Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Crumb Rubber Modifier

Caricato da

Perkresht PawarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Crumb Rubber Modifier

Caricato da

Perkresht PawarCopyright:

Formati disponibili

Crumb Rubber Modifier (CRM)

Advantages:

Easy to use Cost effective compatible with bitumen Increase softening point of your product Easy storage stable and no hazard to health No other additive required (Except bitumen) Resist degradation of bitumen at mixing temperature Maintain coating viscosity at application temperature It is capable to processed by conventional mixing and laying machine Maintain premium properties during storage, application and in service

Percentage of CRM for quality CRMB:

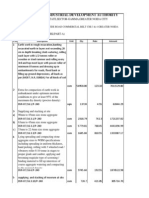

S.No I II III

Grades of CRMB CRMB 50 CRMB 55 CRMB 60

% of CRM with VG 10 8% 10 % 12 %

% of CRM with VG 30 6% 8% 10 %

Use Crumb Rubber Modifier according to above mentioned for Quality Crumb Rubber Modified Bitumen at different ratio for different grade. For example for 1 Ton ( One ton) CRMB 60 with Bitumen VG 10 it is required to have (880 Kg. Bitumen + 120 Kg. CRM Superfine [ 12% of CRMB Quantity]).

standard and qualitative.

Advantages: Easy to use Cost effective compatible with bitumen Increase softening point of your product Easy storage stable and no hazard to health No other additive required (Except bitumen) Resist degradation of bitumen at mixing temperature Maintain coating viscosity at application temperature It is capable to processed by conventional mixing and laying machine Maintain premium properties during storage, application and in service Percentage of CRM for quality CRMB: S.No I II III Grades of CRMB CRMB 50 CRMB 55 CRMB 60 % of CRM with VG 10 8% 10 % 12 % % of CRM with VG 30 6% 8% 10 %

Use Crumb Rubber Modifier according to above mentioned for Quality Crumb Rubber Modified Bitumen at different ratio for different grade. For example for 1 Ton ( One ton) CRMB 60 with Bitumen VG 10 it is required to have (880 Kg. Bitumen + 120 Kg. CRM Superfine [ 12% of CRMB Quantity]). The particles are sized and classified based on various Mesh size: 20 Mesh 30 Mesh 40 Mesh 60 Mesh 80 Mesh Features: Dimensional accuracy Longevity Customizable Durability High quality

Specifications: Ash content: 7.5 % Maximum Retention: Nil Moisture: 1 % Maximum Carbon: 20 % Minimum RHC content: 30 % Minimum

A Review on the Effect of Crumb Rubber Addition to the Rheology of Crumb Rubber Modified Bitumen

Mohd Rasdan Ibrahim,1 Herda Yati Katman,1,2 Mohamed Rehan Karim,1 Suhana Koting,1 and Nuha S. Mashaan1

1 2

Centre for Transportation Research, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia Universiti Tenaga Nasional, Putrajaya Campus, Jalan Ikram-Uniten, 43000 Kajang, Selangor, Malaysia

Received 31 May 2013; Accepted 11 September 2013 Academic Editor: John W. Gillespie Copyright 2013 Mohd Rasdan Ibrahim et al. This is an open access article distributed under theCreative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. Abstract Crumb rubber modification has been proven to enhance the properties of pure bitumen. This paper looks at some of the international standards for producing crumb rubber modified bitumen (CRMB) and reviews the effect of crumb rubber to the rheology of crumb rubber modified bitumen. The review shows that the rheology of CRMB depends on internal factors such as crumb rubber quantity, particle size, and pure bitumen composition, and external factors such as the mixing time, temperature, and also the modification technique. These factors govern the swelling process of crumb rubber particles that lead to the increase of viscosity of the modified bitumen. However, the mixing temperature and duration can cause rubber particles to depolymerize and subsequently cause loss of viscosity. Crumb rubber modification also improves the properties of bitumen by increasing the storage and loss modulus and enhancing the high and low temperature susceptibility. The effect of crumb rubber to aging properties of CRMB is also discussed. Finally several techniques of chemical modification to terminal blends of CRMB and the subsequent improvement to the settling property of CRMB are explained. 1. Introduction Crumb rubber from waste tyres has been used in pavement construction since the 1930s. The usage has currently increased due the potential it offers in improving the performance of the asphaltic mixes and the potential solution in reducing waste tyres in landfills. Rubber crumbs can be mixed with aggregates within the asphaltic mix (dry process) or blended in bitumen at a specific temperature where rubber crumbs serves as a binder modifier (wet process). Crumb rubber modification by the wet process has been shown to have the ability to help improve the rutting resistance, resilience modulus, and fatigue cracking resistance of asphaltic mixes. This is due to the alteration to the property of the bituminous binder in terms of the viscosity, softening point, [1] loss modulus, and storage modulus [2]. The improvement is governed by the swelling process of rubber particles that interacted with bitumen. Rubber crumbs can swell up to 3 to 5 times its original size due to the absorption of maltenes component of the bitumen [3, 4]. This left a higher proportion of asphaltenes in the binder, therefore increasing its viscosity. The properties of crumb rubber modified bitumen (CRMB) is very sensitive and are highly governed by the mixing process which is dependent on external factors such as the mixing temperature, mixing duration, and type and internal factors such as type of bitumen, crumb rubber quantity, particle size, and type. Accurate selection of the processing variables is the key to successful CRMB production. Table 1 lists the key parameters in for preparing CRMB that are suggested by American Society of Testing Material (ASTM), California Department of Transportation (Caltrans), South African Bitumen Association (Sabita), and Association of Australian and New Zealand Road Transport and Traffic Authorities (Austroads) [5].

Table 1: Important parameters in manufacturing CRMB according to several specifications around the world (adopted from [5]). In recent developments, terminal blend CRMB has gained popularity due to a higher quality product [6,7]. Unlike conventional wet mix that creates gel-like rubber particles through swelling, terminal blend process uses high shear mechanism to completely depolmerize rubber particles, therefore achieving total digestion of crumb rubber into bitumen. Although the viscosity of such mix is reduced, total digestion of crumb rubber resolves the problem of crumb rubber settlement in CRMB. However, some researches argue that too much digestion can cause CRMB to lose its stiffening and elastic effect on the mix [8], thus eliminating the benefit of rubber modification. This paper reviews the effect of crumb rubber to the rheology of crumb rubber modified bitumen. The interaction between bitumen and crumb rubber and the factors governing the interaction process such the modification technique, mixing time, temperature, and crumb rubber characteristics are also being discussed along with the properties of the resulting CRMB. This is to give a comprehensive review on the effect of each factor to the property of the resulting crumb rubber modified bitumen. 2. External Factors The mixing temperature and duration of crumb rubber modified bitumen are very crucial and will affect the performance of the binder. Due to the unique and delicate interaction process and the number of parameters involved, it is important that the mixing process of bitumen with rubber is handled with extra precautions and care. For instance, coarser rubber particles and higher rubber concentrations would require a higher mixing temperature where a more stable binder against rubber segregation and settling can be achieved [6, 11]. However, rubber will be depolymerized and dispersed into the mix if the temperature is too high and the duration is too long [12]. Crumb rubber mesh size, curing time, temperature, and mixing rate are the factors that affect the rubber depolymerisation rate [13]. Table 2summarises the mixing parameters by some of Transportation Agencies in the United States and Canada.

Table 2: Mixing parameters used by several Transportation Agencies (adopted from [9]). The rate of swelling and the extent of swelling are highly dependent on the temperature of the interaction process. The rate of swelling increases when the temperature is increased; however, with the increase in temperature, the extent of swelling on the other hand decreases [14]. Lalwani et al. [15] reported that, at lower temperatures, the rubber-asphalt mix is nonhomogenous and has a higher viscosity; however, when the temperature is increased beyond 200C, depolymerisation occurs causing undesirable hardening of the binder. Depolymerisation process occurs slowly when the temperature is between 150C and 200C and proceeds rapidly

(within several hours) when the temperature is above 200C [16]. Viscosity increases continually at 150C and at 175C or 200C, and the viscosity initially increases rapidly, then reduces its pace, and subsequently decreases. At higher temperatures, (225C) the viscosity reaches a maximum value within 5min and decreases rapidly thereafter [17]. Shen and Amirkhanian [18] concluded that a mixing process for 15 minutes at 177C is adequate for 15% of rubber crumb addition sizing between 30 and 40 mesh size to fully interact with the binder. Jeong et al. [19] on the other hand concluded that, for a 10% crumb rubber mixture, a longer blending time up to 60 minutes and mixing temperature up to 177C can contribute to a higher failure temperature and viscosity of binder at 135C. However, while releasing harmful gases into the environment, longer mixing duration and higher mixing and storage temperature have been shown to cause a higher rubber particles size reduction which leads to depolymerisation and subsequently leads to loss in viscosity. In an attempt to balance performance and storage compatibility of crumb rubber modified bitumen, Attia and Abdelrahman [6] suggested the use of fine rubber crumb to produce terminal blends of CRM. This approach saves energy as only 8% of the total interaction time requires high temperature of 200C and lower temperature can be used for the storage period. Billiter et al. [7] also suggested that by increasing the mixing temperature, mixing time and shear rate can be reduced and this can in fact produce a homogenous and truly elastic terminal blend that have an enhanced performance. At higher temperatures, the viscosity of CRMB was found to increase quite dramatically. According to Jeong et al. [19] compared to binder that was mixed at 177C, at 200C the viscosity is 5% higher, and at 223C the viscosity increased 41%. With regards of the blending time, it was found that the viscosity of binder that was mixed for 5 minutes increases 11%, while at 480 minutes the viscosity increased to 46%. On the other hand, the failure temperature between binder mixed at 177C and 200C was found to be negligible. However, the failure temperature increased with blending time up to 60 minutes. Beyond the 60 minute period, the fail temperature was found not to be affected by blending time. Mixing type too can affect the properties of crumb rubber modified bitumen. Low temperature properties, for instance, were improved with high shear mixing, while low shear mixing improves medium and high temperature properties and its resistance to fatigue cracking [20]. Dynamic viscosity, however, is not affected by blending type [21]. For high shear mixing technique, to produce optimal results for softening point and penetration values for modified binder with less than 25% crumb rubber, Li et al. had suggested a shearing time of 40 min and a shearing temperature of 180C with a shearing rotational speed of 7000 rpm. High shear mixing will reduce the size of coarser rubber, thus speeding the interaction process. Storage stability and rubber particle dispersal can also be improved with high speed shear mixing. Attia and Abdelrahman [6] had proven that 88% (0.6% remaining from 5% rubber by the weight of bitumen) of the rubber particle can be digested by the end of the interaction process. The shape of the impeller, on the other hand, does not contribute to any changes to the rheology of binders [11]. Celauro et al. [22], however, mentioned that a low shear mixing can also produce the best performing CRMB provided that the base bitumen and crumb rubber are appropriately selected. 3. Internal Factor: Crumb Rubber Quantity and Type of Bitumen The addition of crumb rubber has been shown to increase the properties of the bitumen such as the softening point, penetration, and the viscosity in proportion of the amount of the rubber [10, 19, 23,24]. Table 3 shows the properties of AC-20 asphalt blended with up to 21% of 1.18mm whole tire crumb rubber size with mixing time of 90 minutes at 176C. Bitumen with higher viscosity will generally have a higher failure temperature and therefore have a longer service life due to higher temperature stability. Comparing crumb rubber addition of 10% and 20%, Jeong et al. [19] show that the 20% crumb rubber addition increased the viscosity by 550% and (stiffness) value by 225%. However, when subjected to Rolling Thin Film Oven test (RTFOT) which simulated short-term aging, it is found that the viscosity decreases with increasing rubber concentration [23]. This is probably due to higher rubber dissolution as demonstrated by Billiter et al. [7].

Table 3: Properties of crumb rubber modified bitumen (adopted from [10]). Apart from increasing the viscosity at high temperature, crumb rubber also contributes to a lower creep stiffness of the asphaltic mix which increases the low temperature cracking resistance of asphaltic pavement and lowering the aging index [2326]. Wang et al. [23] recommended 15% to 20% crumb rubber addition for a significant improvement in aging effects, creep stiffness, and economic factors. Shen and Amirkhanian [18] on the other hand showed that 10% of CRM addition increased the performance grade of bitumen from 64C to 70C and 15% CRM addition increased at least two high temperature performance grades from 64C to 76C. However, Khalid and Artamendi [27] highlight that an addition of crumb rubber of more than 10% would produce a binder that is too viscous for field mixing operations. Crumb rubber modified bitumen, however, can have storage problems due the settling of the rubber crumbs. Shearing the mix in high temperature until the rubber particles depolymerize is one of the options that can eliminate sedimentation problems and subsequently improve the properties of the bitumen if properly manufactured [6]. Very fine rubber particles (100 to 500 mesh) on the other hand have nonsettling properties when processed with high shear mixing. This can reduce the mixing time and temperature and therefore reduce depolymerisation and enhance aging resistance [25]. Cong et al. [28] showed that a high amount of rubber (e.g., 25%), with a high swelling rate and a high lightweight fraction bitumen can improve the storage stability of CRMB. This is due to the reduction of the nondissolved rubber particle, thus reducing the sedimentation trend of the rubber particles. Navarro et al. [29] on the other hand reported that crumb rubber modified bitumen is stable for particles that are sized 0.29mm or less. Crumb rubber from waste tyres typically contains several types of compounds such as synthetic rubber content, natural rubber content, total rubber hydrocarbon content, and acetone extractables [10]. This is due to the different proportion of natural rubber, synthetic rubber, and other components between truck tyres and passenger car tyres. For instance, truck tyres contain more natural rubber when compared to passenger cars (which is higher in synthetic rubber) and this can affect the interaction between bitumen and rubber particles. Higher dissolution of crumb rubber that contains a mixture of truck and passenger car tyres can improve the viscoelastic properties of bitumen, while higher dissolution of crumb rubber solely sourced from truck tyres does not enhance the properties of the modified binder [30]. Table 4shows the chemical composition of passenger car tire and truck tires [10]. Thodesen et al. [31], however, showed that CRMB produced using truck tire crumb poses the highest viscosity, and Cao and Bai [32] reported that crumb rubber that comes from truck tires gives a better performance in terms of a better fatigue resistance and high temperature performance.

Table 4: Chemical composition of various types of tires (adopted from [10]). The properties of pure bitumen used to produce CRMB also are very important to the quality of the modified binder. Softer bitumen with higher lightweight fraction gives a higher swelling rate to the rubber particles and thus displays a better high and low temperature properties compared to harder bitumen with the same amount of rubber modification [12, 28]. Stiffer bitumen will typically show better high temperature stiffness compared to CRMB produced with softer bitumen that have improved low temperature stiffness. Bitumen with a lower lightweight fraction will also produce CRMB that has lower viscosities and lesser degree of modification properties [10]. Ould Henia and Dumont [33] studied the effect of pure bitumen with different composition of saturates, aromatics, resin, and asphaltenes to the viscoelastic properties and the extent of crumb rubber swelling in CRMB. The study shows that aromatic oils perform as lubricant for asphaltenes, hence bitumen with higher aromatic content has a higher viscosity and displays a higher sensitivity to temperature than harder bitumen. The quantity of aromatics in the bitumen is also important to be determined prior to the mixing process in order to obtain the optimum amount of swelling in the rubber particles and subsequently ensuring the consistency of the physical properties of the mix. 4. Internal Factor: Crumb Rubber Type and Particle Size Crumb rubber sizes can be classified into four groups, which are coarse (9.5 mm and 6.3mm); medium size (1030 mesh or 2mm to 600m); fine (4080 mesh or 425m to 180m); and superfine (100200 mesh or 150 m to 75m) [34]. Similar to mixing time and temperature, crumb rubber mesh size is one of the important factors that govern the rubber depolymerization rate [35]. Finer crumb rubber will swell faster due to a larger specific area and therefore gives higher viscosities compared to coarser size. CRMB produced from fine rubber particles will also have a faster viscosity reduction in the heating process due to its faster swelling rate and thus a faster depolymerisation process. Sun and Li mentioned that the factors that influence the viscosity of CRMA according to their order of significance are crumb rubber content, mixing temperature, rubber particle size, and mixing time [17, 36]. Apart from its sizing, crumb rubber properties can also differ in terms of its microstructure. Several methods have been used to improve the microstructure of crumb rubber surface. Microwave irradiation of crumb rubber surface method cleft the surface of the vulcanization network, giving crumb rubber higher surface activity, and

therefore improves its viscoelastic nature and storage stability [37]. Shatanawi et al. [38] explore the possibility of using hot water to activate the surfaces of crumb rubber. This process removes light oil fractions in the crumb rubber particles, where it reduces segregation between rubber particles and binder, thus improving its compatibility. Although the process does improve the settling properties of CRMB, it does not improve the rheology of the binder. The difference in the crumb rubber surface microstructure can also differ due to the method the crumb rubber is manufactured. Rubber crumbs that are produced using the cryogenic method have angular, smooth, and cracked appearance, while crumbs that were produced using ambient grinding have a rather porous surface [18]. This gives the crumb rubber that was produced using the ambient grinding twice the amount of surface area when compared with its cryogenic counterpart [39]. Due to its larger surface area and subsequent swelling rate, ambient processed crumb rubber will generally give a better performance than its cryogenic counterpart [28]. CRMB produced from ambient crumb rubber gives a higher viscosity, complex modulus, and phase angle and thus gives better rutting resistance and higher elasticity [3942]. Porous surface of ambient crumb rubber assisted the absorption of higher light constituents from the asphalt, thus increasing its failure temperature regardless of the mixing time. Lee et al. [41] showed that CRM binders produced with ambient CRM also showed a better resistance on low temperature cracking than those with cryogenic CRM. Crumb rubber particle size also plays an important role in determining the outcome performance of CRMB. Smaller particle size produces modified bitumen that has higher viscosity, softening point, and resilience due to a higher surface area [17, 25, 43, 44] and aspect ratio [45]. Wang et al. [23] reported that finer crumb rubber attains higher viscosity at high temperature and lower creep stiffness at low temperature. Higher viscosity also leads to a better rutting resistance as shown by C. C. Wong and W.-g. Wong [46]. Cao and Bai [32] on the other hand showed that larger crumb rubber gives a better high temperature performance and similar low temperature cracking resistance between CRMB manufactured with smaller crumb rubber particle size. Similar results are demonstrated by Sebaaly et al. [26] where the authors mentioned that while crumb rubber size does not have a significant effect on the low temperature properties of bitumen, different combinations of crumb rubber size and content can either improve or jeopardize the low temperature performance grade of the CRMB. A separate design of optimum rubber content is therefore required for each crumb rubber size and bitumen grade to ensure a properly designed CRMB. Attia and Abdelrahman [6] and Navarro et al. [45] focused on a wide variety of crumb rubber sizes in their attempt to study the effect of crumb rubber particle size to the rheology of bitumen. Their study concluded that the incorporation of coarser rubber into bitumen increases the value [6] and subsequently increases the value of storage () and loss moduli () especially at low frequencies. However, according to Tayebali et al. [47], the coefficient of variance for the values obtained from samples modified with 40 mesh crumb rubber size is statistically in close approximate with the one modified with an 80 mesh crumb rubber. Liu et al. [36] also mentioned that there is no significant difference between basic performances of bitumen modified with different crumb rubber size. However, it is important to note that in this particular research, the crumb rubber sizes used are 60 mesh and 80 mesh size which is rather closely spaced. 5. Aging Properties of CRMB Binder aging is a process of oxidation and loss of lightweight constituents in bitumen that leads to hardening of the material. There are two types of aging, namely, short-term aging and long-term aging. Short-term aging occurs during the mixing period of aggregate and bitumen, while long-term aging occurs in a longer time period after the construction process. In the oxidation process, polar aromatics component of the bitumen is converted into asphaltenes, and this can be indicated by carbonyl formation [48] and resulted in a binder that has a higher viscosity. For this reason, it is important that the selection of pure bitumen to produce CRMB is done correctly since the short-term aging of CRMB manufactured using harder bitumen can create a binder that is too hard and cannot be used for paving applications [49]. Rubber addition can help to reduce the hardening rate and susceptibility of bitumen [4951]. Rubber also helps in lowering viscosity buildup with aging at low temperatures [52]. Gel permeation chromatography analysis shows that a higher proportion of crumb rubber (15% to 20%) in the bitumen contributes to the reduction of large molecular size value of the binder. This is due to the ejection of lighter constituents that were earlier absorbed by the rubber from the bitumen [53]. This helps in reducing the rate of asphaltenes formation, therefore slowing the aging process [51]. In order to further improve the aging characteristics of CRMB, Chipps et al. recommend the use of low-asphaltene bitumen processed with high-cure (terminal blend) CRMB with minimum rubber content of 10% [48]. Although hardening of asphalt cannot be avoided, there are ways that aged bitumen can be rejuvenated to its original properties with the help of rejuvenating agent [54] or other substance such as recycled waste cooking oil [55]. This technology has the potential to be an excellent solution in using recycled asphaltic pavement. 6. Chemical Modification of CRMB Chemical modification of CRMB aims to alter the typical chemical bonding between bitumen and rubber particles. This is typically achieved with terminal blending process enhanced with certain chemicals or activators. Kocevski et al. [56] use grafting process to improve the properties of CRMB. In this process, the surface of crumb rubber is modified by bulk polymerization of acrylic acid. This process also can increase the viscosity and failure temperature of the CRMB. Chemical modifications that generate free radicals on the surface of crumb rubber are used by the US Federal Highway Administration where better interactions with bitumen are achieved resulting in a homogenous CRMB mix, therefore improving storage stability of the mix [57]. Yadollahi and Sabbagh Mollahosseini [58] on the other hand uses polyphosphoric acid and an additive known as Vestenamer to achieve crosslinking between the sulphur elements in the asphaltenes and maltenes in the bitumen to produce macropolymer network. This produces a CRMB that has better elastic properties at high temperatures and lower creep stiffness at low temperatures. Shatanawi et al. [59] showed that storage stability of CRMB can be highly improved with the addition of furfural as an activation agent in the mix. Better storage stability is also achieved by Cheng et al. [60] that uses polymeric compatibilizer containing conjugated diene that reacts as a crosslinking agent. In addition to that, the CRMB produced also has an improved permanent deformation and thermal cracking resistance. 7. Conclusion Crumb rubber modifications of bitumen have been proven to improve characteristics of bituminous binder such as the viscosity, softening point, loss modulus, and storage modulus. This subsequently improves the rutting resistance, resilience, and improving fatigue cracking resistance of asphaltic mixes. In order to achieve a superior and balanced CRMB in term of high and low temperature properties, factors such as the mixing time, temperature, characteristics, and source of the crumb rubber and bitumen type must be considered since these are the factors that govern the resulting performance of asphaltic mixes. Aging mechanism of CRMB is also important to be considered in order that the resulting CRMB has a workable viscosity to be applied in the construction process. Finally, chemical modification of CRMB is a new area that has promising possibilities in the future to further enhance the properties of CRMB and at the same time eliminate rubber particle settling problem that is one of the limiting factor in the current application of crumb rubber modified bitumen. Conflict of Interests

mportant Asphalt Related Issues inIndia

American roads are good not because America is rich, but America is rich because American roads are good. John F. Kennedy

Never doubt that a small group of citizens can change the world. Indeed, it is the only thing that ever has.

Margaret Mead

There are several important asphalt-related issues in

India, which need to be addressed and/or implemented by the government, contractors and consultants to ensure durable asphalt pavements without

any premature distress and potholes. A detailed discussion of the following issues follows.

1. 2. 3. 4.

Why roads in India fail prematurely especially during monsoons? Potholes, potholes and more potholes in India how to repair them especially during monsoons? Why the NHAI is burying bitumen worth hundreds of crores rupees under national highways? Are we really getting viscosity graded (VG) paving bitumen in India?

5. 6. 7. 8.

Are we really getting quality modified paving bitumen in India? Do we need to add mineral filler in bituminous mixes? (Q and A) Applying tack coat over prime coat: fundamentally not necessary and is gross waste of Indias resources! Dire need for training in asphalt technology inIndia, where is the vision?

1. Why roads in India fail prematurely especially during monsoons?

If somebody asks the aam aadmi (common man) in India this question, the majority response would be: Indian highway engineers intentionally construct road in such a way so that it keeps on failing prematurely and they keep on getting fat budget for maintenance (pothole repair) and resurfacing year after year.

Whereas lack of quality control is a contributing factor, there is a major fundamental engineering problem which the Indian public does not know. Of some ten types of bituminous paving mixes used in India, seven are open graded (water-trapping) mixes. Examples: Bituminous Macadam (BM); Semi Dense Bituminous Concrete (SDBC); Dense Bituminous Macadam (DBM) Grading 1; Premix Carpet (PMC); and Mixed Seal Surfacing (MSS). The Built-Up Spray Grout (BUSG) is no different. The remaining three are dense graded (desirable) mixes. Examples are: Dense Bituminous Macadam (DBM) Grading 2; Bituminous Concrete (BC) Grading 1; and Bituminous Concrete (BC) Grading 2.

The water-trapping mixes also happen to be initially cheaper than the dense graded mixes and therefore are used commonly. (It does not matter if they generally last for 1-2 years compared to dense graded mixes which may last for 7-8 years. In other words, they are very expensive based on life cycle costs.) Water is enemy number one of bitumen. That is why, water-trapping mixes fail prematurely especially during monsoons. All across India, the deadly combination of BM and SDBC is being used brazenly. PMC is also used extensively.

Most developed countries in the world generally have three dense graded bituminous mixes in their specifications: one each for base course, binder course and wearing course. And they have good durable roads despite heavy rainfall sometimes throughout the year. It is simply amazing as to why Indian highway engineers need additional seven water-trapping, problematic bituminous mixes for road construction/resurfacing?

Obviously, some engineers are technically ignorant about the fundamental principle of highway engineering to keep the water away from bituminous mixes. Others keep on using these water-trapping bituminous mixes knowing fully well about their impending premature failure resulting in fat budgets for pothole repairs/resurfacing. This is despite the fact that two technical papers have been presented on this topic and discussed at the Indian Roads Congress (IRC) sessions after publication in IRC journals. These two papers give comprehensive, easy to read, technical, and economical justifications to ban the seven watertrapping mixes such as BM, SDBC and PMC. Interested Indian highway engineers can access and download these two IRC papers at the following links: Unfortunately, the continuation of these seven water-trapping bituminous mixes in MORTH and IRC specifications gives them undesirable technical legitimacy and excuse for continual use by highway engineers across India. Those responsible for these specifications should either (a) delete these undesirable bituminous mixes or (b) publish an IRC paper justifying the use of these seven mixes on technical grounds (rebutting one by one alltechnical and economical arguments advanced in the aforementioned two published IRC papers). Vague responses such as: these mixes are good for India; India cannot afford expensive mixes (although the cheap mixes may generally fail within 1-2 years and are really expensive based on life cycle costs); there are success stories (if 80% projects fail prematurely and 20% survive, the latter cannot be called success story); etc.; etc.

Based on past experience and recent deliberations (2012) of the IRC Flexible Pavement Committee, there is not much hope either of these two actions would occur in the near future. Therefore, it is up to young, rational highway engineers of India to challenge the old-timers who apparently have hijacked and sealed the fate of bituminous roads in India.

[Note: Only the Jaipur Development Authority (JDA) which maintains some 6,000 km of roads has banned all 7 water-trapping bituminous mixes and has used only dense graded bituminous mixes since 2010. JDA uses DBM Grading 2 for base course; BC Grading 1 for binder course; and BC Grading 2 for wearing course in new construction as well as resurfacing. This has resulted in smooth and durable roads, which remain largely pothole free after bearing the brunt of the last three heavy monsoons. Example of the JDA needs to be replicated across urban and rural India if good roads are desirable.]

2. Potholes, potholes and more potholes in India how to repair them especially during monsoons?

Unfortunately, it has become an annual ritual when during the monsoons the Indian media reports extensively about potholes on city streets and rural roads across India. The coverage includes traffic jams and people dying or getting injured from potholes. It appears highway engineers in India are downright insensitive to do something about this yearly disgrace on their profession.

Again, just ask aam aadmi (common man) about this, who would say highway engineers are purposely not filling potholes befor e and during the monsoon so that potholes grow in numbers, in size, and in depth and they would get a fat budget later for pothole patching with hot asphalt mix. The public has been brainwashed in believi ng potholes are a natural phenomenon during rains (as if water in the Indian monsoon has some chemical to dissolve the bituminous road!). Public is also told potholes cannot be fixed during the three months of monsoon because the hot mix plants are shut down and/or potholes are damp or wet. This is the situation after 65 years independence!

The above is happening despite the fact that an idiot-proof,unpatented, economical, and effective readymade cold pothole patching mix (called Kandhal Mix by the Jaipur Development Authority in their contract documents) is available and which is the real answer to the pothole problem across India. There is no other better, generic, economical and widely field-proven product for this purpose in India. This mix which costs about Rs. 6 per kg can be manufactured by local contractors using local materials. There are some patented cold mixes such as Shelmac which cost about three times more but are still being used in India sparingly due to high costs. Cost of patching potholes with the Kandhal mix which can be used throughout the year is about the same as patching with hot mix. This is because the latter is labour intensive (cutting and squaring the pothole); material intensive (tack coat material); and equipment intensive (roller required for compaction). Life of the Kandhal mix is equal or more than that of the hot mix patch.

A technical paper describing the so-called Kandhal mix was published by the Indian Roads Congress (IRC) and presented at the IRC session in 2008. This paper can be accessed at the following link:

Kandhal, P.S. A Simple and Effective Method of Repairing Potholes in India. Journal of the Indian Roads Congress, Volume 69-3, October-December 2008.

http://www.scribd.com/doc/19380290/A-Simple-and-Effective-Method-of-Repairing-Potholes-in-India

It is not known at this time (November 2013) as to when the IRC would approve this unpatented Kandhal Mix as a standard; it has been pending there for over three years. But this is not an excuse not to use it. The Jaipur Development Authority (JDA) is using it successfully for the last three years with contracts worth over one crore each year. What is needed is the WILL POWER of the highway engineers to implement this technology, proven both in the US and India, in the interest of general public. All contract documents for inviting tenders such as G Schedule, specifications and rate analyses are available with other information on the performance of this mix at the following link:

http://www.scribd.com/doc/178999054/Potholes-Potholes-and-more-Potholes-in-India

3. Why the NHAI is burying bitumen worth hundreds of crores rupees under national highways?

The National Highway Authority of India (NHAI) has been burying the existing bituminous roads indiscriminately under highway soil embankments. It is especially so on many six-laning highway projects where the road level is being raised by the NHAI to build numerous ramps for overpasses which require soil embankments. Using existing well established asphalt reclaiming and recycling technology, which is over 30 years old, the highly expensive existing bituminous road can be reclaimed and recycled into a new road to be constructed over the soil embankments (asphalt is 100% recyclable). The bitumen and stone in the existing bituminous road are worth crores of rupees. Bitumen is about Rs. 50,000 per ton (moreover, the country has to import more crude from which bitumen is distilled). Net savings of about one crore rupees can be made if one km of an existing 4-lane bituminous road is reclaimed and recycled rather than burying it. Unfortunately, NHAI is burying kilometres and kilometres of roads every year. No civilized country in the world buries its bituminous road; rather reclaims the costly bitumen and stone for recycling.

Although the NHAI has been encouraging the contractors through circulars for some years now, only a few NHAI contractors are reclaiming and recycling the bitumen (called black gold in the industry) and the stone; and are pocketing crores of rupees on a typical NHAI project. A vast majority of cont ractors is simply and brazenly burying this countrys dharohar (property) causing a great loss to the State Exchequer.

Three open letters have been sent to the Chairman of NHAI since November 2011 to make the reclaiming/recycling of the existing bituminous road mandatory to put a stop to this great loss to the State Exchequer, which is estimated to be hundreds of crores every year. However, the NHAI has not taken any action (they are still in the encouraging mode). Therefore, this national loss is continuing due to NHAIs incompetence, indecisiveness and lack of accountability.

Copy of the third open letter to the NHAI Chairman can be accessed at the following link:

http://www.scribd.com/doc/156792722/Third-Open-Letter-to-Chairman-National-Highway-Authority-of-India-on-Recycling-of-Asphalt-Roads

Asphalt milling and recycling is a well established technology as mentioned earlier and has been used for over 30 years across the world. Asphalt pavement guidelines prepared by Prof. Prithvi Kandhal and Dr. Rajib Mallick for the US Federal Highway Administration (FHWA) can be accessed at the following link:

http://www.scribd.com/doc/47299513/Pavement-Recycling-Guidelines-for-State-and-Local-Governments-Federal-Highway-Administration-Publication-No-FHWA-SA-98-042December-1997

4. Are we really getting viscosity graded (VG) paving bitumen in India?

It is very unfortunate that many Indian highway engineers still do not know that it is illegal and unethical to specify, produce, and use penetration graded paving bitumens such as 60/70 and 80/100. The Bureau of Indian Standards (BIS) revised IS:73 Specification for Paving bitumen in July 2006. The revised specification IS:73:2006 outlawed the old (more than 100 year old) penetration grades such as 60/70 and 80/100 and adopted new viscosity grades (VG) such as VG-30 in lieu of 60/70 and VG-10 in lieu of 80/100. [Prof. Prithvi Singh Kandhal was instrumental in introducing the viscosity grading of paving bitumen in India in 2005 with the assistance of 10 Jan Path, New Delhi.]

The Ministry of Road Transport and Highways (MORTH) issued Circular No. RW/NH-33041/3/2001-S&R (R)-Vol. III on04/08/2008 to all the state PWDs, NHAI etc. reminding them to implement the new bitumen viscosity grades as soon as possible. According to the circular, the user must substitute VG-30 in lieu of 60/70, substitute VG-10 in lieu of 80/100, and substitute VG-40 in lieu of 30/40 or 40/50 grades. Is that really hard to do? Just changing the nomenclature in tender notices or project reports is not a rocket science!

If the user would like to know more about viscosity grades (VG), please read the following IRC paper; it can also be downloaded at the link provided.

Kandhal, P.S. An Overview of the Viscosity Grading System Adopted in India for Paving Bitumen. Indian Roads Congress, Indian Highways, April 2007

http://www.scribd.com/doc/19380488/An-Overview-of-the-Viscosity-Grading-System-Adopted-in-India-for-Paving-Bitumen

The BIS has further revised IS:73:2006 Specification for Paving Bitumen in April 2013. The revised IS:73-2013 has the following significant changes. Instead of specifying a penetration range for each VG grade, only minimum penetration values have now been specified. For example: minimum penetration of 80 for VG-10 and 45 for VG-30. Instead of specifying the minimum absolute viscosity at 60 C, viscosity range has been specified for each VG grade. For example: 800-1200 poises for VG-10 and 2400-3600 poises for VG-30. These revisions were warranted and justified as explained in the IRC paper above.

Progressive user agency (be it PWD, contractor, consultant, testing laboratory or university) must purchase the viscosity testing equipment as soon as possible to monitor the grade and quality of the VG bitumen supplied by the oil companies. Research study completed by IIT Madras for BIS in 2011 determined that a significant percentage of VG-30 bitumen samples obtained across India were actually either VG-20 or VG10; that is, softer viscosity grades which may cause premature rutting/bleeding in the asphalt pavements. Therefore, the user agencies must test at least the absolute viscosity at 60 C to ensure right VG grade is being supplied to the project. Only the vacuum capillary viscometer (and not the Brookfield viscometer) can be used for determining the absolute viscosity at 60 C. Brookfield viscometer can be used to determine the kinematic viscosity at 135 C in addition to kinematic capillary viscometer.

Click at the following link to access Prof. Kandhals technical note on equipment details and testing procedure:

http://www.scribd.com/doc/19384126/Bitumen-Viscosity-Testing-Equipment-and-Test-Procedures

5. Are we really getting quality modified paving bitumen in India?

In recent years, traffic loads and tyre pressures have increased, which has created a situation for which modified bituminous binders are needed. In the past, the following two specifications have been used by the highway agencies for specifying modified binders.

1. 2.

Indian Roads Congress Publication SP:53-1999, Tentative Guidelines on Use of Polymer and Rubber Modified Bitumen in Road Construction, December 1999. Bureau of Indian Standards. IS 15462:2004, Polymer and Rubber Modified Bitumen Specification, 2004.

Four types of modified binders are included in the preceding two publications: Polymer Modified Bitumen or PMB (elastomer), PMB (plastomer), Crumb Rubber Modified Bitumen (CRMB), and Natural Rubber Modified Bitumen (NRMB). Since these are different types of modified bitumen materials, separate specifications and criteria in form of four tables are included as is the practice across the world.

These four modified binders are described briefly below.

Elastomers: Elastomeric polymers have the ability to resist permanent deformation and cohesive failure in the bituminous mix by stretching and then recovering their shape when the deforming force is removed similar to a rubber band. Therefore, PMB (elastomer) is resistant to rutting as well as fatigue cracking.

Plastomers: Plastomeric polymers form a tough, rigid, three dimensional networks within the bitumen. These plastomers give high initial strength to the bitumen to resist heavy loads. However, plastomers may crack at high strains. Therefore, PMB (plastomer) is primarily resistant to rutting.

CRMB: Rubber from discarded tyres is ground to a particulate or crumb prior to adding it to bitumen to produce CRMB. CRMB is much more complex and least understood compared to PMBs with elastomers. Because of the complex and varying chemical composition of crumb rubber obtained from tread/side wall of truck and/or car tyres, its compatibility with bitumen is always questionable. That is why; CRMB has given mixed performance in the US.

The quality control requirements right from the production to the end use of CRMB are too cumbersome because of two issues: (a) crumb rubber tends to separate and settle down in the bitumen and (b) crumb rubber is prone to degradation (devulcanization and depolymerization) if it is maintained at high temperatures for more than 6-8 hours. These quality control requirements for CRMB, which are hardly followed in India, are given in the following IRC paper which can be downloaded at the link provided.

Kandhal, P.S., Quality Control Requirements for Using Crumb Rubber Modified Bitumen (CRMB) in Bituminous mixtures, Journal of the Indian Roads Congress, Volume 67-1, 2006.

http://www.scribd.com/doc/19383778/Quality-Control-Requirements-for-Using-Crumb-Rubber-Modified-Bitumen-CRMB

NRMB: Natural rubber modified bitumen is manufactured by adding natural rubber (which is available in south India) to bitumen. However, NRMB should be used with caution because like CRMB it has degradation problems if kept at high temperature for too long.

However, the Flexible Pavement Committee (FPC) of the Indian Roads Congress (IRC) pulled a surprise in 2010 by revising IRC:SP:53-1999. The revised IRC:SP:53-2010 contains a unified single specification table for all four types of modified binders, which is not technically possible unless the unified specification is performance based which it is not. It was like mixing apples with oranges. The elastic recovery requirement was arbitrarily lowered to accommodate the CRMB. This IRC:SP:53-2010 has the following problems:

(a) Lowering the requirements to the level where a weak modifier like crumb rubber can also qualify, would lower the performance standard for all modifiers;

(b) Suppliers of better and more expensive products will tend to downgrade the quality of their products so as to be more competitive price wise if that is the criterion for decision making; and

(c) Lowering the quality will come in the way of producing still better products thus having a negative effect on further R&D activities.

Therefore, the highway agencies (government and contractors) who believe in quality should NOT specify the revised IRC:SP:53-2010. They should only specify: Bureau of Indian Standards. IS 15462:2004, Polymer and Rubber Modified Bitumen Specification, 2004 which remains unchanged in terms of four separate tables. PMB (elastomer) only should be demanded in the specifications in clear terms.

Detailed information on all types of modified binders including their characteristics, specifications and recommended uses in highway construction are given in the following IRC paper which can also be downloaded at the given link.

Kandhal, P.S. and M.P. Dhir. Use of Modified Bituminous Binders in India: Current Imperatives. Journal of the Indian Roads Congress, Volume 72-3, October-December 2011.

http://www.scribd.com/doc/81350307/Use-of-Modified-Bituminous-Binders-in-India-Current-Imperatives

The following salient recommendations have been made in the preceding IRC paper:

1. Polymer modified bitumen (PMB) with elastomers is most commonly used with success on major highways in the developed countries because elasticity in this PMB provides resistance to both rutting and fatigue cracking. Such PMBs are also relatively more stable and maintain their integrity better compared to PMBs with plastomers, CRMB, and NRMB (natural rubber modified bitumen). Superpave performance grades have been made successfully with these PMBs. PMBs with elastomers are therefore recommended for heavily trafficked roads in India.

2. Polymer modified bitumen with plastomers are hardly used in flexible pavements in the developed countries because although they provide higher strength initially, they are prone to cracking at high strains and do not rebound after deforming force is removed. Therefore, there is no need to have a specification inIndia for PMBs with plastomers to avoid its unnecessary and improper use, until proper technical justification is provided. 3. Natural rubber modified bitumen (NRMB) has limited use to support the local industry in southern India. It should not be used on heavily trafficked roads where only PMBs with elastomers should be used as mentioned earlier. However, NRMB should be used with caution because like CRMB it has degradation problems if kept at high temperature for too long. 4. CRMB is much more complex and least understood compared to PMBs with elastomers. Because of the complex and varying chemical composition of crumb rubber, its compatibility with bitumen is always questionable and therefore it has given mixed field performance. Besides, it has potential settling and degradation problems as mentioned earlier. Therefore, CRMB is not recommended for use in

India on

heavily trafficked roads. It can be considered for use on medium trafficked roads its elastic recovery is considerably lower than that of PMBs with elastomers. However, it should be blended on site in close proximity of hot mix plants so that it can be used within 6-8 hours after production. Claims that the so-called chemically modified CRMB in does not have settlement and/or degradation problems have not been validated as yet with any reported meaningful field test data. Obviously, if on-site blending is done, a fully equipped testing laboratory staffed with qualified technicians should be mandatory at the blending terminal. 5. Use of any modified binder in bituminous mix on low volume rural roads such as PMGSY is detrimental to their durability. The current practice of using CRMB in such applications should be discontinued until proper technical justification is provided.

India

6. Do we need to add mineral filler in bituminous mixes? (Q and A)

It is not understood as to why some engineers in India are obsessed with adding some sort of mineral filler (such as portland cement) when the baghouse fines (stone dust) are abundantly available and are as good as those fillers. It is simply a waste of money. The US has one of the best roads in the world, if stone dust works there, why not in India? Hydrated lime can be added if moisture susceptibility is a problem based on mix design test such as AASHTO T 283 as specified in the IRC standards.

There are many other issues related to mineral fillers including stone dust. Mr. Rajib Chattaraj, Executive Engineer P.W.D. West Bengal had asked Prof. Prithvi Singh Kandhal some interesting and good questions about the use of mineral fillers in bituminous mixes in India. Those Questions and Answers (Q and A) should be of interest to the highway community in India and can be accessed and downloaded at the following link:

http://www.scribd.com/doc/19420923/Do-we-need-to-add-mineral-filler-in-bituminous-mixtures

Prof. Kandhal had the privilege of leading research on mineral aggregates and fillers (including baghouse fines) at the national level in the US. The latest Information Manual on Baghouse Fines currently in use in the US was authored by him. Therefore, the responses to Mr. Chattarajs questions are based on his opinions considering the latest research on this subject.

7. Applying tack coat over prime coat: fundamentally not necessary and is gross waste of Indias resources !

Are you applying tack coat over prime coat? If so, it is fundamentally not necessary and it is a sheer waste of Indias resources. Unfortunately, MORTH orange book (2013) Section 503 Tack Coat and Indian Roads Congress IRC: 16-2008 Code for Prime Coat and Tack Coat require tack coat over prime coat.

About 57 crores of rupees are wasted each year by unnecessarily applying tack coat over prime coat. If this useless practice is stopped, India would also need to import less petroleum crude oil because bitumen in the emulsion is obtained from crude oil.

Detailed technical justifications for eliminating the need for tack coat over prime coat and the associated extent of wastage of taxpayers money and Indias resources can be accessed and downloaded at the following link:

http://www.scribd.com/doc/179318013/Applying-tack-coat-over-prime-coat-fundamentally-not-necessary-and-gross-waste-of-India%E2%80%99s-resources

MORTH should immediately issue a corrigendum to the 2013 Orange Book Specifications for Road and Bridge Works eliminating the requirement of tack co at over prime coat. Time is of essence. In the meantime, project engineers must use common sense, show their guts, and eliminate this requirement from the project to realize savings in the interest of country.

8. Dire need for training in asphalt technology in India, where is the vision?

Just ask a typical highway engineer in India the following two questions:

(a)

Which paving grades of bitumen are used in India? [Most engineers would say 60/70 and 80/100 although these penetration grades have been outlawed and replaced with Viscosity Grades (VG): VG-30 and

VG-10 since 2006.] (b) How would you determine if part of the paving bitumen has been replaced with marble dust during transport from refinery to the project site? [Most engineers would not be able to answer. They do not know about the very simple bitumen solubility test to determine the presence and amount of insoluble like dust in the bitumen.] The preceding two questions are about the paving bitumen only, which is the most important and most expensive ingredient in bituminous mixes (about Rs. 50,000 per ton). There are other areas such as aggregate; mix design; construction; maintenance; and recycling. Most highway engineers in limited to the specification book only.

India are technically ignorant in those areas as well. The so-called smart engineers knowledge is generally

Unfortunately, no quality road construction can be expected if the highway engineers are technically ignorant. It is just common sense.

Now, who is responsible for this technical ignorance prevailing among most highway engineers in

India? The engineering institutions cannot be blamed because there is hardly a course (if any) on highway

engineering in the civil engineering curriculum. It is the responsibility of the employers (such as MORTH, NHAI, State PWD, and contractors) who hire the civil engineers for highway design and construction activities to train them. Good example: Indian Railway gives extensive training to civil engineers selected for railway engineering services.

India is spending at least 75,000 crores of rupees in highway construction per year. As mentioned earlier, there cannot be quality without knowledge and training. There is no question that MORTH and NHAI should have the vision (which has been lacking so far) to initiate an ambitious program of training highway engineers across India. It cannot be achieved through the IndianAcademy of Highway Engineers (formerly NITHE) in New Delhi, which is just a drop in the bucket. MORTH should engage a competent engineering institution (through

RFP based on technical competence) to prepare a one-week course on asphalt technology with proper visual aids as a start. Then, that course can be offered continuously at several IITs and regional institutes of technology across

India to train both government and private highway engineers at large. The capability of academia to do this job should not be underestimated (because in some cases they can always learn, India, which is the need of the day. That

if necessary, and then teach).

Even a small percentage of Rs. 75,000 crores, say 0.1 percent or 75 crores spent per year on this training will go a long way to achieve quality road construction across

is hardly any price for quality. Helen Keller has said, The only thing worse than being blind is having sight but no vision. The question is: Does the MORTH and NHAI have the vision?

The thermo mechanical properties of bituminous binder have a major effect on its subsequent in-service performance. The rheology of conventional binders is relatively simple and behavior can be predicted through the use of traditional tests such as penetration, softening point and viscosity testing at various temperatures. On the other hand the rheology of modified binders is highly complex and, although the results from traditional tests may indicate a significant improvement in properties, the in-service performance of these binders is not easily categorized. This paper presents detailed investigations on the physical properties of modified binders in comparison with conventional binder using current Indian specifications. Firstly, it gives a brief description on modification of bitumen its advantages and limitations. It also looks into the present specifications that are followed in India and the need for improved specifications for performance based binder characterization, which may provide fundamental explanations with respect to in-service performance. Introduction The bituminous binder functions as a waterproof, thermoplastic adhesive. In other words, it acts as the glue that holds the mineral aggregates together to act as a structural layer. In its most common form, bituminous binder is simply the residue from petroleum refining. To achieve the necessary properties for paving purposes, binder must be produced from a carefully chosen crude oil blend, and processed to an appropriate grade. Increasing axle loads, climatic variations and traffic growth has posed challenge to paving industry to look into the demands made on the bitumen pavement construction. In this regard, as early as in 1980s modification to base bitumen was done by addition of certain additives like polymers, natural rubber, crumb rubber, plastics etc., to enhance the mechanical behavior of bitumen by physical modification. Also chemical modifications was attempted in the form of polyethylene, poly-phosphoric acid, etc. The use of modified bitumen can serve a number of purposes. It can target a specific improvement in the bitumen, such as permanent deformation (rutting) or low temperature cracking. Benefits that may be derived from binder modification include:

Improved consistency Reduced temperature susceptibility Improved stiffness and cohesion Improved flexibility, resilience and toughness Improved binder aggregate adhesion Improved resistance to in-service aging

However, there needs to be a way to evaluate whether the performance of the modified bitumen is cost effective. Study Objective and Scope The objective of this study can be listed as follow: characterization of the modified and conventional binders through an elaborative laboratory investigations In this investigation, four types of modified binders and a conventional binder were studied. Modified binders like styrene-butadiene-styrene polymer modified binder (PMB) of two grades viz., PMB-40 and PMB-70, Crumb Rubber Modified Binder (CRMB) of two grades viz., CRMB-55 and CRMB-60, natural rubber modified binder (NRMB), waste plastic modified binder (WPMB) and conventional binder (60/70 grade) were studied. From these investigations, the properties affecting the in-service performance in comparison with the specifications developed by other countries was assessed. Background There is a marked difference between the maximum and minimum temperatures in the country, so a flexible pavement should be capable of resisting to the extreme temperature variations and to prevent pavement distress. In this regard, a binder modification is an effective tool to reduce the temperature susceptibility and improve the strength. Hence an ideal modifier should have enhanced cohesion and very low temperature susceptibility throughout the ranges of the temperature to which it will be subjected in service. Its resistance to permanent deformation and fatigue characteristics should be high. It should have at least the same adhesion qualities as conventional binders and material should be such that the whole composition of the mix should be homogenous. Modified Binders Used In Road Applications Table 1 shows a generic classification system that was used to define and classify modifiers, as well as other additives in bituminous mixes (IRC: SP: 53-2002). Polymer

A polymer is a very large molecule comprising hundreds or thousands of atoms formed by the successive linking of one or two, or occasionally more, types of small molecule into chain or network structures (4). To achieve the goal of improving binder properties, a selected polymer should create a secondary network or new balance system within binders by molecular interactions or by reacting chemically with the binder. The formation of a functional modified binder system is based on the fine dispersion of polymer in binder for which the chemical composition of binders is important. The degree of modification depends on the polymer property, polymer content and nature of the binder. Rubber Crumbs Rubber used for these products is derived from pneumatic tyres that have been processed by mechanical means and should be substantially free from ground fabric, steel and other contaminants, including moisture. When introduced to the hot binder the rubber swells through absorption of the aromatic fractions of the binder. As a result of the high blending temperature some of the rubber dissolves in the binder and some is de-vulcanized (14). Properties and Field Performance of Modified Binders In order to relate binder properties to pavement performance, it is necessary to know the fundamental relationships between binder properties and mix properties. To minimize the deterioration of a flexible pavement due to influence of traffic and climate, the bituminous layers should be stiff enough at elevated service temperature to avoid permanent deformation (rutting), show good load-associated fatigue resistance, possess good stripping resistance (low water susceptibility), and have good flexibility at low temperature (resistance to low temperature cracking. All of these performance-related properties of the mix are influenced to some extent by binder properties (5, 6, 10, 12 & 15). Aging Aging is induced by chemical and/or physical changes and is usually accompanied by hardening of the binder. In road applications, binder is exposed to aging at three different stages: (i) storage, (ii) mixing, transport and laying, as well as (iii) during service life. Aging is a very complex process in neat binders and the complexity increases when modifiers are added. The aging properties of neat binders are normally characterized by measuring rheological properties such as viscosity and softening point before and after artificial aging in the laboratory. This procedure is not sufficient in the case of modified binder since thermolytic degradation of the modifier may occur during aging and the fragments formed may contribute to a lowering of the consistency. Therefore, when assessing the aging properties of modified binder, further characteristics, such as elastic recovery and chemical composition have to be evaluated (1 & 16). Indications of improved aging properties by admixture of polymers to the binder have been reported in recent publications (20 & 22). Temperature Susceptibility In cold climates, cracking in pavements may be an extensive problem. Low temperature cracking is caused by thermally induced tensile stresses when these exceed the tensile strength of the pavement material. The main factor influencing the degree of cracking at low temperature is found in the binder properties. Several papers have indicated that the addition of polymers to binders may increase resistance to low temperature cracking (13 & 17 to 20). However, validation of laboratory methods by field performance tests is necessary before a more definite opinion on the matter can be given. Specifications Based on Performance(3)

In most countries, current binder specifications are viscosity or penetration graded and typically based on measurements of viscosity, penetration, ductility and softening point. These measurements are not sufficient to describe properly the linear viscoelastic and failure properties of binder that are needed to relate binder properties to mixture properties. These specifications and test methods are not performance related, because they, lack adequate low-temperature measurements, do not include fundamental binder properties which may be related to fundamental mixture properties or to pavement performance, are not appropriate for measuring consistency at the upper service temperatures, and do not consider longterm in-service aging. In most cases, specification used or proposed for modified binders are derivatives of the specifications of neat binders and are supplemented with tests such as tensile strength and elastic recovery. This is also the reason for developing new specifications within the Strategic Highway Research Program (SHRP), seen in Table 2. In SHRP, new powerful tools for the evaluation of bituminous binders have been developed. The SHRP binder specifications are said to be performance related.

In this specification, new testing instruments, such as the bending beam rheometer and the direct tension tester, are employed. The instruments are used to measure more fundamental properties such as the inverse of loss compliance, storage modulus, stiffness and strain at failure. The parameters determined have been proposed collectively as being related to the rutting, fatigue and thermal cracking behavior of binders (2). Short term aging is simulated using the rolling thin film oven test (RTFOT) and long term aging using the pressure aging vessel (PAV). It is important to emphasize that proposed SHRP specifications are intended for both neat and modified binders, and allow selection of a binder based on the climate in which it is expected to perform. Experiments The main laboratory experiment programme envisages the quantitative analysis in assessment of rheological and empirical properties of both neat and modified binder. This chapter presents properties of neat and modified binders. Experiments are conducted under unaged and TFOT (thin film oven test) aged conditions.

Materials The materials selected for the present investigations are:

60/70: Conventional neat binder PMB-40: SBS modified binder PMB-70: SBS modified binder CRMB-55: Crumb rubber modified binder CRMB-60: Crumb rubber modified binder NRMB-70: Natural rubber modified binder WPMB-40: Waste plastic modified binder

All samples were subjected to a number of characterization evaluations according to IS: 73-2006, IS: 15462-2004 and IRC: SP: 53-2002 in Asphalt Laboratory, IIT Madras by the methods outlined in the above specifications. Results The test results are shown in the Tables 3 to 9.

It is seen from the results both conventional and modified binders to satisfy the specification requirements. Only in case of WPMB, it failed to satisfy the elastic recovery criteria on both unaged and TFOT aged conditions. Elastic behavior indicates that the binder recovers most or all of its initial shape when the load that caused deformation is removed. The elastic recovery of a binder is commonly used to measure the fatigue resistance of a binder or its ability to absorb large stresses without necessarily cracking or deforming. From this, it may be observed that use of waste plastics as modifier forms a rigid phase or network, imparting no elastic recovery properties to the base binder but induces a high stiffness. Loss in weight is also higher than the specified limits in case of WPMB, which may attribute that use of waste (recycled/ non-virgin) plastic as a modifier to the base binder gradually changes over time due to heat, oxidation, ultra violet radiation and l oss of volatile components. Viscosity measurements of unaged PMBs were higher than the specified which may due to higher concentration of polymer itself. Both elastic recovery and viscosity of NRMB was lesser than the CRMBs. This may be due to u se of stiffer base binder in case of CRMBs. Discussions and Conclusions

The aim of this paper is to provide a summary of information found in the current literature regarding test methods, specifications and performance of modified binders. The main purpose of material testing is to characterize the material in question, in such a way that the characteristics measured can be used to predict behavior in practice. For tests on binders to be valid, the tests must be sensitive to properties of the bituminous pavements, such as resistance to rutting, load associated fatigue and low temperature cracking. In general, when assessing the quality of modified binders, traditional methods developed for testing neat inder, are used. These specifications are in general based on empirical test methods, such as penetration, softening point, ductility and viscosity measurements, the performance relations of which are not always obvious. There are several reasons why empirical methods, nevertheless, are used. Above all, these test methods have been used for a very long time, and present knowledge on binders is for the most part based on results obtained using these methods. To describe the properties of modified binders in an overall situation, the modified binder specifications should be supple mented by other test parameters, such as dynamic mechanical analysis and compatibility. There are three critical working ranges for bituminous binders: a range of high temperature and long loading times during which the binders may flow, entailing a risk of rutting of the mixes, a range of low temperature and long loading times during which the mixes are liable to crack under the effects of thermal stress and a range of low temperature and short loading times during which the binder is brittle and may give rise to mechanical cracking. The tests used currently for binder specifications yield little information on the behavior of binders in these critical ranges. Fortunately, advances in rheometers have made it possible to perform dynamic tests at a wide range of temperatures and frequencies, from which various rheological parameters (e.g., complex modulus and phase angle) in different conditions can be obtained. However, recent research (1, 2, 10 & 15)has indicated that dynamic parameters are useful for predicting performance-related properties. Aging occurs during the production of the bituminous mix and during its service life as pavement layer. The circumstances during different aging stages vary considerably. Standardized aging test methods simulate the aging that occurs during the production of the pavement. To simulate long term aging in service, the PAV test has been developed in SHRP. The test is performed after RTFOT or TFOT aging. The chemistry of binder is very complex and is even more complex after the admixture of modifier. No specifications including require ments on the chemical composition of binder or modified binder have been found in the literature. It is doubtful whether this type of requirement should be included at all in specifications, at least not for plain binder. When characterizing the aging properties of modified binders, some chemical tests could be suitable for specification purposes. Conclusion

In conclusion, using the traditionally tests used to characterize the binder, it is very difficult to analyze and predict its in-service performance due to the complexity of the various modified binders as a function of base binder and the type as well as the content of the modifier. Hopefully, the dynamic mechanical analysis and rheological studies, which are intended for both neat and modified binders, may be more suitable in predicting binder performance on roads compared with conventional tests. The pressure aging vessel (PAV) simulates the age hardening of bitumen during the first 5-10 years of pavement service life. The pressure aging vessel conditioning allows further testing by the dynamic shear rheometer and bending beam rheometer to evaluate the binders performance following aging to evaluate whether the performanc e of the modified bitumen is cost effective in its service period.

Potrebbero piacerti anche

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesDa EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesNessuna valutazione finora

- Study of Varying Size of Crumb Rubber in BitumenDocumento6 pagineStudy of Varying Size of Crumb Rubber in Bitumendhanesh kumarNessuna valutazione finora

- Progress Report IIDocumento19 pagineProgress Report IIAkashahZakariaNessuna valutazione finora

- Imp5 Hyun Hwan Kim, Soon-Jae LeeDocumento9 pagineImp5 Hyun Hwan Kim, Soon-Jae LeeacryptfauNessuna valutazione finora

- Final HossainDocumento6 pagineFinal HossainNur AthirahNessuna valutazione finora

- Applied Sciences: Ffect of Addition of AntioxidantDocumento23 pagineApplied Sciences: Ffect of Addition of AntioxidantUlikersSportNessuna valutazione finora

- Ijett V14P211 PDFDocumento6 pagineIjett V14P211 PDFHarish Kumar GiriNessuna valutazione finora

- 1 s2.0 S0950061811003242 MainDocumento8 pagine1 s2.0 S0950061811003242 MainKamaluddin KamalNessuna valutazione finora

- Cure Characteristics and Vulcanizate ProDocumento15 pagineCure Characteristics and Vulcanizate ProSangeetha RangarajanNessuna valutazione finora

- Uses of Crumb Rubber and Natural Rubber BitumenDocumento20 pagineUses of Crumb Rubber and Natural Rubber Bitumennishankgopishetty67% (3)

- Analisis Sobre Leyes de Crecimiento de Fisura Por Fatiga de Una MezclaDocumento8 pagineAnalisis Sobre Leyes de Crecimiento de Fisura Por Fatiga de Una MezclaJuan GonzalezNessuna valutazione finora

- Ali-Sadek2013 Article ExperimentalAnalysisOfTheInfluDocumento6 pagineAli-Sadek2013 Article ExperimentalAnalysisOfTheInflumzh887Nessuna valutazione finora

- Sustainability 14 08999 v2 PDFDocumento18 pagineSustainability 14 08999 v2 PDFOmar MorenoNessuna valutazione finora

- Acknowledgement: G.H. BasavarajappaDocumento13 pagineAcknowledgement: G.H. BasavarajappaSanthu AyanurNessuna valutazione finora

- Microscopic Properties of Hydrogen Peroxide ActivaDocumento13 pagineMicroscopic Properties of Hydrogen Peroxide ActivasreenivasiiscNessuna valutazione finora

- Experimental Characterization of Storage Stability of Crumb Rubber Modified Bitumen With Warm-Mix AdditivesDocumento10 pagineExperimental Characterization of Storage Stability of Crumb Rubber Modified Bitumen With Warm-Mix AdditivesRob DamhuisNessuna valutazione finora

- A Comparative Evaluation of Crumb Rubber and Devulcanized Rubber Modified BindersDocumento7 pagineA Comparative Evaluation of Crumb Rubber and Devulcanized Rubber Modified BindersidelgardNessuna valutazione finora

- Rheological Properties of Crumb Rubber-Modified Bitumen Containing AntioxidantDocumento10 pagineRheological Properties of Crumb Rubber-Modified Bitumen Containing AntioxidantAfroz Sultana ShaikNessuna valutazione finora

- Rubberised Bitumen ForDocumento19 pagineRubberised Bitumen FornishankgopishettyNessuna valutazione finora

- Journal of Cleaner Production: Muhammad Jamal, Filippo GiustozziDocumento13 pagineJournal of Cleaner Production: Muhammad Jamal, Filippo GiustozziWaqas HaroonNessuna valutazione finora

- MODIFIED BITUMEN-Product, Purpose, Advantages Including Global and Indian ScenarioDocumento59 pagineMODIFIED BITUMEN-Product, Purpose, Advantages Including Global and Indian ScenarioSunil BoseNessuna valutazione finora

- Report On Bituminous MixDocumento75 pagineReport On Bituminous MixBibhuti B. BhardwajNessuna valutazione finora

- Matecconf Iccoee2018 05007 PDFDocumento9 pagineMatecconf Iccoee2018 05007 PDFmzh887Nessuna valutazione finora

- Design and Optimization of A Rubber-Bitumen Blend in Preparation For A Rubberized-Asphalt Road Trial in The State of KuwaitDocumento10 pagineDesign and Optimization of A Rubber-Bitumen Blend in Preparation For A Rubberized-Asphalt Road Trial in The State of KuwaitAlhekhmdarNessuna valutazione finora

- 1 s2.0 S0950061823033743 MainDocumento10 pagine1 s2.0 S0950061823033743 Mainjuan danielNessuna valutazione finora

- Paper NewDocumento10 paginePaper NewAsif ZazaiNessuna valutazione finora

- Effect of Sulphur On CRMBDocumento9 pagineEffect of Sulphur On CRMBdhanesh kumarNessuna valutazione finora

- A Review of Crumb Rubber Modification in Dry Mixed Rubberised Asphalt Mixtures PDFDocumento8 pagineA Review of Crumb Rubber Modification in Dry Mixed Rubberised Asphalt Mixtures PDFSarah Syamimi RozaliNessuna valutazione finora

- Properties of Crumb Rubber Concrete Paving Blocks With SBR LatexDocumento7 pagineProperties of Crumb Rubber Concrete Paving Blocks With SBR LatexTung-Chai LingNessuna valutazione finora

- 2687 I J Ctet 17050701Documento4 pagine2687 I J Ctet 17050701Romil SharmaNessuna valutazione finora

- Rubber Fenders Mixing It UpDocumento8 pagineRubber Fenders Mixing It UphaleyNessuna valutazione finora

- Devulcanization of Recycled Tire Rubber Using Supercritical Carbon DioxideDocumento11 pagineDevulcanization of Recycled Tire Rubber Using Supercritical Carbon DioxideJose Perez100% (1)

- Ravi Effect of Clumb RubberDocumento12 pagineRavi Effect of Clumb Rubberbraviteja2002Nessuna valutazione finora