Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

93 15

Caricato da

sharawy12Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

93 15

Caricato da

sharawy12Copyright:

Formati disponibili

TO:

SERVICE MANAGER PARTS MANAGER

TECHNICIAN

= Revised February, 1995

No. 93-15

NOTICE: The information contained in this Service Bulletin supercedes all previous bulletins, including 92-6.

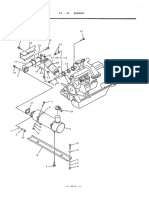

Rochester 4 Barrel Quadrajet Carburetor

MCM 205/4.3LX Rough Idle or Cant Adjust Idle Mixture Screws Possible cause could be air leak through carburetor mounting gasket. This gasket may leak in the area of the screw that holds the throttle body to the float bowl. This screw (a) is in a hole in the base of the carburetor, on the throttle lever side (Figure 1.). Because of this hole, the gasket may not be making an air tight seal. Remove carburetor from intake manifold. Inspect gasket to see if it has covered screw hole completely to seal out air leak. Do not remove screw, just fill screw hole with a silicone sealer. Using new mounting gasket, install carburetor. Torque carburetor mounting nuts and bolts to 20 lb. ft. (27 Nm).

Figure 1. (1) 27-52457--2 Mounting Gasket Engine RPM Hunts at Idle Speed Engine RPM wont hold steady at idle. Varies up and down 300-500 RPM. This indicates that there is a possible vacuum leak. Check for vacuum leak at the normal locations first: intake manifold gasket, carb gasket, etc. If the vacuum leak isnt found at the normal locations, it might be caused by loose base screws (a), in Figure 1. Remove carburetor from engine, and drain fuel from it. Turn carb upside-down and check the tightness of the two screws that hold base to carb float bowl. Remove the screws and apply a small amount of Loctite 271 to the threads. Reinstall screws and tighten securely. (1) 27-52457--2 Mounting Gasket

Printed in U.S.A.

-1-

93-15 295

MCM 4.3LX and 5.7L Alpha Hard Starting or Rich Idle The engines that fall into the serial numbers listed may have the choke linkage installed incorrectly. If you experience this type of problem on an engine in the range given, check the choke rod for correction installation. 4.3LX 0C755446-0C755512 5.7L 0C755369-0C755396 and 0C755528-0C755592

a - Choke Rod

a - Choke Rod

Correct Installation Automatic Choke Problem

Incorrect Installation

If the engine runs rich for a long period of time after start-up or the choke takes a long time to come off, the automatic choke may be at fault. The failure to the choke is that the pin (that anchors the spring to the base) rotates in the base. This causes the choke timing to be off. Start a cold engine and watch the choke operation. If choke doesnt come off or comes off very slowly, the problem could be the choke. Refer to the engines part list for correct replacement part number. Carburetor Flooding When removing the air horn from a carburetor for this problem, look at the pull clip for the needle. This pull clip must be hooked over the end of the float arm, not in the holes. If the clip is hooked in either hole, the needle will not seat properly. This could be the reason for the flooding problem.

70818

a - Hook Over End of Float Arm b - DO NOT Hook in These Holes

93-15 295

-2-

MCM 5.0LX Down in Power We have had some reports of this engine being down in power above 3000 RPM. To correct this problem, do the following; 1. Reset the secondary air valve (a) spring windup to 60 grams. 2. Replace the stepped flame arrestor stud, (b). Replacement stud doesnt have step. The stepped stud could cause the secondary air valve to stick partially closed. 16-91842 11-28941 Stud, (c). Nut, (d), to take the place of the upper step so flame arrestor doesnt get over tightened.

c d a b

74570

Suggested Changes for Running at Altitude For gear ratio changes, see Service Bulletin 93-7. The following is meant to be a guide when the engine is going to be used at altitudes other than sea level. If you are at sea level and your customer is going to a higher elevation for a short period of time, no changes to the gear ratio, timing or carburetor should be done. If your customer will be doing all their boating at higher altitudes, then changes can be done. If the boat is then brought back to sea level, everything has to be changed back for sea level use. Generally, timing can be advanced 2 degrees for every 5000 ft. (1525 m) elevation to help engine performance.

! CAUTION

To prevent engine damage, do not set timing any higher than for the lowest elevation that customer will be running the boat. Before ordering secondary metering rods, look at the chart to try and determine the size of the stock metering rods. We suggest that you look at the size stamped on the secondary metering rods in the carburetor that your working on before ordering jets. IMPORTANT: Change only the secondary metering rods.

-3-

93-15 295

MCM STERN DRIVE ENGINES Model 4.3LX 5.0LX 5.7L Alpha 350 Mag 7.4L Bravo and 454 Mag Alpha 454 Mag Bravo 502 Mag Bravo Carburetor Part Number 3304-9354A_ (17084516) 1347-9661A_ (17080565) 1347-9662A_ (17080561) 1347-8289A_ (17080562) 1347-8291A_ (17080563) 1347-9863A_ (17059280) 1347-814623A_ (17089112) 5000 ft. (1525 m) and Below ED Stock Jet CL Stock Jet CL Stock Jet CH Stock Jet DP Stock Jet DA Stock Jet DC Stock Jet 5000-9000 ft. (1525-2745 m) CL CT CT DB CT DH EL 9000 ft. (2745 m) and Above CT DW DW CG DW CT EC

MIE INBOARD AND SKI ENGINES Model 5.0L 5.7L Ski 5.7L 5.7L 7.4L 7.4L Carburetor Part Number 1347-9415A_ (17080565) 1347-9415A_ (17085013) 1347-8289A_ (17080562) 1347-816373A_ (17090210) 1347-8288A_ (17080560) 1347-816467A_ (17090211) 5000 ft. (1525 m) and Below CL Stock Jet CH Stock Jet CH Stock Jet DA Stock Jet CL Stock Jet DA Stock Jet 5000-9000 ft. (1525-2745 m) CT DB DB DH CT DH 9000 ft. (2745 m) and Above DW CG CG CT DW CT

Notice: The secondary metering rods will have to be purchased from a Rochester products dealer because Quicksilver will not be stocking them.

Metering Rod Letters CG CH CL CT DA DB DC

Rochester Part Number 7045778 7045779 7045782 7045983 7046010 7047806 7047816

Metering Rod Letters DH DP DW EC ED EL

Rochester Part Number 7048992 17053531 17062432 17081095 17081878 17082672

93-15 295

-4-

Potrebbero piacerti anche

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDa EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsValutazione: 5 su 5 stelle5/5 (2)

- Kohler Carburetor Reference Manual TP-2377-EDocumento60 pagineKohler Carburetor Reference Manual TP-2377-EChevronelle100% (1)

- GM 6t70 UpdatesDocumento45 pagineGM 6t70 UpdatesThePokeOne100% (9)

- Rochester Carb 4 BBL Adjustement 94hg5cDocumento12 pagineRochester Carb 4 BBL Adjustement 94hg5cJean-Baptiste Bulliard100% (3)

- Holley Carb AdjustmentsDocumento8 pagineHolley Carb AdjustmentsAaron SteeleNessuna valutazione finora

- Diesel Engine Care and Repair: A Captain's Quick GuideDa EverandDiesel Engine Care and Repair: A Captain's Quick GuideValutazione: 5 su 5 stelle5/5 (1)

- Yamaha DS7 (72) RD250 (73) R5C (72) RD350Documento113 pagineYamaha DS7 (72) RD250 (73) R5C (72) RD350Igor Majksner100% (5)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento15 pagineInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768jesuz_mtz26Nessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- Engine Mechanical PDFDocumento115 pagineEngine Mechanical PDFAndrey GladyshevNessuna valutazione finora

- Att Trans ToolsDocumento72 pagineAtt Trans Toolssharawy12Nessuna valutazione finora

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDa EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesValutazione: 5 su 5 stelle5/5 (1)

- The Interchange of Verbal and Nonverbal Cues in Computer-MediatedDocumento31 pagineThe Interchange of Verbal and Nonverbal Cues in Computer-Mediatedsharawy12Nessuna valutazione finora

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorDa EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNessuna valutazione finora

- Continental TorquesDocumento13 pagineContinental Torquesfredtanner100% (2)

- Tech Tip: Si CarburettorDocumento2 pagineTech Tip: Si CarburettorcesarecontoNessuna valutazione finora

- Injector Bypass Fuel Flow - Test: Previous ScreenDocumento10 pagineInjector Bypass Fuel Flow - Test: Previous ScreenMiguel Gutierrez100% (2)

- STC Oil Control Valve Mechanical 006 007 K38 K50Documento18 pagineSTC Oil Control Valve Mechanical 006 007 K38 K50SpectrumRaijin100% (11)

- Goldcup SVM M11 - M14 D PDFDocumento29 pagineGoldcup SVM M11 - M14 D PDFJoaquínIgnacioNessuna valutazione finora

- XJS 3.6 Service EngineDocumento192 pagineXJS 3.6 Service Enginessinokrot100% (1)

- Service Bulletin Mercarb 97 - 08Documento6 pagineService Bulletin Mercarb 97 - 08hormiganegra431Nessuna valutazione finora

- Manual EatonDocumento92 pagineManual Eatonruben_cruz_34100% (1)

- Calibracion de Inyectores y Jacobs Detroit Series 60Documento28 pagineCalibracion de Inyectores y Jacobs Detroit Series 60Ramon Garcia100% (1)

- Test Transmision 420E CatDocumento8 pagineTest Transmision 420E CatEdin Raul Yalle RafaelNessuna valutazione finora

- Cylinder Head - Install: Cerrar SIS Pantalla AnteriorDocumento21 pagineCylinder Head - Install: Cerrar SIS Pantalla AnteriorReymundo Enrique Dominguez Hernandez100% (1)

- 199R7948 5rev5 PDFDocumento16 pagine199R7948 5rev5 PDFbatman2054Nessuna valutazione finora

- Failures of Cylinder Head Valves On G3500C and G3500E Generator Set Engines (1100, 1105, 1121)Documento5 pagineFailures of Cylinder Head Valves On G3500C and G3500E Generator Set Engines (1100, 1105, 1121)Ahmed Nahrawy100% (1)

- 5 Feeder Protection & Relay CoordinationDocumento51 pagine5 Feeder Protection & Relay CoordinationSatya VasuNessuna valutazione finora

- Basic Preventive Maintenance Check List For ReciprocatingDocumento4 pagineBasic Preventive Maintenance Check List For Reciprocatingsubramanyanvenkat6185100% (1)

- Subsea Pipeline Design Report.Documento26 pagineSubsea Pipeline Design Report.Luke6nNessuna valutazione finora

- Cat 307D Main Pump OperationDocumento3 pagineCat 307D Main Pump Operationkahandawala100% (1)

- Cylinder Head - Install: Desarmado y ArmadoDocumento35 pagineCylinder Head - Install: Desarmado y ArmadoCésar Pérez100% (1)

- Manual 1000 HP Quintuplex MSI QI 1000 PumpDocumento106 pagineManual 1000 HP Quintuplex MSI QI 1000 Pumposwaldo58Nessuna valutazione finora

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Mechanis Quizbee in Math and ScienceDocumento4 pagineMechanis Quizbee in Math and ScienceChristine De San Jose80% (5)

- Manual TransmissionDocumento19 pagineManual TransmissionPaklong Azham100% (1)

- Compressor WabcoDocumento6 pagineCompressor Wabcoruben_cruz_34Nessuna valutazione finora

- Install Cylinder HeadDocumento6 pagineInstall Cylinder Headrahmat sanusiNessuna valutazione finora

- Valve Lash G3408Documento9 pagineValve Lash G3408Djebali MouradNessuna valutazione finora

- 28 Psychrometric ProcessesDocumento19 pagine28 Psychrometric ProcessesPRASAD326100% (7)

- Ashrae 90.1-2010Documento92 pagineAshrae 90.1-2010asarlakNessuna valutazione finora

- Foote-Jones 8000 Series Gear Reducer ManualDocumento20 pagineFoote-Jones 8000 Series Gear Reducer ManualbwelzNessuna valutazione finora

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- CAT 3412 Air Inlet and Exhaust SystemDocumento8 pagineCAT 3412 Air Inlet and Exhaust SystemCEVegaO100% (2)

- Engine Top BracingDocumento14 pagineEngine Top Bracingcall_manishNessuna valutazione finora

- SF6 Outdoor CB Brochure 72.5 - 245kVDocumento8 pagineSF6 Outdoor CB Brochure 72.5 - 245kVtatacpsNessuna valutazione finora

- Manual Cat Grader 24H 31-3-14Documento29 pagineManual Cat Grader 24H 31-3-14Ahmad HandokoNessuna valutazione finora

- BHEL - Agitator Specification PDFDocumento68 pagineBHEL - Agitator Specification PDFRiyaz100% (1)

- 6 60 02a Engine BrakeDocumento6 pagine6 60 02a Engine BrakeGonzalo PerezNessuna valutazione finora

- Grafica de Medidas para Recesion de Valvulas G3400Documento3 pagineGrafica de Medidas para Recesion de Valvulas G3400carlos angelNessuna valutazione finora

- CSL 1007Documento11 pagineCSL 1007oscar horacio flores100% (1)

- Sum-Carb InstrDocumento14 pagineSum-Carb InstrbobNessuna valutazione finora

- Pole Position 14 VKMC 01250 1 EN Highres PDFDocumento6 paginePole Position 14 VKMC 01250 1 EN Highres PDFRita PcomputerNessuna valutazione finora

- MEGA Operating InstructionsDocumento14 pagineMEGA Operating InstructionsSumit SinghaNessuna valutazione finora

- Prueba y Ajuste Presion de Valvula de Salida de ConvertidorDocumento5 paginePrueba y Ajuste Presion de Valvula de Salida de ConvertidorguayanecitroNessuna valutazione finora

- Hydrostatic TestDocumento22 pagineHydrostatic TestGuido Emanuel SteinbachNessuna valutazione finora

- Jet Kit InstallDocumento2 pagineJet Kit InstallmihaisimoNessuna valutazione finora

- D155E 10.02 (DOWMAX English)Documento50 pagineD155E 10.02 (DOWMAX English)Nastase Dan NicusorNessuna valutazione finora

- 25F-PRCServ PDFDocumento38 pagine25F-PRCServ PDFsindelu60Nessuna valutazione finora

- CSL 1023Documento6 pagineCSL 1023oscar horacio floresNessuna valutazione finora

- REHS1037 - Fuel Priming PumpDocumento13 pagineREHS1037 - Fuel Priming Pumpkman548Nessuna valutazione finora

- Technical Service Bulletin: 210-2418 Ed. 4 April 2006 AllDocumento7 pagineTechnical Service Bulletin: 210-2418 Ed. 4 April 2006 AllPyro KDNessuna valutazione finora

- Assembly Compression AirDocumento3 pagineAssembly Compression Airaqshal candraNessuna valutazione finora

- Actuator General KC 03 040Documento10 pagineActuator General KC 03 040Devendrasinh JadejaNessuna valutazione finora

- Power TrimDocumento9 paginePower TrimLeigh GallowayNessuna valutazione finora

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 73-20-01Documento6 pagineRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 73-20-01anony81030% (1)

- Fuel System Pressure - Test: Testing and AdjustingDocumento5 pagineFuel System Pressure - Test: Testing and AdjustingMohamed SaiedNessuna valutazione finora

- Prueva PresionDocumento7 paginePrueva PresionAlonso PachecoNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- 73-91 Chevy Blazer / GMC Jimmy (Full Size) 13401: Do Not Exceed Vehicle Manufacturer'S Recommended Towing Capacity.Documento1 pagina73-91 Chevy Blazer / GMC Jimmy (Full Size) 13401: Do Not Exceed Vehicle Manufacturer'S Recommended Towing Capacity.sharawy12Nessuna valutazione finora

- Removing The Original Master CylinderDocumento5 pagineRemoving The Original Master Cylindersharawy12Nessuna valutazione finora

- Power Window MotorDocumento4 paginePower Window Motorsharawy12Nessuna valutazione finora

- 2011 Measurements of Effective Teaching in The Traditional and Online Contexts Teacher Immediacy, Student Motivation, & Student LearningDocumento66 pagine2011 Measurements of Effective Teaching in The Traditional and Online Contexts Teacher Immediacy, Student Motivation, & Student Learningsharawy12Nessuna valutazione finora

- 2010 Online Learning in Higher EducationDocumento41 pagine2010 Online Learning in Higher Educationsharawy12Nessuna valutazione finora

- Instructional ImmediacyDocumento69 pagineInstructional Immediacysharawy12Nessuna valutazione finora

- Book 1Documento1 paginaBook 1sharawy12Nessuna valutazione finora

- VBX Complete7 09Documento8 pagineVBX Complete7 09FSR1407Nessuna valutazione finora

- ImprintDocumento2 pagineImprintsharawy12Nessuna valutazione finora

- BMW - Us X1 - 2015Documento66 pagineBMW - Us X1 - 2015Alex PaunaNessuna valutazione finora

- Tabla Cargas Grua F4C-892Documento4 pagineTabla Cargas Grua F4C-892Juan Carlos Callas GarayNessuna valutazione finora

- Physics Thermal Chemical Current MCQDocumento5 paginePhysics Thermal Chemical Current MCQAyan GhoshNessuna valutazione finora

- SMK 630 DDocumento8 pagineSMK 630 DMuhammad Chaidir FhadlyNessuna valutazione finora

- Microturbine Developments PDFDocumento26 pagineMicroturbine Developments PDFsfsagfegfdbfdNessuna valutazione finora

- Product Manual 36641 (Revision H) : Governor Oil Heat Exchanger For PG & EG GovernorsDocumento10 pagineProduct Manual 36641 (Revision H) : Governor Oil Heat Exchanger For PG & EG GovernorsMussardNessuna valutazione finora

- 31 Getting Your Refrigerator To RDocumento19 pagine31 Getting Your Refrigerator To Rraypower2004Nessuna valutazione finora

- PDS655S 404 405Documento59 paginePDS655S 404 405Naing Min HtunNessuna valutazione finora

- Fluid MechanicsDocumento35 pagineFluid MechanicsJohn Ely Collado Bantog0% (1)

- Colfax Mechanical Seal LeakageDocumento4 pagineColfax Mechanical Seal Leakagesoumya19800000000Nessuna valutazione finora

- Mapúa University: Shop Practice No. 9Documento5 pagineMapúa University: Shop Practice No. 9marisonNessuna valutazione finora

- Polymers, Natural Polymers, NaturalDocumento3 paginePolymers, Natural Polymers, NaturalPrem KumarNessuna valutazione finora

- Снимок экрана 2023-03-01 в 09.16.43Documento48 pagineСнимок экрана 2023-03-01 в 09.16.43Maksim ZolotarjovNessuna valutazione finora

- Vinod Final Polyplex-1Documento103 pagineVinod Final Polyplex-1Fan of carry minatiNessuna valutazione finora

- Austria PowerpointDocumento6 pagineAustria PowerpointSammie WainainaNessuna valutazione finora

- Heat Transfer ActivityDocumento4 pagineHeat Transfer ActivityMark Angelo UyNessuna valutazione finora

- Isv5 0-Web PDFDocumento2 pagineIsv5 0-Web PDFperulapiaNessuna valutazione finora

- Accident Prevention Program: Thunderstorms - Don't Flirt ... Skirt'EmDocumento5 pagineAccident Prevention Program: Thunderstorms - Don't Flirt ... Skirt'EmLohrasp SuraliwalaNessuna valutazione finora

- Expt 8.7 Finding The Formula of Copper OxideDocumento2 pagineExpt 8.7 Finding The Formula of Copper OxideIra Munirah0% (2)

- Effects of Mass Transfer On Heat and Mass Transfer Characteristics Between Water Surface and AirstreamDocumento11 pagineEffects of Mass Transfer On Heat and Mass Transfer Characteristics Between Water Surface and AirstreamPiterNessuna valutazione finora

- 3.3 Schematic Diagram (Gm-8706Zt/Uc)Documento12 pagine3.3 Schematic Diagram (Gm-8706Zt/Uc)qmarcelNessuna valutazione finora