Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mobile Crane - Lzift Plan-Sample (1) (3

Caricato da

Bharathi SaravananTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mobile Crane - Lzift Plan-Sample (1) (3

Caricato da

Bharathi SaravananCopyright:

Formati disponibili

GE Global Research JFWTC, Bangalore

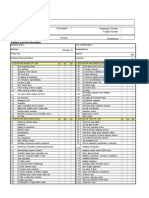

Mobile Crane Hoist Operations - Lift Plan

Date: 27/0108/2014 Prepared By: Ratheesh Competent Supervisor/Manager Approval:Sandeep GEGR Site Safety Engineer Approval:Kevin

EMERGENCY PHONE #GEGR Site Phone 72222 / 75555

Contact Number 9886061541 Contact Number 9741111387 Contact Number 9740192112 Cell Phone 9845382222 / 9980875555 GEGR Site Radio BASE Crane type& Location : Pick and Carry / XX T

Project Work Area Evaluation

Yes No N/A

Task/Job Evaluation

Yes No N/A

Does the crane have sufficient SWL capacity and travel capabilities for the intended lift? Have you walked the project work area? Have Evacuation Routes and emergencyresponse equipment been identified? Emergency Shut off switch Fire Extinguisher&Call Point Nearest Phone First Aid Box Is the work location in a high traffic or common area? If yes, delineate your work area with Danger or caution rope, signs, cones or boundary tape. Have employees of the area been notified of the lifting operation? Has an adequate laydown/staging area been identified/designated?

Has three part communication been established? Has the Lifting team been identified? Are the rigging equipment in acceptable condition? all rigging equipment have proper ID marks all riggingequipment have known WLL/SWL all rigging equipment been inspected Are the rigging equipment being used as per design/manufacturer specs?

Has the item to be lifted been evaluated for sharp edges or other circumstances that may cause rigging equipment to be damaged or slip? Are the attachment points on the object to be lifted designed for lifting? Will there be any side or angular loading?

Mandatory Personal Protective Equipment

Safety Helmet /Hard HatSafety Glasses w/Side Shields Safety Shoes Long Pants

Additional PPE based on Task (check all that apply)

Hearing Protection Dust Mask Tyvek Coveralls Hi-Visibility VestWork GlovesPersonal Fall Arrest System (PFAS) Other __None________________________________

General Rigging and Lifting Reminders

Once rigging equipment has been installed, lift object slowly to ensure level lift, adjust as needed Use tag lines and keep a 45 SAFETY ZONE under the suspended load. (Safety Zone = Height of the bottom of load off ground) Avoid using hands to maneuver load until load is in final placement position. Hands and Feet shall NEVER pass below suspended load If using more than two slings, determine required capacity by assuming only two slings are handling the load and the additional slings are providing stability

Potential Hazard Checklist

Yes No Yes No Yes No Yes No Yes No

Pinch Points High Noise

Falling Objects Defective Tools

Slips and Trips Bump Hazards

Cold Stress Heat Stress

Manual Lifting

Estimated Rated Capacity based on Single-Leg Hitch for Wire Rope and Synthetic Web Slings Vertical Choker (120) 90 Vertical Basket

Estimated Rated Capacity based on Two-Leg or Single Basket Hitch for Wire Rope and Synthetic Web Slings

Vertical (90) 100% each leg, or 200% for basket 60 45 30 Endless Loop

100%

80%

200%

85%

70%

50%

100%

Rigging Best Practices

Rigging Sketch

Reeving through connections to load increases load on connection fittings by 2x DO NOT REEVE

Pick & Carry Crane /Mobile

SWL -2 TON at 67

Width-1800 DO NOT SIDE, BACK, OR TIP LOAD HOOKS Loads shall be applied in the plane of the eye Shouldered lift eyes are preferred Consult manufacturer for angular capacity reductions Shackle pins should fit freely without bindig Avoid side loading Do not bunch slings

40

67

Self Weight0. 8TON Height- 2000

Crane ID & Capacity Weight of Object/Load # of Shackles & WLL # of Slings & WLL # of Eyebolts/Swivel-Eyes & WLL Estimated loop angle Boom angle

Hydra crane 10 T@75 0.8T 2T 2 nos. & 6 T Nil 40 (Included) 67

Sling Tension

Pre-Lift Acknowledgement

Lift Operator/Lift team Member Lift Operator/Lift team Member Lift Operator/Lift team Member Lift Operator/Lift team Member

GE internal for internal distribution only

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Forklift Driver Card and Certificate TemplateDocumento25 pagineForklift Driver Card and Certificate Templatempac99964% (14)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Caterpillar 966HDocumento28 pagineCaterpillar 966HMarcelo Cardozo80% (5)

- Jsa For CPL MonorailDocumento9 pagineJsa For CPL Monorailsanath adhikary0% (1)

- Instruction Manual: Operation / Safety / MaintenanceDocumento28 pagineInstruction Manual: Operation / Safety / MaintenanceSam DamianoNessuna valutazione finora

- 7HBW23 CL340-05Documento159 pagine7HBW23 CL340-05Arl MontacargasNessuna valutazione finora

- ICE251Documento95 pagineICE251Jan Antonius DjunaediNessuna valutazione finora

- Nebosh Igc2 Elmt 1 4Documento31 pagineNebosh Igc2 Elmt 1 4Ndi MvogoNessuna valutazione finora

- ARL-500 UCM Test Instructions For Gearless Machines - enDocumento2 pagineARL-500 UCM Test Instructions For Gearless Machines - enHenri KleineNessuna valutazione finora

- 02 MUSE ACD3 T&C WiringDocumento15 pagine02 MUSE ACD3 T&C WiringMoises PerelloNessuna valutazione finora

- KDL16 Drive - Quick Setup GuideDocumento6 pagineKDL16 Drive - Quick Setup GuideMarta Silva VenturaNessuna valutazione finora

- 9961 Spider SC1000 Operator Manual V1-EnglishDocumento34 pagine9961 Spider SC1000 Operator Manual V1-EnglishdavidrockNessuna valutazione finora

- Manual de Partes - Telehandler TH255CDocumento344 pagineManual de Partes - Telehandler TH255CJonathan Campos SanchezNessuna valutazione finora

- ElevatorDocumento65 pagineElevatorKanaga VaratharajanNessuna valutazione finora

- List of Criteria For HK GradationDocumento1 paginaList of Criteria For HK GradationBharathi SaravananNessuna valutazione finora

- M.K Bismillah: New Lucky Family RestaurantDocumento2 pagineM.K Bismillah: New Lucky Family RestaurantBharathi SaravananNessuna valutazione finora

- Team Management: Part 1 - AttitudeDocumento31 pagineTeam Management: Part 1 - AttitudeBharathi SaravananNessuna valutazione finora

- View - Transfer: Docid Created Date Time Doc Date Doc Num Effective Date Updated Date Time Proximity Card NoDocumento2 pagineView - Transfer: Docid Created Date Time Doc Date Doc Num Effective Date Updated Date Time Proximity Card NoBharathi SaravananNessuna valutazione finora

- Conveyance FormatDocumento4 pagineConveyance FormatBharathi SaravananNessuna valutazione finora

- TNPSC Group 2 Study Material Books Free Download pdf-05 PDFDocumento6 pagineTNPSC Group 2 Study Material Books Free Download pdf-05 PDFBharathi SaravananNessuna valutazione finora

- Experience LetterDocumento1 paginaExperience LetterBharathi SaravananNessuna valutazione finora

- Technician Interview QuestionsaDocumento1 paginaTechnician Interview QuestionsaBharathi SaravananNessuna valutazione finora

- Tobacco Control Act 2003Documento11 pagineTobacco Control Act 2003Bharathi SaravananNessuna valutazione finora

- Assumptions For New Business SssplanDocumento3 pagineAssumptions For New Business SssplanBharathi SaravananNessuna valutazione finora

- C10129004 PDFDocumento20 pagineC10129004 PDFChristopherNessuna valutazione finora

- Differently Abled PersonsDocumento56 pagineDifferently Abled Personssagorika7basuNessuna valutazione finora

- Object-Oriented and Classical Software Engineering: Stephen R. SchachDocumento160 pagineObject-Oriented and Classical Software Engineering: Stephen R. Schachgoflux pwnsNessuna valutazione finora

- TCVN 2622-1995 Fire Prevention Standards (En)Documento49 pagineTCVN 2622-1995 Fire Prevention Standards (En)Huan Dinh QuangNessuna valutazione finora

- R2102011CHECKLIST For ElevdumbwaiterDocumento2 pagineR2102011CHECKLIST For ElevdumbwaiterAlim Ur RahmanNessuna valutazione finora

- Pro-Series LP: Semi-Automatic Platform Stretch Wrapper Installation, Operation & Service ManualDocumento112 paginePro-Series LP: Semi-Automatic Platform Stretch Wrapper Installation, Operation & Service ManualTerry XuNessuna valutazione finora

- Critical Lift PlanDocumento1 paginaCritical Lift PlanRajanNessuna valutazione finora

- Karthik Profile (Updated)Documento7 pagineKarthik Profile (Updated)Karthikeyan MallikaNessuna valutazione finora

- SYNOPSIS Hydraulic PressDocumento10 pagineSYNOPSIS Hydraulic PressDIVYANSHI PHOTO STATENessuna valutazione finora

- Creating Astral TempleDocumento4 pagineCreating Astral TempleChris MoseleyNessuna valutazione finora

- The Kar - Lifts, Escalators and Passenger Conveyors Rules, 2015Documento45 pagineThe Kar - Lifts, Escalators and Passenger Conveyors Rules, 2015FfttNessuna valutazione finora

- 民用航空器维修人员执照英语参考试题(核对版)Documento505 pagine民用航空器维修人员执照英语参考试题(核对版)大雄弗里曼Nessuna valutazione finora

- SAM Feed Wagons - From 2002 v3Documento15 pagineSAM Feed Wagons - From 2002 v3Martin van de HaarNessuna valutazione finora

- Catalog Training Panel System 2014-7 61 - 76 PDFDocumento15 pagineCatalog Training Panel System 2014-7 61 - 76 PDFRijal MtmNessuna valutazione finora

- Cat Forklift Ec30k Schematic Service Operation Maintenance ManualDocumento27 pagineCat Forklift Ec30k Schematic Service Operation Maintenance Manualsamanthamoyer170885csp100% (77)

- The Complete Range of Pillar and Wall Jib Cranes For Loads Up To 6.3 TonnesDocumento13 pagineThe Complete Range of Pillar and Wall Jib Cranes For Loads Up To 6.3 Tonnesabhibho12345Nessuna valutazione finora

- Ath DSH3000-2 - 2014-02-GB PDFDocumento63 pagineAth DSH3000-2 - 2014-02-GB PDFBudai Hunor-AttilaNessuna valutazione finora