Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Types of Cement

Caricato da

alexkeyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Types of Cement

Caricato da

alexkeyCopyright:

Formati disponibili

Types of cement

There are many types of cement in the market to suit every need. Some of them which are included in the revised IS : 456-2000 are as follows: Ordinary Portland Cement 33, 43, 53 grade (OPC), 53-S (Sleeper Cement) Portland Pozzolana Cement (PPC), both Fly Ash and Calcined Clay based Rapid Hardening Portland Cement Portland Slag Cement (PSC) Sulphate Resisting Portland Cement (SRC) Low Heat Portland Cement Hydrophobic Cement Even though only Ordinary Portland Cement is graded according to strength, the other cements too have to gain a particular strength. 33, 43 and 53 grade in OPC indicates the compressive strength of cement after 28 days when tested as per IS: 4031-1988, eg, 33 Grade means that 28 days of compressive strength is not less than 33 N/mm2 (MPa) . Similarly for 43 grade and 53 grade the 28 days compressive strength should not be less than 43 and 53 MPa respectively. 43 and 53 grade are also being introduced in PPC and PSC shortly by the Bureau of Indian Standards (BIS)

Portland Pozzolana Cement (PPC)

PPC is manufactured by inter grinding OPC clinker with 15-35% of pozzolanic material. Pozzolanas are essentially siliceous or aluminous material, which in itself possesses no cementitious properties, which will be in finely divided form and in the presence of moisture react with calcium hydroxide, liberated in the hydration process, at ordinary temperature, to form compounds possessing cementitious properties. The pozzolanic materials generally used are fly ash or calcined clay. PPC produces less heat of hydration and offers greater resistance to attack of aggressive environment, gives long-term strength and enhances the durability of structures.

Portland Slag Cement (PSC)

PSC is obtained by mixing blast furnace slag, cement clinker and gypsum and grinding them together to get intimately mixed cement. The quantity of slag varies from 30-70%. The gain of strength of PSC is somewhat slower than OPC. Both PPC and PSC will give more strength than that of OPC at the end of 12 months. PPC and PSC can be used in all situations where OPC is used, but are preferred in mass construction where lower heat of hydration is advantageous or in marine situations and structures near seacoast or in general for any structure where extra durability is desired. The other types of cement listed above are for special purpose and their nomenclature indicates the purpose for which they are preferred. The following table gives the codal requirements at a glance.

Some important requirements to be met by various types of cement

S Type of no cement Compressive Strength in MPa IS Code Fineness Setting Time Soundness in minutes m2/kg (min) Auto 3 days 7 days 28 days Initial Final Le (min.) (max.) Chatelier Clave (%) (mm) OPC 33 269 : 225 30 600 10 0.8 16 22 33 1989 OPC 43 8112 : 225 30 600 10 0.8 23 33 43 1989 OPC 53 12269 : 225 30 600 10 0.8 27 37 53 1987 PPC (flyash 1489 : 300 30 600 10 0.8 16 22 33 based) 1991 (Part 1) PSC (slag) 455 : 225 30 600 10 0.8 16 22 33 2002 SRC 12330 : 225 30 600 10 0.8 10 16 33 1988 White 8042 : 225 30 600 10 0.8 19.8 29.7 Cement 1989 RHC (Rapid 8041 : 325 30 600 10 0.8 27 16 @ 1 day Hardening 1990 Cement)

1 2 3 4

5 6 7 8

Composition of Portland cement

The basic components of cement are:

17-25 % SiO2 Al2O3 4-8% Fe2O3 0.5-0.6 % CaO 61-63 % MgO 0.1-4.0 % SO3 1.3-3.0 % Na2 + K2O 0.4-1.3 % Cl 0.01-0.1% IR 0.6-1.75 % There are four major compounds in cement and these are known as C2S, C3S, C3A & C4AF, and their composition varies from cement to cement and plant to plant.

In addition to the above, there are other minor compounds such as MgO, TiO2, Mn2O3, K20 and N2O. They are in small quantity. Of these K2O and Na2O are found to react with some aggregates and the reaction is known as Alkali Silica Reaction (ASR) and causes disintegration in concrete at a later date. The silicates C3S and C2S are the most important compounds and are mainly responsible for the strength of the cement paste. They constitute the bulk of the composition. C3A and C4AF do not contribute much to the strength., but in the manufacturing process they facilitate combination of lime and silica, and act as a flux. In a typical Portland cement, the composition of mineralogical compounds could be

Table 1 : The extent of chemical compounds in cement

S no Compound Composition as % 1 C3S 48-52 % 2 C2S 22-26 % 3 C3A 6-10 % 4 C4AF 13-16 % 5 Freelime 1-2 % Role of compounds on properties of cement Characteristic C3S C2S Setting Quick Slow Hydration Rapid Slow Heat Liberation Higher Lower (Cal/gm) 7 days Early Strength High up to 14 days Low up to 14 days

C3A Rapid Rapid Higher

C4AF Higher

Not much beyond 1 Insignificant day -

Later Strength

High at Moderate at later stage later stage after 14 days

Heat of Hydration

Most of the reactions occurring during the hydration of cement are exothermic in nature (heat is generated). This heat is called heat of hydration. It is desirable to know the heat producing capacity of cement in order to choose the most suitable cement for a given purpose. For Ordinary Portland Cement, half of the total heat is liberated between 1-3 days, about th in 7 days and nearly 90% in 28 days. The rate at which the heat is produced is important for practical purposes. It may lead to cracks if not properly dissipated. The sum total heat produced, if spread over a longer period can be dissipated to a greater degree with fewer problems. The hydration of C3S produces higher heat as compared to the hydration of C2S. Fineness of cement also affects the rate of heat development. The heat of hydration generated is generally as follows at 28 days.

Comparative table of heat of hydration produced at the end of 90 days

S Heat of hydration (calories per Compound no gram) 1 C3S 100-110 2 C2S 50-60 3 C3A 300-315 4 C4AF 95-105 It may be seen that the heat produced by C3S is twice that of C2S and that by C3A is still higher. It follows that, reducing the proportions of C3S and C3A, the heat of hydration and its rate can be reduced. What is hydration of cement? When water is added to cement, the paste is formed due to chemical reaction, which hardens into rock like mass over a period of time. Compounds like C3S and C2S react in the presence of moisture and fully hydrated reaction can be expressed as 2C3S +6H -> C3S2H3 +3Ca(OH)2 2C2S +4H -> C3S2H3 +Ca(OH)2 C3S2H3 (Calcium Silicate Hydrate) becomes a hard mass over a period of time and normally called as CS-H gel. While C3S contributes to most of the strength development during the first two weeks, C2S influences gain of strength after two weeks. However, in the long term (over a year) the contribution to strength is same for equal individual weight.

Selection of cement

The type of cement selected should be appropriate for the intended use. Functional requirement of the structure, design parameters, speed of construction, durability characteristics, environmental condition are some of the major factors which affect selection of cement for appropriate application. The suggested uses of various cements are given in the following table. S no Type of cement End Use 1 OPC 33 Used for general civil construction works under normal/mild environmental conditions. OPC 33 grade is normally not used where high grade concrete is required due to limitations of its strength. Nowadays this variety is not generally produced Nowadays 43 grade is being used widely for general construction work. However, 43 grade OPC is gradually being replaced by blended cements. Used in RCC and pre-stressed concrete of higher grades, cement grouts, instant plugging mortars etc. where initial higher strength is the criteria PSC provides better protection against chloride and sulphate attack. PSC is preferred over OPC for usage in constructions where the structures are susceptible to sulphate and chloride attack. eg Marine structure, structures near the sea, sewage disposal treatment works, water treatment plants, etc PPC makes concrete more impermeable, denser as compared to OPC. The long-term strength of PPC is higher compared to OPC. PPC produces less heat of hydration and offers greater resistance to the attack of aggressive waters than normal OPC. PPC can be used for all types of construction.

2 3 4

OPC 43 OPC 53 Portland Slag Cement (PSC)

Portland Pozzolana Cement (PPC)

Sulphate Resisting IIn SRC, amount of C3A is restricted to lower than 5% and 2C3A + C4AF Portland Cement (SRC) lower than 25%. SRC can be used for Foundation, Piles, Basements, Underground structures, sewage and water treatment plants and coastal works, where Sulphate attack due to water or soil is anticipated

Low Heat Portland Cement Rapid Hardening Cement (RHC) Hydrophobic Portland Cement

Low heat Portland cement is particularly suitable for making mass concrete for dams and many other types of water retaining structures, bridge abutments, massive retaining walls, piers and slabs, etc The Rapid hardening cement is used for repair and rehabilitation works and where speed of construction and early completion is required due to limitations of time, space or other reasons It is manufactured under special requirement for high rainfall areas to improve the shelf life of cement. The cement particles are given a chemical coating during manufacturing, which provides water-repelling property, and the cement is not affected due to high humidity and can be stored for longer period. Due to abundant availability of cement in all parts of the country, this cement is very rarely produced these days. White Portland Cement is made from raw materials containing very little iron oxide and manganese oxide. Burning in the kiln is done with furnace oil or gas instead of coal. Limited quantities of certain chemicals, which improve whiteness of cement, are added during manufacturing. This type of cement is generally meant for non-structural works. It is used for architectural purposes such as mosaic tiles, wall paintings, GRC and special effects.

10 White Cement

Test on cement

The usual tests carried out for cement are for chemical and physical requirements. They are given in relevant Indian Standards. IS 4031 (different parts) and IS 4032. The chemical standards gives permissible limits for insoluble residue, loss of ignition and other compounds and impurities like Magnesium Oxide, Sulphate, etc. The physical requirements are for fineness, soundness, setting time and compressive strength. These are mostly conducted at a laboratory. A field engineer is advised to purchase a reputed brand of cement from an authorized dealer, and ask for the test certificate. He can conduct a few field tests at the site itself for ascertaining the quality of cement. Check at random that the packing bags are fresh and that the bags are machine stitched Check that the bag displays Indian Standards mark and number to which it conforms. Check the manufacturing week and the year on the bag Open the bag and take a good look at cement, there should be no lumps Check that the colour of cement is uniform Check for setting. Take some quantity of cement, make it to a paste, place it on a plate and give it a square shape. Immerse the same slowly in to a bucket of water. Check that it has not lost shape and that it hardens after 24hrs

Classification Grade M10 Ordinary M15 M20 M25 M30 M35 M40 Standard M45 M50 M55 High Strength

Applications PCC (Plain Cement Concrete) e.g. Levelling course, bedding for footing, concrete roads, etc. PCC e.g. Levelling course, bedding for footing, concrete roads, etc. RCC (Reinforced Cement Concrete) e.g. Slabs, beams, columns, footings, etc. (for mild exposure) RCC (Reinforced Cement Concrete) e.g. Slabs, beams, columns, footings, etc. RCC e.g. Slabs, beams, columns, footings, etc. RCC e.g. Slabs, beams, columns, footings, etc. RCC e.g. Pre-stressed concrete, slabs, beams, columns, footings, etc. RCC e.g. Runways,Concrete Roads (PQC), Prestressed Concrete Girders, RCC Columns, Prestressed beams RCC e.g. Runways,Concrete Roads (PQC), Prestressed Concrete Girders, RCC Columns, Prestressed beams RCC e.g..Prestressed Concrete Girders and Piers

M60 - RCC work Where high compressive strength is required such as high rise M80 buildings, long span bridges, ultra-thin white topping etc and constructions in aggressive environment e.g. Spillways of dams, coastal construction

In addition to producing normal grade concrete ranging from M10 to M80, we produce customized special types of concrete for different applications. Types of Special Concrete Application High Volume Fly Ash Concrete Mass concrete, raft foundations, roads, pavements etc. Silica fume concrete All high strength concrete applications in extreme environmental exposure condition like marine structure etc. GGBS, Slag based concrete All underground RCC application requiring high chemical resistance and enhanced durability Ternary blend concrete All RCC application directly in contact with aggressive soil / chemicals in marine environment and in sewage / effluent treatment plants Light weight concrete Repair and rehabilitation work, for thermal insulation, light weight structural fill, and light weight pre - cast panel etc Corrosion resistant concrete All types of RCC applications in high water table area including work near coastal areas, water tanks, etc Polymer concrete Repair and rehabilitation work for floorings and buildings where high early strength is required Self Compacting Concrete Thin sections and elements with congested reinforcements. Recently IS 456 has also included SCC with specifications in its codal provision. Coloured Concrete For architectural and aesthetic use Fibre-reinforced Concrete For concrete with higher ductility and abrasion/erosion resistance Pervious Concrete Concrete for parking areas, pavements, drive-ways to ensure drainage or rain-water harvesting Water-proof Concrete Terraces, basements, water contact structures Temperature Controlled Concrete Mass concrete, hot-weather concrete etc.

Potrebbero piacerti anche

- Bogue's Compounds - DR VSR SOEDocumento6 pagineBogue's Compounds - DR VSR SOEvempadareddy100% (1)

- Cement TypesDocumento16 pagineCement TypesNitin GotiNessuna valutazione finora

- Introduction of Cement: When Was Cement Begin?Documento11 pagineIntroduction of Cement: When Was Cement Begin?مايف سعدونNessuna valutazione finora

- Cement Types - Portland Cement Association (PCA)Documento3 pagineCement Types - Portland Cement Association (PCA)Eddy EffendiNessuna valutazione finora

- CR 408 Ceramic TilesDocumento1 paginaCR 408 Ceramic TilesYuri ValenciaNessuna valutazione finora

- Students Project SchemeDocumento9 pagineStudents Project SchemeAnonymous i3lI9MNessuna valutazione finora

- Glass & FiberglassDocumento6 pagineGlass & FiberglasstintinchanNessuna valutazione finora

- Cements, Chemically Resistant: 1. 2. Types of Cement 2.1. Cements Containing Inorganic BindersDocumento8 pagineCements, Chemically Resistant: 1. 2. Types of Cement 2.1. Cements Containing Inorganic BindersjaimeNessuna valutazione finora

- 9th International: Conference & Exhibition 11-13 February, 2013Documento16 pagine9th International: Conference & Exhibition 11-13 February, 2013Ronaldo HertezNessuna valutazione finora

- Bulding Materials IIIDocumento29 pagineBulding Materials IIIKaushik JayaveeranNessuna valutazione finora

- Grouts Standards and TestingDocumento12 pagineGrouts Standards and TestingmithileshNessuna valutazione finora

- C 533 Calcium SilicateDocumento4 pagineC 533 Calcium SilicatereneeNessuna valutazione finora

- Brick Lecture NotesDocumento13 pagineBrick Lecture NoteschinmayihyNessuna valutazione finora

- Assignment of Cement Production ProcessDocumento6 pagineAssignment of Cement Production ProcessSourav hazraNessuna valutazione finora

- en 197 1 2011 SR PDFDocumento1 paginaen 197 1 2011 SR PDFUdari LiyanageNessuna valutazione finora

- ASTM Slag CementDocumento8 pagineASTM Slag CementkhaledNessuna valutazione finora

- CEVA 250-Phyzite 380Documento1 paginaCEVA 250-Phyzite 380hernie w. vergel de dios jrNessuna valutazione finora

- Membrane Cell TechnologyDocumento13 pagineMembrane Cell Technologyup4allNessuna valutazione finora

- Preprufe 300R & 160R PDFDocumento6 paginePreprufe 300R & 160R PDForlandomcortezNessuna valutazione finora

- Portland Cement: Standard Specification ForDocumento9 paginePortland Cement: Standard Specification ForThurain Aung KyawNessuna valutazione finora

- Critical Chloride Content in ConcreteDocumento8 pagineCritical Chloride Content in ConcreteChatchai ManathamsombatNessuna valutazione finora

- Handbook On Concrete Admixtures PDFDocumento25 pagineHandbook On Concrete Admixtures PDFPrasanta ParidaNessuna valutazione finora

- Damp Proofing MaterialDocumento12 pagineDamp Proofing Materialjanani1990Nessuna valutazione finora

- 14 Masonry ConstructionMethodsDocumento78 pagine14 Masonry ConstructionMethodsMaverick LastimosaNessuna valutazione finora

- Engineering Materials: CementDocumento26 pagineEngineering Materials: CementSathvika KodimyalaNessuna valutazione finora

- Analysis For Schedule-2009 PDFDocumento2.393 pagineAnalysis For Schedule-2009 PDFVikrant Narayan VasudevaNessuna valutazione finora

- Cellular Light Weight Concrete Manufacturing Process & Properties Full DetailsDocumento4 pagineCellular Light Weight Concrete Manufacturing Process & Properties Full Detailskinley dorjee100% (1)

- Concret CementDocumento29 pagineConcret CementKamal Hameed Al-taiy100% (1)

- Concrete: From Grey To GreenDocumento12 pagineConcrete: From Grey To GreenOmar Marghani SalmaNessuna valutazione finora

- Renderoc LAXtraDocumento2 pagineRenderoc LAXtrajaga67Nessuna valutazione finora

- Modeling The Prediction of Compressive Strength For Cement andDocumento12 pagineModeling The Prediction of Compressive Strength For Cement andAnil Kumar Sharma100% (1)

- CONCRETE TECHNOLOGY NOTES NustDocumento59 pagineCONCRETE TECHNOLOGY NOTES NustgladNessuna valutazione finora

- Admixture and Fresh ConcreteDocumento57 pagineAdmixture and Fresh ConcretegoogkitNessuna valutazione finora

- Hebel MC v09.11Documento12 pagineHebel MC v09.11subhaschandraNessuna valutazione finora

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsDocumento11 pagine4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- Tips For Designers PDFDocumento5 pagineTips For Designers PDFSushil DhunganaNessuna valutazione finora

- CementDocumento52 pagineCementSugumar BalasubramaniamNessuna valutazione finora

- Supplementary Cementing MaterialsDocumento59 pagineSupplementary Cementing MaterialsTruong Giang VoNessuna valutazione finora

- Life-365 - v2.2.3 - Users - Manual (1) - 26-53Documento28 pagineLife-365 - v2.2.3 - Users - Manual (1) - 26-53Fernando RosalesNessuna valutazione finora

- Lime in Mortars Guidance DocumentDocumento24 pagineLime in Mortars Guidance DocumentRodrigo ZelayaNessuna valutazione finora

- Types of Cementitious MaterialsDocumento9 pagineTypes of Cementitious MaterialsLorna BacligNessuna valutazione finora

- Portland Limestone PCA Show 2014Documento21 paginePortland Limestone PCA Show 2014Agung PrasetyoNessuna valutazione finora

- 01-Battery Room Ceramic Floor TilesDocumento1 pagina01-Battery Room Ceramic Floor TilesJoey RomeroNessuna valutazione finora

- Innovative Building Materials PDFDocumento20 pagineInnovative Building Materials PDFShiena BeasonNessuna valutazione finora

- 02 Introduction To ConcreteDocumento24 pagine02 Introduction To ConcreteS. M. ZAHIDUR RAHMAN 1301129Nessuna valutazione finora

- Section 09260 Gypsum Board AssembliesDocumento10 pagineSection 09260 Gypsum Board AssembliesMØhãmmed ØwięsNessuna valutazione finora

- BarChip Fibres Replace Steel in Chilean HousingDocumento2 pagineBarChip Fibres Replace Steel in Chilean HousingPedro Augusto Delgado NascimentoNessuna valutazione finora

- Using of Borosilicate Glass Waste As A Cement AdditiveDocumento5 pagineUsing of Borosilicate Glass Waste As A Cement AdditiveMateriales FicNessuna valutazione finora

- Erez Allouche Latech Geopolymer ConcreteDocumento9 pagineErez Allouche Latech Geopolymer ConcreteRudra KushalNessuna valutazione finora

- Optimizing The Use of Fly Ash in ConcreteDocumento24 pagineOptimizing The Use of Fly Ash in ConcretePratik RaoNessuna valutazione finora

- Manual of Metal Roofing Sheet Roll Forming MachineDocumento8 pagineManual of Metal Roofing Sheet Roll Forming Machinenovo orderNessuna valutazione finora

- Masonry Chapter 21 - IBC PDFDocumento84 pagineMasonry Chapter 21 - IBC PDFShanmuga SundaramNessuna valutazione finora

- Types of Refractory Materials and Their ApplicationsDocumento4 pagineTypes of Refractory Materials and Their ApplicationsLizienny PeixotoNessuna valutazione finora

- Curing Concrete - Concrete Technology - Portland Cement Association (PCA)Documento6 pagineCuring Concrete - Concrete Technology - Portland Cement Association (PCA)Jay PatelNessuna valutazione finora

- Curing Cement PlasterDocumento3 pagineCuring Cement PlasterChristian LlagasNessuna valutazione finora

- Cement LectureDocumento48 pagineCement LectureJaypee TanNessuna valutazione finora

- Pocs. Also Please Contact The Pocs WithDocumento65 paginePocs. Also Please Contact The Pocs Withrize1159100% (1)

- A Journey Through Indian Reinforcing BarsDocumento5 pagineA Journey Through Indian Reinforcing BarssujupsNessuna valutazione finora

- Hot Metal Ladle & Launder Car Modification StudyDocumento8 pagineHot Metal Ladle & Launder Car Modification StudyNanda Kumar100% (1)

- Specification 2012 Part 3 Roadsand Bridges 10 May 2012Documento453 pagineSpecification 2012 Part 3 Roadsand Bridges 10 May 2012Shashank TiwariNessuna valutazione finora

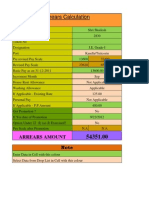

- Arrears CalculationDocumento8 pagineArrears CalculationalexkeyNessuna valutazione finora

- Water Content and Dry Density of Soi SDocumento1 paginaWater Content and Dry Density of Soi SalexkeyNessuna valutazione finora

- Fielddensity, Specific Gravity & Relative DensityDocumento2 pagineFielddensity, Specific Gravity & Relative DensityalexkeyNessuna valutazione finora

- Principles of Concrete Mix DesignDocumento67 paginePrinciples of Concrete Mix DesignAbu Mariam80% (5)

- Concrete TechnologyDocumento118 pagineConcrete Technologyeskinderm100% (30)

- January, 2012: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayDocumento13 pagineJanuary, 2012: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayalexkeyNessuna valutazione finora

- Walkway EstimateDocumento2 pagineWalkway Estimatecrete masterNessuna valutazione finora

- Construction of Self-Supporting Tower (A2Dn Type) Y80 Brgy. Sto - Nino, Masantol PampangaDocumento1 paginaConstruction of Self-Supporting Tower (A2Dn Type) Y80 Brgy. Sto - Nino, Masantol PampangaRoy Bernard BasaNessuna valutazione finora

- OneSteel Composite Structures Design Booklet Db3.1Documento62 pagineOneSteel Composite Structures Design Booklet Db3.1Brian Nasr100% (2)

- Slab Bridge FinalDocumento6 pagineSlab Bridge FinalRohan Persaud100% (1)

- Thumb RuleDocumento6 pagineThumb RuleShafique AhmedNessuna valutazione finora

- Local Supplier of Steel DeckingDocumento19 pagineLocal Supplier of Steel DeckingJia ManceraNessuna valutazione finora

- Comportamiento y Diseño de Puentes Extradosados PDFDocumento176 pagineComportamiento y Diseño de Puentes Extradosados PDFJulio Rafael Terrones Vásquez100% (1)

- Division 04: Brick Works, Patent Stone in Floor and Fancy Screen Block WorkDocumento3 pagineDivision 04: Brick Works, Patent Stone in Floor and Fancy Screen Block Workamit dasguptaNessuna valutazione finora

- Hibbeler Structural Analysis 8th TXTBKDocumento4 pagineHibbeler Structural Analysis 8th TXTBKColdWinterKidNessuna valutazione finora

- Flexural Performance and ToughDocumento20 pagineFlexural Performance and ToughDiana Rose B. DatinguinooNessuna valutazione finora

- Rashtriya Chemicals & Fertilizers LTDDocumento6 pagineRashtriya Chemicals & Fertilizers LTDGoanengineerNessuna valutazione finora

- Analysis, Design, and Detailing of Shear Walls and MRFsDocumento67 pagineAnalysis, Design, and Detailing of Shear Walls and MRFsRamez Bou-Rizk100% (1)

- Cantilever Retaining Wall DesignDocumento6 pagineCantilever Retaining Wall Designprabhu100% (1)

- Plastic AnalysisDocumento10 paginePlastic AnalysisSitiNessuna valutazione finora

- Design of Vertical StirrupDocumento3 pagineDesign of Vertical StirrupAnton_Young_1962Nessuna valutazione finora

- KTA 3205 - 2 - Engl - 2018 - 10 PDFDocumento35 pagineKTA 3205 - 2 - Engl - 2018 - 10 PDFMIKAEL HENRIOTNessuna valutazione finora

- Review of Related LiteratureDocumento54 pagineReview of Related LiteratureCarol MoradosNessuna valutazione finora

- Prestressed Concrete Assignment TU DelftDocumento4 paginePrestressed Concrete Assignment TU DelfttimsykiNessuna valutazione finora

- Fire Boundary ConditionDocumento4 pagineFire Boundary ConditionvsbalintNessuna valutazione finora

- NSCP Design LoadsDocumento10 pagineNSCP Design LoadsShem Barro88% (33)

- Inspection N Test PlanDocumento20 pagineInspection N Test PlanMohd Kamal TajudinNessuna valutazione finora

- Weynand PDFDocumento55 pagineWeynand PDFJie RongNessuna valutazione finora

- Bridge Temporary DesignDocumento4 pagineBridge Temporary DesignRaditya AzkaLaodeNessuna valutazione finora

- Vitsœ UK 606 Planning Guide GBPDocumento20 pagineVitsœ UK 606 Planning Guide GBParchitectintxNessuna valutazione finora

- StaircaseDocumento2 pagineStaircaseMAGED MOHMMED AHMED QASEMNessuna valutazione finora

- Foundation DesignDocumento84 pagineFoundation DesignIngeniero Estructural100% (2)

- List of Data Sheet: Gujarat Water Supply & Sewerage Board GandhinagarDocumento9 pagineList of Data Sheet: Gujarat Water Supply & Sewerage Board GandhinagarPratikNessuna valutazione finora

- DS - en 1999-1-2 DK Na - 2007 eDocumento3 pagineDS - en 1999-1-2 DK Na - 2007 ep_meulendijks108Nessuna valutazione finora

- Lecture 8 - Compression Axial OnlyDocumento9 pagineLecture 8 - Compression Axial OnlyHumberto EstevezNessuna valutazione finora

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDa EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedValutazione: 5 su 5 stelle5/5 (1)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (242)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDa EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseValutazione: 5 su 5 stelle5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDa EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionValutazione: 4.5 su 5 stelle4.5/5 (2)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsDa EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNessuna valutazione finora

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishDa EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishValutazione: 4 su 5 stelle4/5 (3)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftDa EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftValutazione: 5 su 5 stelle5/5 (5)

- Building Construction Technology: A Useful Guide - Part 1Da EverandBuilding Construction Technology: A Useful Guide - Part 1Valutazione: 4 su 5 stelle4/5 (3)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEDa EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEValutazione: 4 su 5 stelle4/5 (1)

- Field Guide for Construction Management: Management by Walking AroundDa EverandField Guide for Construction Management: Management by Walking AroundValutazione: 4.5 su 5 stelle4.5/5 (3)

- Markup & Profit: A Contractor's Guide, RevisitedDa EverandMarkup & Profit: A Contractor's Guide, RevisitedValutazione: 5 su 5 stelle5/5 (11)

- How to Build a Tiny Portable House: With Plans and InstructionsDa EverandHow to Build a Tiny Portable House: With Plans and InstructionsValutazione: 4 su 5 stelle4/5 (1)

- An Architect's Guide to Construction: Tales from the Trenches Book 1Da EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Nessuna valutazione finora

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDa Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideValutazione: 3.5 su 5 stelle3.5/5 (7)

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADa EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANessuna valutazione finora

- Civil Engineer's Handbook of Professional PracticeDa EverandCivil Engineer's Handbook of Professional PracticeValutazione: 4.5 su 5 stelle4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 2Da EverandBuilding Construction Technology: A Useful Guide - Part 2Valutazione: 5 su 5 stelle5/5 (1)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDa EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNessuna valutazione finora

- New Code of Estimating PracticeDa EverandNew Code of Estimating PracticeNessuna valutazione finora

- Construction Project Management 101: For Beginners & New GraduatesDa EverandConstruction Project Management 101: For Beginners & New GraduatesNessuna valutazione finora