Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Thermodynamic Properties of Methanol

Caricato da

Jessica FernandesCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Thermodynamic Properties of Methanol

Caricato da

Jessica FernandesCopyright:

Formati disponibili

!

"#$%$&"' )

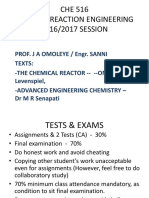

CHEG231-010 Chemical Engineering Thermodynamics

Semester Project: Thermodynamic Properties of Methanol

Jessica Fernandes

!"#$%$&"' *

"#$%&'(%

1hls ro[ecL conLaln some of Lhe Lhermodynamlc properLles of MeLhanol

descrlblng lLs behavlor conslderlng dlfferenL equaLlons of sLaLe. A brlef lnLroducLlon

abouL meLhanol descrlbes Lhe compound and how ls lL applled on Lhe markeL . Serles

of MA1LA8 codes were used Lo ploL known equaLlons LhaL descrlbe Lhe sLaLe of a

compound ln dlfferenL ranges and changlng dlfferenL properLles. 1he eng-8oblnson

equaLlon of sLaLe was chosen Lo descrlbe Lhe Lhermodynamlc funcLlons of Lhe

meLhanol. 1he dlagrams lnclude Lhe real subsLance behavlor for pressure, molar

volume, enLhalpy, speclflc heaL capaclLy and consLanL enLropy coefflclenL. 1he

resulLs are very slmllar Lo expecLed, wlLh a devlaLlon because of Lhe hlgh acenLrlc

facLor value.

!"#$%$&"' +

)*%&+,-(%.+*

MeLhanol, also known as meLhyl alcohol ls Lhe mosL slmple alcohol. lL ls llghL,

colorless, flammable llquld aL room LemperaLure and has a characLerlsLlc odor

sllghLly slmllar Lo eLhanol. lL can be easlly flnd ln Lhe envlronmenL as lL occurs

naLurally, and qulckly breaks down ln boLh aeroblc and anaeroblc condlLlons. lL can

be obLalned from planLs, fossll fuels, and renewable resources llke blomass, landflll

gas, and even power planL emlsslons and CC

2

from Lhe aLmosphere.

1

AL sea level

(101.323 ka), meLhanol bolls aL 64.6 C and solldlfles aL -97.6 C .

1he crlLlcal polnL ls

aL 239 C , 8.084 Ma and lL presenLs crlLlcal molar volume equal Lo 117 cm

3

/mol. AL

20 C , lL presenLs denslLy of 0.7914 g/cc and vlscoslLy 0.380 c. 1he sLrucLure ls:

WlLh chemlcal formula CP

3

CP or CP

4

C , Lhe molecular welghL ls 32.04

g/mol.

2

AL Lhe Lrlple polnL Lhe LemperaLure ls -97.34 C, Lhe pressure ls 0.1863 a

and Lhe denslLy ln llquld phase ls 904.33 kg/m

3

.

3

Consldered one of Lhe mosL versaLlle compounds developed, lL ls Lhe basls

for a large amounL of chemlcals , commodlLles and vlLal producLs LhaL we see on our

dally rouLlne. lL ls Lhe second mosL shlpped maLerlal all around Lhe globe every year.

MeLhanol ls used commonly as chemlcal solvenL, LransporLaLlon fuel as lL has a hlgh

ocLane raLlng LhaL allows for superlor vehlcle performance compared Lo gasollne, on

wasLewaLer denlLrlflcaLlon, on blodlesel LransesLerlflcaLon converLlng Lhe

Lrlglycerldes ln dlfferenL Lypes of olls lnLo usable blodlesel fuel, for energy

generaLlon as Lhe fuel source Lo creaLe sLeam Lo drlve Lurblnes, and ln Lhe

developmenL of dlfferenL Lypes of fuel cells because lL ls an ldeal hydrogen carrler. lL

ls ofLen converLed lnLo formaldehyde, aceLlc acld and oleflns LhaL are Lhe basls for

producLs such as plasLlcs, synLheLlc flbers, palnLs, solvenLs, refrlgeranLs, eLc.

Cur compound blodegrades easlly ln waLer and soll. osslble LreaLmenLs for

accldenL spllls lnclude blologlcal degradaLlon, reverse osmosls, carbon adsorpLlon,

sLeam sLrlpplng and alr sLrlpplng. MeLhanol occurs naLurally durlng Lhe

decomposlLlon of dlfferenL planL and anlmal llfe, and we come lnLo conLacL wlLh lL

!"#$%$&"' ,

every day ln frulLs, [ulces, and even wlne. 1hough larger quanLlLles of meLhanol can

be Loxlc lf lngesLed, Lhls naLurally occurlng molecule has a very low lmpacL when

released lnLo Lhe envlronmenL because of how qulckly lL blodegrades.

When meLhanol ls released lnLo Lhe envlronmenL lL rapldly breaks down lnLo

oLher compounds, ls compleLely mlsclble ln waLer, and serves as food for a number

of dlfferenL bacLerla.

1he lndusLry ls made up of large and small companles LhaL produce meLhanol

all over Lhe world and Lhousands of dlsLrlbuLors, Lechnology lnnovaLors, downsLream

manufacLurers and servlce provlders. Some companles LhaL are parL or Lhls lndusLry

parLlclpaLe from assoclaLlons llke: lnLernaLlonal MeLhanol roducers and Consumers

AssoclaLlon, naLlonal eLrochemlcal 8eflners AssoclaLlon, WaLer LnvlronmenL

lederaLlon, luel Cell & Pydrogen Lnergy AssoclaLlon, ueWlLL & Company lnc.,

Chemlcal MarkeL AssoclaLes, lnc., Culf eLrochemlcals and Chemlcals AssoclaLlon,

naLlonal 8lodlesel 8oard.

4

!"#$%$&"' -

/0%1+,+2+34

ln order Lo analyze Lhe behavlor of real subsLances Lo see Lhe changes ln

enLropy, enLhalpy and any oLher changes of sLaLe we need Lo conslder Lhelr real

pressure, LemperaLure and volume. 8eal subsLances have lnLermolecular

lnLeracLlons LhaL leL Lhelr sLaLe sllghLly dlfferenL, and we need Lo adapL Lhe equaLlon

we use Lo calculaLe properLles conslderlng Lhose devlaLlons from ldeallLy.

1he volumeLrlc equaLlons of sLaLe glve us an lnLerrelaLlonshlp beLween

pressure, LemperaLure and molar volume and descrlbe Lhe sLaLe of maLLer. WlLh

Lhem we can flnd our conLrol varlables LhaL lead Lo flnd enLhalpy, enLropy, Clbbs free

energy, heaL capaclLy, Lhe !oule-1hompson coefflclenL and oLher Lhermodynamlc

properLles. 1hose equaLlons of sLaLe are also a mean Lo calculaLe anoLher lnLenslve

varlable sLarLlng wlLh Lwo oLher known lnLenslve varlables.

1here are several equaLlon of sLaLe LhaL glve Lhe v1 correlaLlon, buL here we

wlll focus on only Lwo: eng-8oblnson and van der Waals equaLlons of sLaLe.

! !

!! !!

!! !!!

!

!

!!

!

!! ! ! !!

!

!

! !

!!!!"#$%& ! !

!

!"

!

!

!"

! !

!!!!"""#$% ! !"!

!"

! ! !! !!!!!"#$# !!!!"##$ !!!!!"##! !

!

! !! !

!

!"

! !

!

: pressure

v: molar volume

1: LemperaLure

1c: crlLlcal LemperaLure

c: crlLlcal pressure

u5 acenLrlc facLor

a: eng-8oblnson

consLanL a

b: eng-8oblnson

consLanL b

8: molar gas consLanL

1he a and b parameLers are relaLed Lo Lhe crlLlcal properLles. 1he ! pameLer

ls LemperaLure dependenL, and also conslder Lhe acenLrlc facLor (u), whlch ls

LabulaLed and speclflc for every compound.

!"#$%$&"' .

1he oLher equaLlon of sLaLe was developed by !. u. van der Waals ln 1873 Lo

descrlbe Lhe volumeLrlc v1 behavlor of boLh vapors and llqulds.

! !

!"

! !!

!

!

!

!

! !

!!"#$"

!"!"

! !

!"#

!!"

1he parameLers a and b are dlfferenL for every subsLance and Lhey are boLh

relaLed Lo c and 1c. 1he b parameLer lmplles LhaL aL very small speclflc volumes, Lhe

molecules begln Lo Louch each oLher, whlch causes Lhe pressure Lo sllghLly rlse. 1he a

parameLer conslders LhaL aL small speclflc volumes, Lhe aLLracLlon beLween Lhe

molecules ls slgnlflcanL. 1he van der Waals equaLlon ls noL very accuraLe buL ls one

of Lhe flrsL equaLlons Lo predlcL Lhe LranslLlon beLween llquld and vapor.

3,6

1he eng-8oblnson equaLlon of sLaLe ls much more accuraLe Lhen Lhe van

der Waals LCS because lL predlcLs beLLer Lhe behavlor of a real subsLance.

Conslderlng LhaL, ln Lhls reporL, we wlll use 8-LCS for Lhe calculaLlons needed.

lor MeLhanol, Lhe acenLrlc facLor ls u = 0.336 and Lhe eng-8oblnson

consLanLs a and b aL room LemperaLure (23 C) are calculaLed as follows:

! ! !! !!!!!"#$# !!!!"##$ !!!!!"! !!!!"##! !!!!!"!

!

! !! !

!"#

!"#!!

! !

!

! ! !!!"#$

! !

!!!"#$%& ! !!!"!# !!!"#$!"

!! !

!"#!!

!

!"!!

! !!!"#$

! !

!!!!"""#$% ! !!!"# !!"

!!

! !"#!!!

!"!!

! !!!" ! !"

!!

SomeLlmes we need speclflc equaLlons Lo analyze lnLerrelaLlonshlps beLween

!"#$%$&"' /

fluld properLles. Cne example of Lhem ls Lhe AnLolne LquaLlon, used Lo esLlmaLe Lhe

LemperaLure dependence of Lhe vapor pressure over small LemperaLure ranges. 1hls

equaLlon ls used Lo correlaLe preclsely Lhe vapor pressure over Lhe range from 1 Lo

200 ka.

!"!

!"#

! ! ! !

!

! !!

Where ls Lhe vapor pressure ln bar and 1 ls Lhe LemperaLure ln kelvln.

6

lor

MeLhanol we flnd on Lhe llLeraLure LhaL Lhe values for Lhe AnLolne consLanLs are:

60780&'%-&0 9'*30

:;<

" = > 90?0&0*(0

333.3 - 312.63 3.13833 1369.613 -34.846 Ambrose, Sprake, eL al., 1973

288.1 - 336.83 3.20409 1381.341 -33.30 Ambrose and Sprake, 1970

333. - 483. 3.31301 1676.369 -21.728 PlraLa and Suda, 1967

!"#$%$&"' 0

Cn Lhe followlng Lable are dlsplayed some of Lhe MeLhanol properLles from

experlmenLal daLa:

@&+80&%4 A'2-0

Molecular WelghL (Mr)

32.04 g/mol

CrlLlcal 1emperaLure (1

c

)

312.6 (k)

CrlLlcal ressure (

c

) 8.09 x10

6

a

CrlLlcal Molar volume (1/p) 1.8 x10

-4

m

3

/mol

normal 8olllng 1emperaLure

[sea level

64 C

normal MelLlng 1emperaLure

[sea level (101.323 ka)

-97.6 C

AcenLrlc facLor (u) 0.336

1rlple polnL 1emperaLure (1

Lrlple

)

173.6 k

1rlple polnL ressure (

Lrlple

) 0.1863 a

CrlLlcal compresslblllLy facLor Z

c

0.223900

!Pvap [298.13k and 101.3ka 1170 k!/kg

!Pfus aL 173.8k and 100ka 100.200 k!/kg

!"#$%$&"' 1

B.'3&'7$

lor all Lhe dlagrams, Lhe flrsL sLep was Lo deflne all Lhe speclflc properLles of

meLhanol LhaL should be used on Lhe equaLlons Lo calculaLe Lhe oLher deslred

varlables. 1hose varlables are mosL of Lhe Llme crlLlcal properLles, Lrlple polnL

properLles, acenLrlc facLor, Lhe gas consLanL, AnLolne parameLers, Cp parameLers,

and any oLhers requlred for Lhe dlagram. Also some equaLlons for cerLaln varlables

are deflned aL Lhe beglnnlng of Lhe codes as kappa and alfa values. 1he codes for

each dlagram are avallable aL Lhe appendlx of Lhls paper.

1. ressure vs Molar volume

1he dlagram shows how Lhe pressure changes wlLh varlaLlons on Lhe molar

volume keeplng consLanL LemperaLure. lor every lsoLherm below Lhe crlLlcal

LemperaLure, we have a loop LhaL leads us Lo Lhe splnodal reglon, where Lhe fugaclLy

value ls consLanL. 1hls was deflned wlLh Lhe help of Lhe eng-8oblnson LCS program

lncluded on SLanley l. Sandler LexLbook's Cu, varylng Lhe pressure ln order Lo flnd a

value wlLh equal values for vapor and llquld fugaclLy. 1he code conLalns an lf"

sLaLemenL LhaL should ploL an horlzonLal llne for Lhe reglon lnslde Lhe splnodal

reglon beLween Lhe llquld and vapor volume llmlLs. 1he lsoLherm above Lhe crlLlcal

LemperaLure we deflne a dlfferenL command as Lhey don'L dlsplay Lhe same

behavlor.

2. ressure vs 1emperaLure hase ulagram

1hls dlagram requlred Lhe deflnlLlon and calculaLlon of Lhe vapor pressure ln

a separaLed code, and Lhen Lhe funcLlon was plugged ln Lhe code LhaL wlll ploL Lhe

x1 dlagram. 1he vapor pressure funcLlon ls responslble for flndlng polnLs where Lhe

fugallLles of boLh llquld and vapor are equal. ln Lhose polnLs Lhe phase are ln

equlllbrlum and have Lhe same value for elLher Clbbs energy and fugaclLy. 8oLh

Clauslus and AnLolne equaLlons were used Lo make a comparlslon. 1he x1 code ls

used Lwlce, one Llme Lo ploL Lhe logarlLhmlc scale and Lhe oLher Lo ploL Lhe non-

logarlLhmlc scale.

!"#$%$&"' )2

3. ConsLanL ressure PeaL CapaclLy vs 1emperaLure

1he relaLlon beLween Cp and Cv need Lo be deflned and Lhe 8LCS ls

used Lo obLaln sLaLe varlables on parLlal derlvaLlves [usL as we worked durlng

classes and ln S.l.S problems. We need Lo flnd Cp as a funcLlon of 1 only, so we

plug Lhe r values glven and Lhe varlables are reduced Lo 1 and v only. 1he

degree of freedom can be reducwd lf we calculaLe Lhe molar volume speclfylng

one LemperaLure range. 1he molar volumes are obLalned agaln wlLh Lhe 8LCS

on Lhe S.l.S LexLbook's Cu. Cne for" funcLlon was lncluded Lo solve Lhe rooLs of

Lhe compresslblllLy facLor. 1he equaLlons are properly used Lo ploL a Cp vs 1

dlagram.

4. Molar LnLhalpy vs LemperaLure deslgn

A slmllar meLhodology was used Lo obLaln Lhls dlagram, buL we needed Lo

plug ln a dlfflrenL equaLlon Lo obLaln Lhe enLhalpy. 1he equaLlon used ln on Lhe

S.l.S LexLbook on page 196. 1he relaLlon for ldeal gas was used Lo obLaln P ln

Lherms of Cp for ldeal gas.

3. ConsLanL LnLropy coefflclenL vs LemperaLure

uslng Lhe same basls for ploLLlng Cp, we deflne uslng Lrlple producL rule

and subsLlLuLlng correcL Maxwell 8elaLlons, all presenL ln page 196 from Lhe S.l.S

LexLbook.

!"#$%$&"' ))

90$-2%$

llgure 1: ConsLanL pressure heaL capaclLy vs 1emperaLure for MeLhanol

llgure 2: Molar LnLhalpy vs 1emperaLure dlagram dor MeLhanol.

!"#$%$&"' )*

llgure 3: ressure vs LemperaLure dlagram for MeLhanol

llgure 4: ressure vs LemperaLure dlagram for MeLhanol

!"#$%$&"' )+

llgure 3: eng-8oblnson LCS ressure vs volume dlagram for MeLhanol.

llgure 6: 1he ConsLanL LnLropy coefflclenL vs 1emperaLure dlagram for

MeLhanol.

!"#$%$&"' ),

ulscusslons

llgure 1: ln Lhe Cp dlagram we can noLe Lwo clearly splkes LhaL

represenL Lhe phase LranslLlons of flrsL and second order. 1he area under Lhe

splke ls correspondenL Lo Lhe laLenL heaL of vaporlzaLlon, Lhe amounL of heaL

needed Lo make Lhe phase LranslLlon. 1he behavlor of Lhe dlagram was

slmllar Lo Lhe llLeraLure for oLher compounds, showlng good resulLs.

llgure 2: 1he ldeal gas llne ls well represenLed. 1he oLher llnes

descrlbe slmllarly Lo a real subsLance behavlor , buL Lhe splkes LhaL lndlcaLe

Lhe phase LranslLlon dldn'L come up very good. Changlng some of Lhe

compound properLles, l found ouL Lhls sLrange behavlor ls due Lo Lhe hlgh

value of Lhe acenLrlc facLor. CLher devlaLlons from Lhe expecLecLed occur for

oLher funcLlons, due Lo Lhe same problem.

llgures 3 and 4: 1he polnL locaLed on Lhe graphlc were obLalned from

llLeraLure, and Lhe curves represenL Lhe calculaLlons for Lhls funcLlons. We

can noLe Lhe approxlmaLlon of Lhe values calculaLed ln Lhe curves Lo Lhe

values ploLLed from known properLles, showlng a very good resulL.

1he flgure 4 shows how close Lhe Lhree meLhods of calculaLlng Lhe

vap

are, and Lhe devlaLlons are due Lo Lhe accuracy of each equaLlon.

llgure 3:ln Lhe flgure we can clearly noLe Lhe reglon of Lhe splnodal

and blmodal because lL's where Lhe fugaclLles are equal boLh Lo vapor and

llquld phases. 1he expecLed horlzonLal llnes were responslble for maklng Lhls

reglon clear Lo see. ln Lhls reglon we also have Lhe llquld-vapor coexlsLence

equlllbrlum. Conslderlng some sllghLly devlaLlons of fluLuaLlons due Lo deep

lnLermolecular lnLeracLlons, Lhe resulL obLalned was very good and

represenLs well our compound behavlor.

llgure 6: As we dlscussed before,Lhere ls a sLrange behavlor

represenLed by Lhe r=1 llne, whlch could be solved changlng Lhe hlgh

!"#$%$&"' )-

acenLrlc value of MeLhanol. Powever, Lhe Lrend of Lhe graphlc sLlll show an

expecLed behavlor for Lhe oLher lsobars, reachlng Lo a good represenLaLlon.

Concluslon

uslng an accuraLe equaLlon of sLaLe l could falrly represenL Lhe

behavlor of a real subsLance. Many funcLlons were used Lo see Lhe changes

when we vary oLher sLaLe properLy and could compare Lhls Lo Lhe ldeallLy

behavlor. WlLh Lhe curves ploLLed we found values LhaL are slmllar Lo Lhe

ones ln llLeraLure for experlmenLal daLa. 1he unexpecLed behavlor on some

on Lhe graphlcs ls due Lo Lhe hlgh value of Lhe MeLhanol acenLrlc facLor and

we can conslder Lhls elLher a parLlcularlLy of Lhls compound ln cerLaln ranges,

elLher [usL a mlsLake durlng Lhe calculaLlon.

1he overall resulL ls very good and Lhe ob[ecLlves of sLudy wlLh all Lhe

knowledge dlscussed ln class durlng Lhe semesLer could be well represenLed.

!"#$%$&"' ).

90?0&0*(0$

1) 1he Chemlcal Company: hLLp://www.Lhechemco.com/chemlcal/meLhanol/

2) MaLweb:

hLLp://www.maLweb.com/search/uaLaSheeL.aspx?MaLCulu=f2c9a3d8608e4f3aac1d

370d37a34ffc&ckck=1

3) Wolfram Alpha

hLLp://www.wolframalpha.com/lnpuL/?l=Lrlple20polnL20LemperaLure20of20

meLhanol&lk=2

4) MeLhanol: hLLp://www.meLhanol.org

3) Wolfram Alpha hLLp://www.wolframalpha.com/lnpuL/?l=meLhanol

6) SLanley l. Sandler 4

Lh

edlLlon Chemlcal, blochemlcal and englneerlng

1hermodynamlcs.

7) llz-Chemle www.flz-chemle.de/lnfoLherm/servleL/lnfoLhermSearch

!"#$%$&"' )/

Appendlx

llgure 1: ConsLanL pressure heaL capaclLy vs 1emperaLure for MeLhanol

clear all;

clc;

%Cp versus T

%Defining Methanol and other important constants%

R=8.314; %Gas constant [J/mol*K]

Tc=512.6; % Methanol Critical Temperature [K]

T=175.61:1200; % The temperature range goes between the triple point

and a value higher than the critical point [K]

Pc=80.9*100000; % Methanol Critical Pressure [Pa]

w=.556; % Methanol Acentric Factor

k=.37464+1.54226*w-.26992*w^2; % Kappa

a=(.45724.*R^2.*Tc^2)./Pc; %a(T) depends of Pc and Tc

% Specifying the desired isobars at Pr=0, Pr=0.02, Pr=0.5, Pr=1 and

Pr=2

P = [[0] [161800] [4045000] [8090000] [16180000]]

for h=1:5

for j=1:1:length(T)

alpha=(1+k.*(1-sqrt(T (j)./Tc))).^2;

b=(.07780.*R.*Tc)./Pc;

A=(a.*alpha.*P(h))./((R.*T(j)).^2);

B=(b.*P(h))./(R.*T(j));

alpha_cubic=B-1;

beta_cubic=A-(3.*B.^2)-(2.*B);

gamma_cubic=-(A.*B)+B.^2+B.^3;

r=[1,alpha_cubic,beta_cubic,gamma_cubic];

z=roots(r);

for i=1:3

if ((imag (z(i))~=0))

z(i)=0;

end

end

z=sort(z);

Zv=z(3);

if (z(1)~=0)

Zl=z(1);

elseif (z(2)~=0)

Zl=z(2);

else

Zl=z(3);

end

Cvap(j)=Zv;

V(j)=(Cvap (j).*R.*T(j))./P(h);

integrand= @(V)

((a.*((k^2+k)./(2.*sqrt(Tc))).*(1/T(j).^1.5))./(V.*(V+b)+b.*(V-b)));

Int=integral(integrand,Inf,V(j));

Cv_ideal=((21.15-R)+(7.092e-02.*T(j))+(2.587e-05.*T(j).^2)+(-

2.852e-08.*T(j).^3));

Cp_ideal(j)=Cv_ideal+R;

Cv_real=((T(j).*Int))+Cv_ideal;

Cv(j)=Cv_real;

!"#$%$&"' )0

alpha=(1+k.*(1-sqrt(T(j)./Tc))).^2;

a_prime=-a.*k.*sqrt(alpha./(T(j).*Tc));

dPdT=(R./(V(j)-b))+(a_prime./(V(j).*(V(j)+b)+b.*(V(j)-b)));

dPdV=(-R.*T (j)/(V(j)-

b).^2)+((2.*a.*alpha.*(V(j)+b))./((V(j).*(V(j)+b)+b.*(V(j)-b))).^2);

Cp_real=Cv(j)-(((T(j).*(dPdT.^2)))./(dPdV));

Cp(j)=Cp_real;

end

%

xlabel('Temperature (K)')

ylabel('Cp (J/(mol*K))')

title('Constant Pressure Heat Capacity vs Temperature for

Methanol')

plot(T,Cp)

hold all

end

plot(T,Cp_ideal, '--') % This line corresponds the ideal gas to check

how the behavior of the real substance is different

llgure 2: Molar LnLhalpy vs 1emperaLure dlagram dor MeLhanol.

% H vs T

R=8.314; % Gas constant (J/mol*K)

Tc=512.6; % Methanol Critical Temperature (K)

T=175.61:1000; % The temperature range goes between the triple point

and a value higher than the critical point [K]

Pc=80.9*100000; % Methanol Critical Pressure (Pascal)

w=.556; % Methanol acentric factor

k=.37464+1.54226*w-.26992*w^2; % Kappa (Constant)

a=(.45724.*R^2.*Tc^2)./Pc; % %a(T) depends of Pc and Tc

% Specifying the desired isobars at Pr=0, Pr=0.02, Pr=0.5, Pr=1 and

Pr=2

P = [[0] [161800] [4045000] [8090000] [16180000]]

for h=1:5

for j=1:1:length(T)

alpha=(1+k.*(1-sqrt(T (j)./Tc))).^2;

b=(.07780.*R.*Tc)./Pc;

A=(a.*alpha.*P(h))./((R.*T(j)).^2);

B=(b.*P(h))./(R.*T(j));

alpha_cubic=B-1;

beta_cubic=A-(3.*B.^2)-(2.*B);

gamma_cubic=-(A.*B)+B.^2+B.^3;

r=[1,alpha_cubic,beta_cubic,gamma_cubic];

z=roots(r);

for i=1:3

if ((imag (z(i))~=0))

z(i)=0;

end

end

z=sort(z);

Zv=z(3);

if (z(1)~=0)

Zl=z(1);

!"#$%$&"' )1

elseif (z(2)~=0)

Zl=z(2);

else

Zl=z(3);

end

Cvap(j)=Zv;

V(j)=(Cvap (j).*R.*T(j))./P(h);

integrand= @(V)

((a.*((k^2+k)./(2.*sqrt(Tc))).*(1/T(j).^1.5))./(V.*(V+b)+b.*(V-b)));

Int=integral(integrand,Inf,V(j));

Cv_ideal=((21.15-R)+(7.09e-02.*T(j))+(2.587e-05.*T(j).^2)+(-

2.852e-08.*T(j).^3));

Cv_real=((T(j).*Int))+Cv_ideal;

Cv(j)=Cv_real;

alpha=(1+k.*(1-sqrt(T(j)./Tc))).^2;

a_prime=-a.*k.*sqrt(alpha./(T(j).*Tc));

dPdT=(R./(V(j)-b))+(a_prime./(V(j).*(V(j)+b)+b.*(V(j)-b)));

dPdV=(-R.*T(j)/(V(j)-

b).^2)+((2.*a.*alpha.*(V(j)+b))./((V(j).*(V(j)+b)+b.*(V(j)-b))).^2);

Cp_real=Cv(j)-(((T(j).*(dPdT.^2)))./(dPdV));

Cp(j)=Cp_real;

enthalpy = Cp(j).*T(j)+ ((V(j)+(T(j).*dPdT./dPdV)).*P(h));

H(j) = enthalpy;

Hstar(j)=((21.15.*T(j))+(0.5*0.709e-01.*T(j).^2)+(0.0863e-

04.*T(j).^3)+(-0.7125e-08.*T(j).^4));

%this is to plot a graph of enthalpy of ideal gas vs. T

end

xlabel('Temperature (K)')

ylabel('Molar Enthalpy (J/mol)')

title('Molar Enthalpy vs Temperature for Methanol')

plot(T, H)

hold all

end

plot(T, Hstar, 'r')

llgure 3: ressure vs LemperaLure dlagram for MeLhanol

llgure 4: ressure vs LemperaLure dlagram for MeLhanol

%P vs T

% Declaring constants and speficic values for Methanol

R=8.314;

Tc=512.6; % Methanol Critical

Pc=80.9*100000; % Methanol Critical pressure to a high value

Tt=175.61; % Methanol Triple Point Temperature

Pt=0.1863; % Methanol Triple Ponit Pressure

Tb=337.75; % Methanol boiling point

Tm=175.55; % Methanol melting point

T=[Tt:0.01:Tc];

T_subline=[100:0.01:Tc];

w=0.556; % Methanol Acentric Factor

!"#$%$&"' *2

deltaHvap = 37440.000; % Methanol vaporization enthalpy

deltaHfus = 3206.0; % Methanol fusion enthalpy

% Antoine Constants for Methanol at the temperature range (353.5 -

512.63) K

Ant_A = 5.15853;

Ant_B = 1569.613;

Ant_C = -34.846;

P_vap_Antoine= 10.^(Ant_A-(Ant_B./(Ant_C+T)))*10^5

P_vap_TripPoint = 10.^((Ant_A-(Ant_B./(Ant_C+Tc))))*10^5; % P(vap) at

the triple point

ClausiusClap_Pvap = exp((-deltaHvap./R).*((1./T)-

(1./Tc))).*P_vap_TripPoint; %defining Clausius Clapyron for

P(vaporisation)

ClausiusClap_Psub = (P_vap_TripPoint).*exp((-

deltaHvap./R).*((1./T_subline)-(1./Tc))); %defining Clausius Clapyron

for P(sublimation)

semilogy(T,P_vap_Antoine,'k')

hold all

xlabel('Temperature (K)')

ylabel('Pressure (Pa)')

title('P-T Phase Diagram for Methanol')

semilogy(T,ClausiusClap_Pvap,'r')

semilogy(T_subline,ClausiusClap_Psub,'c')

semilogy(Tm,100000,'bo')

plot(512.6,8090000,'kd')

plot(175.61,0.1863,'kp')

llgure 3: eng-8oblnson LCS ressure vs volume dlagram for MeLhanol.

% Peng-Robinson EOS Pressure vs Volume for Methanol

% Using one command for each isotherm:

clear all;

clc ;

% For Tr=0.5

V=0.00003:0.0000001:0.5;

for i = 1:1:length(V);

if V(i)>4.58388e-05 & V(i)<2.12517;

f(i) = 0.010023e5;

else

Pc = 80.9*100000; % Methanol Critical Pressure (Pascal)

Tc = 512.6; % Methanol Critical Temperature (K)

Vc = 1.18e-04; % Methanol Critical Volume

t = 0.5*Tc;

R = 8.314; % Gas constant (J/mol*K)

b = 0.07780*(R*Tc/Pc);

!"#$%$&"' *)

w = .556; % Methanol Acentric Factor

k = .37464+1.54226*w-.26992*w.^2; % kappa

a1 = (1 + k*(1-sqrt(0.5))).^2;

a_1 = 0.45724*(R.^2*Tc.^2/Pc)*a1;

f(i)=(((R).*(t))./(V(i)-b)) - ((a_1)./(((V(i)).*(V(i) + b)) +

(b).*(V(i)-b)));

end

end

% For Tr=0.6

for i = 1:1:length(V);

if V(i)>=4.82041e-05 & V(i)<=9.60035e-02;

g(i) = 0.2647e5;

else

Pc = 80.9*100000; % Methanol Critical Pressure (Pascal)

Tc = 512.6; % Methanol Critical Temperature (K)

Vc = 1.18e-04; % Methanol Critical Volume

t=0.6*Tc;

R = 8.314; % Gas constant (J/mol*K)

b = 0.07780*(R*Tc/Pc);

w =.556; % Methanol Acentric Factor

k = .37464+1.54226*w-.26992*w.^2; % kappa

a2 = (1 + k*(1-sqrt(0.6))).^2;

a_2 = 0.45724*(R.^2*Tc.^2/Pc)*a2;

g(i)=(((R).*(t))./(V(i)-b)) - ((a_2)./(((V(i)).*(V(i) + b)) +

(b).*(V(i)-b)));

end

end

% For Tr=0.7

for i = 1:1:length(V);

if V(i)>5.17832e-05 & V(i)<1.26072e-02;

h(i) = 2.2835e5;

else

Pc = 80.9*100000; % Methanol Critical Pressure (Pascal)

Tc = 512.6; % Methanol Critical Temperature (K)

Vc = 1.18e-04; % Methanol Critical Volume

t=0.7*Tc;

R = 8.314; % Gas constant (J/mol*K)

b = 0.07780*(R*Tc/Pc);

w =.556; % Methanol Acentric Factor

k = .37464+1.54226*w-.26992*w.^2; % kappa

a2 = (1 + k*(1-sqrt(0.7))).^2;

a_2 = 0.45724*(R.^2*Tc.^2/Pc)*a2;

h(i)=(((R).*(t))./(V(i)-b)) - ((a_2)./(((V(i)).*(V(i) + b)) +

(b).*(V(i)-b)));

end

end

% For Tr=0.8

for i = 1:1:length(V);

if V(i)>5.77986e-05 & V(i)<2.89411e-03;

l(i) = 10.451e5;

else

Pc = 80.9*100000; % Methanol Critical Pressure (Pascal)

Tc = 512.6; % Methanol Critical Temperature (K)

Vc = 1.18e-04; % Methanol Critical Volume

t=0.8*Tc;

R = 8.314; % Gas constant (J/mol*K)

!"#$%$&"' **

b = 0.07780*(R*Tc/Pc);

w =.556; % Methanol Acentric Factor

k = .37464+1.54226*w-.26992*w.^2; % kappa

a2 = (1 + k*(1-sqrt(0.8))).^2;

a_2 = 0.45724*(R.^2*Tc.^2/Pc)*a2;

l(i)=(((R).*(t))./(V(i)-b)) - ((a_2)./(((V(i)).*(V(i) + b)) +

(b).*(V(i)-b)));

end

end

% For Tr=1

for i = 1:1:length(V);

Pc = 80.9*100000; % Methanol Critical Pressure (Pascal)

Tc = 512.6; % Methanol Critical Temperature (K)

Vc = 1.18e-04; % Methanol Critical Volume

t=Tc;

R = 8.314; % Gas constant (J/mol*K)

b = 0.07780*(R*Tc/Pc);

w =.556; %Methanol Acentric Factor

k = .37464+1.54226*w-.26992*w.^2; % kappa

a2 = (1 + k*(1-sqrt(1))).^2;

a_2 = 0.45724*(R.^2*Tc.^2/Pc)*a2;

s(i)=(((R).*(t))./(V(i)-b)) - ((a_2)./(((V(i)).*(V(i) + b)) +

(b).*(V(i)-b)));

end

% For Tr=2

for i = 1:1:length(V);

Pc = 80.9*100000; % Methanol Critical Pressure (Pascal)

Tc = 512.6; % Methanol Critical Temperature (K)

Vc = 1.18e-04; % Methanol Critical Volume

t=Tc*2;

R = 8.314; % Gas constant (J/mol*K)

b = 0.07780*(R*Tc/Pc);

w =.556; %Methanol Acentric Factor

k = .37464+1.54226*w-.26992*w.^2; % kappa

a2 = (1 + k*(1-sqrt(2))).^2;

a_2 = 0.45724*(R.^2*Tc.^2/Pc)*a2;

q(i)=(((R).*(t))./(V(i)-b)) - ((a_2)./(((V(i)).*(V(i) + b)) +

(b).*(V(i)-b)));

end

figure

loglog(V,f, 'r')

hold all;

loglog(V,g, 'g')

loglog(V,h, 'c')

loglog(V,l, 'b')

loglog(V,s, 'k')

loglog(V,q, '--')

xlabel('V (m^3/mol)'), ylabel('P (Pa)'), title('P vs. V for Peng-

Robinson EOS for Methanol')

!"#$%$&"' *+

llgure 6: 1he ConsLanL LnLropy coefflclenL vs 1emperaLure dlagram for

MeLhanol.

%Mu_S versus Temperature

clear all;

clc;

R=8.314; % Gas constant (J/mol*K)

Tc=512.6; % Methanol Critical Temperature (K)

T=175:800; % Temperature range between triple point to a value higher

than the critical point (K)

Pc=80.9*100000; % Methanol Critical Pressure (Pascal)

w=.556; % Methanol acentric factor

k=.37464+1.54226*w-.26992*w^2; %Kappa (Constant)

a=(.45724.*R^2.*Tc^2)./Pc; %a(T)values at critical temperature and

pressure

% Specifying the desired isobars at Pr=0, Pr=0.02, Pr=0.5, Pr=1,

Pr=1.25, Pr=1.75, and Pr=2

P = [[0] [161800] [4045000] [8090000] [10112500] [14157500]

[16180000]]

for h=1:7

for j=1:1:length(T)

alpha=(1+k.*(1-sqrt(T(j)./Tc))).^2;

b=(.07780.*R.*Tc)./Pc;

A=(a.*alpha.*P(h))./((R.*T(j)).^2);

B=(b.*P(h))./(R.*T(j));

alpha_cubic=B-1;

beta_cubic=A-(3.*B.^2)-(2.*B);

gamma_cubic=-(A.*B)+B.^2+B.^3;

r=[1,alpha_cubic,beta_cubic,gamma_cubic];

z=roots(r);

for i=1:3

if ((imag(z(i))~=0))

z(i)=0;

end

end

z=sort(z);

Zv=z(3);

if (z(1)~=0)

Zl=z(1);

elseif (z(2)~=0)

Zl=z(2);

else

Zl=z(3);

end

Cvap(j)=Zv;

V(j)=(Cvap(j).*R.*T(j))./P(h);

integrand= @(V)

((a.*((k^2+k)./(2.*sqrt(Tc))).*(1/T(j).^1.5))./(V.*(V+b)+b.*(V-b)));

Int=integral(integrand,Inf,V(j));

Cv_ideal=((21.15-R)+(7.092e-02.*T(j))+(2.587e-05.*T(j).^2)+(-

2.852e-08.*T(j).^3));

Cv_real=((T(j).*Int))+Cv_ideal;

Cv(j)=Cv_real;

!"#$%$&"' *,

alpha=(1+k.*(1-sqrt(T(j)./Tc))).^2;

a_prime=-a.*k.*sqrt(alpha./(T(j).*Tc));

dPdT=(R./(V(j)-b))+(a_prime./(V(j).*(V(j)+b)+b.*(V(j)-b)));

dPdT_squared=dPdT.^2;

dPdV=(-R.*T(j)/(V(j)-

b).^2)+((2.*a.*alpha.*(V(j)+b))./((V(j).*(V(j)+b)+b.*(V(j)-b))).^2);

Cp_real=Cv(j)-(((T(j).*dPdT_squared))./(dPdV));

Cp(j)=Cp_real;

mu_s_eq = (-T(j).*dPdT)./(Cp(j).*dPdV);

Mu_S(j) = mu_s_eq;

end

xlabel('Temperature (K)')

ylabel('Mu_S')

title('Constant Entropy Coefficient vs Temperature for Methanol')

semilogy(T, Mu_S)

hold all

end

vap luncLlon:

function[] = Pvap(P,T)

R=8.314;

Tc=512.6;

Pc=8.09e6;

w=0.556;

k = 0.37464 + 1.54226.*w - 0.26992.*w.^2;

aa = (1 + k.*(1 - (T./ Tc).^0.5)).^2;

b = 0.07780 .* ((R .* Tc)./Pc);

a = 0.45724 .* ((R^2 .* Tc^2)./Pc) .* aa;

A = (a.*P)./(R*T).^2;

B = (b.*P)./(R*T);

f = [1 B-1 A-3.*B.^2-2.*B B.^3+B.^2-A.*B];

r = roots(f);

r1 = real(r);

ZL = min(r1);

ZV = max(r1);

fL = P.*exp(ZL-1-log(ZL-B)-

(A./(2.*sqrt(2).*B)).*log((ZL+(1+sqrt(2)).*B)./(ZL+(1-sqrt(2)).*B)));

fV = P.*exp(ZV-1-log(ZV-B)-

(A./(2.*sqrt(2).*B)).*log((ZV+(1+sqrt(2)).*B)./(ZV+(1-sqrt(2)).*B)));

if abs(fV./fL-1)<0.0001

semilogy(T,P,'c')

hold all;

else

P = P .*(fL./fV);

Pvap(P,T);

end

end

Potrebbero piacerti anche

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDa EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNessuna valutazione finora

- Guide to the Physical and Chemical Properties of MethanolDocumento24 pagineGuide to the Physical and Chemical Properties of MethanolKellyCristinaNessuna valutazione finora

- Co2 Utilization ReviewDocumento20 pagineCo2 Utilization ReviewLaila FaeizahNessuna valutazione finora

- Assignment 2 PDFDocumento2 pagineAssignment 2 PDFSaidNessuna valutazione finora

- Chapter 2 - Fundamentals of Fixed-Bed ReactorsDocumento21 pagineChapter 2 - Fundamentals of Fixed-Bed Reactorskim haksongNessuna valutazione finora

- 8.2 - Packed-Bed ReactorsDocumento28 pagine8.2 - Packed-Bed ReactorsHaniif PrasetiawanNessuna valutazione finora

- Isothermal ReactorDocumento58 pagineIsothermal ReactorRoxanna LevineNessuna valutazione finora

- Exp 2 Batch DistillationDocumento12 pagineExp 2 Batch DistillationSabrina AzharNessuna valutazione finora

- CP302 Mass Transfer Principles: Diffusion in SolidsDocumento38 pagineCP302 Mass Transfer Principles: Diffusion in SolidsDeneshVijayNessuna valutazione finora

- Methanol From GlycerinDocumento5 pagineMethanol From GlycerinaudreysosoNessuna valutazione finora

- 1982 Catalytic Air Oxidation of Propylene To AcroleinDocumento12 pagine1982 Catalytic Air Oxidation of Propylene To AcroleinChauNessuna valutazione finora

- Laboratory Scale Water Circuit Including A Photocatalytic ReactorDocumento8 pagineLaboratory Scale Water Circuit Including A Photocatalytic ReactorPatrick_NickelsNessuna valutazione finora

- Che516 Lecture NotesDocumento69 pagineChe516 Lecture NotesifiokNessuna valutazione finora

- Reverse Osmosis ModelingDocumento14 pagineReverse Osmosis ModelingLina ArevaloNessuna valutazione finora

- Mathematical Modeling of CSTR For Polystyrene ProductionDocumento12 pagineMathematical Modeling of CSTR For Polystyrene Productiondwb5307Nessuna valutazione finora

- First Order SystemDocumento21 pagineFirst Order SystemNiranjan BeheraNessuna valutazione finora

- Heterogenus CatalysisDocumento31 pagineHeterogenus CatalysisEdwin FlourenzNessuna valutazione finora

- OverviewDocumento21 pagineOverviewgreenhen15Nessuna valutazione finora

- Reaction Kinetics-Reactor DesignDocumento17 pagineReaction Kinetics-Reactor Designzorro21072107Nessuna valutazione finora

- Flow Patterns and Power Consumption of MixersDocumento26 pagineFlow Patterns and Power Consumption of MixersNawal DaBomb100% (1)

- Reactor Trickle BedDocumento18 pagineReactor Trickle BedCesarNessuna valutazione finora

- UcucucDocumento97 pagineUcucucJV Custodio100% (2)

- Irvin Langmuir 1918, Adsorption IsothermDocumento43 pagineIrvin Langmuir 1918, Adsorption IsothermJayvir100% (3)

- 2012 Coleman Anaerobic Digestion SSO Vs WWTPDocumento16 pagine2012 Coleman Anaerobic Digestion SSO Vs WWTPcolemanpf_39910546Nessuna valutazione finora

- Rate-Based Modeling For CO2 AbsorptionDocumento10 pagineRate-Based Modeling For CO2 AbsorptiongoingtohellwithmeNessuna valutazione finora

- Batch and Semibatch Reactors Guide: Isothermal Batch Reactor Models and ExamplesDocumento44 pagineBatch and Semibatch Reactors Guide: Isothermal Batch Reactor Models and ExamplesManoaki100% (1)

- Energy balance on chemical reactorsDocumento41 pagineEnergy balance on chemical reactorsHotib PerwiraNessuna valutazione finora

- Report Rafael Damar ArjanggiDocumento28 pagineReport Rafael Damar ArjanggiRafael DamarNessuna valutazione finora

- Je300655b PDFDocumento60 pagineJe300655b PDF方琳 徐Nessuna valutazione finora

- Experiment No 18Documento4 pagineExperiment No 18Suvrasoumya Mohanty100% (2)

- 7-Liquid Liquid Extraction - COMPLETEDocumento39 pagine7-Liquid Liquid Extraction - COMPLETERickyWisaksonoNessuna valutazione finora

- Erasmus Mass 2004 PDFDocumento257 pagineErasmus Mass 2004 PDFSherLockNessuna valutazione finora

- A Kinetic Model of Steady State Ethylene Epoxidation Over A Supported Silver CatalystDocumento17 pagineA Kinetic Model of Steady State Ethylene Epoxidation Over A Supported Silver CatalystFrank LordNessuna valutazione finora

- 1-A Comparison of Steady-State Eq and Rate-Based ModelsDocumento10 pagine1-A Comparison of Steady-State Eq and Rate-Based ModelsVinh Vật VãNessuna valutazione finora

- Vapor-Liquid Equilibrium of Systems Containing Alcohols, Water, CarbonDocumento8 pagineVapor-Liquid Equilibrium of Systems Containing Alcohols, Water, CarbonJessica CehNessuna valutazione finora

- Residence - Time DistributionDocumento9 pagineResidence - Time DistributionNik Nur Izzatul IkmalNessuna valutazione finora

- 124 Melting Point2Documento15 pagine124 Melting Point2bluestardiverNessuna valutazione finora

- Water Gas Shift Reaction Kinetics and Reactor Modeling For Fuel Cell Grade Hydrogen PDFDocumento8 pagineWater Gas Shift Reaction Kinetics and Reactor Modeling For Fuel Cell Grade Hydrogen PDFKmilo BolañosNessuna valutazione finora

- PARAXYLENEDocumento2 paginePARAXYLENEslct88Nessuna valutazione finora

- Plant Design of Acetone ProductionDocumento20 paginePlant Design of Acetone ProductionMary Grace VelitarioNessuna valutazione finora

- Steam Methane Reforming Reaction Process Intensification by Using A ReactorDocumento14 pagineSteam Methane Reforming Reaction Process Intensification by Using A ReactorserchNessuna valutazione finora

- UNCLASSIFIED DOCUMENT REVIEWS PHYSICAL AND CHEMICAL PROPERTIES OF MONOETHANOLAMINEDocumento59 pagineUNCLASSIFIED DOCUMENT REVIEWS PHYSICAL AND CHEMICAL PROPERTIES OF MONOETHANOLAMINEbexigaobrotherNessuna valutazione finora

- Kinetics of The Synthesis of Higher Aliphatic Alcohols From SyngasDocumento8 pagineKinetics of The Synthesis of Higher Aliphatic Alcohols From SyngasLina ArevaloNessuna valutazione finora

- Condution Holman 10th-Ed PDFDocumento167 pagineCondution Holman 10th-Ed PDFLizbeth Abril100% (1)

- Lec5 PDFDocumento15 pagineLec5 PDFRaviNessuna valutazione finora

- Aspen Plus Simulation of Saponification of Ethyl Acetate in The Presence of Sodium Hydroxide in A Plug Flow ReactorDocumento8 pagineAspen Plus Simulation of Saponification of Ethyl Acetate in The Presence of Sodium Hydroxide in A Plug Flow ReactorSoumajit SenNessuna valutazione finora

- Adiabatic FBR DesignDocumento10 pagineAdiabatic FBR DesignRana UzairNessuna valutazione finora

- Green ChemistryDocumento3 pagineGreen Chemistrymanbirsshowdown48Nessuna valutazione finora

- Distillation 3Documento36 pagineDistillation 3Renu SekaranNessuna valutazione finora

- Pressure-Swing Reactive Distillation Process For Transesterification of Methyl Acetate With IsopropanolDocumento3 paginePressure-Swing Reactive Distillation Process For Transesterification of Methyl Acetate With IsopropanolMahesh ChantarkarNessuna valutazione finora

- Modeling and Simulation Study of The CSTR For Complex Reation Usong POLYMATHDocumento7 pagineModeling and Simulation Study of The CSTR For Complex Reation Usong POLYMATHtocinopNessuna valutazione finora

- Can Bang Long HoiDocumento370 pagineCan Bang Long HoiKhanh Nguyen100% (1)

- Mass Transfer QuizzesDocumento10 pagineMass Transfer QuizzesNate JamesNessuna valutazione finora

- Science and Technology of Novel Process For Deep Desulfurization of Oil Refinery Streams PDFDocumento25 pagineScience and Technology of Novel Process For Deep Desulfurization of Oil Refinery Streams PDFGabiNessuna valutazione finora

- 8 3 Packed Bed ReactorsDocumento20 pagine8 3 Packed Bed ReactorsridhajamelNessuna valutazione finora

- Sequential Modular and Simultaneous Modular StrategiesDocumento13 pagineSequential Modular and Simultaneous Modular Strategieskim haksongNessuna valutazione finora

- Experiment 4 Laboratory ReportDocumento13 pagineExperiment 4 Laboratory ReportXena Jenn Y. BacsarpaNessuna valutazione finora

- Gas Absorption ReportDocumento15 pagineGas Absorption ReportdaabgchiNessuna valutazione finora

- Practical Chemical Thermodynamics for GeoscientistsDa EverandPractical Chemical Thermodynamics for GeoscientistsNessuna valutazione finora

- 1.1 Energy ScenarioDocumento24 pagine1.1 Energy ScenarioEngr Mohammed UsmaniaNessuna valutazione finora

- Astronomy - Galaxies and The Expanding UniverseDocumento226 pagineAstronomy - Galaxies and The Expanding UniverseDigiSvcNessuna valutazione finora

- 3RN10131BW10 Datasheet enDocumento3 pagine3RN10131BW10 Datasheet enXuân Kiên VũNessuna valutazione finora

- A Train Travelling at 40 M / S Takes 2.0 S To Pass The Man. What Is The Length of The Train? M MC 40 MD 80 MDocumento4 pagineA Train Travelling at 40 M / S Takes 2.0 S To Pass The Man. What Is The Length of The Train? M MC 40 MD 80 MDaniel CannywoodNessuna valutazione finora

- Drag Characteristics of AirplaneDocumento22 pagineDrag Characteristics of AirplaneNouman NadeemNessuna valutazione finora

- Switching Impulse Flashover Performance of Different Types of Insulators at High Altitude Site of Above 2800 MDocumento6 pagineSwitching Impulse Flashover Performance of Different Types of Insulators at High Altitude Site of Above 2800 MdaaanuNessuna valutazione finora

- McQuiston HVAC Analysis Design 6th SolutionsDocumento313 pagineMcQuiston HVAC Analysis Design 6th SolutionsProsperouscross77% (31)

- Us Earth Rite Plus Exd DatasheetDocumento7 pagineUs Earth Rite Plus Exd DatasheetwlyskrdiNessuna valutazione finora

- Model LA-ST120: AC Distribution Panel UnitDocumento2 pagineModel LA-ST120: AC Distribution Panel UnitDaniel JovelNessuna valutazione finora

- VTU-22-12-2018 08:29:13am: TG - TG - TG - TG - TG - TG - TG - TG - TGDocumento9 pagineVTU-22-12-2018 08:29:13am: TG - TG - TG - TG - TG - TG - TG - TG - TGPâvâñ NagarajNessuna valutazione finora

- Power Systems Analysis - Bee 21 & Bew 21Documento3 paginePower Systems Analysis - Bee 21 & Bew 21zy44cwfjjgNessuna valutazione finora

- InvertrDocumento2 pagineInvertrjamesyuNessuna valutazione finora

- Hydro Electricity and Hydro Power Plant: By-Rajkumar Parihar (B11074)Documento34 pagineHydro Electricity and Hydro Power Plant: By-Rajkumar Parihar (B11074)AninVincelyNessuna valutazione finora

- Electricity MarketDocumento27 pagineElectricity MarketcakesandfinancesNessuna valutazione finora

- Ieee Conference Paper - 01Documento9 pagineIeee Conference Paper - 01Asha PatilNessuna valutazione finora

- Practice Problem Set - II PDFDocumento3 paginePractice Problem Set - II PDFMukul ChandraNessuna valutazione finora

- Nicd Battery Charger: Design: K. WalravenDocumento1 paginaNicd Battery Charger: Design: K. WalravenjaliltaghdarehNessuna valutazione finora

- No Voltage Droop - TroubleshootDocumento2 pagineNo Voltage Droop - Troubleshootwagner_guimarães_1Nessuna valutazione finora

- NEMKO File PDFDocumento121 pagineNEMKO File PDFMahmoud HachichaNessuna valutazione finora

- Name: Maturan, Renz Myko B. Date: November 28, 2022 Subject & Section: EE 330 AC/DC Machineries - CDocumento7 pagineName: Maturan, Renz Myko B. Date: November 28, 2022 Subject & Section: EE 330 AC/DC Machineries - CRenz MykoNessuna valutazione finora

- Model: THG1365YLS: Technical Data SheetDocumento3 pagineModel: THG1365YLS: Technical Data SheetAndres VargazNessuna valutazione finora

- Sizing ConductorsDocumento117 pagineSizing ConductorsJeremy McfaddenNessuna valutazione finora

- Turbomachinery GuideDocumento80 pagineTurbomachinery GuideOsama AliNessuna valutazione finora

- Ambipolar Transport Equation Describes Excess CarriersDocumento30 pagineAmbipolar Transport Equation Describes Excess CarriersVikas PsNessuna valutazione finora

- Convection Tutorial Sheet 3Documento4 pagineConvection Tutorial Sheet 3Charlotte BNessuna valutazione finora

- Physics AssignmentDocumento4 paginePhysics Assignmentang_chang_1Nessuna valutazione finora

- Test4-Reading Passage 3Documento2 pagineTest4-Reading Passage 3vanpham248Nessuna valutazione finora

- Fick’s Law for Binary Systems Flux CalculationDocumento11 pagineFick’s Law for Binary Systems Flux CalculationDianaNessuna valutazione finora

- iCanScore - Electricity P1Documento18 pagineiCanScore - Electricity P1JEEMION BIN JEALI KPM-GuruNessuna valutazione finora

- Simply Smart Circuit BreakersDocumento12 pagineSimply Smart Circuit BreakersRajiv ChaudhariNessuna valutazione finora