Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ultima XIR Features and Benefits - en

Caricato da

Ulises FernandezDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ultima XIR Features and Benefits - en

Caricato da

Ulises FernandezCopyright:

Formati disponibili

The Ultima XIR Gas Monitor

Infrared technology for combustible gas detection

certified

Features

DuraSource Technology offers improved IR sensor life Field-selectable algorithms for a variety of hydrocarbon-based gases LCD display with scrolling messages and LEDs Single-board design for ultimate reliability and easy, no-tool servicing 4-20mA, HART, and Modbus (X3 Technology) output Optional quick-check LEDs for increased product visibility Fail-to-safety operation

SIL-2

Benefits

No-gas calibration; zero adjustment meets requirement for full calibration Extremely fast response speed (t90 < 2 sec) Designed without sintered disk for optimum performance in harsh, offshore environments Operates over extended temperature ranges Immune to poisoning No sensor life reduction from gas exposure Automatic compensation for humidity and temperature changes Operates in high gas and low oxygen environments

10-YEAR WARRANTY

The Ultima XIR Gas Monitor is a microprocessor-based, infrared point gas detector for continuous monitoring of combustible gases and vapors. Designed around a rugged, 316 stainless steel enclosure, the Ultima XIR Monitor has multiple entries for maximum flexibility. Ultima XIR Monitor operation is based upon dualwavelength, heated-optics technology, providing definitive compensation for temperature, humidity, and aging effects. IR technology offers excellent long-term stability, eliminates the need for frequent calibrations, and reduces overall cost of ownership.

Ultima XIR Accessories

Specifications

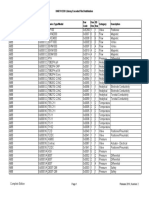

Gas Types and Ranges Temperature Range Stability Repeatability Accuracy Response Times (without sensor guard) t90 Humidity Combustible gases & vapors; 0-100% LEL CO2 0-5% and 0-2% by volume , 0-5000 ppm -40C to +60C (-40F to +140F) 2% full scale/year 1% full scale 3% full scale ( 50% LEL) 5% full scale (> 50% LEL) < 2 sec. 0%-95% RH, non-condensing 10 years for IR source 8-30 VDC, 5 watts 290mA maximum @ 24 VDC 3-wire 4-20mA 3-wire current source One entry, 3/4 NPT (19.05 mm) with optional conduit 316 stainless steel 6 lbs. (2.7 kg) 2.5 dia. x 8 long (64 x 203 mm) cFMus, cULus, CSA Class I, Div. 1 and 2, Groups A, B, C, & D Class II, Div. 1, Groups E, F, & G Class III ANSI/ISA 12.13.01 CSA C22.2 No. 152 Combustible Gas Performance, Class I, Div. 1 and Groups B, C, & D CE EMC Directive: 89/336/EEC CE ATEX Directive: 94/9/EC II 2G EEx d IIc T5 (Tamb -40C to +60C) TYPE 4X, IP 66 SIL 2 assessed to IEC 61508

Principles of IR Technology

The Ultima XI Gas Monitor uses an electronically modulated infrared energy source and two detectors that convert infrared energy into electrical signals. Each detector is sensitive to a different range of wavelengths in the spectrums infrared portion. The source emission is directed through a main enclosure window into an open volume. A mirror at the end of this volume, protected by a second window, directs energy back through the main enclosure window and onto the detectors. Combustible gas presence in the open volume will reduce the source emission intensity reaching the analytical detector but not the source emission intensity reaching the reference detector. The microprocessor monitors the ratio of these two signals and correlates this ratio to a %LEL combustible reading.

Sensor Warranty Power Input Current Draw Wiring Requirements Signal Output Conduit Entries Physical Weight Dimensions

Approval Ratings

Ordering Information

All Ultima X Series Gas Monitors are manufactured using MSA's Assemble-To-Order (ATO) process. For further information on the Ultima X Series Gas Monitors, see bulletins 07-2051-MC and 07-2054-MC.

Note: This Bulletin contains only a general description of the products shown. While uses and performance capabilities are described, under no circumstances shall the products be used by untrained or unqualified individuals and not until the product instructions including any warnings or cautions provided have been thoroughly read and understood. Only they contain the complete and detailed information concerning proper use and care of these products.

MSA Corporate Center 1000 Cranberry Woods Drive Cranberry Township, PA 16066 Phone 724-776-8600 www.msanet.com U.S. Customer Service Center Phone 1-877-MSA-FIRE Fax 1-800-967-0398 MSA Canada Phone 1-800-672-2222 Fax 1-800-967-0398

MSA Mexico Phone 01 800 672 7222 Fax 52-44 2227 3943 MSA International Phone 724-776-8626 Toll-Free 1-800-672-7777 Fax 724-741-1559

Offices and representatives worldwide

For further information:

ID 07-2054-MC / Aug 2011

MSA 2011 Printed in U.S.A.

Potrebbero piacerti anche

- Ap B14 02L 01e - Akm - 38750 PDFDocumento4 pagineAp B14 02L 01e - Akm - 38750 PDFsamsungloverNessuna valutazione finora

- PLG C 3 Natural Gas ChromatographDocumento4 paginePLG C 3 Natural Gas ChromatographYuli_PribadiNessuna valutazione finora

- GIR 3000 Eng ManualDocumento31 pagineGIR 3000 Eng ManualsahilmetroNessuna valutazione finora

- Teledyne 3000taDocumento2 pagineTeledyne 3000taRyanNessuna valutazione finora

- GTD-2000Ex Manual (Eng)Documento26 pagineGTD-2000Ex Manual (Eng)Justice KNessuna valutazione finora

- Xgard Bright: Addressable Fixed Point Gas Detector With DisplayDocumento4 pagineXgard Bright: Addressable Fixed Point Gas Detector With DisplayPunyawich FungthongjaroenNessuna valutazione finora

- BW GasPoint DSDocumento2 pagineBW GasPoint DSgreggherbigNessuna valutazione finora

- LAND FGA 900 Series EnglishDocumento6 pagineLAND FGA 900 Series EnglishRaymundo CorderoNessuna valutazione finora

- IR5500 Data SheetDocumento2 pagineIR5500 Data SheetsirballesterosNessuna valutazione finora

- Model: 331 H S/Total Sulfur AnalyzerDocumento2 pagineModel: 331 H S/Total Sulfur AnalyzerfarshidianNessuna valutazione finora

- S Guard Manual PDFDocumento25 pagineS Guard Manual PDFRomanPochinkovNessuna valutazione finora

- Ultima: X Series Gas MonitorsDocumento6 pagineUltima: X Series Gas MonitorsterminatorNessuna valutazione finora

- Abb El 3060Documento20 pagineAbb El 3060రామకృష్ణ పాశలNessuna valutazione finora

- Data Sheet GCEM40 SeriesDocumento6 pagineData Sheet GCEM40 SerieskaicyemNessuna valutazione finora

- GAS-Guard 8: Answers For EnergyDocumento6 pagineGAS-Guard 8: Answers For Energyeross_saptaNessuna valutazione finora

- Curriculum Vitae - 2019-2Documento2 pagineCurriculum Vitae - 2019-2Wilfredo GutierrezNessuna valutazione finora

- Intellix GLA100 - 032911 - V2 - PrintDocumento2 pagineIntellix GLA100 - 032911 - V2 - PrintDjafri Malin SatiNessuna valutazione finora

- M70XPDocumento2 pagineM70XPDuron SaavedraNessuna valutazione finora

- Yokogawa Flow Meter GS01R04B04-00E-EDocumento32 pagineYokogawa Flow Meter GS01R04B04-00E-Edhanu_lagwankarNessuna valutazione finora

- Intelligent Gas Sensor Monitors Toxic GasesDocumento2 pagineIntelligent Gas Sensor Monitors Toxic GasesVincent GabrielNessuna valutazione finora

- AAS 920 474D Telaire T6615 Sensor 031814 WebDocumento4 pagineAAS 920 474D Telaire T6615 Sensor 031814 WebDiego Arturo Lume AguilarNessuna valutazione finora

- SRI SensorDocumento7 pagineSRI SensorArun GuptaNessuna valutazione finora

- Series AR712/722 Gas Chromatograph: Analysis of Impurities in ArgonDocumento2 pagineSeries AR712/722 Gas Chromatograph: Analysis of Impurities in ArgonZaid MajedNessuna valutazione finora

- Model 480A: Eneral OnitorsDocumento2 pagineModel 480A: Eneral OnitorssudalaimuthuNessuna valutazione finora

- 1000-CO2 Data Sheet R1Documento1 pagina1000-CO2 Data Sheet R1Abdul Hakeem MohammedNessuna valutazione finora

- Subsea Sensor BrochureDocumento16 pagineSubsea Sensor Brochurealkhwarizmi1968100% (1)

- Sensors For Wind Turbines PDFDocumento6 pagineSensors For Wind Turbines PDF13121977Nessuna valutazione finora

- 18 Sensor Proximity SwitchDocumento88 pagine18 Sensor Proximity SwitchPrince Rao MuaazNessuna valutazione finora

- GT 2500-Smart Gas Transmitter PDFDocumento2 pagineGT 2500-Smart Gas Transmitter PDFanilbabu40% (1)

- Hornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetDocumento2 pagineHornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetInstruTech, Inc.Nessuna valutazione finora

- Comb Manual IM 106 6888QSDocumento36 pagineComb Manual IM 106 6888QSsathish2829Nessuna valutazione finora

- FT3.6.1 - Detector Prin Aspiratie - FAAST LTDocumento2 pagineFT3.6.1 - Detector Prin Aspiratie - FAAST LTABBYNessuna valutazione finora

- High Temperature Zirconia Oxygen Probe: ZGP2 SeriesDocumento12 pagineHigh Temperature Zirconia Oxygen Probe: ZGP2 SeriesjoymotiNessuna valutazione finora

- H2S Address Able Transmitter S4100T - DATADocumento2 pagineH2S Address Able Transmitter S4100T - DATATuan CaoNessuna valutazione finora

- A2006 126 Type 68 Datasheet Issue A Draft 2Documento3 pagineA2006 126 Type 68 Datasheet Issue A Draft 2Micah KipropNessuna valutazione finora

- Manual 1 PDFDocumento31 pagineManual 1 PDFdarrel_julioNessuna valutazione finora

- MMY330Documento2 pagineMMY330Nguyen VuNessuna valutazione finora

- GLA100Documento2 pagineGLA100Al De LeonNessuna valutazione finora

- Mini Mcr-Sl-Pt100-Ui-Nc: Order No.: 2864273Documento7 pagineMini Mcr-Sl-Pt100-Ui-Nc: Order No.: 2864273vijicsaNessuna valutazione finora

- CODEL CEMS and Process ProductsDocumento10 pagineCODEL CEMS and Process ProductsnguyenanhtuanbNessuna valutazione finora

- PT295 CombustiblesDocumento2 paginePT295 Combustiblescecilia aguilarNessuna valutazione finora

- IMR 7500 - Continuous Emission Monitoring System (CEM) PDFDocumento4 pagineIMR 7500 - Continuous Emission Monitoring System (CEM) PDFdejavu77Nessuna valutazione finora

- SAT-5 CO Analyser Outstanding Performance & ValueDocumento4 pagineSAT-5 CO Analyser Outstanding Performance & ValueFred StokesNessuna valutazione finora

- Explosion-Proof Asic or Hart Pressure Transmitter: FeaturesDocumento12 pagineExplosion-Proof Asic or Hart Pressure Transmitter: FeaturesMkgt HemaautomationNessuna valutazione finora

- PT205 CombustiblesDocumento2 paginePT205 Combustiblescecilia aguilarNessuna valutazione finora

- MSA Flame & Gas For Oil & GasDocumento8 pagineMSA Flame & Gas For Oil & GasmihahudeaNessuna valutazione finora

- FT2 Measures Gas Flow & TemperatureDocumento4 pagineFT2 Measures Gas Flow & TemperatureMonica AguilarNessuna valutazione finora

- ROOTS Micro Corrector Catalog (DRESSER)Documento4 pagineROOTS Micro Corrector Catalog (DRESSER)Julio OrtegaNessuna valutazione finora

- Marsen Catalog v6.0Documento26 pagineMarsen Catalog v6.0seckin80100% (1)

- H2S SensorDocumento2 pagineH2S SensorSrikanth Reddy YarramNessuna valutazione finora

- ST51 Data Sheet RevCDocumento2 pagineST51 Data Sheet RevCjakkyjeryNessuna valutazione finora

- Transformer A To Z Testing-Ready CatalogueDocumento169 pagineTransformer A To Z Testing-Ready CatalogueUna LakNessuna valutazione finora

- F FL LO OW W: Vampire - Electronic IndicatorDocumento3 pagineF FL LO OW W: Vampire - Electronic IndicatorscribdkhatnNessuna valutazione finora

- Mediciones CEMS - ZZ-025-0802EDocumento4 pagineMediciones CEMS - ZZ-025-0802EdcarunchioNessuna valutazione finora

- UL or ATEX Certified For Hazardous Areas: GPR-7500 AIS PPM H S AnalyzerDocumento36 pagineUL or ATEX Certified For Hazardous Areas: GPR-7500 AIS PPM H S AnalyzerMiguelNessuna valutazione finora

- Model GT-CT8900: G T G TDocumento4 pagineModel GT-CT8900: G T G TGilang ramadhanNessuna valutazione finora

- Continuous Emission Monitoring System Manufacturer in IndiaDocumento4 pagineContinuous Emission Monitoring System Manufacturer in IndiaBhoomi AnalyzersNessuna valutazione finora

- GAS FLOW Series Sales SheetDocumento2 pagineGAS FLOW Series Sales SheetArdhika HermigoNessuna valutazione finora

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentDa EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentValutazione: 4.5 su 5 stelle4.5/5 (3)

- 20 Unbelievable Arduino ProjectsDocumento430 pagine20 Unbelievable Arduino ProjectsCao Anh100% (10)

- A0 OSID Product Guide A4 IE Lores PDFDocumento44 pagineA0 OSID Product Guide A4 IE Lores PDFUlises FernandezNessuna valutazione finora

- MNL 0172 PDFDocumento42 pagineMNL 0172 PDFUlises Fernandez100% (1)

- Parametric Test Systems: Series S600Documento4 pagineParametric Test Systems: Series S600Ulises FernandezNessuna valutazione finora

- Monitor LCDDocumento1 paginaMonitor LCDUlises FernandezNessuna valutazione finora

- Calibracion Kits MsaDocumento2 pagineCalibracion Kits MsaRafa DunkelhaarigNessuna valutazione finora

- 16f8x Serial ProgDocumento16 pagine16f8x Serial ProgIgnacio MartiNessuna valutazione finora

- Scott Freedom 5000 ManualDocumento52 pagineScott Freedom 5000 ManualGabrielNessuna valutazione finora

- MDT Air Quality/CO2 Sensor, Flush MountedDocumento2 pagineMDT Air Quality/CO2 Sensor, Flush MountedSuperhypoNessuna valutazione finora

- Bcga Code of Practice CP 26: Liquid Carbon Dioxide Storage at Users' Premises Revision 3: 2012Documento47 pagineBcga Code of Practice CP 26: Liquid Carbon Dioxide Storage at Users' Premises Revision 3: 2012Justin ChongNessuna valutazione finora

- OGPEDocumento2 pagineOGPEVincent GabrielNessuna valutazione finora

- HART EDD Library Encoded File Distribution DDList19 - 2Documento53 pagineHART EDD Library Encoded File Distribution DDList19 - 2A N ArunkumarNessuna valutazione finora

- CONTROL EXPLOSION HAZARDS WITH PROGRAMMABLE METHANE DETECTORDocumento2 pagineCONTROL EXPLOSION HAZARDS WITH PROGRAMMABLE METHANE DETECTORnguyễn quốc hoànNessuna valutazione finora

- Altair 5X MultiGas Detector ManualDocumento259 pagineAltair 5X MultiGas Detector ManualdigicontentsNessuna valutazione finora

- Net Safety Millennium II Basic Gas DetectorDocumento8 pagineNet Safety Millennium II Basic Gas DetectorsalemNessuna valutazione finora

- H2 Safety Q and A Feedback Webinar1 ENDocumento4 pagineH2 Safety Q and A Feedback Webinar1 ENCristian PopaNessuna valutazione finora

- Pac ExDocumento8 paginePac Exs.kurpishNessuna valutazione finora

- Zaff-Profie MX 4Documento29 pagineZaff-Profie MX 4Haleem Ur Rashid BangashNessuna valutazione finora

- Automatic Fire Extinguishing Robotic VehicleDocumento2 pagineAutomatic Fire Extinguishing Robotic VehiclerajeshNessuna valutazione finora

- Advanced Smart Card Based Digital Energy Meter Using Atmel MicrocontrollerDocumento99 pagineAdvanced Smart Card Based Digital Energy Meter Using Atmel MicrocontrollervinayakaNessuna valutazione finora

- Affordable Portable Helium Sniffers For Leak Detection In EuropeDocumento52 pagineAffordable Portable Helium Sniffers For Leak Detection In EuropeChristos StiapisNessuna valutazione finora

- TXP WtaDocumento2 pagineTXP WtaVincent GabrielNessuna valutazione finora

- Smart Sewage Alert System For Workers in Real-Time Applications Using IotDocumento4 pagineSmart Sewage Alert System For Workers in Real-Time Applications Using IotSUPER HITZZNessuna valutazione finora

- 00 Drilling - Manual.BPDocumento392 pagine00 Drilling - Manual.BPAdel ALkhaligyNessuna valutazione finora

- A Fully Temperature Controlled Test Chamber For The Application of Gas Sensor Characterization PDFDocumento6 pagineA Fully Temperature Controlled Test Chamber For The Application of Gas Sensor Characterization PDFAcuña Lazaro AnthonyNessuna valutazione finora

- C V O Durairaj Ravi: Contact DetailsDocumento9 pagineC V O Durairaj Ravi: Contact DetailsJêmš NavikNessuna valutazione finora

- Coast Guard Updates Natural Gas Fuel System Design CriteriaDocumento14 pagineCoast Guard Updates Natural Gas Fuel System Design CriteriapwmvsiNessuna valutazione finora

- Petronas Technical Standards: Design, Installation, Maintenance of Fire and Gas Detection SystemDocumento33 paginePetronas Technical Standards: Design, Installation, Maintenance of Fire and Gas Detection SystemWael MansouriNessuna valutazione finora

- GF-30136C-EN - CXT-IR Wireless Detector - 2pLetterBro - 0Documento2 pagineGF-30136C-EN - CXT-IR Wireless Detector - 2pLetterBro - 0Sumesh FOSEnergyNessuna valutazione finora

- Catalog King PPEDocumento7 pagineCatalog King PPEAnonymous llBSa7Nessuna valutazione finora

- RMIT CO2 Refrigeration Lab Risk ManagementDocumento1 paginaRMIT CO2 Refrigeration Lab Risk ManagementPrestoneKNessuna valutazione finora

- Risk Assessment for Earthmoving OperationsDocumento42 pagineRisk Assessment for Earthmoving OperationsHolly SmithNessuna valutazione finora

- Toxic Gas DetectorDocumento6 pagineToxic Gas DetectorKvakumarv Vallatharasu100% (1)

- Guidelines for LPG plan submissionsDocumento7 pagineGuidelines for LPG plan submissionsPrathamesh ShevaleNessuna valutazione finora

- BW Clip Operators ManualDocumento4 pagineBW Clip Operators ManualSanthosh MechNessuna valutazione finora

- GP 30 85 Fire and Gas DetectionDocumento45 pagineGP 30 85 Fire and Gas Detectionsgh135586% (7)

- Sensors: A Survey On Gas Sensing TechnologyDocumento31 pagineSensors: A Survey On Gas Sensing TechnologyGerald KhoNessuna valutazione finora