Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

API2000

Caricato da

Sudhanshu ShekharDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

API2000

Caricato da

Sudhanshu ShekharCopyright:

Formati disponibili

1

Venting Atmospheric and

Low-Pressure Storage Tanks

Nonrefrigerated Aboveground Tank

BY T. Supunchalee

2

Low pressure storage Tank Pressure is designed

for 15 psig (1.034 barg)

15 psig (1bar) ATM

Pressure vessel ASME code

API 620

API 650

2 (H

2

O)

API 2000

Venting system

(devices)

3

Low-Pressure Storage Tanks

Normal Venting

Emergency Venting

(fire case)

To prevent

Overpressure

vacuum

(Mostly tank is cone roof type)

Venting system

4

Cause of Overpressure & Vacuum

a. Liquid movement

Into tank

Out of tank

Liquid in

Outbreathing Inbreathing

(flashing or feed liquid

above boiling point

are also considered)

Liquid out

5

Cause of Overpressure & Vacuum

b. Thermal breathing : weather change

Outbreathing Inbreathing

Decrease in

atmospheric temp.

: Condensation of

vapor in tank

Increase in

atmospheric temp.

: Vaporization of

liquid in tank

6

Cause of Overpressure & Vacuum

c. Fire exposure : Emergency case

Strong Expansion

of vapor and

vaporization!!

Heat source

Outbreathing

7

Cause of Overpressure & Vacuum

External or internal heat transfer device

Utility Failure

Equipment failed

Operating error

Chemical reaction

Uninsulated Tanks

Etc.

d. Other circumstances

8

Venting Requirement

Requirement for normal venting capacity

Requirement for emergency venting capacity

Liquid movement

Thermal effect

Fire exposure

9

Venting Requirement

For normal venting capacity : (Liquid movement)

Flash Point 100

o

F

Boiling point 300

o

F

Flash Point < 100

o

F

Boiling point < 300

o

F

SCFH of Air per Barrel per Hour of Liquid Flow

Inbreathing outbreathing

5.6

5.6

5.6

5.6

6

6

12

12

(Table 1A : API2000)

10

Venting Requirement

For normal venting capacity : (thermal effect)

Flash Point 100

o

F

Boiling point 300

o

F

Flash Point <100

o

F

Boiling point <300

o

F

SCFH of Air

Inbreathing outbreathing

Tank capacity

(Gallons)

2,500 60 40 60

126,000 3,000 1,800 3,000

840,000 20,000 12,000 20,000

1,890,000 37,000 23,000 37,000

3,780,000 56,000 34,000 56,000

7,560,000 90,000 54,000 90,000

(Table 2A : API2000)

11

Example

2,500 Gallons storage tank contains benzene. Filling rate = 200

Barrel/hr. And flash point of benzene < 100

o

F. Determine normal

venting requirement.

a) Outbreathing requirement

Liquid movement

Normal vent requirement = 12 x 200 =2,400 SCFH air

Thermal Effect

Normal vent requirement =60 SCFH air

Total Outbreathing requirement =2,400+60 =2,460 SCFH

Flash Point 100

o

F

Boiling point 300

o

F

Flash Point <100

o

F

Boiling point <300

o

F

SCFH of Air per Barrel per Hour of Liquid Flow

Inbreathing outbreathing

5.6

5.6

5.6

5.6

6

6

12

12

Flash Point 100

o

F

Boiling point 300

o

F

Flash Point <100

o

F

Boiling point <300

o

F

SCFH of Air

Inbreathing outbreathing

Tank capacity

(Gallons)

2,500 60 40 60

126,000 3,000 1,800 3,000

840,000 20,000 12,000 20,000

1,890,000 37,000 23,000 37,000

3,780,000 56,000 34,000 56,000

7,560,000 90,000 54,000 90,000

12

Example (Cont)

2,500 Gallons storage tank contains benzene. Filling rate = 200

Barrel/hr. And flash point of benzene < 100

o

F. Determine normal

venting requirement.

a) Inbreathing requirement

Liquid movement

Normal vent requirement =5.6 x 200 =1,120 SCFH air

Thermal Effect

Normal vent requirement =60 SCFH air

Total Inbreathing requirement =1,120+60 =1,180 SCFH

Flash Point 100

o

F

Boiling point 300

o

F

Flash Point <100

o

F

Boiling point <300

o

F

SCFH of Air per Barrel per Hour of Liquid Flow

Inbreathing outbreathing

5.6

5.6

5.6

5.6

6

6

12

12

Flash Point 100

o

F

Boiling point 300

o

F

Flash Point <100

o

F

Boiling point <300

o

F

SCFH of Air

Inbreathing outbreathing

Tank capacity

(Gallons)

2,500 60 40 60

126,000 3,000 1,800 3,000

840,000 20,000 12,000 20,000

1,890,000 37,000 23,000 37,000

3,780,000 56,000 34,000 56,000

7,560,000 90,000 54,000 90,000

13

Venting Requirement

For emergency venting capacity : (Fire exposure)

Tank with weak roof-to-shell

Tank without weak roof-to-shell

Liquid movement

+

Thermal effect

Fire exposure

<

normal venting capacity emergency venting capacity

Venting rate of emergency venting may exceed a combination of normal thermal

effect +liquid movement

14

Tank with weak roof-to-shell

Roof

Top angle

Shell

Connection Fail preferentially by frangible joint.!

(**API 650)

***For tank built this specifications, No need

to consider venting requirement

15

Tank without weak roof-to-shell

5 . 0

091 . 3

|

.

|

\

|

=

M

T

L

QF

SCFH

Required venting capacity :

For emergency venting capacity

Q =heat input from fire exposure

L =Latent heat of vaporization of the stored liquid @ relieving P and T

T =Temperature of the relieving vapor

M =molecular weight

F =Environmental factor (Table 4A API2000)

82 . 0

000 , 21 A Q = And :

16

(Q) (A)

17

F (Environmental factors)

Worst

case

18

Quick Estimation

For emergency venting capacity

Where a lesser degree of accuracy can be tolerate, the required venting

capacity can be determined from Table 3 (API 2000) or Equation 2A (below).

82 . 0

1107FA SCFH =

Wetted surface area (ft

2

) Designed pressure (psig) SCFH

< 2800 15 Table 3 (API 2000)

2800 1 742,000

2800 1< P < 15 Eq. 2A (below)

(Based on Hexane properties)

19

Wetted surface area (ft

2

) Designed pressure (psig) SCFH

< 2800 15 Table 3 (API 2000)

20

For example: Spherical storage tank has radius of 4 ft.

Total area = 4r

2

= 4 (4

2

) = 145 ft

2

wetted area of spherical tank = 55% of 145 ft

2

= 80 ft

2

Wetted Area of tank (A) shall be calculated by:

Shape of storage tank Wetted area

Sphere and spheroid 55% of total area

Horizontal tanks 75% of total area

Vertical tanks Total area

21

From table A3.

Emergency venting

requirement

84,200 SCFH

22

Process

Engineer

Instrument

Engineer

select venting device

Outbreathing venting requirement

Inbreathing venting requirement

Emergency venting requirement

Provide

23

Means of venting : venting devices

Normal venting

PV valve (Flame arrester is not considered necessary for

use in conjunction w/ PV valve)

Open vents w/ flame arrester

Open vents w/o flame arrester

Flash point below 100

o

F

Flash point of or above 100

o

F

(Because Flame speed are less than vapor velocity cross the seat)

24

25

Bird screen

26

Emergency venting

Means of venting : venting devices

Larger or additional open vents

Larger or additional PV valves

Gauge hatch

Manhole cover (bigger size)

Connection between roof and shell is weaker than weakest vertical

joint in the shell or shell-to-bottom connection

Roof-to-shell connection (weakest joint)

Vertical connection

Shell-to-bottom connection

Rupture disk

27

28

Selection

Under normal condition

Pressure-relieving device must be able to prevent

pressure from rising more than 10% above MAWP

Under fire emergency condition

Pressure-relieving device must be able to prevent

pressure from rising more than 20% above MAWP

**Consultation between tank designer, the person specifying venting

devices, and the venting device manufacturer is strongly recommended

to ensure that venting device are compatible with the tank design.

29

Discharge piping

1. Lead to a safe area

Safe location

tank

- Prevent flame impingement

- Prevent vapor entry in

enclosed space

30

Discharge piping

tank

2. Discharge outside of the building

Weak roof-to-shell

connection shall not be

used inside the building

Inside

building

Outside

building

31

Discharge piping

Relief device

discharge line

Common discharge

header

32

Flow al Theorectic

Flow Actual

K =

(

(

(

|

|

.

|

\

|

|

|

.

|

\

|

=

+

k

k

k

P

P

P

P

k MTZ

k

A P SCFH

1

1

2

2

1

2

1

) 1 (

700 , 278

Measure from actual flow

Testing & Sizing

Relief devices should be verified by testing before the devices are place in operation

33

34

Sizing vent tube

(

(

(

|

|

.

|

\

|

|

|

.

|

\

|

=

+

k

k

k

P

P

P

P

k MTZ

k

A P SCFH

1

1

2

2

1

2

1

) 1 (

700 , 278

Requirement capacity

from calculation

Area of flow

(theoretical)

P

1

=pressure @ device inlet

P

2

=pressure @ device outlet

K =C

P

/C

V

T =temp @ device inlet

M =M.W. of test medium

Z =compressibility factor @ inlet

conditions (Z~1.0)

35

Type of venting device

There are 2 basic types

Direct-acting vent valve

Pilot-operates vent valve

open vent

spring loaded vent

Weight loaded vent

Operating : Based on weight of pallet or

spring force

Sizes : 16 24

pilot-operated vent valve

Single

Double

Operating : Set pressure (or operate as

a blowdown device from control room)

Sizes : 2 12

36

37

Open vent

Spring loaded

Weight loaded

Pilot-operated

38

THANK YOU FOR YOUR

ATTENTION

Acknowledgements :

- Process section

- Mechanic section

- Instrument section

39

0.75 x theoretical flow = Actual flow

Potrebbero piacerti anche

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNessuna valutazione finora

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringDa EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillValutazione: 3.5 su 5 stelle3.5/5 (3)

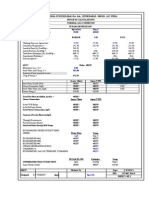

- API 2000 Spread SheetDocumento43 pagineAPI 2000 Spread Sheetjagan100% (3)

- Venting As Per Api 2000Documento6 pagineVenting As Per Api 2000Joshue Adele100% (1)

- API 2000 Venting1Documento5 pagineAPI 2000 Venting1aw_ae100% (1)

- Tank Venting According API 2000Documento34 pagineTank Venting According API 2000Youssef Lagrini50% (2)

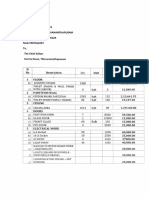

- Inlet Flow For Out Breathing: Total Pump in m3/hr 20Documento9 pagineInlet Flow For Out Breathing: Total Pump in m3/hr 20sonaldivNessuna valutazione finora

- Sizing Tank Blanketing Regulators Using Latest API 2000 7th Edition GuidelinesDocumento11 pagineSizing Tank Blanketing Regulators Using Latest API 2000 7th Edition GuidelinesparykoochakNessuna valutazione finora

- API2000 Tank Venting CalcsDocumento5 pagineAPI2000 Tank Venting Calcsapminshull88% (8)

- Atm Sto Tanks Venting Req API2000 2009 Rev1Documento2 pagineAtm Sto Tanks Venting Req API2000 2009 Rev1fzhou100% (4)

- PVRV Sizing Calculations - Crude Oil Stroage Tank (007486-T-01)Documento2 paginePVRV Sizing Calculations - Crude Oil Stroage Tank (007486-T-01)karthipetro100% (7)

- Valve SizingDocumento38 pagineValve SizingEmmanuel JohnsonNessuna valutazione finora

- Tank Venting According API 2000Documento27 pagineTank Venting According API 2000Pouria Sabbagh100% (1)

- Tank Pressure & Vacuum ReliefDocumento9 pagineTank Pressure & Vacuum Reliefkomalrana2007100% (1)

- Venting Requirement According To Api 2000, Seventh Edition, Mar 2014Documento5 pagineVenting Requirement According To Api 2000, Seventh Edition, Mar 2014sahirprojectsNessuna valutazione finora

- PSV Sizing - API-520 PDFDocumento8 paginePSV Sizing - API-520 PDFAnonymous da6X60VpII100% (1)

- Steam Condensate Pot SizingDocumento1 paginaSteam Condensate Pot SizingSaeid Rahimi Mofrad100% (1)

- Sizing Tank Blanketing Regulators Using Latest API 2000 7th Edition GuidelinesDocumento10 pagineSizing Tank Blanketing Regulators Using Latest API 2000 7th Edition GuidelinesM Scott GreenNessuna valutazione finora

- Knock Out KO Drum SizingDocumento10 pagineKnock Out KO Drum SizingJermaine HeathNessuna valutazione finora

- Venting: As Per Section 4.3 of API 2000, InbreathingDocumento2 pagineVenting: As Per Section 4.3 of API 2000, InbreathingJoshue AdeleNessuna valutazione finora

- Inbreathing Outbreathing of TanksDocumento30 pagineInbreathing Outbreathing of Tanksomesh2008Nessuna valutazione finora

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Documento1 paginaAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Mohammed AttiaNessuna valutazione finora

- Atmospheric Storage Tank Data Sheet & Instructions (In AccorDocumento32 pagineAtmospheric Storage Tank Data Sheet & Instructions (In AccorAhmed Uzair100% (2)

- Basket Type StrainerDocumento12 pagineBasket Type Strainerprateek_bhoir100% (1)

- Tank Relief PhilosophyDocumento8 pagineTank Relief Philosophyking4lifeNessuna valutazione finora

- Storage Tank Normal Venting Capacity Calculations PDFDocumento1 paginaStorage Tank Normal Venting Capacity Calculations PDFNathan MoralesNessuna valutazione finora

- ASME Venting Calculation FB-2007 - PDFDocumento3 pagineASME Venting Calculation FB-2007 - PDFjaganNessuna valutazione finora

- Venting Calculation - PDFDocumento3 pagineVenting Calculation - PDFAmruta100% (1)

- Tank Venting Rate EstimationDocumento3 pagineTank Venting Rate EstimationOmar KallufNessuna valutazione finora

- PRG - GG - GEN - 0001 - R00 - e - Design Pressure N TempeDocumento19 paginePRG - GG - GEN - 0001 - R00 - e - Design Pressure N TempeKorcan ÜnalNessuna valutazione finora

- Gas Blow-By From A Production Separator To Tank PDFDocumento7 pagineGas Blow-By From A Production Separator To Tank PDFebby1100% (1)

- PSV Scenario and CalculationDocumento35 paginePSV Scenario and CalculationBaba Johneh0% (1)

- Closed Drain PaperDocumento4 pagineClosed Drain PaperBehnam Hosseinzadeh100% (1)

- Depressuring Study and Application On BP-A ProjectDocumento35 pagineDepressuring Study and Application On BP-A ProjectTruong Minh Hoang100% (6)

- PSV Scenario and CalculationDocumento35 paginePSV Scenario and Calculationminhphuongpham100% (9)

- PRV Sizing For Exchanger Tube RuptureDocumento5 paginePRV Sizing For Exchanger Tube RuptureNavid Sajedi80% (5)

- Breather Valves2Documento12 pagineBreather Valves2prashant_dc_in100% (1)

- Depressurisation - A Practical GuideDocumento20 pagineDepressurisation - A Practical GuideAhmad Firman Masudi100% (2)

- Iso - 28300 2009Documento3 pagineIso - 28300 2009Joost van den Heuvel100% (2)

- PE D Vi10 422.023 ME CAL 001 01 E - Calculation Sheet Acc. en 14015 - VAR - 3Documento33 paginePE D Vi10 422.023 ME CAL 001 01 E - Calculation Sheet Acc. en 14015 - VAR - 3Virginia Elena Iordache67% (3)

- API 2000 5th Vs 6th FinalDocumento20 pagineAPI 2000 5th Vs 6th Finalbrujula24Nessuna valutazione finora

- Flare KO Drum-3Documento35 pagineFlare KO Drum-3nghiemta1892% (13)

- Blowdown Calc FormulaeDocumento1 paginaBlowdown Calc FormulaeWayne MonneryNessuna valutazione finora

- Tank Vessel Overflow Line SizingDocumento4 pagineTank Vessel Overflow Line SizingSteve Wan100% (1)

- API579 EXAMPLE CalculationsDocumento4 pagineAPI579 EXAMPLE CalculationsJaclyn Henderson80% (5)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsDa EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsValutazione: 3.5 su 5 stelle3.5/5 (14)

- Asme Sec VIII Div IDocumento6 pagineAsme Sec VIII Div IjaganNessuna valutazione finora

- 30 Flc-Tan Sdagenda 06-13-26Documento1 pagina30 Flc-Tan Sdagenda 06-13-26juliosieteNessuna valutazione finora

- Moody DiagramDocumento2 pagineMoody DiagrammarpadanNessuna valutazione finora

- Lecture 3 - TheFirmAndItsCustomersDocumento41 pagineLecture 3 - TheFirmAndItsCustomerssofo mghebrishviliNessuna valutazione finora

- AHU Catalouge-With Design DetailsDocumento28 pagineAHU Catalouge-With Design Detailsmpwasa100% (1)

- Emergency Vent Flam LiquidsDocumento3 pagineEmergency Vent Flam LiquidsSharon LambertNessuna valutazione finora

- Tanks Venting CalcDocumento2 pagineTanks Venting CalcChitu Ionut-LaurentiuNessuna valutazione finora

- Steam Drum LevelsDocumento11 pagineSteam Drum LevelsAnith kumar Reddy100% (1)

- Scan 05-May-2022Documento2 pagineScan 05-May-2022Sundeep VfxNessuna valutazione finora

- Table 2A-Requirements For Thermal Venting Capacity A. English UnitsDocumento1 paginaTable 2A-Requirements For Thermal Venting Capacity A. English Unitssyamsudin2006Nessuna valutazione finora

- Expansion Tank Calculations With TablesDocumento6 pagineExpansion Tank Calculations With TablesRuel Paolo BorlonganNessuna valutazione finora

- Boq-Furniture, FixtureDocumento11 pagineBoq-Furniture, FixtureovifinNessuna valutazione finora

- Transition Zone Critical Zone Laminar FlowDocumento1 paginaTransition Zone Critical Zone Laminar Flowjegan172Nessuna valutazione finora

- Steam Power Plant DesignDocumento20 pagineSteam Power Plant DesignAlvin LoocNessuna valutazione finora

- Exchanger Datasheet - Booster Compressor Discharge Cooler - RevaDocumento1 paginaExchanger Datasheet - Booster Compressor Discharge Cooler - RevaSudhanshu ShekharNessuna valutazione finora

- Eng DocumentDocumento21 pagineEng DocumentAndy DolmanNessuna valutazione finora

- Lube Oil SystemDocumento4 pagineLube Oil SystemSudhanshu ShekharNessuna valutazione finora

- 01 1.3.1 Typical Datum Compressor Ga r1Documento3 pagine01 1.3.1 Typical Datum Compressor Ga r1Sudhanshu ShekharNessuna valutazione finora

- 1-Maximum Shear Stress Theory-DerivationDocumento2 pagine1-Maximum Shear Stress Theory-DerivationMurugan Shanmugam100% (1)

- Long Tower DrawingDocumento10 pagineLong Tower DrawingSudhanshu ShekharNessuna valutazione finora

- General PumpsDocumento178 pagineGeneral PumpsSudhanshu ShekharNessuna valutazione finora

- Lifting Reactions 2731Documento2 pagineLifting Reactions 2731Sudhanshu ShekharNessuna valutazione finora

- Whats New in Asme A 2010Documento19 pagineWhats New in Asme A 2010Sudhanshu ShekharNessuna valutazione finora

- MS 01 27Documento2 pagineMS 01 27Sudhanshu ShekharNessuna valutazione finora

- PVEliteDocumento580 paginePVEliteSudhanshu Shekhar100% (2)

- DNV Bolts Failure Analisys Marine ApplicationDocumento34 pagineDNV Bolts Failure Analisys Marine ApplicationBrian Chmeisse100% (2)

- Polymer Melt Indexer (Extrusion Plastometer) PDFDocumento138 paginePolymer Melt Indexer (Extrusion Plastometer) PDFjrlr65Nessuna valutazione finora

- Avogadro's NumberDocumento5 pagineAvogadro's NumberM J RhoadesNessuna valutazione finora

- Improvement of Soil Properties by Using Waste PlasticDocumento6 pagineImprovement of Soil Properties by Using Waste PlasticnehamyaNessuna valutazione finora

- LM4040 Precision Micropower Shunt Voltage Reference: 1 Features 3 DescriptionDocumento60 pagineLM4040 Precision Micropower Shunt Voltage Reference: 1 Features 3 Descriptionmuhamad faizal yaakubNessuna valutazione finora

- Laser Ignition For Combustion Engines: January 2004Documento21 pagineLaser Ignition For Combustion Engines: January 2004Shekhar ShekharNessuna valutazione finora

- Astm E0169 16Documento6 pagineAstm E0169 16archanaNessuna valutazione finora

- PHYSICS FOR ENGINEERS Chapter 2Documento30 paginePHYSICS FOR ENGINEERS Chapter 2Leo Prince GicanaNessuna valutazione finora

- Mcqs For MCATDocumento26 pagineMcqs For MCATHashir Ahmad KhanNessuna valutazione finora

- Microplan - Katalog 2009 ENDocumento18 pagineMicroplan - Katalog 2009 END.T.Nessuna valutazione finora

- ANSA v17.0.0 Release NotesDocumento63 pagineANSA v17.0.0 Release NotesVishnu RaghavanNessuna valutazione finora

- Course Structure B.tech.2012-13Documento4 pagineCourse Structure B.tech.2012-13fortunatesanjibNessuna valutazione finora

- Problem Set 2Documento2 pagineProblem Set 2engineerNessuna valutazione finora

- Engine Number Guide (2-Page)Documento2 pagineEngine Number Guide (2-Page)Abdul KhaliqNessuna valutazione finora

- Test 2 Semester 2, 2022Documento3 pagineTest 2 Semester 2, 2022Kalana GamageNessuna valutazione finora

- Airfoil NACADocumento277 pagineAirfoil NACAtaufikengineer100% (4)

- B Sc-MathsDocumento24 pagineB Sc-MathsVijayakumar KopNessuna valutazione finora

- Milpass - Catalogo Alluminio EN PDFDocumento174 pagineMilpass - Catalogo Alluminio EN PDFStefanus AndreNessuna valutazione finora

- Electrical Power Plans For Building ConstructionDocumento16 pagineElectrical Power Plans For Building ConstructionKitz DerechoNessuna valutazione finora

- Rutherford Scattering - MITDocumento5 pagineRutherford Scattering - MITBrayan Stiven Pardo RuizNessuna valutazione finora

- Elements of Feedback Control SystemsDocumento53 pagineElements of Feedback Control SystemschanonNessuna valutazione finora

- 1.1 Waves and Particles According To Classical PhysicsDocumento8 pagine1.1 Waves and Particles According To Classical PhysicsLUCKY KUSHWAHANessuna valutazione finora

- Gabion Wall Design - 4.0 MTR Above GLDocumento8 pagineGabion Wall Design - 4.0 MTR Above GLAnkush SharmaNessuna valutazione finora

- Display Unit TechnologyDocumento51 pagineDisplay Unit TechnologyNavin GillmanNessuna valutazione finora

- Chapter1-Propertiesoffluids Semakan2.1Documento35 pagineChapter1-Propertiesoffluids Semakan2.1sufi 3393Nessuna valutazione finora

- Class Xi Physics Annual Exam 2017 18Documento3 pagineClass Xi Physics Annual Exam 2017 18Anupam TiwariNessuna valutazione finora

- Geotechnical Variation of London Clay Across Central LondonDocumento12 pagineGeotechnical Variation of London Clay Across Central LondonChiaraNessuna valutazione finora

- Emma Warlinge - Sterilization of Sterile TanksDocumento6 pagineEmma Warlinge - Sterilization of Sterile Tanksaaro_oraalNessuna valutazione finora

- 31 M.E Ed R2010Documento61 pagine31 M.E Ed R2010Jason JohnsonNessuna valutazione finora