Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Physical and Mechanical Characteristics of Rubber-Bitumen Compounds

Caricato da

Perkresht PawarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Physical and Mechanical Characteristics of Rubber-Bitumen Compounds

Caricato da

Perkresht PawarCopyright:

Formati disponibili

Chemical and Materials Engineering 1(4): 105-110, 2013 DOI: 10.13189/cme.2013.

010401

http://www.hrpub.org

Physical and Mechanical Characteristics of Rubber-Bitumen Compounds

Ye. Tileuberdi1,2, Ye.K. Ongarbaev1,2,*, Z.A. Mansurov1,2, B.K. Tuleutaev2, E.A. Akkazyn1

2 1 Al-Farabi Kazakh National University, 71 al-Farabi av., 050039, Almaty, Kazakhstan Institute of Combustion Problems, 172 Bogenbai Batyr St., 050012, Almaty, Kazakhstan *Corresponding Author: Erdos.ongarbaev@kaznu.kz

Copyright 2013 Horizon Research Publishing All rights reserved.

Abstract In the paper physical and mechanical characteristics of Rubber-Bitumen Compounds (RBC) on based rubber crumb (RC) from worn tires were investigated. At experiment the standard petroleum bitumen BND 60/90 modified with rubber crumb. The spent engine oil was used as additional modifying agent. Images of Scaning Electron Microscopy (SEM) showed that the RC is very low pores heterogeneous material. Physical and mechanical characteristics of rubber modified bitumen with engine oil (R:O=1:1 and R:O=3:2) corresponds to grade of paving rubber-bitumen compounds RBC 60/90, RBC 90/130 and RBC 130/200. Keywords Bitumen, Tire, Rubber Crumb, Rubber-Bitumen Compounds, Penetration, Softening Point, Penetration Index

1. Introduction

Well known, petroleum products play an important role in economic development of any nation. Including the bitumen industry takes 2.6 % on refining. Bitumen is a mixture of organic liquids that is viscous, black and sticky. It is a complex mixture of high boiling point range of compounds and molecules with a relatively low hydrogen-to-carbon ratio. In the United States the terms asphalt and bitumen are synonymous, while in other areas, e.g. in Europe and Asia, both terms have different meanings [1-4]. Petroleum bitumen widely used in many industries, including road building constructions. Main problem with road building is the poor quality of bitumens used in asphalt-concrete pavements. One of the ways to improve the quality of the binders is their modification with polymers and rubber crumb [5, 6]. The utilization of spent rubber materials, for example, automobile tires, is currently one of the most important environmental problems on a global scale because of the rapid growth of the automobile industry [7, 8]. Crumb rubber is a term usually applied to recycled rubber from automotive and truck scrap tires. During the recycling

process steel and fluff is removed leaving tire rubber with a granular consistency. Worn or spent tires are valuable secondary raw materials containing 6570% rubber, 1525% technical-grade carbon, and 1015% high-quality metal [8, 9]. Researchers have been offered variety ways of recycling and utilization of rubber crumb from worn tires. A well known method is to burn the rubber waste to produce energy while producing cement [10] and RC is often used in astroturf as cushioning, where it is sometimes referred to as astro-dirt. RC was used to remove ethylbenzene, toluene and xylene from aqueous solutions at room temperature [11]. Rubber crumb also goes into the manufacturing of several auto parts and manufacturing new tires. A revolutionary nanotechnology process developed by the British group Dena Technology is gearing up worldwide to produce high quality building material as wood-replacement products from used tires. Also uses to paper-replacement materials are investigating [12]. Cut tires are used for the manufacture of drainage tubes, tapes for the protection of cables and pipelines, and soundproof walls along highways and for the protection of downslopes from erosion; Thermal methods for the secondary use of scrap tires are known, in particular, the combustion of tires to generate energy and pyrolysis under conditions of relatively low temperatures to produce light distillate, solid fuel, and metal. In addition, the following technologies are available: the processing of tires to obtain rubber crumbs and powders for the manufacture of polymer mixtures and construction materials and the production of reclaim for the manufacture of rubber mixtures and asphalt-rubber compositions for insulating and roofing materials [13, 14]. In the paper [15] reported that the blending time and temperature required to interact the crumb rubber with an asphalt binder is dependent on many factors including the chemistry of the asphalt binder and the crumb rubber as well as the particle size and texture of the crumb rubber and the amount of the crumb rubber. Crumb rubber modified bitumen can improve the heat-resistance, the crack-resistance at low temperature and the durability of bitumen. Asphalt concrete prepared with Rubber-Bitumen

106

Physical and Mechanical Characteristics of Rubber-Bitumen Compounds

Compounds exhibits high performance, enhanced wear and heat resistance, and resistance to aging. As a result, the pavement quality grows, and its service life becomes a factor of 1.5 - 2 longer [5, 16-19]. R.Z. Shakhnazarli et. al [20] examined the properties of bitumen compounds prepared with secondary polyethylene, polyamide fiber waster and CR as filler. The complex modifier of asphalt concrete KMA [21] and UNIREM [22] were found. In our work, aim of improving the physical and mechanical characteristics of rubber modified bitumen were examined spent engine oil as additional modifying agent. At experiment RBC samples were prepared with rubber crumb and with rubber-oil mixture. RBC was produced in the laboratory using four percentages of RC (3; 5; 7; 10 % by compound weight). Rubber-oil mixtures were prepared by mixing spent engine oil into rubber crumb with a ratio at 5:6, 1:1 and 3:2. After a day it used for preparing rubber-bitumen compounds. Bitumen samples were heated at 160-170 and variety content of rubber-oil mixtures (10; 15; 20; 25 wt.%) were added in bitumen. The compound were stirred for 5 minutes at 165-180 .

Figure 1. Apparatus Penetrometer

2. Experimental Materials and Methods

2.1. Materials At work were used standard paving bitumen BND 60/90 (from Ltd. Asphaltobeton-1 in Almaty, Kazakhstan); Rubber crumb from spent tires (from Kazakhstan Rubber Recycling LLP (in Astana, Kazakhstan)) which have two different particle sizes: one type of the rubber crumb is activated, particle size less than 0.6mm. The other one type is no activated, which particle size between 0.6mm and 1mm; Spent engine oil from Car service in Almaty city. 2.2. Physical and Mechanical Testing Methods The properties of bitumen were described by physical tests. Usually, consistency or some combination of consistency with other basic properties is measured. Testing and the control of properties through specifications are important in any discourse on bitumen [3, 4, 19]. The most commonly used standardized tests were covered in this paper. Penetration involves the determination of the extent to which a standard needle penetrates a properly prepared sample of bitumen under specified conditions of temperature, load, and time. The unit of penetration is 0.1 mm, which is generally omitted in favor of reporting just the measured number. It was determined by a apparatus Penetrometer PNB-03 (Figure 1) in accordance with standard 11501-78. For the analyses the bitumen sample cup was placed in a water bath at a temperature of 25 0C for 1 hour and determined by a standard needle penetration depth when the load of 100 g for 5 sec. At standard BND 60/90 means a standard paving grade bitumen with a penetration range between 61 and 90 0.1 mm.

Softening temperature - the temperature at which the bitumen of a relatively solid state into the liquid state. The softening point was determined by the method of "ring and ball" according to standard 11506-73. It is a measure of the temperature at which a steel ball passes through a disk of the sample and falls a distance of 25.0 mm when the specimen, ball, and bath of distilled water were heated on a hot plate at a rate of 5C per minute. The penetration index characterizes the degree of penetration of colloidal bitumen or rejection of his status from a purely viscous. It is determined by the following empirical formula:

Where,

PI = 1+50A 10 A=

2.9031 log P SP 25

30

(1)

(2)

where PI - penetration index, P - penetration at 25 C, 0.1 mm, SP - softening point, C. The Ductility test gives a measure of adhesive property of bitumen and its ability to stretch. Tensile properties were determined at apparatus Ductilometer CDB-974N (Figure 2) according to standard 11505-75. Ductility of a bituminous material is a measure of the distance in centimeters that it elongates before breaking when the two ends of a briquet specimen are pulled apart at a specified rate and temperature. Water bath was maintained within 0 C or 25 0.1 C of the specified test temperature.

Figure 2. Apparatus Ductilometer

Chemical and Materials Engineering 1(4): 105-110, 2013

107

3. Results and Discussion

3.1. Characteristics of Base Bitumen Physical and mechanical characteristics of petroleum bitumen BND 60/90 were determined according to standard 22245-90. It is presenting in table 1. The standard bitumen BND 60/90 have been using on the road construction in Almaty city. 3.2. SEM Analyses of Rubber Crumb The microstructures and microanalysis of rubber crumb were investigated with a Scaning Electron Microscopy (SEM) (Quanta 3D 200i) at an accelerated voltage of 20 kV and pressure at 0.003 Pa. Prepared by National Nanotechnological Laboratory Open Type of Kazakh National University. SEM images (figure 3) showed that the crumb rubber has variety of morphological structures. It was determined, RC is very low pores heterogeneous material.

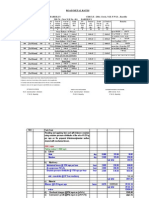

Table 1. Characteristics of base bitumen Characteristics Penetration, at 25 C Penetration, at 0 C Softening point Ductility, at 25 C Penetration index Changing SP after heating Results 78 17 47 96 -0.9 4 Units 0.1 mm 0.1 mm C cm C

mechanical characteristics were poor indicator, because of lower extensibility. Ductility of rubber modified products was between 7 cm and 11 cm. In fact, all of the samples were close to standard or mismatch standard requirements of the rubber-bitumen compounds. The dispersion degree and the swelling capacity of crumb rubber in the bitumen have an important effect on improving properties of bitumen. The swelling of crumb rubber in bitumen is the process that light components in bitumen, such as saturated component, aromatic component, permeate into the crumb rubber. Obviously, the swelling can promote the formation of the elastic network of crumb rubber modified bitumen. So the better the swelling of bitumen to crumb rubber, the better the properties of crumb rubber modified bitumen [6, 17-18].

3.3. Activated Rubber Crumb Modified Bitumen At first we tested only rubber crumb modified bitumen, which was heated at 1605 and 3-10 weight percentage of activated crumb rubber were added in to bitumen. It was prepared by stirring for 5 min at 170-180 . But, results of analyses showed that the samples on the physical and

Figure 3. SEM images of rubber crumb

Table 2. Physical and mechanical characteristics of rubber-bitumen compounds with activated rubber crumb Names of indicators Penetration at 25C, 0.1mm Softening point, C Ductility at 25C, cm Penetration index Changing of SP after heated, C Standard accordance Rubber-oil ratio R:O=1:1 R:O=3:2 R:O=1:1 R:O=3:2 R:O=1:1 R:O=3:2 R:O=1:1 R:O=3:2 R:O=1:1 R:O=3:2 R:O=1:1 R:O=3:2 Rubber-oil percentage in bitumen 10 wt% 90 75 51 58 25 19 0.6 1.7 5 4 RBC 60/90 15 wt% 127 130 46 47 19 31 0.3 0.7 5 5 20 wt% 126 109 50 55 26,5 17 1.5 2.2 5 5 RBC 90/130 RBC 90/130 25 wt% 170 150 48 46 22 25 2.2 0.9 5 6 RBC 130/200 RBC 130/200 Methods of testing According to standard 11501 According to standard 11506 According to standard 11505 By empirical formula According to standard 18180 According to R RK 218-76-2008

108

Physical and Mechanical Characteristics of Rubber-Bitumen Compounds

Table 3. Physical and mechanical characteristics of rubber-bitumen compounds with no activated rubber crumb Names of indicators Penetration at 25C, 0.1mm Softening point, C Ductility at 25C, cm Penetration index Changing of SP after heated, C Standard accordance Rubber-oil ratio R:O=1:1 R:O=3:2 R:O=1:1 R:O=3:2 R:O=1:1 R:O=3:2 R:O=1:1 R:O=3:2 R:O=1:1 R:O=3:2 R:O=1:1 R:O=3:2 Rubber-oil percentage in bitumen 10 wt% 67 87 50 53 12 17 -0.5 1.0 4 4 RBC 60/90 15 wt% 71 160 59 45 13.5 20 1.8 0.9 4 6 RBC 60/90 RBC 130/200 20 wt% 90 195 51 45 12.5 18 0.6 1.8 5 6 RBC 130/200 25 wt% 91 108 58 52 11.5 13 2.3 1.5 5 5 Method of testing According to standard 11501 According to standard 11506 According to standard 11505 By empirical formula According to standard 18180 According to R RK 218-76-2008

At experiment the spent engine oil was used as additional modifying agent. Standard accordance of rubber modified bitumen was determined according to Recommendation on the application of crumb rubber in road construction R RK 218-76-2008. Physical and mechanical characteristics of rubber-bitumen compounds with activated rubber crumb and spent engine oil (rubber:engine oil=1:1 and rubber:engine oil=3:2) are given in table 2. As shown on table 2, physical and mechanical characteristics of RBC with 20 wt.% rubber-oil (R:O=1:1) corresponds to grade of paving rubber-bitumen compounds RBC 90/130 and 25 wt.% rubber-oil modified sample is according to standard RBC 130/200. The table showing physical and mechanical characteristics of RBC with 10 wt.% rubber-oil (R:O=3:2) corresponds to grade of paving rubber-bitumen compounds RBC 60/90. Then RBC with 20 wt.% rubber-oil added sample according to standard RBC 90/130 and 25 wt.% rubber-oil modified bitumen corresponds to grade of paving rubber-bitumen compounds RBC 130/200. Whereas the 15 wt.% modified sample mismatch any standard of RBC. 3.4. No Activated Rubber Crumb Modified Bitumen No activated rubber crumb modified bitumen was investigated same method and same experimental conditions with activated rubber-crumb modified samples. There are kindred phenomena, too: poor indicators, lower extensibility. Prepared samples were mismatch standard requirements of the rubber-bitumen compounds. Physical and mechanical characteristics of rubber-bitumen compounds with no activated rubber crumb and spent engine oil (rubber:engine oil=1:1 and rubber:engine oil=3:2) are given in table 3. When we use no activated rubber crumb (06-1) in ratio R:O=1:1 only one composition is a according to standard RBC 60/90. This is the 15 wt.% rubber-oil modified sample, which is showing in table 3.

As seen from the table that the sample of RBC added 10 wt. % rubber-oil (R:O=1:1) mixtures are according to standard RBC 60/90, with 15 wt. % and with 20 wt. % rubber-oil modified bitumen correspond to grade of paving rubber-bitumen compounds RBC 130/200. Table 2 and table 3 showed, all the changing of softening temperature after heated results are according to standard requirements, which not more than 5 and 6 C. Penetration index are normal, too. Thus, all the tabulated results are allows knowing in ratio 3:2 rubber-oil mixture modified bitumen better than ratio of 1:1. 3.5. Comparisons Characteristics of RBC The resulting rubber-bitumen compounds exhibit elasticity, increased softening point, decreased brittle point, and enhanced strength. These properties allow RBCs to be used both as binders for asphalt concretes and as mastics for pavement repair. Physical and mechanical characteristics of prepared rubber-bitumen compounds were compared. Dependence of depth of needle penetration on the rubber-oil content of RBCs is showing in figure 4.

Figure 4. Dependence of penetration on the rubber-oil content of RBC, Rubber-oil ratio: 1 1:2, 2 2:3, 3 1:1, 4 3:2

Chemical and Materials Engineering 1(4): 105-110, 2013

109

Figure 4 presents, with increasing content of rubber-oil mixture from 5 wt. % to 25 wt. % in bitumen, the penetration of rubber-bitumen compounds were increased. Otherwise softening point of RBC isnt more changing in any content of rubber-oil mixture. Dependence of ductility on the rubber-oil content of rubber-bitumen compounds is presenting at figure 5. It was shown that the ductility of RBC are decreasing depended to increase content of rubber-oil mixture in bitumen. This is due to the action of rubber particles as stress concentrators. It means the viscosity of bitumen compounds increased and starts to harden. These bitumen composition functions as a liquid or pseudo-thermoplastic matrix, the rubber particles provide resilient power frame in the amount of binder.

spent engine oil were investigated experimentally. Scanning Electron Microscopy analyzes showed that crumb rubber has variety of morphological structures. It was determined, the RC is very low pores heterogeneous material. Standard accordance of rubber modified bitumen was determined according to Recommendation on the application of crumb rubber in road construction R RK 218-76-2008. It is established that the quantity of entered binders depending on physical and chemical conditions, which was optimal composition of rubber-oil at a ratio of 1:1 and 3:2 and introduction to bitumen in amount of 15-25 wt.%. On the physical and mechanical characteristics of rubber modified bitumen with engine oil (R:O=1:1 and R:O=3:2) correspond to grade of paving rubber-bitumen compounds RBC 60/90, RBC 90/130 and RBC 130/200. Adding of rubber crumb and modifier to bitumen were improved characteristics of prepared samples. At that time, rubber crumb and spent engine oil use to road construction will allow decrease environmental pollution with industrial wastes.

REFERENCES

[1] Songhun Yoon, Sharad Durgashanker Bhatt, Wonkyu Lee, Heung Yeoun Lee, Soon YongJeong, Jin-Ook Baeg, and Chul Wee Le. Separation and characterization of bitumen from Athabasca oil sand, Korean Journal of Chemical Engineering, Vol. 26, No. 1, 64-71, 2009. Mansurov Z.A., Ongarbaev E.K., Tuleutaev B.K., Utilization of Oil Wastes for Production of Road-building materials, Eurasian Chemico-Technological Journal, Vol. 2, No. 2, 161-166, 2000. E.K. Ongarbaev, Z.A. Mansurov. Oil Wastes and Methods of utilization them, Kazakh University, Almaty, 2003. Asphalt and bitumen. Encyclopedia of chemistry (Ullmanns), Vol. 4, 273-294. DOI: 10.1002/14356007.a03_169.pub2 D.G. Shunin, A.G. Filippova, N.A. Okhotina, A.G. Liakumovich, and Ya.D. Samuilov. Possibilities of Production and Use of Rubber-Bitumen Compounds, Russian Journal of Applied Chemistry, Vol. 75, No. 6, 1020-1023, 2002. Ongarbaev Ye., Doszhanov E.O., Mansurov Z.A. Processing heavy oil, oil residue and waste products, Kazakh University, Almaty, 2011. E.E. Gorlova, B.K. Nefedov, E.G. Gorlov, and A.A. Olgin. Reprocessing of Industrial Rubber Waste in a Mixture with Shale, Solid Fuel Chemistry, Vol. 42, No. 2, 9394, 2008. Crumb rubber. Recycled pavement material, Online available from http://en.wikipedia.org E.E. Gorlova, B.K. Nefedov, and E.G. Gorlov. Manufacture of an AsphaltRubber Binder for Road Pavements by the Thermolysis of Tire Chips with Heavy Petroleum Residues, Solid Fuel Chemistry, Vol. 43, No. 4, 224228, 2009.

Figure 5. Dependence of ductility on the rubber-oil content of RBC, Rubber-oil ratio: 1 1:2, 2 2:3, 3 1:1, 4 3:2

The properties of crumb rubber modified bitumens, including the RC and crumb rubber with spent engine oil in ratio 1:1, are summarized in Table 4. By comparison, the properties of modified bitumen with the rubber-oil mixture are best, because of it is according to standard mark RBC 90/130. Its penetration and ductility are the highest, while softening point decrease. And RC modified bitumen due to poor extensibility (7 cm) were mismatch standard requirements of the rubber-bitumen compounds. It can be describe elasticity properties of engine oil for preparing modified bitumen on based rubber crumb.

Table 4. Properties Comparison of activated Crumb Rubber Modified Bitumens Kind of modifier Base bitumen Rubber crumb, 10 wt.% Rubber-oil mixture, 20 wt.% Penetration, .1mm 78 52 126 Softening point, 47 57 50 Ductility, cm 96 7 26,5

[2]

[3] [4] [5]

[6]

[7]

[8] [9]

4. Conclusion

In the study physical and mechanical characteristics of rubber-bitumen compounds on based spent rubber items and

[10] Mareike Hess, Harald Geisler, and Robert H. Schuster.

110

Physical and Mechanical Characteristics of Rubber-Bitumen Compounds

Devulcanization as an opportunity to recycle rubber, Chem. Listy 103, s1s148, PMA 2009 & 20th SRC 2009, 58-60, 2009. [11] L.A. Alamo-Nole, F. Roman and O. Perales-Perez. Sorption of Ethylbenzene, Toluene and Xylene onto Crumb Rubber from Aqueous Solutions, Online available from http://www.nsti.org [12] Tyre and rubber recycling, http://www.dena.co.uk Online available from

No.1, 83-85, 2003. [17] Austruy F., Tileuberdi Ye., Ongarbaev Ye., Mansurov Z. Study of Production of Rubber-Bitumen Compounds, Eurasian Chemico-Technological Journal, Vol. 14, No. 2, 133-138, 2012. [18] Tileuberdi Ye., Kozbakarova S., Ongarbaev Ye., Tuleutaev B., Mansurov Z. Use of rubber crumb for preparation asphalt-concrete, KazNU bulletin, chemical series, Vol. 65, 1, 196-199, 2012. [19] AO Ying, CAO Rongji. Interaction Theory of Asphalt and Rubber. Journal of Wuhan University of TechnologyMaterial Science Edition, Oct. 853-855, 2010. [20] R.Z. Shakhnazarli, N. Ya. Ishchenko, Kh, G. Nazaraliev, B.A. Mamedov, A.M. Guliev. Polymer-Bitumen Compounds with Crumb Rubber, Secondary Polyethylene, and Polyamide Fiber Waste, Russian Journal of Applied Chemistry, Vol. 82, No. 7, 1310-1313, 2009. [21] The complex modifier of asphalt concrete KMA koltech, Online available from http://koltech-stroy.ru [22] UNIREM, Online available from http://ru.wikipedia.org

[13] Artificialturf, Online available from http://www.ct.gov [14] Waste Tire Disposal, http://www.state.tn.us Online available from

[15] Kyu-Dong Jeong, Soon-Jae Lee, Serji N. Amirkhanian, Kwang W. Kim. Interaction effects of crumb rubber modified asphalt binders, Construction and Building Materials, Vol. 24, 824831, 2010. [16] YE Zhi-gang, KONG Xiang ming, YU Jian-ying, WEI Lian-qi. Microstructure and Properties of Desulfurized Crumb Rubber Modified Bitumen, Journal of Wuhan University of Technology-Material Science Edition, Vol.18,

Potrebbero piacerti anche

- BLY BOQ FDR 2013-14 EstimatesDocumento3 pagineBLY BOQ FDR 2013-14 EstimatesPerkresht PawarNessuna valutazione finora

- Office MaintenanceDocumento19 pagineOffice MaintenancePerkresht PawarNessuna valutazione finora

- Letter For TRDocumento6 pagineLetter For TRPerkresht PawarNessuna valutazione finora

- 210741571.xls - Ms - Office BOQ FDR 2013-14 ROIDocumento2 pagine210741571.xls - Ms - Office BOQ FDR 2013-14 ROIPerkresht PawarNessuna valutazione finora

- Maintenance & EstimateDocumento40 pagineMaintenance & EstimatePerkresht PawarNessuna valutazione finora

- EPC Workshop ProgrammeDocumento2 pagineEPC Workshop ProgrammePerkresht PawarNessuna valutazione finora

- Maintenance KM 295.00 To 304.00 of NH-74Documento33 pagineMaintenance KM 295.00 To 304.00 of NH-74Perkresht PawarNessuna valutazione finora

- Maintenance KM 295.00 To 304.00 of NH-74Documento15 pagineMaintenance KM 295.00 To 304.00 of NH-74Perkresht PawarNessuna valutazione finora

- Bareily NHD PWDDocumento1 paginaBareily NHD PWDPerkresht PawarNessuna valutazione finora

- GO Supply OrderDocumento2 pagineGO Supply OrderPerkresht PawarNessuna valutazione finora

- Certified Rates for Road WorkDocumento1 paginaCertified Rates for Road WorkPerkresht PawarNessuna valutazione finora

- Maintenance Work KM 264.000 To 274.000 of NH-74Documento16 pagineMaintenance Work KM 264.000 To 274.000 of NH-74Perkresht PawarNessuna valutazione finora

- Bar Binder Upto31jan.09Documento4 pagineBar Binder Upto31jan.09Perkresht PawarNessuna valutazione finora

- Compaction control field testing methodsDocumento11 pagineCompaction control field testing methodsRaj BakhtaniNessuna valutazione finora

- InstructionsDocumento1 paginaInstructionsPerkresht PawarNessuna valutazione finora

- Is List For Plastic PipesDocumento4 pagineIs List For Plastic PipesSunil Devdutt ThakoreNessuna valutazione finora

- Par ShantDocumento1 paginaPar ShantPerkresht PawarNessuna valutazione finora

- Handy Android Scanner App ReviewDocumento1 paginaHandy Android Scanner App ReviewPerkresht PawarNessuna valutazione finora

- 1081Documento34 pagine1081dnageshm4n244Nessuna valutazione finora

- Beam Deflection FormulaeDocumento2 pagineBeam Deflection Formulae7575757575100% (6)

- Is List For Plastic PipesDocumento4 pagineIs List For Plastic PipesSunil Devdutt ThakoreNessuna valutazione finora

- Analysis For BuildingDocumento51 pagineAnalysis For BuildingPerkresht PawarNessuna valutazione finora

- Is List For Plastic PipesDocumento4 pagineIs List For Plastic PipesSunil Devdutt ThakoreNessuna valutazione finora

- Sector 16CDocumento87 pagineSector 16CPerkresht PawarNessuna valutazione finora

- EWS Housing Bar-ChartDocumento2 pagineEWS Housing Bar-ChartPerkresht PawarNessuna valutazione finora

- Sftn6 Ye (T Uttar Pradesii T Ak) 4 4 0 9 5: 'Y,: (''' ','' L': R ExecuranrDocumento1 paginaSftn6 Ye (T Uttar Pradesii T Ak) 4 4 0 9 5: 'Y,: (''' ','' L': R ExecuranrPerkresht PawarNessuna valutazione finora

- Construction Contract Details for AGffiNESES 3ruEDocumento4 pagineConstruction Contract Details for AGffiNESES 3ruEPerkresht PawarNessuna valutazione finora

- 2nd Floor, Krishna Complex, Main Nithari Road, Sector-31, Noida Tel: (95-120) 3259880, 3259881, 9818435888Documento1 pagina2nd Floor, Krishna Complex, Main Nithari Road, Sector-31, Noida Tel: (95-120) 3259880, 3259881, 9818435888Perkresht PawarNessuna valutazione finora

- Concrete Mix Design Comparison Between BIS and ACIDocumento7 pagineConcrete Mix Design Comparison Between BIS and ACIPraveen JainNessuna valutazione finora

- CIVIL ENGINEERING MANUAL UPDATEDocumento0 pagineCIVIL ENGINEERING MANUAL UPDATEAshokan KelothNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Groundwater and Surfacewater Connection2Documento20 pagineGroundwater and Surfacewater Connection2Dang AnNessuna valutazione finora

- Physics QuizDocumento24 paginePhysics QuiznyshahidaNessuna valutazione finora

- The mystery of missing Rashis in Vedic textsDocumento36 pagineThe mystery of missing Rashis in Vedic textsSampathKumarGodavarthiNessuna valutazione finora

- ATM BANKING MANAGEMENT SYSTEM USING JAVADocumento24 pagineATM BANKING MANAGEMENT SYSTEM USING JAVAVivek SinghNessuna valutazione finora

- FC50 User Guide 0521Documento90 pagineFC50 User Guide 0521PedroMiguelCamizanVillegasNessuna valutazione finora

- The Impact Message Inventory - Circumplex (IMI-C) Manual: Manual, Instrument, Scoring Guide, and WorksheetsDocumento105 pagineThe Impact Message Inventory - Circumplex (IMI-C) Manual: Manual, Instrument, Scoring Guide, and WorksheetsElmckNessuna valutazione finora

- 2022 10GMA VCE GENERAL MATHS U2 VECTORS SAC FEEDBACK FINAL MERGED - Part16JackDocumento4 pagine2022 10GMA VCE GENERAL MATHS U2 VECTORS SAC FEEDBACK FINAL MERGED - Part16JackjackNessuna valutazione finora

- 6 Pulse ConverterDocumento19 pagine6 Pulse Converterfalu_2964% (11)

- V Model SE PDFDocumento38 pagineV Model SE PDFduy nguyễn lê thếNessuna valutazione finora

- The Set School Computer Worksheet Topic: Flowchart Name: - Class:VII DateDocumento6 pagineThe Set School Computer Worksheet Topic: Flowchart Name: - Class:VII DateAisha Anwar0% (1)

- E5 SteeringunitDocumento57 pagineE5 SteeringunitSam JacobNessuna valutazione finora

- 10-100kVA ATLAS3000 USER MANUAL-UpdatedDocumento37 pagine10-100kVA ATLAS3000 USER MANUAL-UpdatedAlwyn GeorgeNessuna valutazione finora

- MSDS Isobutane EUDocumento4 pagineMSDS Isobutane EUmrnickmrnickNessuna valutazione finora

- IS 6934 1998 RecoDocumento13 pagineIS 6934 1998 RecoJan BakosNessuna valutazione finora

- Logic Game (41st) - Easter - For Elementary Ss - With Key - Fully Editable - B&WDocumento3 pagineLogic Game (41st) - Easter - For Elementary Ss - With Key - Fully Editable - B&WpersonnaliteviagensevistosNessuna valutazione finora

- IT03344 Circuits ACCP AnswersDocumento6 pagineIT03344 Circuits ACCP Answerswebdog77Nessuna valutazione finora

- Ashrae 2009 - Climatic Design InformationDocumento17 pagineAshrae 2009 - Climatic Design InformationJack SparrowNessuna valutazione finora

- Maxwell Equations Rewritten in Differential Forms and Clifford AlgebraDocumento8 pagineMaxwell Equations Rewritten in Differential Forms and Clifford AlgebraJames ChapelNessuna valutazione finora

- Study Copper Complex Colour Changes LigandsDocumento6 pagineStudy Copper Complex Colour Changes LigandsNazrizal Fitri100% (1)

- Standard Method For Making and Curing Cubes Made From Pre-Bagged Grouts and Polymer Modified Mortars PDFDocumento7 pagineStandard Method For Making and Curing Cubes Made From Pre-Bagged Grouts and Polymer Modified Mortars PDFVCNessuna valutazione finora

- Probability Problems Worked Examples Step-by-StepDocumento6 pagineProbability Problems Worked Examples Step-by-StepNET TECHNessuna valutazione finora

- Adding fingering to notes with the Tin Whistle pluginDocumento3 pagineAdding fingering to notes with the Tin Whistle pluginwadwadNessuna valutazione finora

- 2.AIX For System Administrators - LVDocumento9 pagine2.AIX For System Administrators - LVjpeg144Nessuna valutazione finora

- Chisquare GonzalesDocumento32 pagineChisquare GonzalesJ-Roe ArdemilNessuna valutazione finora

- PhA 067 - Cleary - Aristotle and Mathematics - Aporetic Method in Cosmology and Metaphysics 1995 PDFDocumento597 paginePhA 067 - Cleary - Aristotle and Mathematics - Aporetic Method in Cosmology and Metaphysics 1995 PDFPhilosophvs AntiqvvsNessuna valutazione finora

- Transpiration POGIL Answer KeyDocumento8 pagineTranspiration POGIL Answer KeyJade Tapper50% (2)

- Chapter 4 Introduction To Probability - Jaggia4e - PPTDocumento105 pagineChapter 4 Introduction To Probability - Jaggia4e - PPTpeter shlomoNessuna valutazione finora

- Marginal Cost1Documento7 pagineMarginal Cost1Randy KempNessuna valutazione finora

- CMOS Digital Integrated Circuits Analysis and Design 4th Edition Kang Solutions Manual 1Documento24 pagineCMOS Digital Integrated Circuits Analysis and Design 4th Edition Kang Solutions Manual 1james100% (36)