Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Dimensiuni Canale Pana

Caricato da

cristi_amaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Dimensiuni Canale Pana

Caricato da

cristi_amaCopyright:

Formati disponibili

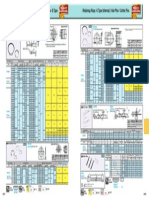

Engineering Data

Mounting Requirements

For all overrunning clutch inner races

connected to shaft by a key, our standard bore tolerance is H7, with keyway

to JS10.

As with standard bearings, suitable

tooling must be used for press fitting

such that no axial load is transmitted

through the inner part of the clutch

during assembly.

(Metric keyseat dimensions listed on page 123.)

b

Shaft and bore tolerances are specified

on the pages for each type where press

fitting is appropriate.

t2

Metric Key assemblies

t1

Press fit assemblies

We recommend a shaft tolerance of h6

or j6. For maximum indexing accuracy,

adjusted keys should be machined to

give no clearance.

Mounting Examples

Non-supported models

FS-50

AS

RSCI

FSR

GFR

Bearing supported models

RSBW

F1

F2

F5

F6

Combined bearing/clutch models

CSK

RL

FSO

126 ________________________________________________ Warner Electric/Formsprag (800-927-3262) www.formsprag.com

Engineering Data

Mounting Requirements

Metric Keyseat Dimensions

DIN 6885.1 (mm)

t1

Bore size (mm)

bJS 10

6 8.0

8.1 10.0

2 0,020

3 0,020

2

3

1,2 + 0,1

1,8 + 0,1

1 + 0,3

1,4 + 0,3

0,024

0,024

0,024

0,029

0,029

0,035

0,035

0,035

0,035

4

5

6

7

8

8

9

10

11

2,5

3

3,5

4

5

5

5,5

6

7

1,8

2,3

2,8

3,3

3,3

3,3

3,8

4,3

4,4

65.1 75.0

75.1 85.0

85.1 95.0

20 0,042

22 0,042

25 0,042

12

14

14

7,5 + 0,2

9 + 0,2

9 + 0,2

95.1 110.0

110.1 130.0

130.1 150.0

28 0,042

32 0,050

36 0,050

16

18

20

10 + 0,2

11 + 0,3

12 + 0,3

10.1

12.1

17.1

22.1

30.1

38.1

44.1

50.1

58.1

12.0

17.0

22.0

30.0

38.0

44.0

50.0

58.0

65.0

4

5

6

8

10

12

14

16

18

t2

+ 0,1

+ 0,1

+ 0,1

+ 0,2

+ 0,2

+ 0,2

+ 0,2

+ 0,2

+ 0,2

bJS 10

+ 0,3

+ 0,3

+ 0,3

+ 0,4

+ 0,4

+ 0,4

+ 0,4

+ 0,4

+ 0,4

5

6

8

10

12

14

16

18

DIN 6885.3 (mm)

t1

+ 0,1

+ 0,1

+ 0,1

+ 0,2

+ 0,2

+ 0,2

+ 0,2

+ 0,2

t2

0,024

0,024

0,029

0,029

0,035

0,035

0,035

0,035

3

4

5

6

6

6

7

7

1,9

2,5

3,1

3,7

3,9

4

4,7

4,8

1,2

1,6

2

2,4

2,2

2,1

2,4

2,3

+ 0,3

+ 0,3

+ 0,3

+ 0,3

+ 0,3

+ 0,3

+ 0,3

+ 0,3

4,9 + 0,4

5,4 + 0,4

5,4 + 0,4

20 0,042

22 0,042

25 0,042

8

9

9

5,4 + 0,2

6 + 0,2

6,2 + 0,2

2,7 + 0,3

3,1 + 0,4

2,9 + 0,4

6,4 + 0,4

7,4 + 0,4

8,4 + 0,4

28 0,042

32 0,050

36 0,050

10

11

12

6,9 + 0,2

7,6 + 0,2

8,3 + 0,2

3,2 + 0,4

3,5 + 0,4

3,8 + 0,4

Deviation

h5

upper

lower

0

-.004

0

- .005

0

-.006

0

- .008

0

- .009

0

- .011

0

- .013

0

- .015

0

- .018

0

- .020

h6

upper

lower

0

-.006

0

- .008

0

-.009

0

- .011

0

- .012

0

- .016

0

- .019

0

- .022

0

- .025

0

- .029

h7

upper

lower

0

-.007

0

- .012

0

-.015

0

- .018

0

- .021

0

- .025

0

- .030

0

- .035

0

- .040

0

- .045

j6

upper

lower

+.004

-.002

+ .006

- .002

+.007

-.002

+ .008

- .003

+ .009

- .004

+ .011

- .005

+ .012

- .007

+ .013

- .009

+ .014

- .011

+ .016

- .013

k6

upper

lower

-.006

0

+ .009

+ .001

+.010

+.001

+ .012

+ .001

+ .015

+ .002

+ .018

+ .002

+ .021

+ .002

+ .025

+ .003

+ .028

+ .003

+ .033

+ .004

n6

upper

lower

+.010

+.004

+ .016

+ .008

+.019

+.010

+ .023

+ .012

+ .028

+ .015

+ .033

+ .017

+ .039

+ .020

+ .045

+ .023

+ .052

+ .027

+ .060

+ .031

p5

upper

lower

+.010

+.006

+ .017

+ .012

+.021

+.015

+ .026

+ .018

+ .031

+ .022

+ .037

+ .026

+ .045

+ .032

+ .052

+ .037

+ .061

+ .043

+ .070

+ .050

p6

upper

lower

+.012

+.008

+ .020

+ .012

+.024

+.015

+ .029

+ .018

+ .035

+ .022

+ .042

+ .026

+ .051

+ .032

+ .059

+ .037

+ .068

+ .043

+ .079

+ .050

p7

upper

lower

+.018

+.008

+ .024

+ .012

+.030

+.015

+ .036

+ .018

+ .043

+ .022

+ .051

+ .026

+ .062

+ .032

+ .072

+ .037

+ .083

+ .043

+ .096

+ .050

r6

upper

lower

+.016

+.010

+ .023

+ .015

+.028

+.019

+ .034

+ .023

+ .041

+ .028

+ .050

+ .034

Nominal Shaft Dimension in mm

Tolerance Dimension in mm

over over

3

6

incl. incl.

6

10

over

10

incl.

18

over

18

incl.

30

over

30

40

incl. incl.

40

50

Nominal Hole/Bore Dimension in mm

Deviation

ISO tolerance

limits for

holes/bores

1

incl.

3

Tolerance zone

ISO tolerance

limits for shafts

Tolerance zone

Note: For key assemblies on outer race (models GFRN, ALP, RIZN) the outer member bore should be to H7 tolerance.

over

3

incl.

6

over

6

incl.

10

over

10

incl.

18

over

18

incl.

30

over

30

40

incl. incl.

40

50

over

50

65

incl. incl.

65

80

+.060

+.041

80

incl.

100

+.062

+.043

over

100

incl.

120

+.073

+.051

+.076

+.054

120

incl.

140

+.088

+.063

140

incl.

160

+.090

+.065

160

incl.

180

+.093

+.068

180

incl.

200

200 225

incl. incl.

225 250

+.113

+.084

+.106

+.077

+.109

+.080

225

incl.

250

over

250 280

incl. incl.

280 315

Tolerance Dimension in mm

over

50

65

incl. incl

65

80

over

80

100

.incl .incl.

100 120

120

incl.

140

over

140

incl.

160

160

incl.

180

180

incl.

200

over

200

incl.

225

H6

upper + .008 + .009 + .011 + .013

lower

0

0

0

0

+ .016

0

+ .019

0

+ .022

0

+ .025

0

+ .029

0

+ .032

0

H7

upper + .012 + .015 + .018 + .021

lower

.00

0

0

0

+ .025

0

+ .030

0

+ .035

0

+ .040

0

+ .046

0

+ .052

0

H11

upper + .075 + .090 + .110 + .130

lower

.00

0

0

0

+ .160

0

+ .190

0

+ .220

0

+ .250

0

+ .290

0

+ .320

0

K6

upper + .002 + .002 + .002 + .002

lower - .006 - .007 - .009 - .011

+ .003

- .013

+ .004

- .015

+ .004

- .018

+ .004

- .021

+ .005

- .024

+ .005

- .027

N6

upper - .005

lower - .013

- .007

- .016

- .009

- .020

- .011

- .024

- .012

- .028

- .014

- .033

- .016

- .038

- .020

- .045

- .022

- .051

- .025

- .057

P6

upper - .009

lower - .017

- .012

- .021

- .015

- .026

- .016

- .031

- .021

- .037

- .026

- .045

- .030

- .052

- .036

- .061

- .041

- .070

- .047

- .079

R6

upper - .012

lower - .020

- .015

- .025

- .020

- .031

-.024

- .037

- .029

- .045

- .035

- .054

-.037

-.056

-.044

-.066

-.047

-.069

-.056

-.081

-.058

-.083

-.061

-.086

-.068

-.097

- .071

- .100

- .075

- .104

-.085

-.117

-.089

-.121

R7

upper - .011

lower - .023

- .013

- .026

- .016

- .034

- .020

- .041

- .025

- .050

- .030

- .060

-.032

-.062

-.038

-.073

-.041

-.076

-.048

-.088

-.050

-.090

-.053

-.093

- .060

- .106

-.063

- .109

- .067

- .113

- .074

- .126

- .078

- .130

Warner Electric/Formsprag (800-927-3262) www.formsprag.com ________________________________________________ 127

Potrebbero piacerti anche

- CS Series Operation Manual PDFDocumento70 pagineCS Series Operation Manual PDFDArio Mainini60% (10)

- Rotork ActuatorsDocumento10 pagineRotork Actuatorsthavaselvan80% (5)

- Vietnam Market Insight: Q4 2019 in VNDDocumento16 pagineVietnam Market Insight: Q4 2019 in VNDTuan Nguyen100% (1)

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocumento350 pagineCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- Metric Thread Gages Standard Pitch Diameter Chart: Gage Assembly CompanyDocumento1 paginaMetric Thread Gages Standard Pitch Diameter Chart: Gage Assembly CompanyAnandh VairakkannuNessuna valutazione finora

- Milling Systems CatalogDocumento593 pagineMilling Systems CatalogStoia BogdanNessuna valutazione finora

- Oral Notes Rupesh PillaiDocumento172 pagineOral Notes Rupesh PillaiRachit100% (4)

- Chip BreakersDocumento38 pagineChip BreakersrosmarinanordinNessuna valutazione finora

- Checklist B MV Underground Cable Systems - Cable TrenchingDocumento3 pagineChecklist B MV Underground Cable Systems - Cable Trenchingsasikala100% (1)

- Power Stream Couplings-Specn SheetsDocumento6 paginePower Stream Couplings-Specn SheetsAmol PatkiNessuna valutazione finora

- Fits & TolerancesDocumento6 pagineFits & Tolerancessuperman92makNessuna valutazione finora

- Catalog HRC Jaw CouplingsDocumento8 pagineCatalog HRC Jaw CouplingsMadan Yadav100% (1)

- SKF BRG ClearenceDocumento6 pagineSKF BRG ClearenceNath Boyapati100% (2)

- OUTPUTbeaDocumento449 pagineOUTPUTbeaDaniel BritoNessuna valutazione finora

- Boring Bar ManualDocumento41 pagineBoring Bar ManualPranjal Chakraborty100% (1)

- FST Technical Manual 2015 Sec04 O-Rings and Static SealsDocumento51 pagineFST Technical Manual 2015 Sec04 O-Rings and Static SealsSuresh Kumar Mittapalli100% (1)

- RD Reflex TolerancesDocumento10 pagineRD Reflex TolerancesJonathan LynchNessuna valutazione finora

- Maintenance Arpex enDocumento39 pagineMaintenance Arpex enPatrick BaridonNessuna valutazione finora

- Assembly ManualDocumento36 pagineAssembly ManualOscar SalazarNessuna valutazione finora

- Manual de Operacion y Mantenimiento HSM-Shaft Manual (Ing) PDFDocumento16 pagineManual de Operacion y Mantenimiento HSM-Shaft Manual (Ing) PDFJorge A VilalNessuna valutazione finora

- FITTING OPERATION and MAINTENANCE - Flexible Unit PWM SeriesDocumento9 pagineFITTING OPERATION and MAINTENANCE - Flexible Unit PWM SeriesDênis DáyolNessuna valutazione finora

- CDP AT FINGER PIER - StudyDocumento25 pagineCDP AT FINGER PIER - Studyd_mazieroNessuna valutazione finora

- Assignment - 05Documento19 pagineAssignment - 05Harun Ar RashidNessuna valutazione finora

- Ser 200 IMDocumento5 pagineSer 200 IMshadialameddinNessuna valutazione finora

- 23Documento30 pagine23stringstrangeNessuna valutazione finora

- 140k Motor Grader Jpa00001-Up (Machine) Powered by c7 Engine (Sebp5013 - 65) - Systems & ComponentsDocumento16 pagine140k Motor Grader Jpa00001-Up (Machine) Powered by c7 Engine (Sebp5013 - 65) - Systems & ComponentsJimmy Morales GonzalesNessuna valutazione finora

- CDP AT FINGER PIER - StudyDocumento25 pagineCDP AT FINGER PIER - Studyd_mazieroNessuna valutazione finora

- Gimbal Mirror Mounts (300mm 5208Documento2 pagineGimbal Mirror Mounts (300mm 5208kirancallsNessuna valutazione finora

- Rexnord Elastomer CouplingDocumento20 pagineRexnord Elastomer Couplingidontlikeebooks100% (1)

- Adjustable Machine Feet From GMTDocumento2 pagineAdjustable Machine Feet From GMTGMT Rubber-Metal-TechnicNessuna valutazione finora

- Elasticna Spojnica LitostrojDocumento8 pagineElasticna Spojnica LitostrojDudás ÁrpádNessuna valutazione finora

- Shimpo Able EVS BrochureDocumento4 pagineShimpo Able EVS BrochureElectromateNessuna valutazione finora

- Microswitches Subminiature v4ncDocumento4 pagineMicroswitches Subminiature v4ncAlecu ElenaNessuna valutazione finora

- Man Ten C I On Shaft MountedDocumento15 pagineMan Ten C I On Shaft Mountedemuno008Nessuna valutazione finora

- RMA Tolerances CRS 2014Documento2 pagineRMA Tolerances CRS 2014Pelatihan TerusNessuna valutazione finora

- Backing BearingsDocumento8 pagineBacking BearingsJurun_BidanshiNessuna valutazione finora

- Sheet Metal FastenersDocumento15 pagineSheet Metal FastenersSudath KularathnaNessuna valutazione finora

- Tabla de Ajustes, Aplicaciones y ComportamientosDocumento2 pagineTabla de Ajustes, Aplicaciones y ComportamientosabacciadNessuna valutazione finora

- BevelDocumento4 pagineBevelDennis OmilaNessuna valutazione finora

- ASLI 02 Supply Air Grilles Set - AIR ConditioningDocumento21 pagineASLI 02 Supply Air Grilles Set - AIR ConditioningAminul Hassan50% (2)

- Seguros R - Hairpin Cotter Pin p2017Documento1 paginaSeguros R - Hairpin Cotter Pin p2017MAZM17Nessuna valutazione finora

- Installation, Operation and Maintenance InstallationDocumento15 pagineInstallation, Operation and Maintenance InstallationMuralikrishna ArigondaNessuna valutazione finora

- How To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincDocumento15 pagineHow To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincAndré BuysNessuna valutazione finora

- BIG Daishowa Profit Maker ToolsDocumento40 pagineBIG Daishowa Profit Maker Toolsgeav25653855Nessuna valutazione finora

- Technical Data Products 2009 CompletDocumento62 pagineTechnical Data Products 2009 CompletRobert NedelcuNessuna valutazione finora

- 2 Supply - Air - Grilles Set Catalogue PDFDocumento21 pagine2 Supply - Air - Grilles Set Catalogue PDFmunim87Nessuna valutazione finora

- Elastomeric Bearing Pads and Strips Brochure 2010Documento4 pagineElastomeric Bearing Pads and Strips Brochure 2010Anton Husen PurboyoNessuna valutazione finora

- Assembly TECHLOK 3 Fold English v3 2013Documento2 pagineAssembly TECHLOK 3 Fold English v3 2013Chup AlaNessuna valutazione finora

- Keyway ChartDocumento3 pagineKeyway Chartcharles_boyle_350% (2)

- Geometrical TolerancingDocumento12 pagineGeometrical TolerancingItalo Venegas100% (1)

- SMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesDocumento5 pagineSMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesVictor NoschangNessuna valutazione finora

- Dynamic Spine Calculator Rev 7-18-10Documento20 pagineDynamic Spine Calculator Rev 7-18-10Dominique Ayn BarlarNessuna valutazione finora

- Shimpo Able VRS BrochureDocumento4 pagineShimpo Able VRS BrochureElectromateNessuna valutazione finora

- VirgoDocumento8 pagineVirgorohitalurkarNessuna valutazione finora

- PM-0002-0011 Manual de Chancado - 419 - 501Documento83 paginePM-0002-0011 Manual de Chancado - 419 - 501Christian SantillanNessuna valutazione finora

- TYCO Keystone F14.Lined - Butterfly.valve enDocumento4 pagineTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuNessuna valutazione finora

- Downhole MotorsDocumento31 pagineDownhole MotorsRFVNessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDa EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyValutazione: 5 su 5 stelle5/5 (1)

- IBM System 360 RPG Debugging Template and Keypunch CardDa EverandIBM System 360 RPG Debugging Template and Keypunch CardNessuna valutazione finora

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsDa EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsValutazione: 5 su 5 stelle5/5 (1)

- Concrete Block Egglayer EB12 - 10 OctDocumento12 pagineConcrete Block Egglayer EB12 - 10 Octcristi_amaNessuna valutazione finora

- Hydraulic Proportional Servo TechnologiesDocumento37 pagineHydraulic Proportional Servo Technologiescristi_amaNessuna valutazione finora

- Reteta PaveleDocumento6 pagineReteta Pavelecristi_amaNessuna valutazione finora

- Garden Paving StonesDocumento5 pagineGarden Paving Stonescristi_amaNessuna valutazione finora

- ATOS-Instr. Punere FCTDocumento4 pagineATOS-Instr. Punere FCTcristi_amaNessuna valutazione finora

- Concrete Bricks BlocksDocumento6 pagineConcrete Bricks BlocksSalim ShNessuna valutazione finora

- Concrete Block MakerDocumento3 pagineConcrete Block MakervbezuglyNessuna valutazione finora

- Overcenter ValvesDocumento4 pagineOvercenter ValvesAnonymous jSTkQVC27b100% (1)

- 10 Metode de Marire Viteza Instalatii HidrauliceDocumento4 pagine10 Metode de Marire Viteza Instalatii Hidraulicecristi_amaNessuna valutazione finora

- Example Quality PlanDocumento12 pagineExample Quality PlanZunair ShahidNessuna valutazione finora

- Hydraulic Cylinder TroubleshootingDocumento8 pagineHydraulic Cylinder Troubleshootingcristi_ama100% (1)

- Numatics Valve TrainingDocumento57 pagineNumatics Valve TrainingRaymond EsmeraldaNessuna valutazione finora

- Improving Performance of An Energy Efficient Hydraulic Circuit PDFDocumento175 pagineImproving Performance of An Energy Efficient Hydraulic Circuit PDFIjabiNessuna valutazione finora

- Hydraulic SymbolsDocumento1 paginaHydraulic Symbolsshaken56Nessuna valutazione finora

- SPECTRO Mobile Metal Analyzers enDocumento6 pagineSPECTRO Mobile Metal Analyzers enMahmoud FathyNessuna valutazione finora

- SPECTRO iSORT 0412 Engl LowresDocumento4 pagineSPECTRO iSORT 0412 Engl Lowrescristi_amaNessuna valutazione finora

- Unionocel Big-New enDocumento24 pagineUnionocel Big-New encristi_amaNessuna valutazione finora

- Accumulator CircuitsDocumento2 pagineAccumulator Circuitscristi_amaNessuna valutazione finora

- Ec 0411Documento7 pagineEc 0411cristi_amaNessuna valutazione finora

- Komatsu WA320 5Documento7 pagineKomatsu WA320 5cristi_ama100% (2)

- Understanding Schematics: (Return To Table of Contents) 123Documento15 pagineUnderstanding Schematics: (Return To Table of Contents) 123bmrajahNessuna valutazione finora

- CounterbalanceDocumento5 pagineCounterbalancecristi_amaNessuna valutazione finora

- Ceed Mazda3 C4Documento4 pagineCeed Mazda3 C4cristi_amaNessuna valutazione finora

- Gasm İngilizceDocumento84 pagineGasm İngilizceozveoz100% (2)

- A-320 - Fire Proofing of Steel StructureDocumento11 pagineA-320 - Fire Proofing of Steel StructurePoorvi Bhave75% (4)

- Undisturbed Soil SampleDocumento4 pagineUndisturbed Soil SampleDissasekaraNessuna valutazione finora

- KP Traffic LawsDocumento11 pagineKP Traffic LawsAbhishek BoseNessuna valutazione finora

- MS For Installation - Hypochlorination 23.10.07 HamdyDocumento8 pagineMS For Installation - Hypochlorination 23.10.07 HamdyunnicyriacNessuna valutazione finora

- Modified Division 15 Written ReportDocumento17 pagineModified Division 15 Written ReportJaymar Palomares OrilloNessuna valutazione finora

- The IncotermsDocumento3 pagineThe IncotermsVrinda GuptaNessuna valutazione finora

- Axxessor SSV10 Store Support VehicleDocumento12 pagineAxxessor SSV10 Store Support VehicleForklift Systems IncorporatedNessuna valutazione finora

- Doosan Heavy Industries Vietnam Haipong CoDocumento42 pagineDoosan Heavy Industries Vietnam Haipong CoUhrinImreNessuna valutazione finora

- IrcDocumento9 pagineIrcAshwani KesharwaniNessuna valutazione finora

- Seminar On Underground and Underwater TunnellingDocumento9 pagineSeminar On Underground and Underwater Tunnellingrahulmahajan1437519Nessuna valutazione finora

- BoqDocumento30 pagineBoqPrashant Singh Chauhan100% (1)

- Project Schedule ExampleDocumento1 paginaProject Schedule Examplegman444100% (1)

- ASLI 03 Return Air Grilles SetDocumento23 pagineASLI 03 Return Air Grilles SetAminul HassanNessuna valutazione finora

- Thread Cutting Tools For WoodDocumento23 pagineThread Cutting Tools For WoodGermanHundNessuna valutazione finora

- A Comparative Study of Levi's & ProvogueDocumento17 pagineA Comparative Study of Levi's & Provoguepiyush.blue9301Nessuna valutazione finora

- Gap Analysis ReportDocumento17 pagineGap Analysis ReportVageesha Shantha Veerabhadra SwamyNessuna valutazione finora

- HiPosMicro UOMT INNO 7850629 PDFDocumento1 paginaHiPosMicro UOMT INNO 7850629 PDFDado OgameNessuna valutazione finora

- Ultratech TDS Leaflet - FixoblockDocumento1 paginaUltratech TDS Leaflet - FixoblockRabish ANessuna valutazione finora

- User Manual 5E EMEA.889Documento8 pagineUser Manual 5E EMEA.889SemaccaLHNessuna valutazione finora

- MCQ TransportationDocumento4 pagineMCQ Transportationbam zeppeleinNessuna valutazione finora

- Revenue Cycle ManagementDocumento12 pagineRevenue Cycle ManagementJarjitha ANessuna valutazione finora

- RMG AbbreviationsDocumento3 pagineRMG AbbreviationsFarabbi AdittoNessuna valutazione finora

- Brooklyn Fact SheetDocumento2 pagineBrooklyn Fact SheetskiftnewsNessuna valutazione finora

- Elco Catalog 072011Documento48 pagineElco Catalog 072011Jonathan DouglasNessuna valutazione finora