Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SV Shop Ring Roller

Caricato da

kuzaryDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SV Shop Ring Roller

Caricato da

kuzaryCopyright:

Formati disponibili

MAKING A SMALL RING ROLLER Winter, 2009

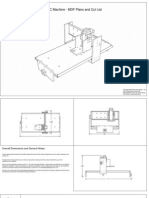

Tools: Metal saw: Chop saw, cutting wheel on a grinder, jig saw with a metal cutting blade, sawzall with a metal cutting blade, or a band saw. Drill press Welder (Optional) Lathe Materials: (cut offs from previous projects use what you have and modify the design to suit) 1/8 plate steel (the body) (3) pieces of rod; 2 3 long, to 1 for the rollers. (2) pieces of rod for handles 3/8 1/2 diameter bolt and (3) nuts to fit; (2) washers (Clevis pins, cotter pins, or wire if you do not have a lathe)

I needed a ring roller that would handle 1 to 1.25 wide bar, up to 1/8 thick. A second design criterion was using the materials I had around the shop. A third was to avoid bearings since I do not have an arbor press. There are lots of plans for big ring rollers that use bottle jacks and can bend tube but very few for something lighter weight. After looking at pictures on the Internet I designed this roller. Although I used a lathe and a mill to improve my machining skills the basic design does not need them. I used a jigsaw with a metal blade. The drill press is essential a hand held power drill will not do the job. There are two fixed rollers at the bottom and a movable roller in the middle. A 3/8 diameter machine screw is used to adjust the height of the movable roller and control the amount of bending. The horizontal rod at the top is used to turn the screw and adjust the movable roller. The horizontal rod at the bottom is used to turn the middle roller which pulls the material through the rollers. The middle roller is held by a three sided cage (not seen in the photo) attached to the machine screw with nuts. As the screw is turned it moves this roller up and down in the slot that is in both sides. The roller is screwed to a scrap piece of 2 x 4 that can be clamped to a table.

Here are some results. At the top is some 5/16 rod with a slight curve. This rod is too stiff to work well in this ring roller. Underneath it is 1 wide by 1/8 thick bar in an 7 1/2 circle.

Note the flat part at the end of the circle. This is an inherent problem with ring rollers and you have to build in to your cutting calculations about 2 of flat bar.

PARTS These are all of the parts except for the rollers and the two rods. They are all cut from 1/8 plate steel except for two small pieces made from plate 1/8 probably would have been sufficient. At the top are the three parts that form a cage holding the movable roller. Next is a ruler to show rough measurements. At the bottom from left to right is the left side, bottom, right side, and top. All the roller holes are . The bolt holes are 3/8.

Cage parts

6 rule

L side Bottom R side Top

I made the slots by drilling the holes and then using a jigsaw. If you do not have a jigsaw you could drill a hole at the top and at the bottom of the slot, and use a hack saw or an abrasive cutter to cut the rest of the slot. If you only had a chop saw you could just drill the bottom hole, and then cut the sides all the way to the top. The only critical dimensions are the relationships of the three rollers. The slot holding the middle roller has to extend below the two fixed rollers and be long enough so that the movable roller can be raised above the top of the fixed rollers. Top position with material inserted Bottom position with material bent

This photo shows how the pieces fit together. The fixed rollers are long enough to fit through both sides; i.e. the width of the bottom piece plus or so. The movable roller in the middle has to be even longer so the rod that turns it will not hit against the movable rollers. You can see the cage holding the movable roller with the plate at the top and the two 1/8 plates holding the roller. These rollers are 1 steel and I used the lathe to turn the ends down to . My original design did not require a lathe and used clevis or cotter pins to hold them in place. NOTE: The assembly sequence is important and the following pictures are used to show how the pieces fit together. Do not weld anything at this point!

L side Cage Roller in slot

Bottom

R side

Here is a picture looking down at the top of the cage. Bottom Fixed roller Movable roller in cage Hole for adjusting screw Left plate

This is a picture from the side showing the machine screw attached to the cage.

The middle roller is at the bottom position of the slot.

ASSEMBLY The following sequence shows the assembly. It begins with the adjuster. This is a machine screw that moves the center roller up and down in the slot. The parts from left to right are a small tank valve wheel I found that just fit the 3/8 machine bolt. This was a mistake since it did not provide enough leverage to bend the steel and it was eventually discarded. Next is a 3/8 nut welded to the top piece. Next is another 3/8 nut, a washer, the top of the cage, and a final 3/8 nut. These bottom two nuts are slightly loose since they have to allow the bolt to turn within the cage assembly. First weld one side of the cage to the top of the cage. Next weld one nut to the top piece, Assemble as shown and then do a small weld of the screw to the bottom most nut. Do not weld this nut or the machine screw to the cage.

Tank wheel

Bolt

Nut Top

Nut Washer

Top of cage Side of cage Nut

Insert the middle roller, fit the other side of the cage, and weld it to the cage top. Here is the finished cage assembly upside down. Note that there is hole drilled through middle roller for the rod handle.

Here is another picture right side up. Note the groove in the middle roller. This was cut on the lathe so round rod would not wobble all over in the bender.

Now assemble the rest of the roller. Weld one side to the bottom, insert the two fixed rollers and the cage, and then weld the other side. Finally weld the top. This photo was taken before welding the cage so the parts are loose but it shows how everything fits.

To finish the top I welded a piece of rod to the machine screw and drilled a hole in it for the turning lever rod. This turning lever is loose because you may need to remove it when bending a tight circle. Sharp eyes may also note that the final roller sticks up . The roller side looks like the drawing below.

The reason for this change is my design did not take into consideration the thickness of the nuts. When the movable roller is screwed up to the topmost position there has to be enough room for whatever is being bent to fit between the fixed rollers and the movable rollers

While the slot was long enough the nut prevented the movable roller from going to the full height. This was discovered after everything was welded. The solution was to cut off the top, and extend the height by adding to each side, and then weld the top back.

How it works Raise the movable roller to the top. Insert the material to be bent so it touches both fixed rollers. Screw down the movable roller until it meets the material, and then give it another turn to slightly bend the material. Then roll the material through, screw it down another turn, and roll it back. Repeat until you have the curve or circle that is desired. I had never used a ring roller so I did not know what to expect. Bending the material can take some force the 5/16 rod was very difficult however the 1/8 flat was fairly easy. I also did not know how much force would be needed for the rod that turns the middle lever. It turned out that a single thick rod about a foot long worked well. Sometimes the material will not roll and has to be pushed as the roller turns. Sometimes it goes at an angle and has to be straightened out. This is not a precision instrument. In short the roller is far superior to bending material around a pipe or a trash can lid (my previous methods). It makes nice curves and circles and is suitable for one-offs. It would not be a good tool for making quantities of circles.

Design improvements Apart from the issue with the nuts there are two improvements. First, I would knurl the rollers so they would grip better. Next, I suspect case hardening the rollers will be an improvement time and use will tell. Finally, the basic design does not work for small rings. Any circle less than 6 or so will run into the machine screw. You can make a small curve but cannot make a complete circle. Another approach is to have the rollers stick out beyond the frame, and bend the material outside the frame rather than inside it. This means the forces will be unbalanced, pushing down on one side of the frame and pushing up on the other. However it will allow small rings to be made and easily allow material to be taken off the roller.

Potrebbero piacerti anche

- How To Build A Tube Bender WWDocumento9 pagineHow To Build A Tube Bender WWmikefcebuNessuna valutazione finora

- Worm Harvester 212011Documento0 pagineWorm Harvester 212011mattpac3Nessuna valutazione finora

- DIY 2x72 Belt Grinder for Under $500Documento15 pagineDIY 2x72 Belt Grinder for Under $500Erwan AchmadyaniNessuna valutazione finora

- Horizontal motion mechanismDocumento4 pagineHorizontal motion mechanismSlamet MatematikaNessuna valutazione finora

- Foldable Stool Reverse Engineering The Tallon StooDocumento37 pagineFoldable Stool Reverse Engineering The Tallon StooEnrique CoronelNessuna valutazione finora

- Threading Operations of Lathe SystemDocumento37 pagineThreading Operations of Lathe SystemResshille Ann T. SalleyNessuna valutazione finora

- Machinists Screw JackDocumento3 pagineMachinists Screw Jackmauri_ros100% (1)

- Knurling ToolDocumento5 pagineKnurling Tool4U6ogj8b9snylkslkn3nNessuna valutazione finora

- How To Build A Neck Jig Matt VinsonDocumento23 pagineHow To Build A Neck Jig Matt Vinsoncaesparza100% (1)

- Vintage Playground Plans 1950s PDFDocumento39 pagineVintage Playground Plans 1950s PDFAlexandre Mello100% (1)

- 1911 Frame TutorialDocumento22 pagine1911 Frame Tutorialblackta6100% (5)

- Screw Less ViseDocumento4 pagineScrew Less ViseAmi JohnstonNessuna valutazione finora

- Twin Engine 15' Hovercraft BuildDocumento74 pagineTwin Engine 15' Hovercraft BuildLeonel Rodriguez100% (2)

- Web QCGBDocumento19 pagineWeb QCGBpramponiNessuna valutazione finora

- Facing Operations LatheDocumento7 pagineFacing Operations LatheJennifer Nicky ShakerNessuna valutazione finora

- Uputstvo Za Izradu Vetro Generatora Deo 1Documento18 pagineUputstvo Za Izradu Vetro Generatora Deo 1SinišaNessuna valutazione finora

- Cove Cutting Jigs For The BT3000 by Jim FryeDocumento8 pagineCove Cutting Jigs For The BT3000 by Jim FryeozilogNessuna valutazione finora

- Table Saw Drum Mill: InstructablesDocumento11 pagineTable Saw Drum Mill: InstructablesJazzy VaaltynNessuna valutazione finora

- Stirling Walking Beam EngineDocumento13 pagineStirling Walking Beam EngineTomescu PaulNessuna valutazione finora

- Facing Operations: Using A 4-Jaw ChuckDocumento8 pagineFacing Operations: Using A 4-Jaw ChuckMajida AdilNessuna valutazione finora

- Build Portable Jewelers BenchDocumento26 pagineBuild Portable Jewelers BenchDianaNessuna valutazione finora

- Constructia Unui Ceas Din LemnDocumento6 pagineConstructia Unui Ceas Din LemnGaspar PetruNessuna valutazione finora

- Eolian Gen Diy PDFDocumento0 pagineEolian Gen Diy PDFprozorianuNessuna valutazione finora

- DIY Book ScannerDocumento101 pagineDIY Book Scannerjahanavi pethani100% (1)

- EZClone Recumbent Bicycle PlansDocumento11 pagineEZClone Recumbent Bicycle PlansRob Getman100% (3)

- Building A Six-Inch Turret LatheDocumento5 pagineBuilding A Six-Inch Turret LatheJan SteinmanNessuna valutazione finora

- Ez Engine Build InstructionsDocumento24 pagineEz Engine Build InstructionsAnonymous T7zEN6iLHNessuna valutazione finora

- Router LiftDocumento27 pagineRouter Liftmrivero1983100% (2)

- Swing Garden SwingDocumento7 pagineSwing Garden SwingAlicia MariaNessuna valutazione finora

- Construir Moto ChopperDocumento7 pagineConstruir Moto ChopperAngel Dure100% (2)

- What Are The Types of RollsDocumento78 pagineWhat Are The Types of RollsrcmajhiNessuna valutazione finora

- Facing OperationsDocumento8 pagineFacing OperationsRaihan KabirNessuna valutazione finora

- Product Instructions - Flat Bending Jig InstructionsDocumento34 pagineProduct Instructions - Flat Bending Jig InstructionsDale WadeNessuna valutazione finora

- 71 - Cam-Lever Quick ReleaseDocumento2 pagine71 - Cam-Lever Quick ReleaseGsmHelpNessuna valutazione finora

- Plantas CNC de Madeira Kit 1-1 PDFDocumento15 paginePlantas CNC de Madeira Kit 1-1 PDFalexandrearume5392Nessuna valutazione finora

- Beds - Four Poster Bed PlansDocumento8 pagineBeds - Four Poster Bed Planspoimandres100% (1)

- Junior Backhoe: Half-Pint Sidewalk Superintendents Will Go Ape For This Boy-Size, Rugged, Easy-To-Build DiggerDocumento5 pagineJunior Backhoe: Half-Pint Sidewalk Superintendents Will Go Ape For This Boy-Size, Rugged, Easy-To-Build Diggermagatsu2099Nessuna valutazione finora

- Home made wooden tripods: Build your own lightweight tripod for under $20Documento7 pagineHome made wooden tripods: Build your own lightweight tripod for under $20korki777Nessuna valutazione finora

- Shopnotes 88 Dovetailed Shoulder PlaneDocumento8 pagineShopnotes 88 Dovetailed Shoulder PlaneJulio Cesar OliveiraNessuna valutazione finora

- Wookies Words - Finnish Suomi M31 BuildDocumento25 pagineWookies Words - Finnish Suomi M31 BuildWilmer Howard BenderNessuna valutazione finora

- Make Simple Wood Toggle Clamps for Shop JigsDocumento7 pagineMake Simple Wood Toggle Clamps for Shop JigsGermanHund100% (2)

- Modern Bamboo SplitterDocumento14 pagineModern Bamboo SplitterSenthil Kumar100% (1)

- Indexable Turning Tools ProjectsDocumento21 pagineIndexable Turning Tools ProjectsEmijo.ANessuna valutazione finora

- Easy To Build Stirling Engine FanDocumento14 pagineEasy To Build Stirling Engine Fanpatel_kalpesh1241100% (1)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsDa EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsValutazione: 5 su 5 stelle5/5 (1)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideDa EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNessuna valutazione finora

- How to Make Picture Frames (Best of AW): 12 Simple to Stylish Projects from the Experts at American Woodworker (American Woodworker)Da EverandHow to Make Picture Frames (Best of AW): 12 Simple to Stylish Projects from the Experts at American Woodworker (American Woodworker)Valutazione: 5 su 5 stelle5/5 (1)

- Poor Man Hydrogen Generator on Demand: Smcs Hho Stephens Multi Cell Systems Hydrogen Generator on DemandDa EverandPoor Man Hydrogen Generator on Demand: Smcs Hho Stephens Multi Cell Systems Hydrogen Generator on DemandValutazione: 5 su 5 stelle5/5 (2)

- Traditional Ironwork DesignsDocumento96 pagineTraditional Ironwork DesignsguatavitaNessuna valutazione finora

- Switch On To The Best: Cam Operated Rotary SwitchesDocumento32 pagineSwitch On To The Best: Cam Operated Rotary Switchesbagastc100% (1)

- How To Make Origami Airplanes That Fly PDFDocumento91 pagineHow To Make Origami Airplanes That Fly PDFRoxana IonNessuna valutazione finora

- 116 Wing Tsun Wooden Dummy TechniquesDocumento119 pagine116 Wing Tsun Wooden Dummy Techniquesdewdzz100% (54)

- Playera Talla L PDFDocumento10 paginePlayera Talla L PDFkuzaryNessuna valutazione finora

- Higher Algebra - Hall & KnightDocumento593 pagineHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- 17 - Gears and Gear CuttingDocumento69 pagine17 - Gears and Gear CuttingPardeep Singh100% (1)

- Use The Taig 1210 Radius Turner To Create Radii On Round WorkpiecesDocumento11 pagineUse The Taig 1210 Radius Turner To Create Radii On Round WorkpieceskuzaryNessuna valutazione finora

- Wb314 Sofa BedDocumento4 pagineWb314 Sofa BedReneCarrillo100% (1)

- Wall KnotDocumento3 pagineWall KnotkuzaryNessuna valutazione finora

- Material Release: Tnspectton (RRN)Documento44 pagineMaterial Release: Tnspectton (RRN)ANIL PLAMOOTTILNessuna valutazione finora

- BS 2782-8-Method 820A-1996 (1998) Methods of Testing Plastics. Other Properties. Determination of Water Vapour Transmission Rate (Dish Method) .Documento17 pagineBS 2782-8-Method 820A-1996 (1998) Methods of Testing Plastics. Other Properties. Determination of Water Vapour Transmission Rate (Dish Method) .ironfaceNessuna valutazione finora

- Drilling Machine: Fierda Lestari Sarpangga Putri NRP 0516040128 D4 Teknik K3 Ppns (Lintas Jenjang)Documento7 pagineDrilling Machine: Fierda Lestari Sarpangga Putri NRP 0516040128 D4 Teknik K3 Ppns (Lintas Jenjang)Fierda SarpanggaNessuna valutazione finora

- 3M - GPT020 & GPT020FDocumento4 pagine3M - GPT020 & GPT020FOlivier DuclosNessuna valutazione finora

- Liberating valuables from tailings with ball mill designDocumento5 pagineLiberating valuables from tailings with ball mill designEngineering Office ShahrakNessuna valutazione finora

- Rapid Casting Solutions - A ReviewDocumento24 pagineRapid Casting Solutions - A ReviewAlex BurdeNessuna valutazione finora

- 6.4 Procedure For InsulationDocumento11 pagine6.4 Procedure For Insulationrendra syamNessuna valutazione finora

- Welding HandoutDocumento5 pagineWelding HandoutcatrinaguinsoduganionNessuna valutazione finora

- Firepower TIG 200 AC/DC: Operating ManualDocumento80 pagineFirepower TIG 200 AC/DC: Operating ManualAlejandro CKNessuna valutazione finora

- NFPA 24 Ch10 PDFDocumento8 pagineNFPA 24 Ch10 PDFMazhar Hayat HattarNessuna valutazione finora

- Grade 8 Week 1 CARPENTRY Q2Documento7 pagineGrade 8 Week 1 CARPENTRY Q2Israel Marquez50% (2)

- Cetinkaya Pano A.S.: Catalogue Trade CatalogueDocumento6 pagineCetinkaya Pano A.S.: Catalogue Trade Catalogueanmn123Nessuna valutazione finora

- Design and Manufacturing of Low-Cost Wood Lathe MachineDocumento41 pagineDesign and Manufacturing of Low-Cost Wood Lathe MachineBelay Shibru100% (1)

- Lijevani Viktorijanski NamještajDocumento22 pagineLijevani Viktorijanski NamještajJoško BogdanovićNessuna valutazione finora

- Assignment 6Documento5 pagineAssignment 6Anonymous G6QkwTykKNessuna valutazione finora

- SP-50-15H Rev 2Documento18 pagineSP-50-15H Rev 2JacquesBritsNessuna valutazione finora

- CONLIT DUCTROCK BrochureDocumento16 pagineCONLIT DUCTROCK BrochureFlorinBobeNessuna valutazione finora

- Surface Vehicle Recommended Practice: Reaf. FEB1998Documento7 pagineSurface Vehicle Recommended Practice: Reaf. FEB1998Ricardo luzars.Nessuna valutazione finora

- Bar ChartDocumento15 pagineBar Chartdharmendrasaini70Nessuna valutazione finora

- Nalco at A Glance: Chapter - 2Documento74 pagineNalco at A Glance: Chapter - 2Aditya AnandNessuna valutazione finora

- Sandvik Wx7000 Tensioned Screening MediaDocumento6 pagineSandvik Wx7000 Tensioned Screening MediaLachezar VelkovNessuna valutazione finora

- BULLDOG Industrial CatalogueDocumento12 pagineBULLDOG Industrial CatalogueHYDRO-LECNessuna valutazione finora

- Delta Rigging Brochure PDFDocumento398 pagineDelta Rigging Brochure PDFrekstromNessuna valutazione finora

- Welding 3&4 REV21Documento40 pagineWelding 3&4 REV21Muhd Shabeeb ANessuna valutazione finora

- Jigs and Fixtures-SBPDocumento136 pagineJigs and Fixtures-SBPVinay PanditNessuna valutazione finora

- PrintingDocumento1.148 paginePrintingSwati SinghNessuna valutazione finora

- #J800 Slitting Handbook July 2016Documento13 pagine#J800 Slitting Handbook July 2016Ahmed SalahNessuna valutazione finora

- 2.9.1. Disintegration of Tablets and CapsulesDocumento3 pagine2.9.1. Disintegration of Tablets and CapsulesPikiy PutriNessuna valutazione finora

- BhandupDocumento69 pagineBhandupMrudulaNessuna valutazione finora

- MSS-SP-94 (1999)Documento12 pagineMSS-SP-94 (1999)Islam SolimanNessuna valutazione finora