pagineOptimizing A Beverage Can Production Line by MaterAnonymous jSNHYv0UdNessuna valutazione finora

- DK ResumeDocumento5 pagineDK ResumeMandar NaikNessuna valutazione finora

- Introduction - Types of BuildingDocumento15 pagineIntroduction - Types of BuildingOmar SakibNessuna valutazione finora

- 9-Introduction To Software Testing - Failure, Error, Fault, Defect, Bug-09-08-2023Documento26 pagine9-Introduction To Software Testing - Failure, Error, Fault, Defect, Bug-09-08-2023ramanentertainsNessuna valutazione finora

- United Institute of Technology United Institute of Technology United Institute of TechnologyDocumento1 paginaUnited Institute of Technology United Institute of Technology United Institute of Technologychinnarasu132Nessuna valutazione finora

- Tech Spec Flow OrificeDocumento63 pagineTech Spec Flow OrificeSHIVAJI CHOUDHURY100% (1)

- SIM CEE 108 Week 1-3 PDFDocumento28 pagineSIM CEE 108 Week 1-3 PDFIah Belleza MedelNessuna valutazione finora

- NSCP Definition of TermsDocumento25 pagineNSCP Definition of TermsMary AnneNessuna valutazione finora

- Risk Assessment of Floating Offshore Wind Turbine Based On Correlation FMEADocumento7 pagineRisk Assessment of Floating Offshore Wind Turbine Based On Correlation FMEA洪琳雅Nessuna valutazione finora

- YaDocumento3 pagineYaIrma DamanikNessuna valutazione finora