Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Natural Gas Compression

Caricato da

Arjun Pratap SinghCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Natural Gas Compression

Caricato da

Arjun Pratap SinghCopyright:

Formati disponibili

COMPRESSION OF NATURAL GAS

Jn Steinar Gumundsson

TPG4140 Natural Gas

September 17, 2012

Compression in oil and gas production

Types of compressors (piston and centrifugal)

Characteristic curves

Adiabatic and reversible (=isentropic) compression

Real vs. ideal, isentropic head, polytropic compression

Surge and stonewall

Compression in stages (inter-cooling)

System curves and parallel/series service

Compression in Oil and Gas Production

Recompression in separation train of gas and

condensate (same as in oil production).

Export compression (from platform to pipeline).

Reinjection compression (from platform to subsurface).

Various air compressors for control equipment in

processing facilities (offshore and onshore).

Export compression, from receiving and processing

terminal to pipeline.

Pressure boosting, onland compression.

Gas storage in salt caverns.

Subsea compression (soon to be installed)

A: Recompression, B: Gas Drying, C: Fuel Gas, D: Export Compression,

E: Gas Pipeline, F: Injection Compression, G: Injection Well

Compressor

Station

Compressor

Station

Production

32,000 Compressors

Processing

5,000 Compressors

Transmission & Storage

8,500 Compressors

Distribution

0 Compressors

Compressor

Station

USA Natural Gas Industry

CO

2

Emissions Norway

Oil and gas industry 29 %, Cars and trucks 22 %, Industry processes 18 %, Heating 16 %, Boats

and ships 9 %, Other sources 6 %

Gas Turbines Offshore Norway 2007

Offshore Gas Turbines

The oil and gas industry in 2007 represented 25 % of CO

2

emissions

in Norway.

At that time, the requirement for electricity offshore was 15 TWh

(Norways total electricity production was then about 125 TWh).

In 2007 there were 167 gas turbines on offshore installations

amounting to 3000 MW.

About 45 % of the power is for electrical equipment. The remaining

power is for compressors and other equipment.

The thermal efficiency of the gas turbines is in the range 30-37 %.

Thermal recovery is used in most of the installations, increasing the

thermal efficiency to about 40 %

Kraft fra land til norsk sokkel (2008), OD o.a.

Simplistic Gas Turbines Working Principles

1-2 Isentropic compression (in a compressor)

2-3 Constant pressure heat addition (in a combustor)

3-4 Isentropic expansion (in a turbine)

4-1 Constant pressure heat rejection

6

Kristin Prosess

18.3 MSm/sd

210 bar

50C

Pcric <105 barg

Kristin

GT

sgard Transport

Meter

Scavenger, back-up

Fuel Gas

87 bar

121C

26C

31C

25C

Meter

TVP 0.965bar @ 30C

sgard C

26 bar

2 bar

20000 Sm3/sd

67 bar

70C

30C 30C

30C

Types of Compressors

Reciprocating piston compressors

Low flow rate

High compression ratio

Rotating centrifugal compressors

High flow rate

Low compression ratio each stage

Several stages higher compression ratio

Axial Flow Compressor

Radial Flow Compressor

Centrifugal Compressor

Reciprocating Compressor

Twin Screw Compressor for Subsea

Subsea Compressor

Usage of Compressors

Characteristic Curve

Characteristic Curves

A: Centrifugal, B: Axial,

C: Piston, D: Screw

Left: Radial,

Middel: xxx,

Right:Axia

Thermodynamic Processes

k=C

p

/C

v

k=0

k=1

k=C

p

/C

v

k<n

k=

dq=0

dp=0

dT=0

ds=0

ds=0

dV=0

Adiabatic

Isobaric

Isothermal

Isentropic

Polytropic

Isometric

Exponent Condition Process

Reversible adiabatic process = Isentropic process

Compressor Work

}

=

2

1

vdp W

A = Suction, B = Compression, C =Delivery, D = Expansion

Piston Compressor

The Carnot Cycle

Adiabatic/Isentropic Process

nRT pV =

RT pv =

v

p

C

C

k =

k

k

p

p

T

T

1

1

2

1

2

|

|

.

|

\

|

=

k k

v p v p

2 2 1 1

=

Adiabatic/Isentropic Compression

}

=

2

1

vdp W

(

(

(

|

|

.

|

\

|

=

1

1

1

1

2

1 1

k

k

p

p

k

k

v p W

(

(

(

|

|

.

|

\

|

=

1

1

1

1

2

1

k

k

p

p

k

k

RT

M

m

P

v [m3/mol], p [Pa=N/m2], W [Nm/mol=J /mol] =Specific work

pv=RT, Wm/M [J /mol kg/s mol/kg=J /s=W] =Power

nRT pV =

RT pv =

Ideal, Real, Efficiency, Head,

Polytropic

(

(

(

|

|

.

|

\

|

|

|

.

|

\

|

=

|

|

.

|

\

|

1

1

1

1

2

1

p

k

k

p

p

p

k

k

RT

M

m

P

q

q

8 , 0 6 , 0 < <

p

q

(

(

(

|

|

.

|

\

|

=

1

1

1

1

2 1

k

k

s

p

p

k

k

M

RT

h

q

1

ideal real

P P =

h

s

[J /kg]

p

k

k

n

n

q

1 1

=

P [W=J /s]

Surge and Stone Wall

A: Surge line, B: Stonewall line

Surge Control

Compression in Two Stages

2

3

1

2

p

p

p

p

=

3 1 2

p p p =

Above pressures give

minimum power

Intercooling

System Characteristic

Scaling Laws

Isentropic Head Example

0,0

10,0

20,0

30,0

40,0

50,0

60,0

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

q [m3/h]

h

_

S

[

k

J

/

k

g

]

|

|

.

|

\

|

=

1 1

2 2

1 2

d N

d N

q q

2

1 1

2 2

1 2

|

|

.

|

\

|

=

d N

d N

h h

3

1 1

2 2

1 2

|

|

.

|

\

|

=

d N

d N

P P

6000, 7000 and 8000 RPM

Parallel and Series

Summary

Recompression, export compression, reinjection

compression

Reciprocating piston compressors and rotating

centrifugal compressors (radial and axial)

Characteristic curves P [W] or h [J/kg] vs. q [m3/h]

Calculation of compression power (isentropic)

Efficiency and polytropic compression

Surge (solved by recycle) and stonewall (speed of

sound)

Compression in stages with intercooling (minimum

power when equal power)

System curves (the need) and >1 compressor

List of companies and their products

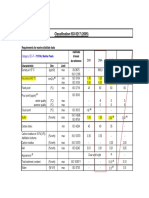

Industrial Aero-derivatives

Overhaul Life 48,000 hours 30,000 hours

Hot section inspection 8000 hours 6000 hours

Overhaul Life On-site Gas generator removal

Engine weight Heavy Duty Light

Fast start capability No Yes

Tolerance to poor fuel Fair Poor

Ease of automation Good Good

Suitable for off-shore Fair Good

Power Up to 325 MW Up to 55 MW

Thermal Efficiency 25-39% 25-42%

Difference between Heavy Duty and Aeroderivative Turbines

Evolution of products : Uprates

Potrebbero piacerti anche

- Macro Economics - Tackling High Food Inflation & GST IndiaDocumento8 pagineMacro Economics - Tackling High Food Inflation & GST IndiaArjun Pratap SinghNessuna valutazione finora

- Corruption & Cronyism in IndiaDocumento15 pagineCorruption & Cronyism in IndiaArjun Pratap SinghNessuna valutazione finora

- AbdominalsDocumento13 pagineAbdominalsBeniamin CociorvanNessuna valutazione finora

- Major Oil and Gas Related CompaniesDocumento4 pagineMajor Oil and Gas Related CompaniesArjun Pratap SinghNessuna valutazione finora

- Corruption & Cronyism in IndiaDocumento15 pagineCorruption & Cronyism in IndiaArjun Pratap SinghNessuna valutazione finora

- DC - Coupled, Selectable-Gain Headphone Amplifier CircuitDocumento30 pagineDC - Coupled, Selectable-Gain Headphone Amplifier CircuitArjun Pratap SinghNessuna valutazione finora

- Telecom Industry & Reasons For Switching Operators in The IndustryDocumento21 pagineTelecom Industry & Reasons For Switching Operators in The IndustryArjun Pratap Singh100% (1)

- Indian Aviation Industry - Indigo AirlinesDocumento13 pagineIndian Aviation Industry - Indigo AirlinesArjun Pratap SinghNessuna valutazione finora

- Indian Aviation Industry - Indigo AirlinesDocumento13 pagineIndian Aviation Industry - Indigo AirlinesArjun Pratap SinghNessuna valutazione finora

- How Can HUL Expand Its Reach To Rural Markets in India (Ideation)Documento3 pagineHow Can HUL Expand Its Reach To Rural Markets in India (Ideation)Arjun Pratap SinghNessuna valutazione finora

- A Positive Attitude EbookDocumento19 pagineA Positive Attitude Ebookhuy22983Nessuna valutazione finora

- Bharat Petroleum (BPCL) Refinery 2009 - 2010 PresentationDocumento40 pagineBharat Petroleum (BPCL) Refinery 2009 - 2010 PresentationArjun Pratap SinghNessuna valutazione finora

- Solar Energy - Photo Voltaic CellDocumento22 pagineSolar Energy - Photo Voltaic CellArjun Pratap Singh100% (1)

- Engineer in Society - BEM Code of Professional Conduct & Ethical TheoriesDocumento38 pagineEngineer in Society - BEM Code of Professional Conduct & Ethical TheoriesArjun Pratap Singh90% (30)

- Windows XP Hidden ApplicationsDocumento3 pagineWindows XP Hidden ApplicationsArjun Pratap SinghNessuna valutazione finora

- PLC & Pneumatic SystemDocumento38 paginePLC & Pneumatic SystemArjun Pratap Singh88% (8)

- Alternative English Dictionary Comprehensive, Vulgar Slang and Sex Related)Documento38 pagineAlternative English Dictionary Comprehensive, Vulgar Slang and Sex Related)pasooriNessuna valutazione finora

- Development of Electric Drives in Light Rail Transit (LRT) SystemDocumento31 pagineDevelopment of Electric Drives in Light Rail Transit (LRT) SystemArjun Pratap Singh100% (1)

- 10 Things They Never Tell You When You Start Work and WhyDocumento24 pagine10 Things They Never Tell You When You Start Work and WhyArjun Pratap SinghNessuna valutazione finora

- Ultrasonic or MFL InspectionDocumento4 pagineUltrasonic or MFL InspectionArjun Pratap Singh100% (3)

- College Students and Personal Finance EducationDocumento6 pagineCollege Students and Personal Finance EducationArjun Pratap SinghNessuna valutazione finora

- Value Co-Creation of Social NetworkingDocumento18 pagineValue Co-Creation of Social NetworkingArjun Pratap SinghNessuna valutazione finora

- Impacts of Globalization On E-Commerce Adoption and Firm PerformanceDocumento8 pagineImpacts of Globalization On E-Commerce Adoption and Firm PerformanceArjun Pratap SinghNessuna valutazione finora

- Challenges That Might Be Faced by Maersk & Damco MergersDocumento4 pagineChallenges That Might Be Faced by Maersk & Damco MergersArjun Pratap SinghNessuna valutazione finora

- Autonomous Underwater Vehicle (AUV)Documento44 pagineAutonomous Underwater Vehicle (AUV)Arjun Pratap Singh100% (1)

- Economic Recession 2008-2009 Impact On Indian Auto Industry's Management PracticesDocumento14 pagineEconomic Recession 2008-2009 Impact On Indian Auto Industry's Management PracticesArjun Pratap Singh100% (2)

- L Light A Amplification S Stimulated E Emission R RadiationDocumento8 pagineL Light A Amplification S Stimulated E Emission R RadiationArjun Pratap SinghNessuna valutazione finora

- Engineering Project Management Hypothetical)Documento96 pagineEngineering Project Management Hypothetical)Arjun Pratap Singh100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- ECU MS 3 Sport GT3 Cup Manual Setup GuideDocumento26 pagineECU MS 3 Sport GT3 Cup Manual Setup GuideAngel LópezNessuna valutazione finora

- Symmetry & Crystal StructuresDocumento37 pagineSymmetry & Crystal StructuresNurnajihah Sukimi JiehaNessuna valutazione finora

- Ufc 3 430 09Documento106 pagineUfc 3 430 09carlcrowNessuna valutazione finora

- Power Generation SystemDocumento72 paginePower Generation SystemAbshir Mohamed HajjiNessuna valutazione finora

- 1 PDFDocumento60 pagine1 PDFdexterNessuna valutazione finora

- Rpdir-L12 Shielding WebDocumento73 pagineRpdir-L12 Shielding WebWiie ArdiNessuna valutazione finora

- TDFC Global Engineering Solutions CompanyDocumento189 pagineTDFC Global Engineering Solutions CompanyplanningNessuna valutazione finora

- Pepsin Enzyme Activity LabDocumento4 paginePepsin Enzyme Activity LabDebrah DebbieNessuna valutazione finora

- Ethics IndividualDocumento3 pagineEthics IndividualJustin JJNessuna valutazione finora

- Master Plan 2021Documento172 pagineMaster Plan 2021Rajnish MishraNessuna valutazione finora

- 568100Documento2 pagine568100Talha TariqNessuna valutazione finora

- 908 PM Expertise and Equipment Contribute To CHP Success at Sodra Cell VaroDocumento2 pagine908 PM Expertise and Equipment Contribute To CHP Success at Sodra Cell Varoshashikanth79Nessuna valutazione finora

- EssayDocumento3 pagineEssayKarina RamirezNessuna valutazione finora

- SMT - Kashibai Navale College of Engineering, Vadgaon Pune: Heat TransferDocumento8 pagineSMT - Kashibai Navale College of Engineering, Vadgaon Pune: Heat TransferFS18ME046 MAYUR NikamNessuna valutazione finora

- Gas Chromatograph OptimizationDocumento18 pagineGas Chromatograph OptimizationUmair KazmiNessuna valutazione finora

- Makita 8271DWAE Bedienungsanleitung D328acDocumento48 pagineMakita 8271DWAE Bedienungsanleitung D328acJonathan Giovanni Asti CastilloNessuna valutazione finora

- LG Refridge ServiceManualDocumento79 pagineLG Refridge ServiceManualMichael Dianics100% (1)

- KR AGILUS Hygienic Machine Fast Cleaning Food PharmaDocumento2 pagineKR AGILUS Hygienic Machine Fast Cleaning Food PharmaValke Athletes HandcareNessuna valutazione finora

- Unu GTP SC 26 14Documento30 pagineUnu GTP SC 26 14Ernesto RomeroNessuna valutazione finora

- AC Biasing in TransisterDocumento61 pagineAC Biasing in TransisterHariom RavatNessuna valutazione finora

- 2013 Midterm 3Documento16 pagine2013 Midterm 3billbyoag123Nessuna valutazione finora

- Futuro Continuo Afirmativo y NegativoDocumento4 pagineFuturo Continuo Afirmativo y NegativoSkoNessuna valutazione finora

- Classification ISO 8217 (2005)Documento5 pagineClassification ISO 8217 (2005)Salah JallaliNessuna valutazione finora

- Aviation Tinning and SolderingDocumento16 pagineAviation Tinning and SolderingRebecca RiversNessuna valutazione finora

- Industrial ReactorsDocumento10 pagineIndustrial ReactorssarahNessuna valutazione finora

- Damper mechanism details for Atlas Copco rock drills under 40 charactersDocumento27 pagineDamper mechanism details for Atlas Copco rock drills under 40 characterssalvador341100% (2)

- ABB Terminal BlocksDocumento236 pagineABB Terminal BlocksBenoit LefebvreNessuna valutazione finora

- Easy Genset Control: OperationDocumento51 pagineEasy Genset Control: OperationdonothearNessuna valutazione finora

- Voith Thyricon Excitation SystemDocumento8 pagineVoith Thyricon Excitation SystemKeshab ShresthaNessuna valutazione finora

- Waste Water-Sewage PumpDocumento111 pagineWaste Water-Sewage Pumpcharadeg100Nessuna valutazione finora