Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3256r 88

Caricato da

Sulaiman Mohsin AbdulAzizTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3256r 88

Caricato da

Sulaiman Mohsin AbdulAzizCopyright:

Formati disponibili

ACI 325.

6R-88

(Reapproved 1997)

Texturing Concrete Pavements

Reported by ACI Committee 325

Ralph L. Duncan* Chairman Richard O. Albright Walid Abu-Onk Glen Bollin Jerry A. Breite Benjamin Colucci Michael 1. Darter Robert J. Fluhr Wilbur C. Greer, Jr. Starr D. Kohn Torbjorn J. Larsen Richard A. McComb, Sr. B. Frank McCullough Carl P. Meglan Jon I. Mullarky Thomas J. Pasko, Jr. Robert W. Piggott Steven A. Ragan John L. Rice* Raymond S. Rollings Shiraz D. Tayabji Secretary Michel Amin Sargious Terry W. Sherman Douglas C. Staab William V. Wagner, Jr. C. Philip Weisz* Gerald E. Wixson William A. Yrianson*

The importance of the need for skid-resistant pavement has been known for many years. Increased traffic volumes and speeds have increased the need for an improved skid-resistant surface. The emphasis has been to improve skid resistance by creating new surface textures that increase the macrotexture of the concrete pavement. These textures are created by forming the deeper textures in the plastic concrete during the finishing operations. Skid resistance has also been improved in existing concrete pavements by sawing grooves in the hardened concrete with cutting heads composed of a number of circular diamond saw blades. The traveling public may better understand this as a process of placing a tread in the pavement surface, which complements the tread on the car tires, and stops the vehicle without skidding or loss of control by permitting the rapid escape of water.

Keywords: concrete finishes (hardened concrete); concrete finishing (fresh concrete); concrete pavements; maintenance; measurement; skid resistance; texture.

Chapter 4-Maintenance, p. 325.6R-9

4.1-Snow and ice removal 4.2-Retexturing

Chapter 5-Standards related to this report, p. 325.6R-9 Chapter 6-References, p. 325.6R-10

6. l-Cited references 6.2-Related references

CONTENTS Chapter 1-Need for texture, p. 325.6R-1

1.l-Development of textures 1.2-Benefits of texturing 1.3-Factors affecting skid resistance

Chapter 2-Texture types, p. 325.6R-3

2.l-Texturing plastic concrete

2.2-Texturing hardened concrete

Chapter 3-Testing, p. 325.6R-8

3.1-Measuring skid resistance 3.2-Measuring texture

CHAPTER 1 - NEED FOR TEXTURE 1.1- Development of textures The importance of the need for a uniform surface texture to increase skid resistance of both highways and airport pavements has been recognized for many years. s2 The problem of skidding vehicles is not considered to be critical when low volumes of traffic and low speeds are prevalent .3 During the late 1940s and early 1950s, civil engineers raised serious concerns about pavement safety on the highway system. Increasing traffic volumes and speeds, which were contributing to a constantly increasing number of accidents and fatalities in the United States, were the two main factors that led engineers to believe that pavement skid resistance needed to be improved if skidding accidents were to be reduced.

ACI Committee Reports, Guides, Standard Practices, and Commentaries are intended for guidance in designing, planning, executing, or inspecting construction and in preparing specifications. Reference to these documents shall not be made in the Project Documents. If items found in these documents are desired to be part of the Project Documents they should be phrased in mandatory language and incorporated into the Project Documents.

Copyright @I 1988, American Concrete Institute. All rights reserved including rights of reproduction and use in any form or by any means, including the making of copies by any photo process, or by any electronic or mechanical device, printed, written, or oral, or recording for sound or visual reproduction or for use in any knowledge or retrieval system or device, unless permission in writing is obtained from the copyright proprietors. *Texturing Concrete Pavement Task Group. The committee would like to recognize the contribution made by Martin L. Cawley for background information and editorial help in preparing this report.

325.6R-1

325.6R-2

ACI COMMITTEE REPORT

During the same period, aircraft runways were being more critically examined in terms of pavement slipperiness. The advent of jet-powered aircraft quickly established that high-performance airplanes, with accompanying higher takeoff and landing speeds, were much more difficult to control on wet runways than were piston-type aircraft .4 Published reports on the adverse effect of pavement slipperiness on vehicle control go back to the late nineteenth century. The first concrete street in the United States, built in Belfontaine, Ohio, had 4 x 4 in. (102 x 102 mm) squares formed in the plastic concrete to provide traction for horses hooves. Grooving hardened concrete pavement appears to have been a British innovation that was used in 1956 on a number of airfield pavements in England. In the United States in the early 1 9 6 0 s the California State Division of Highways started sawing grooves in pavements to reduce hydroplaning on curves.4 Textures have also been constructed on bridges and parking-deck ramps by building up a multicomponent epoxy coating system, as indicated in ACI 503.3-79. For many years, pavement texturing in plastic concrete had been accomplished with a burlap drag or a belt drawn longitudinally along the pavement surface. During the late 1960s, deeper texturing efforts were initiated. Textures on pavements have been made with both longitudinal and transverse patterns using brooms, tining combs or rakes, roller imprints, and a longitudinally drawn, coarse polyethylene artificial-turf drag inverted to provide texture. The concerns of engineers in developing new deeper textures in concrete whether in the plastic state or in the hardened state were: 1. The possibility of objectionable pavement noise. 2. The possibility of increased roughness, which would cause objectionable vehicle handling characteristics. 3. Problems associated with vehicles, particularly motorcycles, experiencing sensations of tracking or loss of handling control of the vehicle on longitudinal grooves. 4. Increased aircraft-tire wear associated with highspeed landings on deeper textured pavements. 5. Increased pavement wear and rutting. Highway and airport designers have no control over vehicle speed and tire characteristics, and therefore must pay attention to the skid resistance of the pavement surfaces in their designs. Specifications should be adopted for constructing new portland cement concrete pavements with satisfactory surface textures and crowns for existing older pavements that have lost their skid resistance. Cross slopes (or crowns) built into concrete pavements, airport runways, and high-speed turnoffs provide for draining the water from the surface rapidly. Generally, a minimum cross slope on highways of 1 percent is recommended. Slopes greater than this can be used provided they are consistent with road safety and driveability of the vehicles using them. Cross slopes on

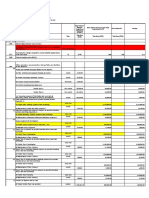

airport runways and taxiways vary from 1 percent to a maximum of 1.5 percent. The cross slopes enhance the skid resistance of textures by proving a good drainage characteristic. 1.2 - Benefits of texturing The results of testing with a standard skid trailer (ASTM E 274) indicate that transverse textures produce higher friction numbers than longitudinal textures (higher friction numbers indicate greater skid resistance). However, it does not necessarily follow that transverse textures should be used throughout the highway system, since friction numbers, as measured with the locked-wheel device, are not sensitive to cornering friction. It is apparent from studies of grooved pavement that longitudinal grooving increases cornering friction significantly, whereas transverse grooving increases mainly longitudinal braking friction.5 Transverse grooves provide a path perpendicular to the direction of travel for the escape of water under the tire, which is an important factor in reducing hydroplaning. The Edens Expressway in Cook County, Ill., was constructed as a jointed portland cement concrete pavement in the early 1950s. The pavement was resurfaced with a bituminous concrete mix in the late 1960s. Between 1979 and 1980, it was reconstructed as a continuously reinforced concrete pavement. The texturing technique used in the reconstructed pavement was a longitudinally drawn artificial turf drag followed by a transverse tine device. The positive benefits of surface tining are reflected in a comparison of the accident statistics compiled for the four years before and after its reconstruction, as shown in Table 1.2. The northbound lanes were installed in 1979 with tining combs that had tines spaced at 1/2 in. (13 mm). In 1980, the southbound lanes were constructed; however, the tine spacTable 1.2 - Statistics compiled by Illinois Department of Transportation, District 1 Bureau of Traffic

Safety impact of Edens Expressway reconstruction - Four years before-after comparison of Edens Expressway versus System* Accidents before Accidents after econstruction: Change, reconstruction: 1 1974 to 1977 1981 to 1984 percent

Accident type

59,869 3249 181 11 13,677 1001

- 3.9 - 22.9 - 7.7 - 8.3 - 8.9 - 22.8

16,470 851

+ 8.9 - 40.8

7769 510

+ 2.4 - 40.8

*Chicago Metropolitan Expressway System accident experience excluding Edens Expressway. Note: Edens Expressway under construction 1978 to 1980.

TEXTURING CONCRETE PAVEMENTS

325.6R-3

ing was changed to 3/4 in. (19 mm) to reduce tearing of the concrete surface. Although a slight increase in noise level was anticipated, it was negligible when measured and actually screened out by other noises. The 3/4 in. (19 mm) tine s pa cingis now standard in Illinois. The reduction of the wet, snow/ice road surface conditions accidents in Table 1.2 shows a very impressive safety impact has been achieved by reducing accidents. This improvement has been attributed to the improved surface texture. Additional benefits observed on pavements with the deeper textures are: 1) a reduction in water spray from traffic due to improved surface drainage, by providing channels for the expulsion of water at the tire-pavement interface into the grooves or deeper striations; 2) a reduction in headlight glare due to the rougher surface of the pavement; and 3) a slower buildup of rubber on runways due to airplane touchdowns on grooved airport pavements. 1.3 - Factors affecting skid resistance Skid resistance of pavements is affected by both the microtexture of the pavement as related to the sand in the mortar portion of the concrete mixture; and by the macrotexture, which is defined as the measurable deeper striations or grooves formed in the plastic concrete during the finishing operations, or the shallow grooves cut in the hardened pavement with cutting heads composed of uniformly spaced circular diamond saw blades. This report will not discuss microtexture. The term hydroplaning refers to the separation of tire contact from the pavement surface by a layer of water. This separation causes a loss of steering and braking control of the vehicle. Hydroplaning is a complex phenomenon that is affected by 1) water depth; 2) pavement texture; 3) tire-tread depth; 4) tire-inflation pressure; 5) tire-contact area; and 6) vehicle speed. An approximate relationship exists between the speed at which hydroplaning will occur and the tire inflation pressure ___________ Hydroplane speed = 10.35 \/ tire pressure when speed is in mph and pressure is in psi.

Some of the earliest investigations and technical reports on loss of vehicle control, which came from the National Aeronautics Space Administration (NASA), were primarily concerned with hydroplaning of aircraft during wet weather operations. The U.S. Army Air Corps, and its successor the U.S. Air Force, also did valuable work on this subject. Later, the Road Research Laboratory in Great Britain began investigations related to hydroplaning of automobiles. Concurrent with this research, the Americans and Germans studied tires and road surfaces to seek their own theories of the factors contributing to skidding.5

CHAPTER 2 - TEXTURE TYPES 2.1 - Texturing plastic concrete 2.1.1 Artificial turf texture - This finish (Fig. 2.1.1) 2.1.1) may be accomplished by using artificial turf inverted and suitably attached to a device that will permit control of the time and rate of texturing. A transverse artificial turf with approximately 2 ft. in contact with the pavement surface and operated longitudinally in the direction that the pavement is being placed should be required. The artificial turf may be weighted to produce a deeper and more uniform texture. One artificial turf that provides a satisfactory texture is made of molded polyethylene with turf blades approximately 0.85 in. (21.6 mm) long, and containing 7200 individual blades per ft2 (930 cm2). 2.1.2 Transverse tine texture - This finish (Fig. 2.1.2) may be obtained by using a single pass of an artificial turf or burlap followed by a mechanically operated transverse-texturing device. The texturing device consists of a single line of flat, slightly flexible, tempered spring steel tines, spaced at not less than 1/2 in. (12.7 mm) nor more than 1 in. (25 mm) centers. Closer centering of the tines will lead to early raveling while larger spacing may lead to objectionable road noise. Random spacings have been used on some projects due to the concern for noise developing from a uniform spacing. The tine width should be 1/8 in. (3.2 mm). Texturing is applied while the concrete is still plastic

Fig. 2.1.1-Artificial turf texture

325.6R-4

ACI COMMITTEE REPORT

enough to obtain a depth of at least 1/8 in. (3.2 mm) but not more than 1/4 in. (6.4 mm). The texture is obtained by one continuous pass of the width of pavement being textured. Additional passes or overlapping are not desirable because they create weak narrow ridges of mortar that will break easily under traffic. 2.1.3 Longitudinal tine texture - The longitudinal tine texture (Fig. 2.1.3) is accomplished with the same basic materials, equipment, and care as the transverse tine texture, except that the tines are pulled in a line parallel with the centerline of pavement.

2.1.4 Transverse broom texture - This finish (Fig. 2.1.4) may be obtained by using a mechanically operated transverse broom finishing device. The broom consists of multiple rows of stiff bristles capable of producing striations 1/16 to 1/8 in. (1.6 to 3.2 mm) deep in the plastic concrete. The striations are uniform in appearance with a spacing approximately equal to their depth and are transverse to the pavement centerline. 2.1.5 Longitudinal broom texture - The longitudinal broom texture (Fig. 2.1.5) is accomplished with the same basic materials, equipment, and care as the trans-

Fig. 2. 1 .2- Transverse tine texture

Fig. 2.1.3-Longitudinal tine texture

Fig. 2. 1. 4- Transverse broom texture

TEXTURING CONCRETE PAVEMENTS

325.6R-5

verse broom finish except that the brooms are operated in a direction parallel to the pavement centerline. 2.1.6 Transverse tine with longitudinal artificial turf texture - The transverse tine texture preceded by the longitudinal artificial turf finish (Fig. 2.1.6) is recommended for high-speed highways or where sudden acceleration or deceleration (panic stops) may occur. The transverse texture provides 1) a better drainage pattern; 2) improved initial skid resistance in a longitudinal direction; 3) a longer lasting texture due to deeper valleys as compared to the broom; and 4) a slight improvement in cornering control provided by the initial pass of longitudinal artificial turf. A longitudinal tine texture could be used on areas such as curves where cornering forces are required. Other textures may be appropriate on low-speed roads or city streets and highways; they provide satisfactory initial skid resistance, but they will wear smooth at an earlier age. 2.1.7 Friction numbers of textures - Table 2.1.7, for friction numbers at 30, 40, and 50 mph, indicates that the best results were obtained by the various textures as follows.7 The results are listed from highest (best) to lowest: 1. Longitudinal artificial turf and transverse tine 2. Transverse tine

3. Transverse broom 4. Longitudinal artificial turf 5. Longitudinal tine 6. Longitudinal broom The values were obtained when the various surface textures were tested in accordance with ASTM E 274 for a locked-wheel skid trailer. The following graphs illustrate the changes in friction numbers obtained in October, 1976 (when constructed) and for three succeeding years for each of the textures constructed in plastic concrete. Fig. 2.1.7(a) and 2.1.7(b) are plotted for regular (treaded) tires at 40 mph from data listed in Table 2.1.7. 2.1.8 Factors affecting pavement texture - The depths obtained with the various types of texturing in plastic concrete depend upon the timing of the texturing operation. Therefore, field-inspection personnel should work with the contractor to achieve the desired depth of texture. Because timing is critical, it is recommended that the texturing machine be a separate piece of equipment. Combining this operation with another one, such as a membrane-curing machine, may delay the texturing until less than desirable depths of texturing are obtained. The benefit of the deeper texture is longer service life, assuming studded tires are not per-

Fig. 2.1.5-Longitudinal broom texture

Fig. 2.1.6 -Transverse tine texture with longitudinal artificial turf texture

325.6R-6

ACI COMMITTEE REPORT

Table 2.1.7 - Friction number at 30,40 and 50 mph (Reference 7)

Texture Transverse tine and 10-05-76 07-18-77 10-24-77 04-24/25-78 04-24/25-78 10-10-78 10-10-78 07-06-79 07-06-79 10-19-79 10-19-79 Transverse tine 10-05-76 07-18-77 10-24-77 04-24/25-78 04-24/25-78 10-10-78 10-10-78 07-06-79 07-06-79 10-19-79 10-19-79 Range FN30 ___ Lane 2 Lane 1 Lane 2 Lane 1 __ 67 63 61 57 56 61 60 55 52 68 71 75 71 62 58 62 61 65 62 __ 65-72 68-74 73-78 66-76 61-65 55-61 58-65 57-66 63-68 59-65 __ 67 68 71 66 60 54 63 60 64 57 Range FN 60 Range____ Lane 1 Lane 2 Lane 1 Lane 2 Lane 1 Lane 2 __ 63-71 66-70 69-74 61-73 58-62 45-57 61-64 58-62 60-68 50-60 __ 63 64 68 57 58 51 61 58 60 52 __ 60-68 61-69 66-69 48-64 56-59 44-57 58-65 44-62 57-61 49-55

artificial turf (longitudinal)

Reg.* Slic Reg. Slicks Reg. Slicks Reg. Slicks

69-87 62-69 65-69 61-67 56-65 55-61 52-61 60-64 54-65 52-58 48-53

71 62 64 56 51 54 48 57 54 53 46

62-77 61-64 62-67 54-58 46-57 52-55 46-49 55-58 48-57 51-57 43-49

62 57 59 53 47 50 46 53 50 50 41

53-74 54-59 56-61 52-55 45-50 48-54 39-50 50-55 48-51 48-54 38-44

Reg. Slicks Reg. Slicks Reg. Slicks Reg. Slicks

79 62 67 61 54 57 47 58 54 57 47

__ 65 68 72 61 61 50 61 56 61 56

72-86 61-64 64-69 59-64 40-61 55-60 42-55 54-64 38-61 53-61 39-53

__ 62-70 64-73 68-75 45-72 59-64 36-54 59-64 44-64 58-64 43-63

65 56 61 56 45 54 39 56 43 53 41

__ 58 63 66 60 56 44 59 53 59 50

59-73 53-59 57-63 52-58 29-55 52-55 23-45 54-58 28-52 50-55 27-47

__ 54-60 60-65 63-68 46-66 53-58 31-50 56-62 45-58 57-62 34-55

56 51 55 50 35 51 35 52 43 47 36

__ 56 59 62 49 53 40 56 43 54 44

52-61 45-53 53-58 47-53 26-42 48-54 18-40 50-54 29-49 45-49 25-43

__ 53-62 54-62 58-64 36-59 50-55 31-47 54-58 30-53 49-57 29-49

Transverse broom 10-05-76 07-18-77 10-24-77 04-24/25-78 Reg. 04-24/35-78 Slicks 10-10-78 Reg. 10-10-78 Slicks 07-06-79 Reg. 07-06-79 Slicks 10-19-79 Reg. 10-19-79 Slicks Artificial turf (longitudinal) 10-05-76 07-18-77 10-24-77 04-24/25-78 Reg. 04-24/25-78 Slicks 10-10-78 Reg. 10-10-78 Slicks 07-06-79 Reg. 07-06-79 Slicks 10-19-79 Reg. 10-19-79 Slicks Longitudinal tine 10-05-76 07-18-77 10-24-77 04-24/25-78 04-24/25-78 10-10-78 10-10-78 07-06-79 07-06-79 10-19-79 10-19-79

69 61 62 61 29 53 25 55 33 53 29

__ 66 70 73 40 61 37 65 37 62 39

60-74 56-67 59-66 59-62 25-31 48-55 23-27 53-57 29-37 51-55 24-31

__ 53-71 68-73 71-77 33-46 56-64 34-39 63-67 32-40 60-64 32-42

61 53 59 52 21 51 19 52 27 49 21

__ 57 64 65 42 56 26 60 30 60 32

56-66 48-57 56-62 51-54 17-25 48-53 18-22 49-54 22-30 46-53 18-23

__ 50-62 60-67 59-69 36-48 55-57 23-30 58-61 22-39 57-62 28-38

50 45 53 45 14 46 15 48 22 44 16

__ 50 56 61 21 51 22 54 25 54 24

45-55 39-53 51-55 40-47 12-18 45-47 13-18 44-50 19-26 42-46 14-20

42-52 54-59 57-63 14-28 50-53 18-26 51-57 21-33 53-56 16-27

68 57 63 60 33 54 31 58 39 54 29

__ 64 65 73 48 61 45 62 46 64 39

61-78 47-63 62-66 54-63 27-39 50-59 24-40 56-59 28-51 51-57 25-37

__ 60-67 61-68 66-78 34-61 59-64 35-50 60-65 38-52 62-65 29-44

55 48 52 51 23 49 21 50 27 49 21

__ 55 58 65 38 56 31 60 35 57 26

42-65 40- 50 48-58 46-57 15-33 44-54 18-27 50-51 21-34 47-54 17-26

48-60 54-64 60-68 29-48 53-58 23-34 57-61 23-41 53-60 22-34

42 40 49 43 16 44 16 47 24 44 16

__ 46 51 54 24 49 25 54 26 50 23

38-48 31-47 42-57 39-46 10-25 38-48 13-22 43-52 18-30 41-47 9-19

__ 41-50 49-53 51-59 15-34 46-52 18-32 49-57 21-34 47-55 17-28

Reg. Slicks Reg. Slicks Reg. Slicks Reg. Slicks

66 61 64 61 56 56 54 61 53 58 48

__ 62 64 70 64 58 47 62 59 60 50

60-72 56-67 61-68 58-66 45-61 54-59 49-57 58-64 45-58 54-60 37-54

55-66 62-68 66-72 51-74 56-59 39-55 60-63 53-62 59-62 42-56

53 54 58 53 36 52 40 59 49 55 41

__ 54 59 65 48 54 39 59 50 56 40

46-60 47-60 52-63 49-59 22-50 48-55 33-47 57-61 41-55 52-57 30-48

__ 46-60 55-62 62-67 28-58 50-57 31-46 58-61 42-55 53-58 28-48

45 47 54 48 38 49 35 52 39 49 34

__ 48 52 58 41 49 31 57 43 50 31

39-57 36-53 49-58 46-51 25-45 45-52 24-41 49-56 30-45 46-52 24-41

__ 41-56 46-57 54-61 22-59 45-51 23-45 53-60 34-59 46-53 21-41

Longitudinal broom __ 65 10-05-76 07-18-77 56 60 10-24-77 62 63 04-24/25-78 Reg. 61 71 04-24/25-78 Slicks 31 42 10-10-78 Reg. 55 59 10-10-78 Slicks 35 39 07-06-79 Reg. 60 63 07-06-79 Slicks 36 38 ,, *Reg. denotes treaded tires ; slicks are smooth or nontreaded tires.

52-76 52-61 58-64 55-63 29-33 53-58 31-38 58-61 34-39

__ 57-64 60-66 68-73 36-47 58-60 35-44 61-65 35-44

52 49 57 49 23 53 21 53 28

__ 51 56 62 28 53 26 61 26

43-65 46-52 55-59 45-52 19-40 52-54 18-23 49-56 26-31

__ 45-56 54-59 61-64 23-30 49-56 22-33 59-64 22-29

37 43 50 44 14 45 20 48 20

__ 46 49 55 17 48 21 56 21

35-41 38-49 46-52 42-45 12-16 42-47 15-32 45-50 18-23

__ 41-48 47-51 53-57 14-21 46-50 18-30 54-58 17-23

TEXTURING CONCRETE PAVEMENTS

65 64 63 62 61 60 59 56 57 56 55 54 53 52 51 50 49 1976 1977 1976 1979

325.6R-7

CALENDAR YEARS

Fig. 2.1.7(a)-Friction __number changes: Various textures ( __ = transverse tine; X = longitudinal tine; \/ = transverse broom)

70 66 66

56

54 52 50 46 1976 1977 1976 1979

CALENDAR YEARS

Fig. 2.1.7(b)-Friction number changes: Various textures (0 = longitudinal broom; T = transverse tine and longitudinal turf; 0 = artificial turf [longitudinal])

mitted on vehicles using the road. There is no known texture that can survive wear in the tire paths caused by normal volumes of traffic using studded tires. Rain on a pavement surface during construction may obliterate the texture if the concrete has not hardened sufficiently. 8 This can be corrected by grinding the pavement and grooving the concrete in the hardened state by the use of diamond-blade saws. Leaving a raindamaged texture uncorrected will create an area of pavement with a surface of a different texture. This will cause different vehicle-handling characteristics, especially during rain, snow, or icing conditions, which may cause an operator to lose control of his or her vehicle. 2.2 - Texturing hardened concrete Skid resistance on worn, polished, contaminated, or slippery hardened concrete may be improved by several methods, including diamond grinding and/or grooving, sandblasting, waterblasting, or chemically treating of the pavement surface. Sandblasting, chemical treatment, or grinding can produce an improved skid resistance; however, sawed transverse grooves will result in

325.6R-8

ACI COMMITTEE REPORT

Fig. 2.2.2-Diamond saw-blade texture

improved texture, better drainage, greater skid numbers and a longer life with improved skid resistance. 2.2.1 Groove patterns - Sawed groove patterns for highways should be not less than 1/8 in. (3.2 mm) wide or more than 1/4 in. (6.4 mm) deep and centered at not less than 1/2 in. (13 mm) nor more than 1 in. (25 mm). Highway grooving may be transverse or longitudinal. The transverse grooves are cut at 90 deg to the centerline of the pavement while the longitudinal grooves are cut parallel to the centerline of the pavement. Generally, transverse grooving is recommended for highways, particularly where frequent braking action is required. The exception might be on curves or heavily traveled highways. However, the interference to traffic caused by closing more than one lane at a time, along with the greatly increased time to groove the pavement and increased cost, has resulted in longitudinal grooving being used in lieu of transverse grooving. Transverse textured surfaces tend to be noisier than longitudinally textured surfaces when the textures are new. As the surfaces experience traffic wear, the variations between the noise levels decrease and are insufficient to rule out their use as a final finish.7 For airports, the Federal Aviation Administration of the U.S. Department of Transportation recommends that the sawed-groove pattern on runways should be transverse (perpendicular to the direction of aircraft motion). The grooves should be 1/4 in. (6.4 mm) wide by 1/4 in. (6.4 mm) deep with center-to-center groove spacing not less than 1 1/8 in. (28.6 mm) nor more than 2 in. (50.8 mm).9 2.2.2 Reprofiling pavements - Before texturing hardened concrete, particularly in areas where studded tires are permitted, field checks should be made to determine whether ruts have been worn in the pavement surface, creating water channels and making hydroplaning very probable. A suggested method of reprofiling pavements is the use of a multiple diamond sawblade grinding machine. These machines have been developed specifically to restore the cross slope or crown in the pavement, and will leave a texture of shallow fins of concrete, as shown in Fig. 2.2.2. CHAPTER 3 - TESTING 3.1 - Measuring skid resistance 3.1.1 Airport pavements - The skid resistance of airport pavements is measured by the British Mu-Meter (ASTM E 670), which is used throughout the world. It is a simple device and consistent when used on level, tangent sections of pavement and has the mobility needed to take measurements with a minimum amount of runway downtime.9 3.1.2 Highway pavements 3.1.2.1 Skid trailer - Surface friction-number measurements of highway pavements in the United States are typically made using a locked-wheel skid trailer that meets the requirements of ASTM E 274. This procedure measures the frictional force on a locked test wheel as it is dragged over a wet pavement surface under constant load and a constant speed, with its major plane parallel to the direction of motion and perpendicular to the pavement. The standard reference speed is usually 40 mph, and the results are expressed as a friction number (FN). Well-textured new pavements will have friction numbers above 60 when tested at a speed of 40 mph. 3.1.2.2 British pendulum- The British pendulum device (ASTM E 303) has also been used to measure surface friction properties. A number of other devices have been used, including the diagonal brake vehicle, Swedish skiddometer, James brake decelerometer, and the Miles friction trailer.

3.2 - Measuring texture Pavement textures are complex, and therefore efforts at correlating skid resistance with texture measurements have had marginal success. There are many different proposed methods for measuring pavement texture. All attempt to set some minimum value that would produce an acceptable macrotexture.10 They all give a measurement of the average texture depth. The sand-patch test, the NASA grease smear technique, the silicone-putty test, static drainage (outflow meter), and stereo photo interpretation are methods that have been used.

TEXTURING CONCRETE PAVEMENTS

325.6R-9

3.2.1 Sand patch test - A measured amount of sand is poured on the pavement and the pile is carefully spread over the surface to form a circle. The texture depth of the surface is then determined from the diameter of the circle of sand. 3.2.2 NASA grease smear technique - A measured amount of grease is placed on the pavement and spread on the pavement between two lines of masking tape 4 in. (102 mm) apart. The grease is then worked into the voids of the pavement with a rubber squeegee, with care taken that no grease is left on the tape or squeegee. The distance along the taped lines is measured and the area is then computed.9 3.2.3 Silicone putty test - A known volume of silicone putty is formed into an approximate sphere and placed on the pavement surface. A recess in a plate is centered over the putty, and the plate is pressed down in firm contact with the surface. The average diameter of the deformed putty is recorded. 3.2.4 Static drainage (outflow meter) test - A specified-size cylinder with a rubber ring glued to its bottom face is placed on the pavement surface and loaded so that the rubber ring will drape over the aggregate particles, similar to that expected of tire tread elements. Water is poured into the cylinder, and the time required for a known volume of water to escape through the pavement and between the rubber ring and surface is measured.10 3.2.5 Stereophotograph test (E 770-80) - The stereophotographs of the pavement surface are viewed through a transparent grid with a 10 x 10 mm grid. The six texture parameter numbers for each of ten random centimeter-squares are noted. The texture parameter number of the pavement photograph is the average of the parameter number of the ten squares.

4.2 - Retexturing Large areas of smoother textures, such as those caused by rain damage in plastic concrete surfaces, have been reported to ice up faster than areas with deeper textures, thereby lowering the friction number. Drivers traveling from a new section of pavement with the deeper textures onto a rain-damaged pavement, or to an older pavement surface where the surface texture has been worn smooth, may experience inferior vehicle-handling characteristics. This is particularly true in rainy, snowy, or icing conditions. These areas can be corrected by grooving the older pavement with multiple diamond saw-blade grinding or grooving machines.

CHAPTER 5- STANDARDS RELATED TO THIS REPORT The documents of the various standards-producing organizations referred to in this document are listed below with their serial designation, including year of adoption or revision. The documents listed were the latest effort at the time this document was written. Since some of these documents are revised frequently, generally in minor detail only, the user of this document should check directly with the sponsoring group if it is desired to refer to the latest revision.

American Concrete Institute

503.3-79 (Reapproved 1986) Standard Specification for Producing a Skid-Resistant Surface on Concrete by the Use of a Multi-Component Epoxy System Standard Test Method for Skid Resistance of Paved Surfaces Using a Full-Scale Tire Standard Method for Measuring Surface Frictional Properties using the British Pendulum Tester Standard Specification for Standard Tire for Pavement Skid-Resistance Tests Standard Specification for Smooth-Tread Standard Tire for Special-Purpose Pavement SkidResistance Tests Standard Method for Calibrating a Wheel Force on Torque Transducer Using a Calibration Platform (User Level) Standard Practice for Accelerated Polishing of Aggregates or Pavement Surfaces Using a Small-Wheel, Circular Track Polishing Machine Standard Test Method for Side Friction on Paved Surfaces Using the Mu-Meter

ASTM

E 274-85

CHAPTER 4 - MAINTENANCE 4.1 - Snow and ice removal Pavements that are located in areas with snow or icing conditions, and which require deeper textures to obtain higher skid resistance, may require an increased maintenance effort to remove the snow and ice. Snowplows may experience more rapid wear of the plow blades. Windblown snow tends to accumulate more on deeper textures, especially when the wind is blowing in a direction which is at right angles to the striations of the texture. In some cases, increased quantities of snow-removal chemicals will correct the condition. Although concern has been expressed by some observers that the increased use of deicing chemicals on pavements with the deeper textures may cause earlier deterioration (especially in areas adjacent to curb and gutter sections and on bridge decks adjacent to the curb sections where brine accumulations may occur), this has not been verified by field observation. Salt-exposure laboratory tests on properly air-entrained concrete indicate that increasing amounts of deicing salts do not contribute to increased texture deterioration.

E 303-83

E 501-82

E 524-82

E 556-82

E 660-83

E 670-85

325.6R-10

ACI COMMITTEE REPORT

E 707-79 (Reapproved 1984)

E 770-80 (Reapproved 1985) E 965-83

Standard Test Method for Skid Resistance of Paved Surfaces Using the North Carolina State University Variable-Speed Friction Tester Standard Test Method for Classifying Pavement Surface Textures Standard Test Method for Measuring Surface Macrotexture Depth Using a Sand Volumetric Technique

These publications may be obtained from the following organizations: American Concrete Institute P.O. Box 19150 Detroit, MI 48219-0150 ASTM 1916 Race St. Philadelphia, PA 19103 CHAPTER 6 - REFERENCES 6.1 - Cited references

1. Murphy, William E., The Skidding Resistance of Concrete Pavements: A Review of Research, Development and Practice in the United Kingdom, Roadways and Airport Pavements, SP-51, American Concrete Institute, Detroit, 1975, pp. 231-256. 2. Guidelines for Texturing of Portland Cement Concrete Pavements, Technical Bulletin No. 19, American Concrete Pavement Association, Arlington Heights, 1975, 13 pp. 3. Davis, J. L.; Ledbetter, W. B.; and Meyer, A. H., Final Report on Concrete Experimental Test Sections in Brazos County, Texas, Research Report No. 141-4F, Texas Transportation Institute, College Station, 1974. 4. A Guide to Highway Grooving, General Electric, Worthington, Ohio. 5. Gallaway, B.M.; Ivey, D. L.; Ross, H. E., Jr.; Ledbetter, W. B.; Woods, D. L.; and Schiller, R. E., Jr., Tentative Pavement and Geometric Design Criteria for Minimizing Hydroplaning, Report No. FHWA-RD-79-3 1, Federal Highway Administration, Washington, D.C., 1979.

6. Standard Specifications for Road and Bridge Construction, Illinois Department of Transportation, Springfield, Oct. 1983, 238 pp. 7. Dierstein, Phil G., A Study of P.C.C. Pavement Texturing Characteristics in Illinois, IDOT Physical Research Report No. 95, Illinois Department of Transportation, Springfield, 1982, 54 pp. 8. Interim Guidelines for Protection and Acceptance of Concrete Pavements Exposed to Rain During Construction, Technical Bulletin No. 17, American Concrete Pavement Association, Arlington Heights, 1974, 11 pp. 9. Methods for the Design, Construction, and Maintenance of Skid Resistant Airport Pavement Surfaces, Advisory Circular No. 150/5320-12, Federal Aviation Administration, Washington, D.C., 1975, 73 pp. 10. Rose, J. G.; Hutchinson, J. W.; and Gallaway, B. M., Summary and Analysis of the Attributes of Methods of Surface Texture Measurement ," Skid Resistance of Highway Pavements, STP-530, ASTM, Philadelphia, 1973, pp. 60-77. 11. Chamberlin, William P., and Amsler, Duane E., Measuring Surface Texture of Concrete Pavements by the Sand-Patch Method, Report No. FHWA-NY-78-RR62, New York State Department of Transportation, Albany, 1978, 18 pp.

6.2 - Related references

12. Skid Resistance, NCHRP Synthesis No. 14, Highway Research Board, Washington, D.C., 1972, 66 pp. 13. Guidelines for Skid Resistant Pavement Design, American Association of State Highway and Transportation Officials, Washington, D.C., 1976, 20 pp. 14. Ryell, J.; Hajek, J. J.; and Musgrove, G. R., Concrete Pavement Surface Textures in Ontario - Development, Testing and Performance, paper presented at Transportation Research Board, Washington, D.C., Jan. 1976. 15. Skidding Accidents-Pavement Characteristics, Transportation Research Record No. 622, Transportation Research Board, 1977, 110 pp. 16. Balmer, G. G., The Significance of Pavement Texture, Report No. FHWA-RD-75-12, Federal Highway Administration, Washington, D.C., 1975, 44 pp. 17. Interim Report for Runway Rubber Removal Specification Development: Field Evaluation Results and Data Analysis, Report No. DOT/FAA/PM-85/32, Federal Aviation Administration, Washington, D.C., July 1984-July 1985, 106 pp. 18. Rubber Removal Specification Development-Final Report, Report No. DOT/FAA/PM-85/33, Federal Aviation Administration, Washington, D.C., May 1983-Sept. 1985, 51 pp. This report was submitted to letter ballot of the committee and was approved in accordance with ACI balloting procedures.

Potrebbero piacerti anche

- Calculus For BeginnersDocumento21 pagineCalculus For BeginnersJay LawsonNessuna valutazione finora

- Structuro W437-Formerly RXDocumento2 pagineStructuro W437-Formerly RXSulaiman Mohsin AbdulAziz0% (1)

- Chapter One: 1.1 GeneralDocumento1 paginaChapter One: 1.1 GeneralSulaiman Mohsin AbdulAzizNessuna valutazione finora

- Water For ConcreteDocumento6 pagineWater For Concreteazim_malpekar303Nessuna valutazione finora

- Design For Torsion and Shear According To ACI-318-99Documento1 paginaDesign For Torsion and Shear According To ACI-318-99Sulaiman Mohsin AbdulAzizNessuna valutazione finora

- Curing ConcreteDocumento10 pagineCuring ConcreteShariq KhanNessuna valutazione finora

- World Atlas JanDocumento0 pagineWorld Atlas JanMasbooksNessuna valutazione finora

- ADAPT-PT Non Prismatic DesignDocumento2 pagineADAPT-PT Non Prismatic DesignMahmoud Hamdy BadawyNessuna valutazione finora

- Design of Monolithic Corbels and Brackets According To Aci 318 - 99Documento1 paginaDesign of Monolithic Corbels and Brackets According To Aci 318 - 99Sulaiman Mohsin AbdulAzizNessuna valutazione finora

- Ferro Cement 11Documento11 pagineFerro Cement 11Cage PrabhuNessuna valutazione finora

- المدخل لعمل المساحة في الطرق - Introduction to roadDocumento29 pagineالمدخل لعمل المساحة في الطرق - Introduction to roadehssan8743% (7)

- Reinforcement WorkDocumento20 pagineReinforcement WorkSulaiman Mohsin AbdulAzizNessuna valutazione finora

- Font MapDocumento5 pagineFont MapFuat ArslanNessuna valutazione finora

- Lincoln Wastewater SystemDocumento4 pagineLincoln Wastewater SystemSulaiman Mohsin AbdulAzizNessuna valutazione finora

- ADAPT-PT Non Prismatic DesignDocumento2 pagineADAPT-PT Non Prismatic DesignMahmoud Hamdy BadawyNessuna valutazione finora

- FOOTING STRESSESDocumento6 pagineFOOTING STRESSESSulaiman Mohsin AbdulAziz100% (1)

- ADAPT-Modeler PT Design ProcessDocumento2 pagineADAPT-Modeler PT Design ProcessAnonymous ELujOV3Nessuna valutazione finora

- L6 FoundationsDocumento10 pagineL6 FoundationsAntonio MontanaNessuna valutazione finora

- Decentralized Wastewater Treatment Highlights BrochureDocumento20 pagineDecentralized Wastewater Treatment Highlights BrochureSulaiman Mohsin AbdulAzizNessuna valutazione finora

- Magoosh GRE Math Formula EbookDocumento33 pagineMagoosh GRE Math Formula EbookLavina D'costa100% (1)

- ETABSDocumento5 pagineETABSSulaiman Mohsin AbdulAzizNessuna valutazione finora

- 39 TransportationDocumento7 pagine39 Transportationmpe1Nessuna valutazione finora

- IntroductionDocumento1 paginaIntroductionSulaiman Mohsin AbdulAzizNessuna valutazione finora

- Adobe Acrobat Reader Help: Opening PDF DocumentsDocumento9 pagineAdobe Acrobat Reader Help: Opening PDF Documentsanon-537450Nessuna valutazione finora

- Test Taker GRE Verbal Reasoning SamplesDocumento11 pagineTest Taker GRE Verbal Reasoning SamplesShreyas GoṏnayNessuna valutazione finora

- Shear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsDocumento2 pagineShear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsSulaiman Mohsin AbdulAziz100% (1)

- About A-PDF WatermarkDocumento1 paginaAbout A-PDF WatermarkSulaiman Mohsin AbdulAzizNessuna valutazione finora

- Reinforcement Steel SpecificationsDocumento1 paginaReinforcement Steel SpecificationsSulaiman Mohsin AbdulAzizNessuna valutazione finora

- All Sheets ConcreteDocumento72 pagineAll Sheets ConcreteSulaiman Mohsin AbdulAziz100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Screenshot 2023-01-03 at 9.25.34 AM PDFDocumento109 pagineScreenshot 2023-01-03 at 9.25.34 AM PDFAzri ZakwanNessuna valutazione finora

- Municipal Incinerated Solid Waste Bottom Ash As Sustainable Construction Material in The Construction of Flexible PavementsDocumento10 pagineMunicipal Incinerated Solid Waste Bottom Ash As Sustainable Construction Material in The Construction of Flexible PavementsAakash GuptaNessuna valutazione finora

- Determination of The Flakiness and The Elongation Index For The Given Aggregate Sample.Documento4 pagineDetermination of The Flakiness and The Elongation Index For The Given Aggregate Sample.Shaheer AhmadNessuna valutazione finora

- Concrete Streets Guide SpecsDocumento24 pagineConcrete Streets Guide SpecswickremasingheNessuna valutazione finora

- Agra Lko Expressway Feasibility ReportDocumento199 pagineAgra Lko Expressway Feasibility ReportAnuj SachdevNessuna valutazione finora

- 6.5 Marshal Stability Test-LecturepdfDocumento36 pagine6.5 Marshal Stability Test-LecturepdfRajesh KhadkaNessuna valutazione finora

- Design and Construction Aspects of PavementDocumento27 pagineDesign and Construction Aspects of PavementMaria Divina Romero TabuaNessuna valutazione finora

- Home Construction Cost Code ListDocumento37 pagineHome Construction Cost Code ListPedro GonzalezNessuna valutazione finora

- Principles of Transportation EngineeringDocumento99 paginePrinciples of Transportation EngineeringJed mariñasNessuna valutazione finora

- D4123Documento4 pagineD4123FranklinNessuna valutazione finora

- Safety Edge: Reducing Run-Off AccidentsDocumento3 pagineSafety Edge: Reducing Run-Off AccidentsGadisa AbrahimNessuna valutazione finora

- What Is The Purpose of Reinforcement in Concrete RoadsDocumento1 paginaWhat Is The Purpose of Reinforcement in Concrete RoadsJaime Manalili LandinginNessuna valutazione finora

- White Topping Concrete RoadsDocumento20 pagineWhite Topping Concrete RoadsSohan MeharwadeNessuna valutazione finora

- Projet: Bill of QuantityDocumento4 pagineProjet: Bill of QuantityMahnooranjumNessuna valutazione finora

- Pavement Structure PDFDocumento6 paginePavement Structure PDFSayantan ChakrabortyNessuna valutazione finora

- Repairs of Asphalt RoadsDocumento16 pagineRepairs of Asphalt RoadsPradeepLokhandeNessuna valutazione finora

- Steel Orthotropic Decks: Developments in The 1990sDocumento8 pagineSteel Orthotropic Decks: Developments in The 1990sMARIONessuna valutazione finora

- Designing Asphalt Mix for Road UpgradeDocumento25 pagineDesigning Asphalt Mix for Road UpgradeAmiry Halifa HidaNessuna valutazione finora

- Irc 37 2001Documento1 paginaIrc 37 2001Gampa Vamshi KrishnaNessuna valutazione finora

- Concrete Pavement Design Method for Fiber-Reinforced ConcreteDocumento10 pagineConcrete Pavement Design Method for Fiber-Reinforced ConcreteBakhtiyar Q.KhawajaNessuna valutazione finora

- Scholar List CivilDocumento40 pagineScholar List CivilVignesh Kumar NagarajanNessuna valutazione finora

- Lot 1 BoQDocumento8 pagineLot 1 BoQelbaraniNessuna valutazione finora

- Stabilization of Clay Soil Using Seashells and Coconut HusksDocumento5 pagineStabilization of Clay Soil Using Seashells and Coconut Husksdela rosaNessuna valutazione finora

- Bituminous Mix DesignDocumento62 pagineBituminous Mix DesignShaim RehanNessuna valutazione finora

- HMA Overlay ProceduresDocumento210 pagineHMA Overlay ProceduresAnonymous 4iwNEpaGM1Nessuna valutazione finora

- Optimize for 8-19-08 LEAN CONCRETE BASE documentDocumento5 pagineOptimize for 8-19-08 LEAN CONCRETE BASE documentSarjerao PatilNessuna valutazione finora

- Seminar Report On Highway Management SystemDocumento22 pagineSeminar Report On Highway Management SystemAditya ansuman RoutNessuna valutazione finora

- Colpor 200 : Cold Applied, High Performance, Hydrocarbon Resistant, Polyurethane Pavement Joint SealantDocumento4 pagineColpor 200 : Cold Applied, High Performance, Hydrocarbon Resistant, Polyurethane Pavement Joint SealantjoshepNessuna valutazione finora

- Comparison UR ACDocumento19 pagineComparison UR ACTewodros TadesseNessuna valutazione finora

- Reinstatement of Trenches Along Local Asphalt Roads A101.01Documento2 pagineReinstatement of Trenches Along Local Asphalt Roads A101.01Nicholas VineyNessuna valutazione finora