Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

VFD Design Guide

Caricato da

Khaldoon AlnashiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

VFD Design Guide

Caricato da

Khaldoon AlnashiCopyright:

Formati disponibili

VFD design guide Purchasing and applying variable frequency drives (VFD) in HVAC applications

Introduction Modulating airflow and water flow in HVAC applications is a primary way of minimizing energy consumption while providing desired temperature and ventilation control. Modulating flow can be accomplished by varying resistance to flow with valves and dampers. Another more efficient way to modulate flow is by adjusting pump or fan speed to provide the minimum pressure needed to satisfy the prevailing needs. Although many ways of modulating pump and fan speed have been developed, V ! motor control has become the dominant method for HVAC e"uipment. V !s got off to a roc#y start in the HVAC industry. irst, they were "uite e$pensive. %e$t, a new output device called an &'() was used to reduce the cost but early &'() V !s damaged some motors. More recently, V ! manufacturers have learned to compensate for the damaging characteristics of &'()s, motor manufacturers have made standard motors more tolerant and we have learned some installation techni"ues to prevent motor damage. )oday, V !s are reliable and cost effective. *hen properly applied, they provide substantial energy savings for HVAC and other motor driven e"uipment including+ ans, ,umps, Chillers, Vacuum ,umps and Air Compressors echnical ips fro! the Field "perate !ultiple variable speed devices in parallel rather than one at a ti!e# )his concept ma#es people nervous but it can save energy and improve reliability. &f you find this information confusing or intimidating, see# out the services of a "ualified consultant with plenty of V ! retrofit e$perience. Consider the following+ A pump or fan designer can select just the right device so it operates in your building in -the sweet spot. but often designers add -fudge factors. so the installed device is a bit too strong and re"uires permanent flow restriction /thin# of this as a 0123 energy parasite4. ,erhaps you have V !s installed already and the need for permanent flow restriction has been eliminated. )he bottom line is that many e$isting pumps and fans can satisfy your needs most of the time at significantly reduced speed.

Hospitals tend to have redundant fans and pumps for important systems. )here may be a -lead2lag. control se"uence that runs one device at a time and balances run hours so neither device remains inactive too long /an inactive bearing or seal is unreliable4. )he following statement uses ball par# numbers and is only true if the device has e$cessive pressure capability /remember the fudge factors4 and if the system flow resistance is dominated by variable flow devices /control valves 5 dampers4 rather than long pipe or duct runs. ,lease note that this may not wor# well for constant volume fan systems unless the fans are way over designed /too much fudge factor or a change in system4. A device running at 678 flow might use 068 of the energy used at 9778 flow. )wo devices running at 678 flow each can potentially provide a total of 9778 flow with a total energy consumption of 678 compared to one device providing 9778 flow.

:tudies have shown that a device running at half speed may last 1 times as long as at full speed. &f two 6 year lifetime devices operate lead2lag at full speed, they may provide a total of 97 years of service. &f the same two devices both operate full time at half speed, they may provide a total of 07 years of service. &n a lead2lag control se"uence, if the operating device fails, flow will stop until the control se"uence senses the failure and starts the lag device. &t is also common for devices to fail at start;up so the lag device may be at greatest ris# when it is needed most.

&s this way too much information< Consider this approach+ &f you have redundant e"uipment with V !s, give it a try manually on a medium load day= meter the energy consumption going into the V ! to account for the energy wasted by the V !. (e sure and run both devices at an e"ual speed. >pen circuit setters, inlet vanes and other flow restricting devices /remember previous positions and settings4. ,ressure independent flow control devices may not be field adjustable and can mess up your results. >nce you have opened up your system, chec# energy consumption for -one device. automatic operation. %ow go to manual operation of both devices. ?eep gradually reducing device speed until your total energy consumption drops below the -one device. energy consumption or until you notice some temperature or pressure control limitations. &f this test produces some energy benefits, then consider permanent implementation with the necessary control se"uence changes. >f course you@ll get more savings if you remove permanent restrictions such as circuit setters and pressure independent flow control devices.

$ini!i%e the &iring length bet&een VFD and !otor with a ma$imum length of A7 feet at 1B7 VAC. Ceduce motor voltage to less than D77 if wire length is over A7 feet. Avoiding bearing failure+ >ne of the "uir#s of &'() V !s is that they can induce voltage to build up in motor shafts. &f that voltage gets very high, electric arcs will pass through and eventually destroy bearings. )he conditions that lead to bearing failure are difficult to anticipate but can be easy to identify and resolve. )he first step is to measure voltage from the operating motor shaft to ground using an electronic meter. (e very careful measuring voltage on a rotating shaft. )he author uses a short piece of solid 90 ga. wire on the end of the electronic meter probe and applied at the dimple in the center of most motor shafts. 'o through the entire range of anticipated speeds. &f that voltage e$ceeds about D.6 VAC to motor base, you may have a problem. A simple solution may be to adjust the V ! -carrier fre"uency.. &f that does not wor#, consider attaching a grounding brush to the shaft. Eour V ! vendor may have some other tric#s up their sleeve. Consider re"uiring that shaft voltage be chec#ed and e$cess voltage conditions be resolved if discovered during V ! start;up. Ceset temperature and pressure setpoints to ma$imize value of V !s. &ncrease temperature differential across system to ma$imize value of V !s. !on@t use V !s for motors that constantly run at full speed+ Ce"uirements for more air changes, ductwor# lea#s, partially closed dampers, plugged water systems and poorly implemented renovations are often addressed in hospitals by speeding up fans and pumps. Fventually, V !s simply run at full speed 0123. /:ee Ceducing >pposition to low4. V ! electronics waste about D8 of the energy that passes through the V ! at full load and they waste a higher 8 at lower loads. ortunately, energy savings start building rapidly as motor speed is reduced so the speed where energy savings compensate for V ! losses is about GB8. &f you have V !s that must run full speed 0123 and the opposition to flow or lea#age cannot be reduced, put the V ! into bypass or eliminate the V ! until the flow problem is resolved. !on@t #eep spare V !s on the shelf an e$pect them to wor# immediately after installation.

V ! capacitors lose their ability to immediately be charged if left discharged for several months. &t can ta#e D or 1 days to get them bac# in wor#ing condition. >ne medical center is #eeping a 077 H, V ! on the shelf under a constant tric#le charge. )his V ! is the bac#up for 906 H,, 967 H, and 077 H, V !s. !iscuss bac#up issues with the vendors to determine your best approach.

$a'i!i%ing the use of VFDs at your facility( ("verco!ing )tagnation) :ome of your consultants and some of your staff have had bad e$periences with V !s or they have heard bad stories. )hey may still be hesitant to use V !s. &f they are hesitant to use V !s, they may not be very s#illful at ma#ing the best use of V !s. Design Concepts and Clarifications A. :heaves and &mpellers Motor :peed should be used as the adjustment mechanism for balancing critical paths in air and water systems. After testing and balancing is complete, adjust sheaves, impellers and motor sizes as necessary so that the motor operates at 66 to A7 Hz and motor amperage should be between 378 and G68 of full load amperage when the ma$imum desired system pressures and flows are produced. *hen the motor operates in V ! bypass at A7 Hz, system pressures and flows shall not cause problems and the motor current shall not e$ceed full load amperage. &t may be necessary to install pressure protection switches and2or duct blowout panels to protect variable air volume systems from over;pressure. Coordinate these re"uirements with the )esting and (alancing re"uirements. (. Hine Ceactance ,rovide between D8 and 68 of input line reactance. )his may be provided in the form of separate line reactors at the input of the V !, reactors included as part of the !C bus or a combination of the two totaling D8 to 68. C. >utput Cate of Cise, ,ea# >utput Voltage and *ire Hength A primary purpose of the specification is to purchase and install V !s that will not damage typical premium efficiency motors. &mplementing the following re"uirements should eliminate motor insulation and bearing failures associated with V ! use. 94 Control the output rate of rise or use output circuitry, which prevents the pea# output voltage from reaching 9,777 volts to ground at the motor. 04 Himit 1B7 VAC wire length to less than A7 feet between the motor and V ! /shorter is better4. D4 &f a small motor must be mounted on the roof /typically an e$haust fan4 consider using a lower voltage /017 VAC or less4 motor so an unlimited wire length can be used. !. Mounting V !

Mount the V ! close enough to the 1B7 VAC motor to #eep the wire length below A7 feet /shorter is better4. Coordinate with !ivision 9A designer to insure that this re"uirement is met. &t is also necessary that the V ! be solidly mounted to structural members. Inistrut type structures can be used in most mounting circumstances. !o not mount V !s directly to the fle$ible sides of air handling units, plenums or ductwor#. F. (y;,ass :tarter or Cedundant V ! A manual by;pass starter is typically re"uired. Critical need applications may re"uire an automatic bypass feature. &n some critical applications, a bac#up fan or pump with V ! is provided, in which case, by;pass starters may not be necessary. Motors larger than 36 H, may re"uire a soft;start feature in the by; pass starter. &f motors are typically driven faster than A7 Hz or multiple motors are driven by a single V ! such as in a an*all, bypassing to another V ! may be most appropriate and manufactures are beginning to offer these products. . Amperage &nterrupt Capacity Ce"uirements can vary depending on the electrical system design. )he nominal re"uirement is a A6,777 CM: symmetrical ampere interrupting capacity. :ome electric services re"uire less capacity so the !ivision 96 designer should coordinate with the !ivision 9A designer to determine the appropriate specification. . Cadio re"uency :ensitive Applications A V ! may be installed in the vicinity of highly sensitive electronic e"uipment. An appropriate CC rating may be necessary in these applications and this re"uirement may result in the use of older A;step technology V !s. :ome of the control and interface re"uirements in the guide specification may not be possible with A;step V !s so it may be more practical to heavily filter an &'() V ! if all of the modern control features are needed. '. &nterface with HVAC Controls Most V !s now have low cost2no cost ways of interfacing digitally with the HVAC control system. )he cost is usually lowest if the interface is included in the bid documents rather than added later so it is usually a good idea to include this at the time of purchase. :ome critical e"uipment may need to continue running even if the HVAC control system is having problems. Consider hardwiring >%2> and speed controls directly to an appropriate stand;alone control panel so that it can operate V !s in an ade"uate manner even if communications to the rest of the system are inoperable. H. &nterface with the ire2Hifesafety :ystems

A V ! specification should re"uire all features that might ever be needed for interface with ire2Hifesafety systems. Coordinate with !ivision 9A designer to insure compliance with all prevailing re"uirements.

Perfor!ance )pecification V !s are a mature product that is well suited to HVAC applications. )he application and se"uences of operation will have the most dramatic impact on the value of the product. )hese performance specifications may help insure long motor life and allow you to use standard off;the;shelf premium efficiency motors instead of waiting for an inverter rated motor. Inder no operating conditions shall the line voltage to the motor e$ceed 9777 volts /to ground and from leg to leg4 at any measurable fre"uency using an electronic meter. )his test may be performed at the disconnect or at the motor. Verify this performance as part of the e"uipment start;up for 117J VAC applications. Inder no operating conditions shall the voltage from the motor shaft to ground e$ceed D.6 volts using an electronic meter. Verify this performance as part of the e"uipment start;up. All V ! bypass features shall wor# and start the driven e"uipment without difficulty or slipping belts. Verify this performance as part of the e"uipment start; up.

Calculating and *sti!ating *nergy Consu!ption A V ! vendor might tell you that in a given piping or ventilation system, changing flow through speed modulation will change energy consumption by the cube of the flow change. )hat is, if flow is reduced to B78 then the energy consumption will be reduced to B78 of B78 of B78 or 69.08 of full flow energy consumption. Conversely, increasing flow to 9078 will increase energy consumption to 9078 of 9078 of 9078 or 930.B8. Alas, e$isting HVAC systems usually have a mi$ture of both frictional and control device elements that can be difficult to characterize. *hat we find in the real world is that if you retrofit an e$isting system to reduce flow during some of the operating hours, the change in energy consumption fre"uently seems to wor# out closer to a -change s"uared. result. )his means that if we can reduce flow to B78, the new energy consumption will be B78 of B78 or A18. )he utilities usually have standard calculators that estimate the energy savings associated with replacing fan inlet vane control with V !s.

Potrebbero piacerti anche

- A Rapid Reading Book for Fresh Electrical Engineering Graduates: For Job AspirantsDa EverandA Rapid Reading Book for Fresh Electrical Engineering Graduates: For Job AspirantsNessuna valutazione finora

- Variable Frequency Drives Purchasing TipsDocumento7 pagineVariable Frequency Drives Purchasing TipsMaintenance CircleNessuna valutazione finora

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Da EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Nessuna valutazione finora

- Medium Voltage SwitchgearDocumento5 pagineMedium Voltage SwitchgearGideon MoyoNessuna valutazione finora

- Arc Control in Circuit Breakers: Low Contact Velocity 2nd EditionDa EverandArc Control in Circuit Breakers: Low Contact Velocity 2nd EditionNessuna valutazione finora

- Current Transformer SelectionDocumento4 pagineCurrent Transformer SelectiondceylNessuna valutazione finora

- Coherent Wireless Power Charging and Data Transfer for Electric VehiclesDa EverandCoherent Wireless Power Charging and Data Transfer for Electric VehiclesNessuna valutazione finora

- Motor Calculations - HTMDocumento4 pagineMotor Calculations - HTMDaniel Bejarano SánchezNessuna valutazione finora

- Resistance GroundingDocumento4 pagineResistance Groundingjawad_13Nessuna valutazione finora

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringDa EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNessuna valutazione finora

- Motor Control and Protection PDFDocumento40 pagineMotor Control and Protection PDFAfiq TaibNessuna valutazione finora

- Electrical Power Engineering Reference AmpDocumento27 pagineElectrical Power Engineering Reference AmpTony lorenzNessuna valutazione finora

- Wind Power Generation A Clear and Concise ReferenceDa EverandWind Power Generation A Clear and Concise ReferenceNessuna valutazione finora

- Danfoss Active Harmonic Filter Design GuideDocumento59 pagineDanfoss Active Harmonic Filter Design GuidenaveedfndNessuna valutazione finora

- VFD SpecificationDocumento16 pagineVFD SpecificationkalpeshnishuNessuna valutazione finora

- MV VFD SpecDocumento17 pagineMV VFD Specronfrend100% (1)

- Ground TestingDocumento3 pagineGround Testingpeter_fernandasNessuna valutazione finora

- Abb VFD Pres PDFDocumento31 pagineAbb VFD Pres PDFArun GuptaNessuna valutazione finora

- Pump Applications Using VFDS: Are Vfds Worth It For Pump Applications? Have They Been Oversold To The Market?Documento29 paginePump Applications Using VFDS: Are Vfds Worth It For Pump Applications? Have They Been Oversold To The Market?123sam456Nessuna valutazione finora

- EDS 06-0014 Secondary Substation Earthing DesignDocumento54 pagineEDS 06-0014 Secondary Substation Earthing DesignRohit ShahNessuna valutazione finora

- Troubleshooting Three-Phase AC Motors With U1210 Series Handheld Clamp Meters5990-5192ENDocumento6 pagineTroubleshooting Three-Phase AC Motors With U1210 Series Handheld Clamp Meters5990-5192ENecomujNessuna valutazione finora

- Electrical Trouble Shooting TrainersDocumento30 pagineElectrical Trouble Shooting TrainersSyed Muhammad Farhan100% (1)

- Variable Frequency Drive SelectionDocumento6 pagineVariable Frequency Drive Selectionhasbi fadliNessuna valutazione finora

- Example:-: How To Calculate How Much Battery Capacity (SLA Battery) You NeedDocumento12 pagineExample:-: How To Calculate How Much Battery Capacity (SLA Battery) You Needyeo_wh8977Nessuna valutazione finora

- Gas Insulated SubstationDocumento4 pagineGas Insulated SubstationRiteshPradhanNessuna valutazione finora

- Substation Power FlowDocumento22 pagineSubstation Power FlowVISHALNessuna valutazione finora

- What Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPDocumento47 pagineWhat Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPXuxu TooNessuna valutazione finora

- Unit Auxiliary Transformer DatasheetDocumento6 pagineUnit Auxiliary Transformer DatasheetYulianti Rahmi PurnamawatiNessuna valutazione finora

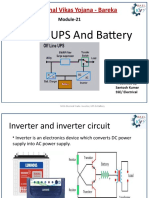

- English M21 Inverter, UPS and Battery (SSEE4)Documento12 pagineEnglish M21 Inverter, UPS and Battery (SSEE4)john power100% (1)

- B L Theraja Volume 1Documento8 pagineB L Theraja Volume 1Umar MajeedNessuna valutazione finora

- Numerical RelaysDocumento38 pagineNumerical Relaysashutosh2009Nessuna valutazione finora

- Electrical Engineering Portal ComDocumento45 pagineElectrical Engineering Portal ComRitesh SharmaNessuna valutazione finora

- 228 Power System ProtectionDocumento2 pagine228 Power System ProtectionRamesh Prajapat100% (1)

- Power System SoftwareDocumento10 paginePower System Softwareசக்திவேல் கார்த்திகேயன்Nessuna valutazione finora

- Standby - Prime - Continuous Ratings of DGDocumento4 pagineStandby - Prime - Continuous Ratings of DGamiteshNessuna valutazione finora

- Defining Control Strategies For MicroGrids Islanded OperationDocumento9 pagineDefining Control Strategies For MicroGrids Islanded OperationNaveen AmarasingheNessuna valutazione finora

- Electrical Power System Design For Industrial FacilitiesDocumento29 pagineElectrical Power System Design For Industrial Facilitiesgusgon521292100% (1)

- AC Generator and Motor ProtectionDocumento76 pagineAC Generator and Motor ProtectionAtif Husayn100% (1)

- Electrical Distribution Design - 040719Documento75 pagineElectrical Distribution Design - 040719Little Trees BorneoNessuna valutazione finora

- Basic TransformerDocumento10 pagineBasic TransformerPin SantosNessuna valutazione finora

- Switching Transients and Surge Protection For MV Transformers in Data CentersDocumento12 pagineSwitching Transients and Surge Protection For MV Transformers in Data CentersTaner ErtürkNessuna valutazione finora

- Battery Charger SizingDocumento10 pagineBattery Charger SizingAlam ArjunoNessuna valutazione finora

- Soft StartersDocumento4 pagineSoft StartersShah JayNessuna valutazione finora

- Distribution and Substation Transformers For Utility Solar Power Generation FacilitiesDocumento9 pagineDistribution and Substation Transformers For Utility Solar Power Generation FacilitiesJose MustafhaNessuna valutazione finora

- M.Tech Power System PDFDocumento30 pagineM.Tech Power System PDFRaja RamachandranNessuna valutazione finora

- DC MotorsDocumento216 pagineDC Motorsdin_thorpe3248Nessuna valutazione finora

- Hydraulic Institute Knowledge Series: Motors & VFDS: Variable Frequency DrivesDocumento32 pagineHydraulic Institute Knowledge Series: Motors & VFDS: Variable Frequency DrivesKarin GzaNessuna valutazione finora

- Synchronous CondensersDocumento4 pagineSynchronous Condensersmvgonzalez2020Nessuna valutazione finora

- 3882 1 RG3CatalogueDocumento12 pagine3882 1 RG3CatalogueJose Domingo Castro100% (1)

- Calculating The Short-Circuit Heating of BusbarsDocumento3 pagineCalculating The Short-Circuit Heating of BusbarsPetranthosNessuna valutazione finora

- 7671 18th Edition Ebook SchneiderDocumento38 pagine7671 18th Edition Ebook Schneidersalmansabir900100% (1)

- Module 13 Panelboards and SwitchboardsDocumento32 pagineModule 13 Panelboards and SwitchboardsCamilla AlbaNessuna valutazione finora

- Design of Motor Control CenterDocumento8 pagineDesign of Motor Control CenterFarhan SaadatNessuna valutazione finora

- Learn To Interpret Single Line Diagram (SLD) - EEPDocumento9 pagineLearn To Interpret Single Line Diagram (SLD) - EEPtusarNessuna valutazione finora

- Project PresentationDocumento50 pagineProject PresentationJijo FrancisNessuna valutazione finora

- Electric Motor For Centrifugal CompressorDocumento10 pagineElectric Motor For Centrifugal Compressoralex696100% (1)

- Short-Circuit CaculationsDocumento10 pagineShort-Circuit CaculationsYousif_AbdalhalimNessuna valutazione finora

- MetalEnclosedCapacitor ApplicationGuide en 110A LTR 2018 04 R001 LRDocumento12 pagineMetalEnclosedCapacitor ApplicationGuide en 110A LTR 2018 04 R001 LRMuhammad FarazNessuna valutazione finora

- WinccDocumento2 pagineWinccKhaldoon AlnashiNessuna valutazione finora

- Modbus Master Needs To Use READ-REQ BLOCK SUCH AS FB7 and WRITE-REQ Block FB8 in Siemens CP341Documento1 paginaModbus Master Needs To Use READ-REQ BLOCK SUCH AS FB7 and WRITE-REQ Block FB8 in Siemens CP341Khaldoon AlnashiNessuna valutazione finora

- Technical Abstract: 1. Conductor and Earthwire DataDocumento3 pagineTechnical Abstract: 1. Conductor and Earthwire DataKhaldoon AlnashiNessuna valutazione finora

- CP 341Documento1 paginaCP 341Khaldoon AlnashiNessuna valutazione finora

- Wincc Types HMIDocumento2 pagineWincc Types HMIKhaldoon AlnashiNessuna valutazione finora

- 2011 NEC Code 310.15B3cDocumento7 pagine2011 NEC Code 310.15B3cKhaldoon AlnashiNessuna valutazione finora

- Siemens CP-341 Used The Modbus Protocol, in Master Mode It Uses Two Function BlockDocumento1 paginaSiemens CP-341 Used The Modbus Protocol, in Master Mode It Uses Two Function BlockKhaldoon AlnashiNessuna valutazione finora

- At A Glance: Correspondence of Program Objects Between Step7 and Unity ProDocumento28 pagineAt A Glance: Correspondence of Program Objects Between Step7 and Unity ProKhaldoon AlnashiNessuna valutazione finora

- Ohm Meter Between Phase R Phase S Phase T: Thy 1 Thy 2Documento1 paginaOhm Meter Between Phase R Phase S Phase T: Thy 1 Thy 2Khaldoon AlnashiNessuna valutazione finora

- Cables SelectionDocumento17 pagineCables SelectionKhaldoon Alnashi100% (1)

- DMC 300 Digital Master Control Will Be Used As Part of The Parallel System in Cummnis Power Command Generators ControlDocumento1 paginaDMC 300 Digital Master Control Will Be Used As Part of The Parallel System in Cummnis Power Command Generators ControlKhaldoon AlnashiNessuna valutazione finora

- Differential Protection Relay Setting and Testing 1-Id 0.3in 2 - M1 0.25 3 - M2 0.5 4 - Ir, m2 4.0 inDocumento1 paginaDifferential Protection Relay Setting and Testing 1-Id 0.3in 2 - M1 0.25 3 - M2 0.5 4 - Ir, m2 4.0 inKhaldoon AlnashiNessuna valutazione finora

- Loop ControllerDocumento1 paginaLoop ControllerKhaldoon AlnashiNessuna valutazione finora

- Flash MixerDocumento2 pagineFlash MixerKhaldoon AlnashiNessuna valutazione finora

- TransformerDocumento1 paginaTransformerKhaldoon AlnashiNessuna valutazione finora

- Transformer Protection Mainly The Differential Protection Biased Current To Be Set Carefully Due To Inrush CurrentDocumento1 paginaTransformer Protection Mainly The Differential Protection Biased Current To Be Set Carefully Due To Inrush CurrentKhaldoon AlnashiNessuna valutazione finora

- The Power For Pump Need To Overcome The Break Power of The Motor With Its Operat Ing Point Near The Best EfficiencyDocumento1 paginaThe Power For Pump Need To Overcome The Break Power of The Motor With Its Operat Ing Point Near The Best EfficiencyKhaldoon AlnashiNessuna valutazione finora

- Easygen 2500 Is Synchronizing and Load Sharing For FG Wilson Generators Up To 8 Generator Sets Can Be SetDocumento1 paginaEasygen 2500 Is Synchronizing and Load Sharing For FG Wilson Generators Up To 8 Generator Sets Can Be SetKhaldoon AlnashiNessuna valutazione finora

- Literature Grammar Humanities Math Science Music Art PE Kurdish Komalayat I ArabicDocumento1 paginaLiterature Grammar Humanities Math Science Music Art PE Kurdish Komalayat I ArabicKhaldoon AlnashiNessuna valutazione finora

- Moore 353 Loop Controller Has Main Mpu Card and An I/o Extension It Has 1-Four Analog Inputs 2-Two Analog OutDocumento1 paginaMoore 353 Loop Controller Has Main Mpu Card and An I/o Extension It Has 1-Four Analog Inputs 2-Two Analog OutKhaldoon AlnashiNessuna valutazione finora

- VSD Calculator For PumpsDocumento10 pagineVSD Calculator For PumpsKhaldoon AlnashiNessuna valutazione finora

- Asme B16.5Documento11 pagineAsme B16.5jacquesmayol100% (1)

- ENG 046 CVVT OCV InspectionDocumento5 pagineENG 046 CVVT OCV Inspectionpacosworld100% (1)

- S05 TMNDocumento33 pagineS05 TMNJacquelineNessuna valutazione finora

- Toyota BT Traigo 9FBMK20T-35T Chapter 15 (Oil Control Valve) 25 - 03 - 2022 Service TrainingDocumento28 pagineToyota BT Traigo 9FBMK20T-35T Chapter 15 (Oil Control Valve) 25 - 03 - 2022 Service TrainingDennis SteinbuschNessuna valutazione finora

- Gastester G4125 InstructionsDocumento20 pagineGastester G4125 InstructionsTom ToyeNessuna valutazione finora

- Dry Air FilterDocumento5 pagineDry Air FilterNeeteshNessuna valutazione finora

- Working As A Mechanical EngineerDocumento13 pagineWorking As A Mechanical EngineerNikita PawarNessuna valutazione finora

- VERTI-G Cuttings DryerDocumento4 pagineVERTI-G Cuttings DryerLoganBohannon100% (1)

- Caterpillar 3208 Diesel Engine Service Manual Copy One (PDF, ENG, 154 MB) PDFDocumento350 pagineCaterpillar 3208 Diesel Engine Service Manual Copy One (PDF, ENG, 154 MB) PDFАлександр80% (5)

- Craftsman Chipper Shredder L0209166Documento26 pagineCraftsman Chipper Shredder L0209166Mark AllenNessuna valutazione finora

- Air Conditioning 2022-2023Documento127 pagineAir Conditioning 2022-2023Ali BandarNessuna valutazione finora

- Study Ghap4Documento40 pagineStudy Ghap4sententialL peetNessuna valutazione finora

- Installation Manual: Generator SetDocumento72 pagineInstallation Manual: Generator SetVictor EstrellaNessuna valutazione finora

- Hydraulic Power Unit EDocumento8 pagineHydraulic Power Unit EDipankar KhawasNessuna valutazione finora

- Nonlinear Buckling of Micropiles FinalDocumento15 pagineNonlinear Buckling of Micropiles FinalcenglertNessuna valutazione finora

- PV776 TSP23762 1Documento70 paginePV776 TSP23762 1Benjamin Miranda FloresNessuna valutazione finora

- Valves S&S B Series 8-Inch Globe: Instruction ManualDocumento12 pagineValves S&S B Series 8-Inch Globe: Instruction ManualpedroNessuna valutazione finora

- Class 18 March 2020 PDFDocumento13 pagineClass 18 March 2020 PDFMuskan NehraNessuna valutazione finora

- Manual Compresor Water FurnaceDocumento50 pagineManual Compresor Water FurnaceFred GarciaNessuna valutazione finora

- AT 402 - OM 1 DescriptionDocumento17 pagineAT 402 - OM 1 DescriptionCarlos Alberto Rozo R.Nessuna valutazione finora

- Gen 00 104265 Qa 6050 00514 0000 03 PDFDocumento11 pagineGen 00 104265 Qa 6050 00514 0000 03 PDFchandana kumarNessuna valutazione finora

- Fai Filtri Oil Filter Codes PDFDocumento8 pagineFai Filtri Oil Filter Codes PDFSebastian GanciNessuna valutazione finora

- The Pure Substance:: A Pure Substance Is One That Has A Homogeneous and Invariable Chemical CompositionDocumento113 pagineThe Pure Substance:: A Pure Substance Is One That Has A Homogeneous and Invariable Chemical CompositionHrishikesh ReddyNessuna valutazione finora

- Report - Maintainability Design ReviewDocumento94 pagineReport - Maintainability Design ReviewNtoko100% (1)

- GB E4313 - AWS A5.1 E6013 Welding Rods - Carbon Steel ElectrodeDocumento2 pagineGB E4313 - AWS A5.1 E6013 Welding Rods - Carbon Steel ElectrodeArfanAli100% (1)

- 36 504 Welding of High Pressure Temperature Tube and Pipework RevDocumento40 pagine36 504 Welding of High Pressure Temperature Tube and Pipework Revmanojballa100% (1)

- CH6 - NDE SymbolsDocumento32 pagineCH6 - NDE SymbolsEdgar SerafinNessuna valutazione finora

- Strength of Material Chapter 3Documento22 pagineStrength of Material Chapter 3naserunnNessuna valutazione finora

- Clutch Gp-TransmissionDocumento10 pagineClutch Gp-TransmissionLucas EduardoNessuna valutazione finora

- TICA модульный чиллер TCADocumento16 pagineTICA модульный чиллер TCAКирилл ЛевкевичNessuna valutazione finora

- Electric Motor Control: DC, AC, and BLDC MotorsDa EverandElectric Motor Control: DC, AC, and BLDC MotorsValutazione: 4.5 su 5 stelle4.5/5 (19)

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceDa EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNessuna valutazione finora

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDa EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsValutazione: 4.5 su 5 stelle4.5/5 (12)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADa EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANessuna valutazione finora

- Solar Energy: Survive Easily on Solar Power Off the GridDa EverandSolar Energy: Survive Easily on Solar Power Off the GridNessuna valutazione finora

- A Practical Handbook for Drilling Fluids ProcessingDa EverandA Practical Handbook for Drilling Fluids ProcessingNessuna valutazione finora

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDa EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentValutazione: 4.5 su 5 stelle4.5/5 (21)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingDa EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNessuna valutazione finora

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningDa EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningValutazione: 5 su 5 stelle5/5 (4)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Handbook on Battery Energy Storage SystemDa EverandHandbook on Battery Energy Storage SystemValutazione: 4.5 su 5 stelle4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDa EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsValutazione: 4.5 su 5 stelle4.5/5 (2)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDa EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNessuna valutazione finora

- Global Landscape of Renewable Energy FinanceDa EverandGlobal Landscape of Renewable Energy FinanceNessuna valutazione finora

- The Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadDa EverandThe Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadValutazione: 4.5 su 5 stelle4.5/5 (10)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDa EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsNessuna valutazione finora

- Power Electronics Diploma Interview Q&A: Career GuideDa EverandPower Electronics Diploma Interview Q&A: Career GuideNessuna valutazione finora

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- Thermal Power Plant: Design and OperationDa EverandThermal Power Plant: Design and OperationValutazione: 4.5 su 5 stelle4.5/5 (23)