Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage Tank

Caricato da

nguyenquoc1988Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage Tank

Caricato da

nguyenquoc1988Copyright:

Formati disponibili

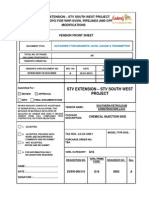

STV EXTENSION STV SOUTH WEST PROJECT (SVSW) EPCI FOR WHP-SVSW, PIPELINES AND CPP SuTuVangSouthWest MODIFICATIONS

S VENDOR FRONT SHEET

DOCUMENT TITLE

DATASHEET FOR CHEMICAL STORAGE TANK

TOTAL NO. OF PAGES

(INCLUDING FRONTSHEETS)

04

VENDOR'S ORDER NO. VENDOR'S APPROVAL (NAME AND SIGNATURE)

VENDOR'S OWN DOCUMENT NO

REV. NO

DATE

SVSW-004110-G8-0001

15-01-2013

LE ANH VU

Submitted For : REVIEW INFO APPROVAL FINAL DOCUMENTATION

STV EXTENSION STV SOUTH WEST PROJECT

SOUTHERN PETROLEUM CONSTRUCTION J.S.C

REVIEW DOES NOT CONSTITUTE ACCEPTANCE OF DESIGN DETAILS, CALCULATIONS, TEST METHODS OR MATERIALS DEVELOPED OR SELECTED BY VENDOR NOR DOES IT RELIEVE VENDOR FROM FULL COMPLIANCE WITH CONTRACTUAL OR OTHER OBLIGATIONS.

VENDOR NAME :

PACKAGE DESCRIPTION:

CHEMICAL INJECTION SKID

1. ACCEPTED

2. ACCEPTED, PROCEED WITH WORK AND INCORPORATE COMMENTS AND RE-SUBMIT 3. NOT ACCEPTED. REVISE AND RE-SUBMIT. 4. FOR INFORMATION ONLY. NO SIGNATURE REQUIRED.

TAG NOS.: ABJ-4208 / ABJ-4218 PURCHASE ORDER NO: TBA

MODEL TYPE NOS.:

VDRL CATEGORY:

G8

VDRL PRIME CODE. SEQUENCE NO.: Rev.

REQUISITION NO. NAME : DATE : SIGNATURE :

SVSW-004110

G8

0001

CLIENT

CONTRACTOR

CUU LONG JOC

VENDOR

ALPHA ECC

Su Tu Vang South West

STV EXTENSION PLAN - STV SOUTH WEST WELLHEAD PLATFORM (SVNE)

CHEMICAL INJECTION SKID

DATASHEET FOR CHEMICAL TANK

COVER SHEET

DOCUMENT NO.: SVSW-004110-G8-0001

A REV.

14-Jan-14 DATE

ISSUE FOR REVIEW/APPROVAL DESCRIPTION

N.T.V PREP'D

VU CHK'D VENDOR

L.A.V APP'D APP'D CLT/CONT

CLIENT

CONTRACTOR

Requisition No. : N/A

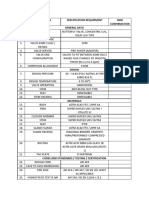

DATASHEET CHEMICAL STORAGE TANK

Document No. Sheet No. Rev. No. Item Tag No.

: SVSW-004110-G8-0001 : 1 OF 2 : A : ABJ-4208 / ABJ-4218 :

VENDOR

Services

PROJECT NAME: STV EXTENSION PLAN- STV SOUTH WEST

PROJECT TITLE: PROVISION OF DETAILED DESIGN

POUR POINT DEPRESSANT SYSTEM & CORROSION INHIBITOR SYSTEM

1 Manufacturer 2 Quantity 3 Tank Type 4 5 6 7 8 9 10 11 12 13 14 15 B MECHANICAL DESIGN 16 17 18 19 20 21 22 23 24 C INTERNAL DETAILS 25 26 27 28 29 30 31 D EXTERNAL DETAILS 32 33 34 35 36 37 38 39 40 41 E INSPECTION AND TESTING 42 43 44 45 46 47 48 Hydrostatic Test Pressure, barg Inspection by Special Inspection Requirements : : : Ladder Manway Padeyes Anchor Bolt Holes Insulation External Coating : Inlet Diverter Vortex Breaker Oil Compartment Internal Material : : : : Tank Size, L x W, H, m Shell / Roof / Bottom Material Nozzle material Flange material Internal /External Attachment Internal Corrosion Allowance, mm : : : : : : Design Code Design Pressure, barg Design Temperature, oC Nominal Capacity, m Blast load, bar Design Specification

3

ALPHA-ECC ONE - MULTI-COMPARTMENTED TANK RECTANGULAR / COMPARTMENTED

Service Location Code Stamp

VARIOUS CHEMICALS SVSW NO

A DESIGN DATA

: : : : : :

NOTE 24 FULL OF WATER (Note 10) 65 / 0 NOTE 3 N/A 2013-3200-1L-0003

Operating Pressure, barg Operating Temperature, oC

: :

ATM AMB

3.46 m x 1.4 m x 2.0 m (Note 6) SS 316L SS 316L SS 316L SS 316L 0 Shell/Roof/Bottom Wall Thickness, mm Operating Weight, kg Dry Weight, kg Base Frame Name plate : : : : : 8.0 mm 11482 3204 A36 / SS400 SS 316L

NO NO NO SS 316L

Internal Pipe Drain Sump Special Internal Internal Coating

: : : :

YES NO NO NO

YES

Platform Handrail (Tank top) Davit Legs Earthing Bosses Special External Stiffeners

: : : : : : :

NO YES (NOTE 7) NO YES YES NO YES

: YES, ONE FOR EACH COMPARTMENT : : : : YES YES NO NO

FULL OF WATER + 2 Mtr. COMPANY'S REPRESENTATIVE

CLIENT

CONTRACTOR

Requisition No. : N/A

DATASHEET CHEMICAL STORAGE TANK

Document No. Sheet No. Rev. No. Item Tag No.

: SVSW-004110-G8-0001 : 2 OF 2 :A : ABJ-4208 / ABJ-4218 :

VENDOR

Services

PROJECT NAME: STV EXTENSION PLAN- STV SOUTH WEST

PROJECT TITLE: PROVISION OF DETAILED DESIGN

FOUR POINT DEPRESSANT SYSTEM & CORROSION INHIBITOR SYSTEM

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

NOTES

1) Tank shall be designed and fabricated in accordance to "Specification for Atmospheric Tank" No. 2013-3200-1L-0006. 2) Design pressure is based on compartment filled with water with adjacent compartment empty. Wall thickness shall be calculated based on API 650 and Roark's formula. 3) Tank capacity and size shall be as follows : (Note 6) Tag No. ABJ-4208 ABJ-4218 Chemical Pour Point Depressant Corrosion Inhibitor Working Capacity (m3) 6.3 (14 Days) 2.4 (28 Days) Length (m) 2.50 0.96 Width (m) 1.40 1.40 Height (m) 2.00 2.00

4) Tank shall be designed to withstand: - Transportation acceleration: horizontal 0.6g; Vertical: 0.35g - Wind speed: 38.76 m/s 5) Tank plate seam shall be subjected to minimum 10% Spot Radiography or UT. Welds on lifting lugs shall be using full penetration / continuous weld and subject to NDT using 100 % RT or UT. 6) The tank dimension listed is indicative only. VENDOR to determine tank dimension sufficient to have the working capacity taking into account the visible length of LG and elevation of overflow nozzle. Full range of working capacity shall be visible on the LG. Allocated skid size is 5M (L) x 2M (W) x 3M (H). 7) Tank shall be provided with caged ladder handrails on top around tank periphery with safety gage. 8) LG and LT shall be magnetic level gauge. 2"-150 # RF flanged connections with 3/4" vent and drain valves. 9) LG to be installed to facilitate easy removal of the float without requiring removal of gauge from the tank. 10) Design pressure shall also consider filling of flame arrestor pipe (approximately 1.5 m above the tank top). 11) All stud bolts and nuts shall be PTFE coated 12) No valve / manway / vent connection shall protrude beyond the skid. 13) Roof and bottom plate shall be flat curved construction type. 14) Vendor shall supply all the equipment in the package limit such as ball valve, Gasket, Bolt /Nuts, etc. 15) Vent with flame arrestor. 16) Pickling and passivation is required for SS316L tanks. 17) Vendor to advise actual tank dimensions and thickness. 18) All testing and examination shall have an inspection certificate. 19) Overflow line is flush with top of tank and routed internally to skid drain. 20) Permanent tank. 21) Refer to Painting & Protective Coating Specification No. 2012-3189-6L-0010. 22) Cover shall be furnished with handles. The manhole shall be light weight type and designed in according with API 650. 23) Bottom plate shall slope towards to the drain nozzle 24) Tank wall thickness calculation shall be based on the Standard Engineering Practice using the Pressure Design Hand Book or Roark & Young "Formulas for Stress and Strain".

Potrebbero piacerti anche

- Pv-Elite He 101 - Rev 7Documento118 paginePv-Elite He 101 - Rev 7Dwi Putra100% (1)

- Quant Job Application ChecklistDocumento4 pagineQuant Job Application Checklistmetametax22100% (1)

- Questions To Client On SAP HCMDocumento19 pagineQuestions To Client On SAP HCMeurofighterNessuna valutazione finora

- Calculations Tank S6Documento19 pagineCalculations Tank S6Joshue Adele100% (1)

- DH01 M E 0007 - Mechanical Datashet For TankDocumento4 pagineDH01 M E 0007 - Mechanical Datashet For TankDuy NamNessuna valutazione finora

- 2013-6031-2L-0010-Specification For Polyurethane Insulation Coating - Re IDCDocumento42 pagine2013-6031-2L-0010-Specification For Polyurethane Insulation Coating - Re IDCnguyenquoc1988100% (1)

- SP-2069 Specification For Pressure VesselsDocumento68 pagineSP-2069 Specification For Pressure Vesselsarjunprasannan7Nessuna valutazione finora

- STD PIP VECV1001 2012 Design Criteria and Purchasing Requirements For Vessels Div 1 & 2Documento28 pagineSTD PIP VECV1001 2012 Design Criteria and Purchasing Requirements For Vessels Div 1 & 2Nikunj KNessuna valutazione finora

- Ejma7r2 Bellows Worksheet 1Documento8 pagineEjma7r2 Bellows Worksheet 1NamıkNessuna valutazione finora

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocumento1 paginaK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNessuna valutazione finora

- Flange Calculation Sheet..Documento2 pagineFlange Calculation Sheet..nguyenquoc198850% (2)

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocumento6 pagineSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988Nessuna valutazione finora

- Blessing of The Advent WreathDocumento3 pagineBlessing of The Advent WreathLloyd Paul ElauriaNessuna valutazione finora

- Multiple AllelesDocumento14 pagineMultiple AllelesSabs100% (2)

- Mechanical Design of Tall Columns:Guide For DesignDocumento45 pagineMechanical Design of Tall Columns:Guide For Designdip_maan100% (1)

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocumento4 pagineWI06-0260 Calculations For Obround Nozzle ConnectionskumarNessuna valutazione finora

- TQ - Air Fin Cooler (CS) - ModificationDocumento6 pagineTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNessuna valutazione finora

- Forced Evaporation Ponds DesignDocumento10 pagineForced Evaporation Ponds Designfotikos100% (1)

- Report Rectangular Tank - REV 0 - 28.11.12Documento26 pagineReport Rectangular Tank - REV 0 - 28.11.12JijinJohn100% (1)

- PVV Cal Sheet LabixDocumento45 paginePVV Cal Sheet LabixPranpath Narupantawart50% (2)

- Stack Design CalculationDocumento6 pagineStack Design CalculationSabir Nasim100% (2)

- Bspd5500 Nozzle CalculationDocumento24 pagineBspd5500 Nozzle CalculationrsubramaniNessuna valutazione finora

- Rectangular Tanks:: Rectangle Tank DesignDocumento23 pagineRectangular Tanks:: Rectangle Tank Designshna jabarNessuna valutazione finora

- Student ChecklistDocumento9 pagineStudent Checklistapi-251493243Nessuna valutazione finora

- Final Bulk Storage CalculationDocumento2 pagineFinal Bulk Storage CalculationokahertaberNessuna valutazione finora

- Chemical Storage Tank Buying Guide Poly ProcessingDocumento16 pagineChemical Storage Tank Buying Guide Poly ProcessingKhalil FaridNessuna valutazione finora

- Design of Atmospheric Tanks - API650Documento25 pagineDesign of Atmospheric Tanks - API650Faizal CANessuna valutazione finora

- Nozzle Calculation - Primary Reformer Stack-R0Documento22 pagineNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- 6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiDocumento15 pagine6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiAvinash ShuklaNessuna valutazione finora

- Storage Tank Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDocumento39 pagineStorage Tank Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignAlexander100% (1)

- Reading Test - 3 Clinical Depression Text ADocumento17 pagineReading Test - 3 Clinical Depression Text AJisha JanardhanNessuna valutazione finora

- FRP Vessel Calc Asme RTP 1Documento7 pagineFRP Vessel Calc Asme RTP 1GautamNessuna valutazione finora

- Engineering Notes For Design of Skids - Rev J - 03 Mar 2015Documento38 pagineEngineering Notes For Design of Skids - Rev J - 03 Mar 2015MariaNessuna valutazione finora

- Compress EvaluateDocumento23 pagineCompress EvaluateVishalDhiman100% (1)

- Compress Report For Pressure VesselDocumento394 pagineCompress Report For Pressure VesselgaurangNessuna valutazione finora

- Fire Water Tank API 650 DatasheetDocumento16 pagineFire Water Tank API 650 DatasheetUjwal KhandokarNessuna valutazione finora

- API 650 Baseplate DesignDocumento3 pagineAPI 650 Baseplate DesignmjlazoNessuna valutazione finora

- 7-12-0009 Rev 6Documento2 pagine7-12-0009 Rev 6cynideNessuna valutazione finora

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDocumento2 pagineMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002Nessuna valutazione finora

- FRP RF CalcDocumento1 paginaFRP RF CalcmukeshNessuna valutazione finora

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocumento8 pagineHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNessuna valutazione finora

- Tank Insulation CalculatorDocumento4 pagineTank Insulation CalculatorJoshua JohnsonNessuna valutazione finora

- Service Manual - DM0412SDocumento11 pagineService Manual - DM0412SStefan Jovanovic100% (1)

- SVSW-004110-G16-0003-Rev.a-datasheet For Magnectic Level Gauge & TransmitterDocumento4 pagineSVSW-004110-G16-0003-Rev.a-datasheet For Magnectic Level Gauge & Transmitternguyenquoc1988Nessuna valutazione finora

- Tank Calculation Kasikan Gs Rev BDocumento20 pagineTank Calculation Kasikan Gs Rev BTrian Desta Rizal80% (5)

- Flange Weight ChartDocumento1 paginaFlange Weight Chartabhishek198327Nessuna valutazione finora

- 500-KL Tank Calculation Report Rev. BDocumento64 pagine500-KL Tank Calculation Report Rev. Bmochammad reygyansyahNessuna valutazione finora

- HRD Hot Water Pump P001Documento6 pagineHRD Hot Water Pump P001nguyenquoc1988Nessuna valutazione finora

- HRD Hot Water Pump P001Documento6 pagineHRD Hot Water Pump P001nguyenquoc1988Nessuna valutazione finora

- List of HVAC SpecificationsDocumento46 pagineList of HVAC Specificationsnguyenquoc1988100% (1)

- Finite Element Analysis For The Design Validation of Mounded LPG BulletsDocumento8 pagineFinite Element Analysis For The Design Validation of Mounded LPG BulletsMuhammed NoufalNessuna valutazione finora

- Pressure Vessel Design Old (Eugyene F Megysey)Documento31 paginePressure Vessel Design Old (Eugyene F Megysey)David FonsecaNessuna valutazione finora

- Datasheet For Butterfly ValveDocumento3 pagineDatasheet For Butterfly ValvevishnuvarthanNessuna valutazione finora

- Calc' Diesel Fuel (Rev)Documento10 pagineCalc' Diesel Fuel (Rev)joko_tm02Nessuna valutazione finora

- Urinary Tract Infection (UTI) - 4 Nursing Diagnosis InterventionsDocumento4 pagineUrinary Tract Infection (UTI) - 4 Nursing Diagnosis InterventionsEricsonMitra0% (2)

- Design of Shell & Tube HXDocumento62 pagineDesign of Shell & Tube HXUmirahRashidahNessuna valutazione finora

- Aeration Tank Blower Calcns Package - US UnitsDocumento24 pagineAeration Tank Blower Calcns Package - US UnitsSoufian El AlamiNessuna valutazione finora

- TBE For UG Knock Out Drum - Draft For Rev.C1Documento22 pagineTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskNessuna valutazione finora

- 1-25 Process Tanks and SilosDocumento14 pagine1-25 Process Tanks and Silosthongtn2007Nessuna valutazione finora

- Linkage 2 Lab ReportDocumento25 pagineLinkage 2 Lab Reportapi-25176084883% (6)

- Design of 5 Tons Capacity Cone Bottom STDocumento26 pagineDesign of 5 Tons Capacity Cone Bottom SThgagselim2012Nessuna valutazione finora

- On-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemDocumento4 pagineOn-Site Electrolytic Chlorination Skid-Mounted OSEC B-Pak SystemgohviccNessuna valutazione finora

- 17 Asmeviii A-2 Reverse Integral FlangeDocumento1 pagina17 Asmeviii A-2 Reverse Integral FlangepastylNessuna valutazione finora

- THK Design CalculationDocumento3 pagineTHK Design CalculationalexnomitaNessuna valutazione finora

- 10P87-D0003-046-R0-WHRU by TEPLDocumento23 pagine10P87-D0003-046-R0-WHRU by TEPLjigarNessuna valutazione finora

- Design of Pressure Vessel - CADEMDocumento88 pagineDesign of Pressure Vessel - CADEMgkdora574Nessuna valutazione finora

- Design of Incinerator Plant For Vasai-Virar RegionDocumento4 pagineDesign of Incinerator Plant For Vasai-Virar RegionVIVA-TECH IJRINessuna valutazione finora

- Sa-516 70 TDCDocumento2 pagineSa-516 70 TDCshazan100% (1)

- Mechanical Data Sheet For Centrifugal Pumps (P-1203A/B) : Poly Butadiene II (35000 TPY)Documento7 pagineMechanical Data Sheet For Centrifugal Pumps (P-1203A/B) : Poly Butadiene II (35000 TPY)you kackNessuna valutazione finora

- BE-WI-248-01-F19 Datasheet Breather ValveDocumento3 pagineBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNessuna valutazione finora

- 2WallTank NFPA ULDocumento1 pagina2WallTank NFPA ULPolo VarsanNessuna valutazione finora

- PV Newsletter - Skirt Connections PDFDocumento5 paginePV Newsletter - Skirt Connections PDFDivyesh PatelNessuna valutazione finora

- Appendix A: Variable Ranges For Filter Cycle Calculations: Basic Properties of Solids, Solutes and FluidsDocumento10 pagineAppendix A: Variable Ranges For Filter Cycle Calculations: Basic Properties of Solids, Solutes and FluidsBrendaline EnopiaNessuna valutazione finora

- Burner - Api 560Documento3 pagineBurner - Api 560wado11Nessuna valutazione finora

- 03 Metal Packing Support PlatesDocumento3 pagine03 Metal Packing Support PlatesypatelsNessuna valutazione finora

- FR48-003-D03-0047 2D MDS Water AccumulatorDocumento5 pagineFR48-003-D03-0047 2D MDS Water AccumulatorpragatheeskNessuna valutazione finora

- Diesel Sigma S 10w API CDSFDocumento1 paginaDiesel Sigma S 10w API CDSFnguyenquoc1988Nessuna valutazione finora

- MAXROY Series A, B & D DatasheetDocumento4 pagineMAXROY Series A, B & D Datasheetnguyenquoc1988Nessuna valutazione finora

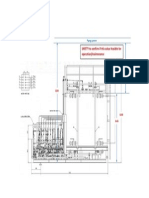

- SAFETY To Confirm If This Value Feasible For Operation/maintenanceDocumento1 paginaSAFETY To Confirm If This Value Feasible For Operation/maintenancenguyenquoc1988Nessuna valutazione finora

- How To Use This Tool Bar: 1 To Place A Cloud, You First Have To Highlight The Cells or Regions To Be CloudDocumento2 pagineHow To Use This Tool Bar: 1 To Place A Cloud, You First Have To Highlight The Cells or Regions To Be Cloudnguyenquoc1988Nessuna valutazione finora

- Quoc IQDocumento1 paginaQuoc IQnguyenquoc1988Nessuna valutazione finora

- AD Oracle ManualDocumento18 pagineAD Oracle ManualAlexandru Octavian Popîrțac100% (2)

- Chem Sba 2019-2020Documento36 pagineChem Sba 2019-2020Amma MissigherNessuna valutazione finora

- Selectivities in Ionic Reductions of Alcohols and Ketones With Triethyisilane - Trifluoroacetic AcidDocumento4 pagineSelectivities in Ionic Reductions of Alcohols and Ketones With Triethyisilane - Trifluoroacetic AcidJan Andre EriksenNessuna valutazione finora

- BU2508DFDocumento3 pagineBU2508DFRaduNessuna valutazione finora

- Reuse DNA Spin ColumnDocumento6 pagineReuse DNA Spin ColumnashueinNessuna valutazione finora

- AudiometerDocumento3 pagineAudiometerVasanth VasanthNessuna valutazione finora

- Public Health Interventions: Applications For Public Health Nursing PracticeDocumento249 paginePublic Health Interventions: Applications For Public Health Nursing PracticeJemimah AdaclogNessuna valutazione finora

- Congenital Malformation of The Lung and AirwaysDocumento48 pagineCongenital Malformation of The Lung and AirwaysrubyniNessuna valutazione finora

- Air Pollution Emissions 2008-2018 From Australian Coal Mining: Implications For Public and Occupational HealthDocumento11 pagineAir Pollution Emissions 2008-2018 From Australian Coal Mining: Implications For Public and Occupational HealthMaria Stephany CalisayaNessuna valutazione finora

- Case Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenDocumento7 pagineCase Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenTrishani NahaNessuna valutazione finora

- 01 Mono Channel BurnerDocumento1 pagina01 Mono Channel BurnerSelwyn MunatsiNessuna valutazione finora

- RA 9344 (Juvenile Justice and Welfare Act)Documento10 pagineRA 9344 (Juvenile Justice and Welfare Act)Dan RamosNessuna valutazione finora

- Materials Management in Hospital Industry Nandi ProjectDocumento27 pagineMaterials Management in Hospital Industry Nandi Projectkumaraswamy226Nessuna valutazione finora

- Aronson AffidavitDocumento18 pagineAronson AffidavitNorthDecoder2Nessuna valutazione finora

- Oral PresentationDocumento4 pagineOral PresentationYaddie32Nessuna valutazione finora

- Textile Reinforced - Cold Splice - Final 14 MRCH 2018Documento25 pagineTextile Reinforced - Cold Splice - Final 14 MRCH 2018Shariq KhanNessuna valutazione finora

- February 2023 PROGRAM OF THE MPLEDocumento8 pagineFebruary 2023 PROGRAM OF THE MPLEDale Iverson LacastreNessuna valutazione finora

- Surgical Management in LeprosyDocumento33 pagineSurgical Management in Leprosynsv.epicNessuna valutazione finora

- TG Chap. 10Documento7 pagineTG Chap. 10Gissele AbolucionNessuna valutazione finora

- SCL NotesDocumento4 pagineSCL NotesmayaNessuna valutazione finora

- Tenses Các NămDocumento4 pagineTenses Các NămAnh MinhNessuna valutazione finora