Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Thread Type

Caricato da

vikram_007Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Thread Type

Caricato da

vikram_007Copyright:

Formati disponibili

Finding the Right Thread Type

The increasing demand for hydraulic and pneumatic equipment has resulted in numerous fittings and connectors worldwide. This has resulted in a variety of threads making the task of identifying the right thread type difficult. Pipe threads are the most common to people involved in fluid and pneumatic industry. For identification purposes tube fittings and threaded connectors can be divided into four different thread types: UN/NF NPT/NPTF BSPP/BSPT(tapered) Metric parallel/Metric tapered

Pipe threads can be broadly classified as:

Joining threads These joints are made pressure tight by sealing the threads. The threads are tapered

externally and are tapered parallel. They may also taper internal threads.

Fastening threads Here both threads are parallel and sealing is performed by compression of a soft material

on to a flat gasket.

Taper vs. Parallel thread

Most of the pneumatic fittings are based on Taper threads. The main advantage of using Taper threads is the self sealing of threads. Because of taper a pipe thread can only screw into a fitting a certain distance before it jams. The standard calls the distance as effective length of engagement. A simple rule of thumb is finger tight plus two turns with a wrench. A parallel thread will have some means of sealing at the top of the thread, either by O-ring, gasket, metal seal, or possibly by a machined ring in the hex itself. Most widely used taper thread is NPT thread type. It has taper of 1/16 or for an overall length of 1 or 1 foot respectively. The NPT threads can be external (Male) or internal (Female). The external threads are usually designated as MPT and internal as FPT. When joining NPT tapered pipe thread to make a leak-proof seal, professionals recommend using a sealer such as polytetrafluoroethylene (PTFE) pipe thread tape. PTFE, more commonly known as Teflon, is also the name of the best known brand of sealing tape. Sealing tape makes it easy to drive the male pipe deeper by allowing the threads to slip past one another, while filling minute gaps to prevent seepage. Pipe thread tape also makes it easier to disassemble the joint later, if need be, by reducing thread galling, or the tendency of some types of pipe threads to stick together over time. Despite the various available standards Taper Pipe threads are inexact and are susceptible to leakage during the course of use. The area where the crest and the root of the thread meet can form spiral leak path. A number of variations of the NPT threads have been introduced to overcome the problem of spiral leakage and are known as Dry-seal threads. The most common is NPTF. The design ensures that the crest displaces or crushes material into the root of the mating thread thus providing effective sealing.

British Standard Pipe Thread

Two of the more popular thread forms used in the world today is the British Standard Pipe Tapered (BSPT) and the British Standard Parallel Pipe (BSPP). Both of these thread forms have a 55 thread flank angle as shown below. BSPT has a taper of 1 inch for an overall length of 16 inches equivalent to 1 47 as shown below.

British Pipe threads have similar sizes as American Pipe threads BSP but they are not interchangeable due to different flank angle except at and where both have same pitch.

How to identify a correct thread type

The thread identification process can be greatly simplified using the following 4-step processes: 1. Check if the thread is taper or parallel: Taper thread diameter reduces as we move from one end to other while parallel threads maintain the same diameter.

Note: The threaded pipe is tapered and so the Caliper touches the Pipe at two points

2. Determine Pitch: Pitch is defined as number of threads per inch (TPI) Usually the pitch is measured using a Pitch gauge .To determine the correct pitch several gauges have to be used to ensure that the right gauge mate the required thread type.

3.

Determine Size: The two methods for sizing threads are based on fact that the threads are either pipe or non-pipe. Pipe sizes do not refer to any physical dimensions. To determine the size of a pipe, the outside diameter of each pipe or fitting must be measured and compared to the table for size identification. Refer to the table at the end of the

article for Taper and Straight thread dimensions. Pipe threads are base on inside diameter threads the actual size is measured using the caliper. 4.

(1)

(ID). For non pipe type

Designate the thread This process is designating the thread type in standard format. For example a Pipe thread with a nominal inside diameter of having a defined pitch of 18 is designated as -18 NPT. The most common global pipe thread forms are NPT NPSC NPTR NPSM NPSL NPTF BSPP BSPT American Standard Pipe Taper Thread American Standard Coupling Pipe Thread American Standard Taper Railing Pipe Thread American Standard Straight Mechanical Pipe Thread American Standard Straight Locknut Pipe Thread American Standard Pipe Thread Tapered(Dry seal) British Standard Pipe Thread Parallel British Standard Pipe Thread Tapered

The British standard threads are usually designated by letter G. A typical reference on a drawing might be G12, for internal thread; G12 A, for external thread, class A and G 12 B, for external thread, class B. Where no class reference is stated for external threads that of class B will be assumed.

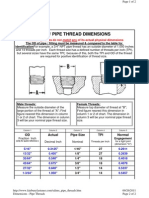

Nominal Dimensions of Standard Pipe Thread

ODM- Outside Dimater of Male

IDF-Inside Diameter of Female

TPI-Threads Per Inch

Tapered Thread

NPT Size (in) 1/8 1/4 3/8 1/2 3/4 1 1 1/4 1 1/2 Pipe O.D. 0.405 0.54 0.675 0.84 1.05 1.315 1.66

1.9

Straight Threads

NPSH ODM (max) IDF (min) NPSM ODM (max) 0.397 0.526 0.662 0.823 1.034 1.293 1.638

1.877

BSPT

BSPP IDF (min) 0.358 0.468 0.603 0.747 0.958 1.2 1.546

1.785

TPI 27 18 18 14 14 11.5 11.5

11.5

TPI 28 19 19 14 14 11 11

11

TPI

TPI 27 18 18 14 14 11.5 11.5

11.5

TPI 28 19 19 14 14 11 11

ODM (max) 0.383 0.516 0.656 0.825 1.041 1.309 1.65 1.882

IDF (min) 0.337 0.45 0.588 0.733 0.95 1.193 1.534 1.766

14 14 11.5 11.5

11.5

0.843 1.035 1.295 1.639

1.8788

0.739 0.95 1.192 1.536

1.7758

1) Nominal diameter: Nominal size is different than the actual size. It is a dimensionless number. The nominal is a theoretical size with no tolerances. In reality the actual diameter is never equal to nominal diameter. For example a bolt when measured is usually less than .

Potrebbero piacerti anche

- Pipe ThreadsDocumento2 paginePipe Threadsehab2003yeNessuna valutazione finora

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Pipe Threads: The Two Main Pipe Thread Standards Are As FollowsDocumento2 paginePipe Threads: The Two Main Pipe Thread Standards Are As Followssushant shirsatNessuna valutazione finora

- National Pipe ThreadDocumento10 pagineNational Pipe ThreadLodyNessuna valutazione finora

- Paracord Outdoor Gear Projects: Simple Instructions for Survival Bracelets and Other DIY ProjectsDa EverandParacord Outdoor Gear Projects: Simple Instructions for Survival Bracelets and Other DIY ProjectsValutazione: 4.5 su 5 stelle4.5/5 (2)

- NPTDocumento2 pagineNPTaaaNessuna valutazione finora

- The Weir Direct-Acting Feed Pump - Working InstructionsDa EverandThe Weir Direct-Acting Feed Pump - Working InstructionsNessuna valutazione finora

- NaptDocumento2 pagineNaptaaaNessuna valutazione finora

- Math Tools - Pipe Diameters, Threads and Sizes A3Documento3 pagineMath Tools - Pipe Diameters, Threads and Sizes A3Ram CaceresNessuna valutazione finora

- NPT vs. BSP Pipe - Pipe andDocumento2 pagineNPT vs. BSP Pipe - Pipe andreview20Nessuna valutazione finora

- Chainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyDa EverandChainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyValutazione: 5 su 5 stelle5/5 (4)

- ASME B1.20.1 Threaded Fittings SpecDocumento3 pagineASME B1.20.1 Threaded Fittings SpecJimmy Alfaro Hernandez0% (1)

- The Gun Digest Book of Tactical Weapons Assembly/DisassemblyDa EverandThe Gun Digest Book of Tactical Weapons Assembly/DisassemblyNessuna valutazione finora

- PIPE THREAD DimensionDocumento2 paginePIPE THREAD DimensionAriel AnascoNessuna valutazione finora

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Thread ID Course - OficialDocumento63 pagineThread ID Course - OficialBruno SalasNessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Xdims Pipe ThreadsDocumento2 pagineXdims Pipe ThreadsamevaluacionesNessuna valutazione finora

- PDMSDocumento39 paginePDMSprathikNessuna valutazione finora

- National Pipe Thread - Wikipedia, The Free EncyclopediaDocumento5 pagineNational Pipe Thread - Wikipedia, The Free EncyclopediaRahul VermaNessuna valutazione finora

- Pipe Thread NPT and BSPT Fittings Compatibility PDFDocumento5 paginePipe Thread NPT and BSPT Fittings Compatibility PDFrefaeNessuna valutazione finora

- NPT Pipe SizesDocumento3 pagineNPT Pipe SizesGMHHENessuna valutazione finora

- AB EnginData No3 11 PCLDocumento35 pagineAB EnginData No3 11 PCLsalamrefighNessuna valutazione finora

- NPT Vs BSPDocumento1 paginaNPT Vs BSPphyo7799Nessuna valutazione finora

- Pipe Thread SizeDocumento1 paginaPipe Thread SizeJeffrey WalkerNessuna valutazione finora

- Identifying Threads Identifying Threads: How To Use The CaliperDocumento6 pagineIdentifying Threads Identifying Threads: How To Use The CaliperkyletgerberNessuna valutazione finora

- Thread and Thread CuttingDocumento9 pagineThread and Thread Cuttinglyk zNessuna valutazione finora

- NPT ThreadDocumento3 pagineNPT ThreadaniruddhkrsharmaNessuna valutazione finora

- Pipe Thread DiameterDocumento3 paginePipe Thread DiameterNabil RamehNessuna valutazione finora

- Pipe Thread NPT and BSPT Fittings CompatibilityDocumento5 paginePipe Thread NPT and BSPT Fittings CompatibilityEduardoNessuna valutazione finora

- Types of Threads PDFDocumento21 pagineTypes of Threads PDFAhmed SaifeldinNessuna valutazione finora

- Stub Onin ConnectionsDocumento4 pagineStub Onin ConnectionsMehman NasibovNessuna valutazione finora

- Threads and Sealing MethodsDocumento80 pagineThreads and Sealing MethodsabdulmuhaimenNessuna valutazione finora

- BSP Identification PDFDocumento3 pagineBSP Identification PDFrefaeNessuna valutazione finora

- British Standard Pipe ThreadDocumento3 pagineBritish Standard Pipe ThreadBharat PrajapatiNessuna valutazione finora

- Btech Man Pro Lab Exp No 3 - Internal Thread Cutting by Using TapsDocumento10 pagineBtech Man Pro Lab Exp No 3 - Internal Thread Cutting by Using Tapsfotick100% (1)

- 35Documento10 pagine35phankhoa83Nessuna valutazione finora

- Pages From B1-20-1 - 2013 PDFDocumento3 paginePages From B1-20-1 - 2013 PDFAhmad Jukliv Pandu YoedhawanNessuna valutazione finora

- Mall Pipe ThreadsDocumento14 pagineMall Pipe Threadsanac_mathNessuna valutazione finora

- BSPP - BSPT - NPT ThreadsDocumento7 pagineBSPP - BSPT - NPT ThreadsRaghuNessuna valutazione finora

- Pipe Thread SizeDocumento1 paginaPipe Thread SizeDJoko Trend RedsNessuna valutazione finora

- Threads in Pneumatics: (Threads For The Air Supply)Documento2 pagineThreads in Pneumatics: (Threads For The Air Supply)Vinh TonyNessuna valutazione finora

- Pipe FittingsDocumento10 paginePipe Fittingssreelu100% (5)

- Understanding Pipe Threads: Types and Designations: by Mark SchmidtDocumento5 pagineUnderstanding Pipe Threads: Types and Designations: by Mark Schmidtدانيا الأبراجNessuna valutazione finora

- British Standard PipeDocumento3 pagineBritish Standard PipeskluxNessuna valutazione finora

- NPT (Asme B1.20.1)Documento5 pagineNPT (Asme B1.20.1)Afronie Cepoz D'nextNessuna valutazione finora

- Threads and FastenersDocumento21 pagineThreads and FastenersSunil DeoNessuna valutazione finora

- Thread Specification NPT NPSM ANSI B1.20.1Documento1 paginaThread Specification NPT NPSM ANSI B1.20.1nargissuhailNessuna valutazione finora

- API Spec 5CT IntroductionDocumento37 pagineAPI Spec 5CT IntroductionChandrasekhar Sonar100% (2)

- Tubing Thread Type, External Upset Tubing, Yaosheng Non Upset Tubing ManufacturerDocumento2 pagineTubing Thread Type, External Upset Tubing, Yaosheng Non Upset Tubing ManufacturerEDWIN M.PNessuna valutazione finora

- Threads and FastenersDocumento89 pagineThreads and Fastenerstheleovn0% (1)

- 1 2 NPSC Thread DetailDocumento4 pagine1 2 NPSC Thread DetailRamani Elampooranan K ENessuna valutazione finora

- TreadsDocumento1 paginaTreadspepe555Nessuna valutazione finora

- ThreadingDocumento8 pagineThreadingVivek SDNessuna valutazione finora

- Thread Guides PDFDocumento6 pagineThread Guides PDFFelix RanillaNessuna valutazione finora

- Industrial Project Mangement: Faculty of Management EngineeringDocumento19 pagineIndustrial Project Mangement: Faculty of Management Engineeringvikram_007Nessuna valutazione finora

- Ifsa Chapter7Documento49 pagineIfsa Chapter7Noor SalmanNessuna valutazione finora

- Chicken Curry IngredientsDocumento2 pagineChicken Curry Ingredientsvikram_007Nessuna valutazione finora

- Sem 5Documento18 pagineSem 5Chiranjibi SahooNessuna valutazione finora

- Manufacturing Execution System - MESDocumento276 pagineManufacturing Execution System - MESDexter100% (5)

- Role of CPS in Manufacturing: Workshop "Platforms For Connected Factories of The Future"Documento18 pagineRole of CPS in Manufacturing: Workshop "Platforms For Connected Factories of The Future"vikram_007Nessuna valutazione finora

- Dahe FastenersDocumento22 pagineDahe FastenersNguyễn Văn BanNessuna valutazione finora

- Steelmaking - Electric Arc FurnaceDocumento19 pagineSteelmaking - Electric Arc FurnaceVikrant GuptaNessuna valutazione finora

- Pietro Lombardo: Curriculum VitaeDocumento3 paginePietro Lombardo: Curriculum Vitaevikram_007Nessuna valutazione finora

- Savings 2016Documento2 pagineSavings 2016vikram_007Nessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Best Tours in ItalyDocumento52 pagineThe Best Tours in Italyvikram_007Nessuna valutazione finora

- Career Planning - Industrial View (Noon, Rolls Royce, 2011)Documento19 pagineCareer Planning - Industrial View (Noon, Rolls Royce, 2011)arnauNessuna valutazione finora

- AA Master Key System Design GuideDocumento20 pagineAA Master Key System Design GuidepalosotNessuna valutazione finora

- Advt - 12 - 16 - JWM MechDocumento46 pagineAdvt - 12 - 16 - JWM MechAnkit SrivastavaNessuna valutazione finora

- AA Master Key System Design GuideDocumento20 pagineAA Master Key System Design GuidepalosotNessuna valutazione finora

- PagesDocumento91 paginePagesvikram_007Nessuna valutazione finora

- Management Engineering - Study PlanDocumento12 pagineManagement Engineering - Study Planvikram_007Nessuna valutazione finora

- Cover Letter InternshipDocumento1 paginaCover Letter InternshiptiashbdNessuna valutazione finora

- 69 04Documento11 pagine69 04vikram_007Nessuna valutazione finora

- Biography As Form of Life Narrative-1Documento25 pagineBiography As Form of Life Narrative-1vikram_007Nessuna valutazione finora

- PHD Student CV For Rolls RoyceDocumento2 paginePHD Student CV For Rolls Roycevikram_007Nessuna valutazione finora

- Steelmaking - Electric Arc FurnaceDocumento19 pagineSteelmaking - Electric Arc FurnaceVikrant GuptaNessuna valutazione finora

- HandS Hydraulics Safety AwarenessDocumento39 pagineHandS Hydraulics Safety Awarenessvikram_007100% (1)

- Iso GD&TDocumento39 pagineIso GD&TSanjay Kumar SinghNessuna valutazione finora

- Sardar PatelDocumento39 pagineSardar Patelvikram_007Nessuna valutazione finora

- TimeTable MeterologistDocumento13 pagineTimeTable Meterologistvikram_007Nessuna valutazione finora

- Maurice Nicoll The Mark PDFDocumento4 pagineMaurice Nicoll The Mark PDFErwin KroonNessuna valutazione finora

- Transeals Identifying Hydraulic SealsDocumento28 pagineTranseals Identifying Hydraulic Sealsvikram_007Nessuna valutazione finora

- ELSGS04DDocumento1 paginaELSGS04DJhonny RinconesNessuna valutazione finora

- Audi A4 No. 41 / 1Documento23 pagineAudi A4 No. 41 / 1Martins JansonsNessuna valutazione finora

- E20s HAP50 - Manual HAP PDFDocumento144 pagineE20s HAP50 - Manual HAP PDFAnonymous XhkjXCxxsT100% (1)

- Chennai CMBT Metro Station AIC Access Audit ReportDocumento44 pagineChennai CMBT Metro Station AIC Access Audit ReportDisability Rights AllianceNessuna valutazione finora

- AmerFrame - RenuFrame AFP 1 113F NewDocumento2 pagineAmerFrame - RenuFrame AFP 1 113F NewChuy CantúNessuna valutazione finora

- Tender For Carrying Out Construction of Compound W Tender Notice 22486835 HPCL UttaranchalDocumento5 pagineTender For Carrying Out Construction of Compound W Tender Notice 22486835 HPCL UttaranchalVeena NageshNessuna valutazione finora

- Pow 17J00012Documento41 paginePow 17J00012amroussyNessuna valutazione finora

- Sika PDS - E - Sika Padding MortarDocumento2 pagineSika PDS - E - Sika Padding Mortarlwin_oo2435Nessuna valutazione finora

- Duplex & Super Duplex Intermetallic PhasesDocumento3 pagineDuplex & Super Duplex Intermetallic Phasesemperor_vamsiNessuna valutazione finora

- (Cementitious) Stocrete 4222Documento2 pagine(Cementitious) Stocrete 4222ginasuhandiniNessuna valutazione finora

- Albasia-Glugu As A Structural Glued Laminated TimberDocumento5 pagineAlbasia-Glugu As A Structural Glued Laminated TimberFakhri MuhammadNessuna valutazione finora

- PIP 1 - Guide To Specifying Pervious ConcreteDocumento4 paginePIP 1 - Guide To Specifying Pervious ConcretemirzaNessuna valutazione finora

- Marine Air Systems ManualDocumento32 pagineMarine Air Systems ManualKyaw MyoNessuna valutazione finora

- Reference List 1983-1995Documento23 pagineReference List 1983-1995Đi Để ĐếnNessuna valutazione finora

- Iot Based Real Time Early Age Concrete Compressive Strength MonitoringDocumento6 pagineIot Based Real Time Early Age Concrete Compressive Strength MonitoringKhizra SarwarNessuna valutazione finora

- Consolidation Settlement Examples 3 - Solutions (2) - 2Documento6 pagineConsolidation Settlement Examples 3 - Solutions (2) - 2Sujani MaarasingheNessuna valutazione finora

- Fixotec Technical CatalogueDocumento71 pagineFixotec Technical CatalogueSaqib AliNessuna valutazione finora

- For Tender: Staircase 5, 6 and 7 Section ArchitectureDocumento1 paginaFor Tender: Staircase 5, 6 and 7 Section ArchitectureJinxian XuNessuna valutazione finora

- BS 476-23-1987 Fire Tests On Building Materials and StructuresDocumento24 pagineBS 476-23-1987 Fire Tests On Building Materials and Structuresbatara2007Nessuna valutazione finora

- Chapter 3 PDFDocumento64 pagineChapter 3 PDFMuhammad Asyraf Bin RusliNessuna valutazione finora

- Masonry Design Examples To BS5628Documento11 pagineMasonry Design Examples To BS5628mys85100% (3)

- 30RB 21siDocumento76 pagine30RB 21sixavierxo50% (2)

- Statement of Requirements For Roof ProjectDocumento2 pagineStatement of Requirements For Roof ProjectJun OrtizNessuna valutazione finora

- RICS NRM Slide PDFDocumento33 pagineRICS NRM Slide PDFlengyianchua206100% (2)

- AVANTI Product Catalogue 2014 EnglishDocumento36 pagineAVANTI Product Catalogue 2014 EnglishArouna GoudiabyNessuna valutazione finora

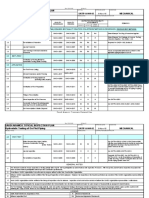

- Saudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingDocumento10 pagineSaudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingAhdal NoushadNessuna valutazione finora

- This Part Describes Preliminary and Basic Services Which An Architect Will Normally ProvideDocumento9 pagineThis Part Describes Preliminary and Basic Services Which An Architect Will Normally ProvidedodsmNessuna valutazione finora

- 9999999999999999FAQs About Mechanical Splices - ETN-M-4-14 PDFDocumento8 pagine9999999999999999FAQs About Mechanical Splices - ETN-M-4-14 PDFSeahorseNessuna valutazione finora

- Tender For Construction of Reinforced Concrete Trapezoidal Drain in Palm Loop PDFDocumento37 pagineTender For Construction of Reinforced Concrete Trapezoidal Drain in Palm Loop PDFabdirahmanNessuna valutazione finora