Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Corning Leaf Fiber Spec Sheet

Caricato da

colinyDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Corning Leaf Fiber Spec Sheet

Caricato da

colinyCopyright:

Formati disponibili

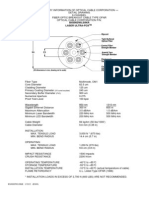

Corning® LEAF® Optical Fiber

Product Information

Optical

Fiber

The Standard for Long-Haul Networks

In the race to satisfy the global demand for telecommunications bandwidth, the need

for technically advanced, high-capacity networks is paramount. Since 1998, the world

has relied on Corning® LEAF® optical fiber to transmit information at higher bit

rates and over longer distances than ever before. Corning LEAF optical fiber is:

The world’s first large effective area, non-zero dispersion-shifted fiber (NZ-DSF)

*

Optimized for long-haul and high-data-rate metro networks

*

The world’s most widely deployed NZ-DSF

*

The industry leader in polarization mode dispersion (PMD) specifications, enabling

* evolution from today’s 10 Gb/s networks to the 40 Gb/s systems of the future

The world’s first low-water-peak NZ-DSF

*

In compliance with the industry’s most stringent requirements, including:

*

• ITU-T G.655 (Tables A, B, C, D)

• IEC Specifications 60793-2-50 Type B4

• TIA/EIA 492-EA00

• Telcordia’s GR-20

Telecommunications networks require high capacity and broad system flexibility in

order to compete today and to meet the challenges of tomorrow. The technological

strength of Corning LEAF optical fiber provides an advanced foundation for today’s

sophisticated networks and those of the future.

Issued: September 2009

PI1107 TL9000/ISO 9001 Registered

Supersedes: February 2008

Fiber for Today and Tomorrow

With more NZ-DSF in the ground than any other fiber manufacturer in the world, Corning and

Corning LEAF fiber set the standard for long-haul networks. Corning places a strong emphasis on

system performance and is committed to delivering products that enable superior networks now and

in the future. This commitment has led system manufacturers to develop design rules optimized

specifically for LEAF fiber. Low-water-peak attenuation, exceptional transmission capability, moder-

LEAF

ate dispersion, outstanding geometry, large A eff and unique fiber characteristics give LEAF fiber

the advanced functionality and quality required to enable 10 Gb/s, Raman and 40 Gb/s networks.

LEAF fiber’s characteristics also enable extended transmission reach in analog CATV networks.

Over the years, Corning has adapted its fiber product offerings in conjunction with evolving market

needs and industry trends. In addition to being the lowest cost-per-bit solution in digital networks,

LEAF fiber now provides this same advantage to analog networks. This capability is enabled by LEAF

fiber characteristics that allow for a higher stimulated Brillioun scattering (SBS) threshold than standard

single-mode fiber and other ITU-T G.655 fibers with smaller effective area. The SBS threshold is

commonly approached in applications such as analog video transmission. In these applications, LEAF

fiber’s elevated SBS threshold enables higher relative optical powers. Along with the higher SBS, LEAF

fiber’s low chromatic dispersion in the C-band mitigates analog signal intermodulation distortions and

eases the requirements on emerging digital baseband applications. This combination allows LEAF fiber

to support longer distances, improved signal quality and higher signal distribution densities.

The Next Generation

Corning continually pursues innovative methods for integrating LEAF optical fiber’s revolutionary

technology into next-generation solutions. Enriched by unmatched network performance that advances

transmission systems to the next level, LEAF fiber prevails as the world’s most sophisticated NZ-DSF.

Furthermore, LEAF fiber’s consistent uniformity, excellent splicing and longer uncompensated reach

capabilities are backed by the quality, service and support our customers expect.

Built upon Corning’s reputation for reliability and groundbreaking innovation, LEAF fiber delivers

proven performance today and a bright future in emerging networks.

Corning® Optical Fiber – The Measure of Trust

Corning’s Service Advantage

Corning Optical Fiber delivers the world’s most comprehensive package of innovative products

and services, including:

* Worldwide sales support and door-to-door customer service

Full range of fibers and special order capabilities

* Specialized support from technical experts

* Extensive fiber delivery capabilities with proven success rates

* Real-time, Web-based customer information

* Dedicated account support for our long-term supply customers

* Fiber support services and technical information for end-customers

*

At Corning Optical Fiber, we strive to provide the best possible customer service and technical

support – before, during and after the sale. As a customer, you’ll benefit from our established and

extensive support infrastructure that’s ready to meet your specific needs.

Corning’s Product Advantage

Our enhanced, dual acrylate CPC® coatings provide excellent protection. Designed to be mechanically

stripped, they are optimized for many single- and multi-fiber cable designs, including loose tube,

ribbon, slotted core and tight buffer cables.

Corning is committed to product excellence and meeting the evolving needs of our customers. As

updates to fiber characteristics or performance specifications become available, they will be posted

on the Corning Optical Fiber website at www.corning.com/opticalfiber

Optical Specifications

Fiber Attenuation Mode-Field Diameter

Maximum Attenuation Wavelength MFD

(nm) (µm)

Wavelength Maximum Value

1550 9.6 ± 0.4

(nm) (dB/km)

1383 ± 3* ≤ 0.4

1410 ≤ 0.32 Dispersion

1450 ≤ 0.26 Wavelength Min – Max Dispersion Value

1550 ≤ 0.20 (nm) [ps/(nm•km)]

1625 ≤ 0.22 1530 2.0 – 5.5

*Attenuation values at this wavelength represent post-hydrogen 1565 4.5 – 6.0

aging performance. 1625 8.5 – 11.2

Attenuation vs. Wavelength

Range Ref. λ Max. α Difference Polarization Mode Dispersion (PMD)

(nm) (nm) (dB/km) Value (ps/√km)

1525 – 1575 1550 0.02 PMD Link Design Value ≤ 0.04*

1625 1550 0.03 Maximum Individual Fiber ≤ 0.1

The attenuation in a given wavelength range does not exceed the *Complies with IEC 60794-3: 2001, Section 5.5, Method 1,

attenuation of the reference wavelength (λ) by more than the value α. (m = 20, Q = 0.01%), September 2001.

Macrobend Loss

The PMD link design value is a term used to describe the PMD

Mandrel Number Wavelength Induced

of concatenated lengths of fiber (also known as PMDQ ). This value

Diameter of (nm) Attenuation*

represents a statistical upper limit for total link PMD. Individual PMD

(mm) Turns (dB)

values may change when fiber is cabled. Corning’s fiber specification

32 1 1550 & 1625 ≤ 0.50

supports emerging network design requirements for high-data-rate

60 100 1550 & 1625 ≤ 0.05

systems operating at 10 Gb/s rates and higher.

*The induced attenuation due to fiber wrapped around a mandrel

of a specified diameter.

Point Discontinuity

Wavelength Point Discontinuity

(nm) (dB)

1550 ≤ 0.05

Dimensional Specifications

Glass Geometry Coating Geometry

Fiber Curl ≥ 4.0 m radius of curvature Coating Diameter 242 ± 5 µm

Cladding Diameter 125.0 ± 0.7 µm Coating-Cladding Concentricity < 12 µm

Core-Clad Concentricity ≤ 0.5 µm

Cladding Non-Circularity ≤ 0.7%

Environmental Specifications

Induced Attenuation

Environmental Test Test Condition 1550 nm & 1625 nm

(dB/km)

Temperature Dependence -60°C to +85°C* ≤ 0.05

Temperature Humidity Cycling -10ºC to +85ºC* up to 98% RH ≤ 0.05

Water Immersion 23º ± 2ºC ≤ 0.05

Heat Aging 85º ± 2ºC* ≤ 0.05

Damp Heat 85°C at 85% RH ≤ 0.05

*Reference temperature = +23ºC

Operating Temperature Range: -60ºC to +85ºC

How to Order

Contact your sales representative,

or call the Optical Fiber Customer

Service Department:

Ph: 607-248-2000 (U.S. and Canada)

+44-1244-287-437 (Europe)

Email: opticalfibcs@corning.com

Please specify the fiber type, attenuation

and quantity when ordering.

Mechanical Specifications

Proof Test

The entire fiber length is subjected to a tensile stress

≥100 kpsi (0.7 GPa)*.

* Higher proof test levels available.

Performance Characterizations

Characterized parameters are typical values.

Numerical Aperture 0.14

NA is measured at the one percent

power level of a one-dimensional

far-field scan at 1550 nm.

Effective Area (Aeff ) 1550 nm: 72 µm2

Effective Group Index

of Refraction (Neff ) 1550 nm: 1.468

1625 nm: 1.469

Fatigue Resistance

Parameter (nd ) 20

Coating Strip Force Dry: 0.6 lbs. (3N)

Wet, 14-day room temperature:

0.6 lbs. (3N)

Rayleigh Backscatter

Coefficient 1550 nm: -81 dB

(for 1 ns Pulse Width) 1625 nm: -82 dB

Chromatic Dispersion 1550 nm at 4 ps/(nm•km)

1625 nm at 10 ps/(nm•km)

Spectral Attenuation (Typical Fiber)

Formulas

Dispersion Corning Incorporated

www.corning.com/opticalfiber

One Riverfront Plaza

Corning, NY 14831

Ph: 800-525-2524 (U.S. and Canada)

607-248-2000 (International)

Email: cofic@corning.com

Corning, LEAF and CPC are registered trademarks of

Corning Incorporated, Corning, N.Y.

Any warranty of any nature relating to any Corning

Cladding Non-Circularity optical fiber is only contained in the written agreement

between Corning Incorporated and the direct purchaser

of such fiber.

©2009 Corning Incorporated

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Ur5 KinematicsDocumento12 pagineUr5 KinematicsNikhil GuptaNessuna valutazione finora

- Solution Manual For Essential University Physics 3rd Edition by Wolfson PDFDocumento18 pagineSolution Manual For Essential University Physics 3rd Edition by Wolfson PDFa5496735350% (1)

- ANSI-SMACNA 2006 HvacDuctStandardsDocumento64 pagineANSI-SMACNA 2006 HvacDuctStandardsErica MorrisonNessuna valutazione finora

- 16 TewariDocumento22 pagine16 TewariNebojsa BascarevicNessuna valutazione finora

- S014548Documento1 paginaS014548colinyNessuna valutazione finora

- S2YYM2FISPDocumento1 paginaS2YYM2FISPcolinyNessuna valutazione finora

- Siemon Fiber Optic Splicing Products: UltraspliceDocumento4 pagineSiemon Fiber Optic Splicing Products: UltrasplicecolinyNessuna valutazione finora

- Bx006dwls9kr Similar M62bk06iorDocumento1 paginaBx006dwls9kr Similar M62bk06iorcolinyNessuna valutazione finora

- USCHS Data SheetDocumento2 pagineUSCHS Data SheetcolinyNessuna valutazione finora

- Fiber Systems International: Tfoca-Ii 12-Channel Fiber Optic ConnectorsDocumento4 pagineFiber Systems International: Tfoca-Ii 12-Channel Fiber Optic ConnectorscolinyNessuna valutazione finora

- S09RB08CDocumento1 paginaS09RB08CcolinyNessuna valutazione finora

- PM15 U25A Specialty FibersDocumento4 paginePM15 U25A Specialty FiberscolinyNessuna valutazione finora

- PC1 SPLC 04RDocumento7 paginePC1 SPLC 04RcolinyNessuna valutazione finora

- S123M12Documento4 pagineS123M12colinyNessuna valutazione finora

- Molex Wall OuntsDocumento24 pagineMolex Wall OuntscolinyNessuna valutazione finora

- Corning CCH Connector Housing Spec SheetDocumento12 pagineCorning CCH Connector Housing Spec SheetcolinyNessuna valutazione finora

- M62rb12c3nro M62rb012croDocumento2 pagineM62rb12c3nro M62rb012crocolinyNessuna valutazione finora

- M20 SX01 LNRBDocumento1 paginaM20 SX01 LNRBcolinyNessuna valutazione finora

- CCH CP06 19TDocumento1 paginaCCH CP06 19TcolinyNessuna valutazione finora

- NN254 and CFS 2 (46107)Documento44 pagineNN254 and CFS 2 (46107)colinyNessuna valutazione finora

- SM2Documento2 pagineSM2colinyNessuna valutazione finora

- Baf112 MSDSDocumento12 pagineBaf112 MSDScolinyNessuna valutazione finora

- CCH CP12 E7Documento1 paginaCCH CP12 E7colinyNessuna valutazione finora

- Description Part Number (UPC) Part Number (APC) : SpecificationsDocumento2 pagineDescription Part Number (UPC) Part Number (APC) : SpecificationscolinyNessuna valutazione finora

- Instruction For Launch BoxDocumento1 paginaInstruction For Launch BoxcolinyNessuna valutazione finora

- Corning Cable Systems Splice TraysDocumento8 pagineCorning Cable Systems Splice TrayscolinyNessuna valutazione finora

- Fibrskope Portable MicroscopeDocumento6 pagineFibrskope Portable MicroscopecolinyNessuna valutazione finora

- Ripley: Instruction SheetDocumento1 paginaRipley: Instruction SheetcolinyNessuna valutazione finora

- FCP1Documento3 pagineFCP1colinyNessuna valutazione finora

- FDSCGATOR12FTDocumento2 pagineFDSCGATOR12FTcolinyNessuna valutazione finora

- F1 CledDocumento9 pagineF1 CledcolinyNessuna valutazione finora

- F1 MC125Documento1 paginaF1 MC125colinyNessuna valutazione finora

- F1 CP83Documento2 pagineF1 CP83colinyNessuna valutazione finora

- F1 SCLCMFDocumento1 paginaF1 SCLCMFcolinyNessuna valutazione finora

- Analog Vs Digital DataDocumento3 pagineAnalog Vs Digital Datanmuhunthan100% (1)

- SSG-NG01017365-GEN-CS-8180-00007 - C01 - Pig Launch Analysis and DSG RPTDocumento53 pagineSSG-NG01017365-GEN-CS-8180-00007 - C01 - Pig Launch Analysis and DSG RPTDaniel Dambo100% (1)

- Result and DiscussionDocumento3 pagineResult and DiscussionWenalyn Grace Abella LlavanNessuna valutazione finora

- Machining PDFDocumento5 pagineMachining PDFlambrosNessuna valutazione finora

- Quiz 6 EnergyDocumento2 pagineQuiz 6 Energyeloizamay100% (1)

- Iso 76 Rolling BearingsDocumento14 pagineIso 76 Rolling BearingsSezgin Bayrak50% (2)

- Advanced Math SyllabusDocumento2 pagineAdvanced Math Syllabusapi-232573717Nessuna valutazione finora

- 2012, AAG, Tachi - Interactive Freeform Design of TensegrityDocumento10 pagine2012, AAG, Tachi - Interactive Freeform Design of TensegrityPierre ClrNessuna valutazione finora

- Che 0411 Steam Heat Exchangers Are UnderworkedDocumento5 pagineChe 0411 Steam Heat Exchangers Are UnderworkedXpizmonNessuna valutazione finora

- Shear Strength of Coal Mine OverburdenDocumento15 pagineShear Strength of Coal Mine Overburdenjrhst36Nessuna valutazione finora

- Governing 11Documento35 pagineGoverning 11rahul100% (2)

- The Zeeman EffectDocumento11 pagineThe Zeeman EffectAlex TarrNessuna valutazione finora

- Molecular SpectrosDocumento6 pagineMolecular SpectrosabdooufNessuna valutazione finora

- Use of Fiber-Reinforced Soil For Blast ProtectionDocumento16 pagineUse of Fiber-Reinforced Soil For Blast ProtectionSameer ShashwatNessuna valutazione finora

- Maxwell-Boltzmann DistributionDocumento8 pagineMaxwell-Boltzmann DistributionlamyantingNessuna valutazione finora

- Continuous Time Fourier Analysis: Level-1Documento18 pagineContinuous Time Fourier Analysis: Level-1kalyanNessuna valutazione finora

- Thermal Physics Self-Made NotesDocumento4 pagineThermal Physics Self-Made NotesYee Xien LimNessuna valutazione finora

- Mixing Time Jet MixerDocumento9 pagineMixing Time Jet MixerLTE002Nessuna valutazione finora

- DESIGNDocumento9 pagineDESIGNRowena Remorosa GalayNessuna valutazione finora

- Introduction To Linear MeasurementDocumento6 pagineIntroduction To Linear MeasurementLalali LiNessuna valutazione finora

- 10aug 2015 VJTIDocumento34 pagine10aug 2015 VJTIAyush Saxena100% (1)

- Midas Gen: RC Beam Serviceability Checking ResultDocumento2 pagineMidas Gen: RC Beam Serviceability Checking ResultakankwasaNessuna valutazione finora

- Please Make A Note - 2Documento5 paginePlease Make A Note - 2Ishan MahtoNessuna valutazione finora

- Thermodynamics MST 2011Documento3 pagineThermodynamics MST 2011greenhoochyNessuna valutazione finora

- 8.6C PosttestDocumento2 pagine8.6C PosttestYohanes RatnodiyantoNessuna valutazione finora