Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cement From Plants

Caricato da

in59tDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cement From Plants

Caricato da

in59tCopyright:

Formati disponibili

Making Cements with Plant Extracts page -1-

Making cements

with

plant extracts

Reprint of papers published in 1981/82

presented at international archaeometry SYMPOSIA Brookhaven, N.Y. / bradford, U.K.

THE PROCEEDINGS

OF THE

22nd SYMPOSIUM ON ARCHAEOMETRY

HELD AT

THE UNIVERSITY OF BRADFORD, BRADFORD, U.K. 30th MARCH - 3rd APRIL 1982

EDITED BY

A. ASPINALL and S.E. WARREN

PUBLISHED BY SCHOOLS OF PHYSICS AND ARCHAEOLOGICAL SCIENCES UNIVERSITY OF BRADFORD, BRADFORD, W. YORKSHIRE BD7 1DP

Geopolymer Institute

ALL RIGTHS RESERVED

1997

Geopolymer Institute 16, rue Galile O 02100 SAINT-QUENTIN O France tel: +33/ 323 62 65 37 O FAX: +33/ 323 67 69 88 O e-mail: contact@geopolymer.org Oweb: www.geopolymer.org

Making Cements with Plant Extracts page -2-

Abstract of the paper presented at the 21st International Symposium for Archaeometry Brookhaven National Laboratory, New-York, USA, 1981, page 21

FABRICATION OF STONE OBJECTS, BY GEOPOLYMERIC SYNTHESIS, IN THE PRE-INCAN HUANKA CIVILISATION (PERU) by Joseph DAVIDOVITS* and Francisco AL IAGA* * *) Geopolymer Jnstitute,20 rue de la Fe re, F-02100 SAINT-QUENTIN (FRANCE) * * ) Depart. de Folklore, Instituto Nacional de Cultura , HUANKAYO (PERU) It is now agreed, that the TIHUANACO civilisation is modeled on the pre-incan HUANKA civilisation revealed by an extraordinary skill in fabricating objects in stone.A recent ethnological discovery shows that some witch-doctors in the HUANKA tradition, use no tools to make their little stone objects, but still use a chemical dissolution of the stone material by plant extracts. The starting stone material (silicate or silico-aluminate) is dissolved by the organic extracts, and the viscous slurry is then poured into a mould where it hardens. Already known are examples of fabrication of objects in hard stone by moulding a geopolymeric compound of the Na-,K-poly(sialate)(silico-oxo-aluminate) type. In this case, alcaline mineral reactants such as alcaline frit, caustic soda, soda (the Natron salt of the ancient egyptians) are used (l).On the other hand , in the case of pre-incan HUANKA civilisation, the geopolymeric reaction takes place through organo-mineral complexes as intermediate (plants).These chemical mechanism are known in geochemical, mineralogical, and geopolymeric sciences, especially in certain synthesis of zeolithic type poly(sialates) (2). The organo-mineral complexes are obtained through the intermediary of oxalates, tartrates, succinates, fulvates, etc. . (3). It is known also that the organo-mineral complexes have a very strong dissolving action on the natural silico-aluminates (feldspar, hornblende, laterite, chlorite,...), their dissolving action being 2 3 times greater than that of sulphuric acid or hydrochloric acid (4). The most highly activ organo-mineral complexes are those obtained with oxalic acid, which is found in large quantities in numerous plants (5). Statues which could have been made by the technique of the preincan HUANKA, by dissolution followed by geopolymeric agglomeration, are found to contain Caoxalate in the stone (6). This technique, when mastered, allows a sort of cement to be made by dissolving rocks; this chemical cement then serves to agglomerate aggregates or/and sands. The geopolymers obtained by these organo-mineral synthesis methods are either of the zeolithic, feldspathoidic or amphibolic type. The technique of the HUANKA people is illustrated by numerous objects found in the CUZCO site. Stone objects made with this technology all bear marks indicating that moulding has been used.

References

1) J. Davidovits, 2 lnternational Congress of Egyptologists,Grenoble,1979 -session 12: "La fabrication des vases de pierre dure aux V et IV millnaire avant J.C." Theme IV: "Les offrandes de Natron et le symbole de lincarnation divine dans la pierre". 2) D.W. Breck: Zeolite Nolecular Sieves, Chemistry and Uses,J.Wiley & Sons, New York, l974. 3) G.H. Kuehl, US Patent 3.386.801,(1968). 4) D.G. Sapozhnikov: "on the substraction of aluminum by organic acids from minerals and rocks in the course of weathering" Symposium Bauxite,Aluminum Oxyde and Hydroxyde, Zagreb (1963). 5) H. Erhardt: "Itinraires gochimiques et cycle gologique de 1aluminium" Doin Edit. Paris (1973). 6) G. Hyvert: "The statues of Rapa Nui", UNESCO Report n2868/RMO/CLP;Paris 1973.

Making Cements with Plant Extracts page -3-

Proceedings of the 22nd Symposium on Archaeometry, University of Bradford, Bradford, U.K. March 30th - April 3rd 1982. Pages 205 - 212.

THE DISAGGREGATION OF STONE MATERIALS WITH ORGANIC ACIDS FROM PLANT EXTRACTS, AN ANCIENT AND UNIVERSAL TECHNIQUE

J. DAVIDOVITS Geopolymer Institute 20 rue de la Fere, 02100 SAINT-QUENTIN, FRANCE. and A. BONETT and A.M. MARIOTTE Lab. de Pharmacognosie, Univ. de Grenobe I 33 700 LA TRONCHE, FRANCE.

At the XXI Archaeometry Symposium (1), we presented the hypothesis that the large stones in precolumbian monuments were artificial, having been agglomerated with a binder obtained by disaggregating certain rocks ( in agreement with local legend and tradition) . We present here the first results on plant extracts on the dissolution or disaggregation of calcium carbonate containing rocks (Bio-tooling action). The feasibility of chemically working calcium carbonate with strong acids (hydrochloric and formic acid) and various carboxylic acids found in plants (acetic, oxalic and citric acid) has been studied.

Experimental

The calcium carbonate used was from a homogeneous local deposit, broken into lumps. The technique was to scrape a depression in the surface, 2 cm diameter and 0.2 cm deep, then to add 0.5 ml of the acid solution. This was then worked with a flexible plastic spatula chosen to reduce scraping action. The resulting paste was removed when action appeared to have ceased. A furtner 0.5 ml each of acid was added and the process repeated until a total of eight additions of 0.5 ml each of acid has been made, i.e 4 ml in all. The volume of the resulting hole Vh was then measured. The scraping action of the tool was measured using pure water (eight additions of 0.5 ml each, i.e 4 ml in total). The volume of the resulting hole Vh was 14 3.5 ml. Without water, (i.e dry), the volume of the hole Formic acid 12 scraped during the same time (about 15 minutes) was 0.7 Hydrochloric acid ml. The aim was to carry out a quantitative investigation 10 while at the same time trying to use conditions where scraping action of the tool was minimized. It was for 8 this reason that we chose to work with a plastic spatula 6 (polyethylen) and to remove the paste progressively. It is obvious that working with hard tools increases the 4 yield considerably.

Vh ml

2

The action of strong acid solutions in water (formic and hydrochloric acid) is weaker than generally expected (Fig.1). There is no increase in the disaggregation at concentrations higher than 2 moles/liter. Acetic acid (Fig. 2)

0 0 0.5 1 1.5 2 2.5 3

Mole/liter

Figure 1: Volume Vh obtained with Formic and Hydrochloric acids

Making Cements with Plant Extracts page -4-

shows a better bio-tooling effect. Acetic acid is a major component of natural vinegar (1M to 2M concentration). Oxalic acid (Fig. 3) forms an insoluble, very hard, calcium oxalate, which precipitates and hinders the bio-tooling action. Citric acid (Fig.3) shows a maximum between 1 M and 1.5 M concentration. The slowing down with higher concentrations is due to reduced dissociation of the acid. Citric acid is present in large quantities in citrus fruits (1 M citric acid concentration), and in the sap of the succulent plants: Agave, Opuntia.

14 12 10 acetic acid

14 12 10 Citric acid Oxalic acid

Vh ml

Vh ml

8 6 4 2 0 0 0.5 1 1.5 2 2.5 3 3.5

8 6 4 2 0 0 0.5 1 1.5 2 2.5 3 3.5

Mole/liter

Figure 2: Volume Vh obtained with Acetic acid (vinegar)

Mole/liter

Figure 3: Volume Vh obtained with Citric and Oxalic acids

With addition of oxalic acid to vinegar (1 M) (Fig. 4) maximum rate of dissolution is reached after which at higher concentration of oxalic acid, apart from slowing down due to reduced dissociation of the acid, the calcium oxalate precipitates and hinders the action. Addition of citric acid improves the yield (Fig.4), which apart from its own dissolution action, forms a soluble complex with the calcium oxalate and renders the oxalic acid more efficient for the disaggregation. Maximum bio-tooling action is obtained with a solution containing: - vinegar (1 M) (acetic acid) - oxalic acid (0.9 M) - citric acid (0.78 M) Addition of formic acid (Fig.5) slows down the action of citric acid. The high pH of the solution reduces the dissociation of the acids, and consequently the bio-tooling effect.

14 12 10 (B.T.) Vinegar 1M Vin. 1M + Citric acid 0.26M Vin. 1M + Citric acid 0.52M Vin. 1M + Citric acid 0.78M

14 Formic acid A 12 10 Formic acid B

Vh ml

6 4 2 0 0 0.5 1 1.5 2

Vh ml

8 6 4 2 0

2.5

0.5

1.5

Oxalic acid Mole/liter

Figure 4: Volume Vh obtained with a solution of Vinegar 1M acetic acid containing Citric and Oxalic acids

Citric acid Mole/liter

Figure 5: Volume Vh obtained with solutions of Formic acid 0.5 M containing: (A): Citric acid , Vinegar 1M, Oxalic acid 1.2M; (B): Citric acid , Vinegar 1M, Oxalic acid 0.4M

Making Cements with Plant Extracts page -5-

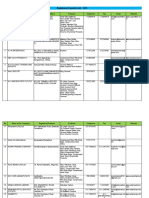

In parallel with these experiments, we have chromatographically identified acids found in various plants and we shall repeat the above experiment with actual plant extracts, basing our choice of plant extract mixtures on the best results obtained above (Table 1).

Table 1: identification of carboxylic acid in various plants

Propionic Glyoxylic

Ascorbic

x x x

Acids

Glycolic Acetic

Succinic

Tartaric

Glyceric

Fumaric

Pyruvic

Butyric

Valeric

Plants

Bourse Pasteur Capsella Bursapastoris Blackberry Bush Rubus Fructicosus

x x

x x x x x x x

x x

x x

x x

x x

Olive Tree Olea Europea

x x

x x

Nettle Urtica Dioixa

x x x x x x x x x x x x x x x x x x x x x x x x x x x

Patience Dock Rumex Crispus

Opuntia O. Ficus Indica

Sorrel Rumex Acetosa

Agave Agave Corulescens

Agave Americana Variete Marginata

medium

x x x

x x x x x

abundance

x x

Discussion

Acetic acid can easily be made in industrial quantities. The simple fermentation of sugar, from fruits, plants and roots, has been used in Antiquity to produce enormous quantities of vinegar (1 M and 2 M) (acetic acid concentration).

major

high

low

Formic

Oxalic

Citric

Lactic

Malic

x x

Making Cements with Plant Extracts page -6-

The great surprise was actually to discover very ancient references to their use since Neolithic times for working materials which are very hard but easily attacked by acids, such as chalk. Thus, a bas-relief from the tomb of Mera, at SAQQARAH (VI dynasty, 3Millenium B.C., Egypt) (Fig.6) shows the hollowing out of Egyptian alabaster (CaCO3) vases by a liquid contained in a water skin or bladder.

Figure 6: A bas-relief from the tomb of Merah at Saqqarah (VI Dynasty, 3 Millenium B.C.), Egypt, shows the hollowing out of "Egyptian alabaster" (CaCO3) vases by a liquid contained in a water skin or bladder.. Hieroglyphic text: wni 'trf i'w pn nwrt (It is for thee Ouni, this vessel is the greatest).

PLINY (2) mentions the use of vinegar (acetic acid) in the disaggregation of limestone rocks, and HANNIBAL (219 B.C.) is known to have used the technique to bore holes in, and burst open rocks obstructing his path through the Alps, in his attempt to conquer ROME. We may suppose this technique to have been used in part for the Avebury circle ditch (U.K.), for The ditch... a floor so smooth.. so well cut... no toolmarks on the walls, vertical and smooth faces.. the finest example of cut chalk.. .the hardest chalk must have been loosened...(3) (Fig.7 and Fig. 8).

Figures 7/8: The work in hard chalk with antler-, bone- and wood- tools, with the aid of vinegar/rumex extract. We may suppose this technique to have been used in part for the Avebury Circle Ditch (U.K.), for: "The ditch.. a floor so smooth ... walls so well cut ... no toolmarks on the walls, vertical and smooth faces .. the finest example of cut chalk .. the hardest chalk must have been loosened ..." (3).

The aliphatic dicarboxilic acids (oxalic, tartaric, succinic,) have a more specialised used in the formation of organo-mineral complexes necessary for certain geopolymerisations. Oxalic acid already belongs with ancient metallurgical techniques universally used: Corinthian Bronze (4) , Precolumbian gilding, Japanese Shaku-do. Oxalic acid in the free state is only found in small quantities in the plants: rhubarb, sloe, sorrel (rumex), oxalis-pubescens, etc..., since these plants contain mainly the salt calcium oxalate, which has to be transformed into oxalic acid. To do this, another organic acid is used: citric acid, present in large quantities in citrus fruits and as up to 70% of the sap of such succulent plants as: Opuntia Ficus Indica, Agave Americana, plants found in great profusion in the mediterranean countries, Australia, and N. and S. America. When sorrel (rumex) is mixed with the sap of Opuntia, the citric acid in the opuntia shifts the oxalate equilibrium in the sorrel towards oxalic acid; thus is obtained an important mixture of acids: oxalic, citric, tartaric, malic, formic...

Making Cements with Plant Extracts page -7-

The precolumbian farmers were quite capable of producing large quantities of acids from such common plants in their region as: fruits, potatoes, maize, rhubarb, rumex, agave americana, opuntia, ficus indica, oxalis pubescens. An experiment of interest was to compare the bio-tooling technique with the shaping of a hole using steel tool and the quartz sand technique recommended by prehistorians. The test was run for 15 minutes and the Vh measured for each technique. Vh after 15 minutes of working steel tool 12 ml (spoon spatula) quartz sand 8.5 ml bio-tooling (point B.T.) on Figure 4 9.5 ml The hole resulting from sand abrasion has rough walls, whereas bio-tooling gives a smooth finish.

References

1) J. DAVIDOVITS and F. ALIAGA: Fabrication of Stone Objects by Geopolymeric Synthesis, in the Pre-Incan Huanka Civilisation/Peru. XXI Archaeometry Symposium, Brookhaven 1981. 2) C.PLINY, Hist. Nat. Liber XXIII, chap. 27. 3) H.ST.G. GRAY ,The Avebury Excavations 1908-1922". Archaeologia, 84 (1935), 99-152. 4) P.T. CRADDCCK , Shakudo alloys from Imperial Rome, a link with Corinthian Bronze. XXI Archaeometry Symposium, Brookhaven 1981.

Potrebbero piacerti anche

- The Fall and Rise of Resonance Science - Mortenson - Abstract - WC2011Documento1 paginaThe Fall and Rise of Resonance Science - Mortenson - Abstract - WC2011in59tNessuna valutazione finora

- Transport Spheres - US20090127383A1 ScribdDocumento24 pagineTransport Spheres - US20090127383A1 Scribdin59tNessuna valutazione finora

- Star Trek - Phi Space Spatial HarmonicsDocumento1 paginaStar Trek - Phi Space Spatial Harmonicsin59tNessuna valutazione finora

- Atheist ProofsDocumento101 pagineAtheist Proofsin59tNessuna valutazione finora

- The Frugivorous Nature of ManDocumento12 pagineThe Frugivorous Nature of Manin59tNessuna valutazione finora

- 1 Trivium 3, 4 Quadrivium 7Documento1 pagina1 Trivium 3, 4 Quadrivium 7in59tNessuna valutazione finora

- Napier's Rods and Genaille-Lucas - RulersDocumento8 pagineNapier's Rods and Genaille-Lucas - Rulersin59tNessuna valutazione finora

- Smoking Helps Protect Against Lung CancerDocumento7 pagineSmoking Helps Protect Against Lung Cancerin59tNessuna valutazione finora

- A Place Called Gratitude and DesiderataDocumento4 pagineA Place Called Gratitude and Desideratain59tNessuna valutazione finora

- Geopolymer - Formula Pyramid Chapt1Documento15 pagineGeopolymer - Formula Pyramid Chapt1in59t100% (1)

- How To Deal With A PsychologistDocumento2 pagineHow To Deal With A Psychologistin59tNessuna valutazione finora

- Who Owns The World by Garry DavisDocumento27 pagineWho Owns The World by Garry Davisin59t0% (1)

- Samuel Laboy - Phi PyramidsDocumento10 pagineSamuel Laboy - Phi Pyramidsin59t100% (1)

- Dor Us4572622Documento3 pagineDor Us4572622in59tNessuna valutazione finora

- Cement From PlantsDocumento7 pagineCement From Plantsin59tNessuna valutazione finora

- Tesla Energy - Microwave Metamaterial With Integrated Power Harvesting Functionality - Tesla Idea - 1.4824473Documento4 pagineTesla Energy - Microwave Metamaterial With Integrated Power Harvesting Functionality - Tesla Idea - 1.4824473in59tNessuna valutazione finora

- Common Law Community Training Manual ITCCSDocumento27 pagineCommon Law Community Training Manual ITCCSin59tNessuna valutazione finora

- FreeMan - Ways You Can Give Up Your Sovereign Power and Accept The Role of PersonDocumento14 pagineFreeMan - Ways You Can Give Up Your Sovereign Power and Accept The Role of Personin59tNessuna valutazione finora

- Napier's Rods With The Square Root BoneDocumento6 pagineNapier's Rods With The Square Root Bonein59tNessuna valutazione finora

- Phi First 1000 in SeriesDocumento50 paginePhi First 1000 in Seriesin59tNessuna valutazione finora

- Paleo-Hebrew Alphabet U10900Documento2 paginePaleo-Hebrew Alphabet U10900in59tNessuna valutazione finora

- Phi KEY - 13 Phi HZ For Rhombic Dodecahedron Type IIDocumento1 paginaPhi KEY - 13 Phi HZ For Rhombic Dodecahedron Type IIin59tNessuna valutazione finora

- Correct Math For Holophonic Sound Is VBM Phi Tori ArrayDocumento3 pagineCorrect Math For Holophonic Sound Is VBM Phi Tori Arrayin59tNessuna valutazione finora

- Phi Pentagon HexagonDocumento1 paginaPhi Pentagon Hexagonin59tNessuna valutazione finora

- Can Mathematicians Be Poets? The History of Symbols in MathematicsDocumento8 pagineCan Mathematicians Be Poets? The History of Symbols in Mathematicsin59t100% (1)

- Cannabis Is More Than You THINKDocumento2 pagineCannabis Is More Than You THINKin59t100% (1)

- MONSTER - Authoritarian, Meat Eating, Solipsist, Money-Phile - La Surconsommation On Vimeo - HTMDocumento1 paginaMONSTER - Authoritarian, Meat Eating, Solipsist, Money-Phile - La Surconsommation On Vimeo - HTMin59tNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- GLOSSARY OF HYDROPOWER TERMSDocumento24 pagineGLOSSARY OF HYDROPOWER TERMSWaleed HassanNessuna valutazione finora

- Landscape Design Principles for Order and BeautyDocumento7 pagineLandscape Design Principles for Order and BeautysaimaNessuna valutazione finora

- Collections 2 0 2 1 Furniture: I B I Z ADocumento119 pagineCollections 2 0 2 1 Furniture: I B I Z ACecilia StraffonNessuna valutazione finora

- National Pollinator Week 2021Documento6 pagineNational Pollinator Week 2021Zachary DeLucaNessuna valutazione finora

- Structure and Biology Floral Nectary Apocynaceae) : of inDocumento5 pagineStructure and Biology Floral Nectary Apocynaceae) : of inKaran KumarNessuna valutazione finora

- Cooling TowerDocumento44 pagineCooling TowerakarczNessuna valutazione finora

- Directorate of Forest Based IndustryDocumento6 pagineDirectorate of Forest Based IndustryamitozaNessuna valutazione finora

- Color Card Eco EmulsionDocumento1 paginaColor Card Eco EmulsionAfif TriyogaNessuna valutazione finora

- PICKLE TYPESDocumento11 paginePICKLE TYPESfarumalikNessuna valutazione finora

- Ecological SuccessionDocumento5 pagineEcological SuccessionKirsten MckenzieNessuna valutazione finora

- A Guide To Home Scale Permaculture by Toby HemenwayDocumento245 pagineA Guide To Home Scale Permaculture by Toby HemenwayEddy Edwin WNessuna valutazione finora

- mw1016 MixoDocumento3 paginemw1016 Mixoapi-292113475Nessuna valutazione finora

- Contoh Soal Pilihan GandaDocumento7 pagineContoh Soal Pilihan GandaRosulianna SipayungNessuna valutazione finora

- Naruto Jinraiden - The Day The Wolf Howled PDFDocumento73 pagineNaruto Jinraiden - The Day The Wolf Howled PDFHaideBrocalesNessuna valutazione finora

- Post Harvest Management - Mid Term - Quiz1 and Quiz2Documento3 paginePost Harvest Management - Mid Term - Quiz1 and Quiz2Vishnuvardhan RavichandranNessuna valutazione finora

- Avant Garden MenuDocumento7 pagineAvant Garden MenuEater NYNessuna valutazione finora

- SailDocumento52 pagineSailcitunairNessuna valutazione finora

- Operation Philosophy of 209HA CCPP BhikkiDocumento34 pagineOperation Philosophy of 209HA CCPP BhikkiMunibNessuna valutazione finora

- Lantana Camara Linn. Chemical Constituents and Medicinal PropertiesDocumento4 pagineLantana Camara Linn. Chemical Constituents and Medicinal Propertieskisame akatsukiNessuna valutazione finora

- Ascorbic Acid in Plant Growth, Development and Stress Tolerance PDFDocumento514 pagineAscorbic Acid in Plant Growth, Development and Stress Tolerance PDFmalin.oloier100% (1)

- MR Shirish Garud Potential of CSP in IndiaDocumento24 pagineMR Shirish Garud Potential of CSP in Indiaaditya29121980Nessuna valutazione finora

- Registered Exporter List - 2019: No. Name of The Company Registered Address Products Telephone Fax Email WebsiteDocumento64 pagineRegistered Exporter List - 2019: No. Name of The Company Registered Address Products Telephone Fax Email WebsiteBismillah SugehNessuna valutazione finora

- Test 2Documento6 pagineTest 2Тимофій СадиковNessuna valutazione finora

- Morel Artificial CultivationDocumento15 pagineMorel Artificial CultivationAsdhrubal del BosqueNessuna valutazione finora

- Etete Food MenuDocumento1 paginaEtete Food MenuTim CarmanNessuna valutazione finora

- Pressure Cooking BookletDocumento10 paginePressure Cooking BookletDragan Fića FilipovićNessuna valutazione finora

- Millets Recipes Healthy FoodDocumento65 pagineMillets Recipes Healthy Foodsan2227Nessuna valutazione finora

- Wonderful Camping Experience in Mount BunderDocumento5 pagineWonderful Camping Experience in Mount BunderHolmes MarbunNessuna valutazione finora

- Feasibility StudyDocumento36 pagineFeasibility Studyclifford15201475% (4)

- Report Sugarcane Lifter 1Documento42 pagineReport Sugarcane Lifter 1Tejas KadamNessuna valutazione finora