Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Automotive CBC

Caricato da

Allan TomasDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Automotive CBC

Caricato da

Allan TomasCopyright:

Formati disponibili

Republic of the Philippines

Department of Education

Public Technical Vocational High Schools

COMPETENCY-BASED CURRICULUM

AUTOMOTIVE SERVICING NC I

TABLE OF CONTENTS

Course Design Course Structure ..... Performing Shop Maintenance . Performing Mensuration and Calculation Reading, Interpreting and Applying Specifications and Manuals Applying Appropriate Sealant/Adhesive .. Using and Applying Lubricants/Coolants Moving and Positioning Vehicle .. Servicing Automotive Battery .. Testing and Repairing Wiring/ Lighting System ... Servicing Ignition System .. Performing Gas Engine Tune-up . Performing Diesel Engine Tune-up . Performing Under-chassis Preventive Maintenance . Acknowledgement ..

1 2 9 14 18 23 28 32 36 41 44 54 63 67 77

COURSE DESIGN COURSE TITLE NOMINAL DURATION : : AUTOMOTIVE SERVICING 1200 Hours NC 1 This course is designed to enhance the knowledge, skills and attitudes of an individual in the field of automotive servicing in accordance with industry standards. It covers basic, common and core competencies such as; gas and diesel tune-up, automotive battery service, ignition system, test and repair wiring/lighting system, under chassis preventive maintenance and shop maintenance.

QUALIFICATION LEVEL : COURSE DESCRIPTION:

ENTRY REQUIREMENTS Candidate/trainee must possess the following qualifications: Can communicate both orally and in writing Physically and mentally fit With good moral character Must have taken the exploratory course in automotive technology.

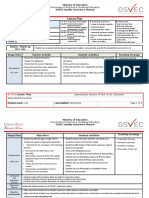

COURSE STRUCTURE FIRST

Unit of Competency Module Title PC Operation Metal Works Entrepreneurs hip Electricity

YEAR

Learning Outcome Suggested No. of Hours 100 100 100 100

SECOND

PERFORM SHOP MAINTENANCE

YEAR

15

PERFORMING LO 1. Inspect/clean SHOP tools and work area MAINTENANCE LO 2. Store/arrange tools and shop equipment LO 3. Dispose waste/used lubricant LO 4. Report damaged tools/equipment LO 1. Select measuring instrument LO 2. Carry out measurement and calculation

10

10 15 30

PERFORM MENSURATION AND CALCULATION

PERFORMING MENSURATIO N AND CALCULATION

40

READ, INTERPRET AND APPLY SPECIFICATION AND MANUAL

READING, INTERPRETIN G AND APPLYING OF SPECIFICATIO N AND MANUAL

LO 3. Maintain measuring instrument 30 LO 1. Identify and assess 10 manual specification LO 2. Interpret manuals LO 3. Apply information in manual LO 4. Store manuals 10 20 10

1

Competency-Based Curriculum for Public Tech-Voc High Schools

APPLY APPROPRIATE SEALANT/ADH ESIVE

APPLICATION OF APPROPRIATE SEALANT/ADH ESIVE

LO 1. Identify appropriate sealant/adhesive

10

LO 2. Prepare surface for 10 sealant/adhesive LO 3. Apply sealant/adhesive evenly LO 4. Store/dispose of sealant/adhesive 20 10

USE AND APPLICATION OF LUBRICANTS/ COOLANT

USING AND APPLYING LUBRICANTS/ COOLANT

Lo 1. Identify types of lubricants/ coolants LO 2. Use and apply lubricants/ coolants LO 3. Perform housekeeping activities LO 1. Prepare vehicle for driving LO 2. Move and position vehicle

10

30 10 50 50

MOVEMENT AND POSITION OF VEHICLE

MOVING AND POSITIONING OF VEHICLE

THIRD

SERVICE AUTOMOTIVE BATTERY SERVICING AUTOMOTIVE BATTERY

YEAR

LO 1. Test automotive battery LO 2. Remove and replace batteries LO 3. Service and charge battery LO 4. Jump start vehicle 30 10 40 20 15 15 20 16

TEST AND REPAIR WIRING/LIGHTI NG SYSTEM

TESTING AND LO 1. Test electrical REPAIRING OF systems WIRING/LIGHT ING SYSTEM LO 2. Repair electrical systems LO 3. Test / repair starting system LO 1. Check ignition system

SERVICE IGNITION SYSTEM

SERVICING IGNITION SYSTEM

2

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Perform spark test LO 3. Check ignition coil resistance LO 4. Check ballast resistor LO 5. Adjust contact point clearance LO 6. Perform ignition wiring installation LO 7. Adjust ignition timing LO 8. Repair nonelectronic ignition system

6 6 5 17 20

10 20

FOURTH

PERFORM GAS ENGINE TUNEUP PERFORMING GAS ENGINE TUNE-UP

YEAR

Lo 1. Check/adjust valve clearance LO 2. Inspect/test spark plug 25 5

LO 3. Check/replace fuel 5 filter and air cleaner LO 4. Inspect/ replace contact points/condenser LO 5. Adjust engine idle speed and mixture LO 6. Test/adjust dwell angle and ignition setting LO 7. Check advance mechanism and adjust ignition timing LO 8. Conduct compression test 10

5 10

20

20

PERFORM DIESEL

PERFORMING DIESEL

Lo 1. Install injection pump following the

60 3

Competency-Based Curriculum for Public Tech-Voc High Schools

ENGINE TUNEUP

ENGINE TUNE- correct timing UP LO 2. Bleeding injection fuel pump LO 3. Conduct compression testing PERFORMING LO 1. Check fluid and UNDERCHASSI lines S PREVENTIVE MAINTENANCE LO 2. Inspect brake system LO 3. Check /change manual transmission and differential gear oil LO 4. Inspect/replace power steering fluid PERFORMING LO 5. Check/refill UNDERCHASSI automatic transmission S PREVENTIVE fluid MAINTENANCE LO 6. Inspect/bleed air tank LO 7. Check tires and tire pressure LO 8. Check underchassis body parts bolts and nuts

20 20 20 50 20

PERFORM UNDERCHASSI S PREVENTIVE MAINTENANCE

10 15

PERFORM UNDERCHASSI S PREVENTIVE MAINTENANCE

15 20 50

ASSESSMENT METHOD: Observation Demonstration and interview Written test Third party report Portfolio

COURSE DELIVERY Modular Demonstration Lecture Discussion Dual Training Self-paced instruction EQUIPMENT 4

Competency-Based Curriculum for Public Tech-Voc High Schools

Engine-Mock-up (Diesel) Engine-Mock-up (Gas) Hydraulic Jack Grinding Machine Timing Light Hydraulic Press Multi-tester Under-chassis Unit Mock-up Air Compressor Electrical Mock-up Running Vehicle Oil Station Portable Crane Welding Machine Solvent Tank Washer Hydraulic Lifter Bench Vise Dwell Meter Compression Tester (Diesel) Compression Tester (Gas) Wheel Alignment Computer Wheel Balancer Computer Mock-up Electrical System Clutch Transmission Drive Line Differential and Axle Spring and Suspension System Oxy Acetylene Steering System (Manual) Steering System (Power) Brake System Piston Ring Compressor (light duty) Hydraulic Transmission Jack Valve Spring Compressor

TOOLS Box Wrench of 28 pcs. 4mm 32mm Open-End Wrench of 28 pcs. 4mm-32mm Set of Socket Wrench Set of Screw Drivers Wire Strippers Set of Mechanics Hammer Apron Impact Wrench Soldering Gun/Iron Carburetor Tool Set Oil Pressure Tester Injection Nozzle 5

Competency-Based Curriculum for Public Tech-Voc High Schools

Torque wrench Cell tester Hydrometer Dial Gauge Bore Gauge Caliper Set Vise Grip Filter Wrench Adjustable Wrench Set of Files Outside Micrometer (0-100mm) Outside Micrometer (0-50 eng. Sys) Push-Pull Rule Outside Snap Ring Inside Snap Ring Hack Saw Set of Punches Set of Flaring tools Feeler Gauge Allen Wrench Voltmeter Multi-Tester Steel Rule Set of Chisels Magnetic Stand Helmet Welding Shield Hack Saw Blade # 12 Set of Twist Drill Bit Oil Seal Remover (light duty) Tri-square# 12 Set of Puller (light duty) Tire Wrench (light duty) Tire Pressure Gauge Vernier Caliper Glove

6

Competency-Based Curriculum for Public Tech-Voc High Schools

MATERIALS Engine Oil Grease Sealant/Adhesive Gear Oil Automatic Transmission fluid Test Lamp Goggle Rags Sandpaper Gasoline/Diesel Grinding Compound Gaskets Plasti gauge ATP Teflon Tape Mechanical Blue

7

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY MODULE TITLE NOMINAL DURATION MODULE DESCRIPTION

: PERFORM SHOP MAINTENANCE : PERFORMING SHOP MAINTENANCE : 50 hours : This module covers the knowledge, skills and attitudes required in inspecting and cleaning of work area including tools and equipment and disposal of used materials are also incorporated in this competency.

SUMMARY OF LEARNING OUTCOMES: Upon completion of this module the students will be able to: LO 1. Inspect/clean tools and work area LO 2. Store/arrange tools and shop equipment LO 3. Dispose waste/used lubricant LO 4. Report damaged tools/equipment

8

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Inspect/clean tools and the work area ASSESSMENT CRITERIA: 1. Cleaning solvent is properly used per workshops/tools and cleaning equipment requirements. 2. Work area is checked and cleaned as per workshop Standard Operating Procedure SOP. 3. Wet surface/spots/stains in work area is wiped and removed in accordance with required performance standards. CONTENT: 1. Methods and techniques in cleaning tools and work area. 2. Kinds, uses and properties of cleaning solvents. 3. 5-S (Sort, Systematize, Sweep, Sanitize, Self-discipline) CONDITIONS: The following resources are needed: Automotive Tools Cleaning materials Personal Protective Equipment

Learning Materials Maintenance Procedure Manual Maintenance Schedule Form

METHODOLOGIES Discussion Demonstration

ASSESSMENT METHODS Observation Practical demonstration

9

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Store/arrange tools and shop equipment ASSESSMENT CRITERIA: 1. Tools/equipment are checked and stored in their respective shelves/location. 2. Tools and equipment are properly labeled. 3. Tools are safely secured and properly recorded. CONTENT: 1. Proper handling of tools and equipment 2. Procedures in storing/arranging tools and equipment 3. Safety measures in storing/arranging tools and equipment CONDITIONS: The following resources are needed: Tools Relevant tools & instruments

Materials Cleaning materials

Learning Materials Maintenance Procedure Manual Maintenance Schedule

METHODOLOGIES: ASSESSMENT: Observation Practical demonstration Discussion Demonstration

10

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 3. Dispose waste/used lubricant ASSESSMENT CRITERIA: 1. Containers for used lubricants are properly labeled. 2. Waste/used lubricants are disposed as per workshop Standard Operating Procedure (SOP). CONTENT: 1. Proper disposal of used lubricants 2. Safety measures in disposing used lubricants CONDITIONS: The following resources are needed: Garbage container Used lubricants

Learning Materials: Module Manuscript

METHODOLOGIES Discussion Demonstration

ASSESSMENT METHODS Observation Practical demonstration

11

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 4. Report damaged tools/equipment ASSESSMENT CRITERIA: 1. Complete inventory of tools/equipment is maintained. 2. Damaged tools/equipment are identified and repair recommendation is given. 3. Reports are prepared without error nor discrepancy. CONTENT: Inventory of functional and non-functional tools/equipment Inventory report Borrowers receipt

CONDITIONS: The following resources are needed: Receipt Cleaning materials Equipment Personal Protective Equipment (PPE)

Learning material Module

METHODOLOGIES Discussion Demonstration

ASSESSMENT METHODS Observation Interview/oral questioning Practical demonstration

12

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY MODULE TITLE NOMINAL DURATION MODULE DESCRIPTION

: : : :

PERFORM MENSURATION AND CALCULATION PERFORMING MENSURATION AND CALCULATION 100 hours This module covers the knowledge, skills and attitudes in identifying, caring, handling, and using of measuring instruments.

SUMMARY OF LEARNING OUTCOMES: Upon completion of this module the students/trainees will be able to: LO 1. Select measuring instrument LO 2. Carry out measurement and calculation work LO 3. Maintain measuring instruments

13

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Select Measuring Instrument ASSESSMENT CRITERIA: 1. Object or component to be measured is identified. 2. Correct specifications from relevant source are obtained. 3. Appropriate measuring instrument is selected according to job requirements. CONTENT: 1. Importance of measuring instruments 2. Classification of measuring instruments CONDITIONS: The following resources are needed: Components to be measured Personal protective equipment (PPE) Measuring instruments Manufacturers specification manual Safety precautions in using measuring instrument Simulated work area

METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Written test Practical Demonstration

14

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Carry out measurement and calculation ASSESSMENT CRITERIA: 1. Measuring tools are selected in line with job requirements. 2. Accurate measurements are obtained in accordance with the job requirements. 3. Calculation needed to complete work facts are performed using the four fundamental operations of addition (+), subtraction (-), multiplication (*), and division (/). 4. Calculations involving fraction, percentage and mixed numbers are used to complete work place tasks. 5. Numerical computation is self-checked and corrected for accuracy. 6. Instruments are read to the limit of accuracy of the tools. CONTENT: 1. Selecting measuring tools 2. Procedure in making measurement 3. Making calculations by using four fundamental operations 4. Interpreting calculations involving fraction and percentage CONDITIONS: The following resources are needed: Tools Measuring tools Materials Ball pen/pencil Bond paper Equipment Vehicle Learning material Module Service manual Related references METHODOLOGIES Lecture/discussion Demonstration ASSESSMENT METHOD Practical demonstration

15

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 3. Maintain Measuring Instrument ASSESSMENT CRITERIA: 1. Measuring instruments are kept free from corrosion. 2. Extra care is undertaken to avoid damage to measuring instruments. 3. Measuring instruments are cleaned before and after using them. CONTENT: 1. Safe handling procedure 2. Maintenance procedure CONDITONS: The following resources are needed: Tools Oiler/can Materials Oil Cleaning material Equipment Tools room Learning materials Module Service manual Related references METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Written test Practical demonstration

16

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY MODULE TITLE NOMINAL DURATION MODULE DESCRIPTION

: : : :

READ, INTERPRET AND APPLY SPECIFICATIONS AND MANUALS READING, INTERPRETING AND APPLYING SPECIFICATIONS AND MANUALS 50 hours This module covers the knowledge, skills and attitudes in reading, interpreting and applying specifications and manuals such as identify and assess specifications found in manuals, interpret manuals, apply salient information taken from manual and store manual.

SUMMARY OF LEARNING Upon completion of this module the students will be able to: LO 1. Identify and assess specifications found in manuals LO 2. Interpret manuals LO 3. Apply salient information taken from manual LO 4. Store manuals

17

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Identify and Apply Specifications/Manuals ASSESSMENT CRITERIA: 1. Appropriate manuals to be used are identified and assessed as per job requirement. 2. Version and date of manual are checked to ensure correct specification and procedure. CONTENT: 1. Importance of manual specification 2. Types of manuals CONDITIONS: The following resources are needed: Equipment Store cabinet Store room Materials Monitoring chart Pentel pen Learning Material Manual METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

18

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Interpret Relevant Information from Manuals ASSESSMENT CRITERIA: 1. Relevant sections, chapters of manual/specification are located in relation to the work to be conducted. 2. Information and procedure in the manual are interpreted in accordance with industry practices. 3. Sequencing and adjustments are interpreted in accordance with information contained on the manual or specification. CONTENT: 1. Proper location of the different kinds of manuals 2. Interpreting information CONDITIONS: The following resources are needed: Materials Record book Ballpen/pencil Learning Materials Manuals METHODOLOGIES Lecture/discussion Demonstration ASSESSMENT METHODS Observation Interview/oral questioning Practical demonstration

19

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 3. Apply Salient Information Taken from Manual ASSESSMENT CRITERIA: 1. Manual is interpreted according to job requirement. 2. Work procedure is correctly identified in accordance with manufacturers specification. 3. Manual data are applied according to the given task. 4. Sequencing and adjustment are interpreted in accordance with information contained on the manual or specification. CONTENT: 1. Reading and interpreting in applying information from manuals CONDITIONS: The following resources are needed: Materials Record book Ball pen/pencil Learning Materials Manuals Module METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

20

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 4. Store Manuals ASSESSMENT CRITERIA: 1. Manual or specifications are stored and arranged in proper places. 2. Inventory of manuals/specifications is conducted and recorded as per shop procedure. 3. Manual/specifications are properly labeled as per storing procedure. CONTENT: 1. Procedure in storing manuals 2. Proper recording and labeling 3. Record book for manuals CONDITIONS: The following resources are needed: Materials Record book Ball pen/pencil Bond paper Cartolina Pentel pen Learning Materials Module Related references METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Interview/oral questioning Practical demonstration

21

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY MODULE TITLE NOMINAL DURATION MODULE DESCRIPTION

: : : :

APPLY APPROPRIATE SEALANT/ADHESIVE APPLYING APPROPRIATE SEALANT/ADHESIVE 50 hours This module covers the knowledge, skills and attitudes in applying appropriate sealant/adhesive. Competencies include identifying appropriate sealant/adhesive, surface preparation, process application and disposing sealant/adhesive.

SUMMARY OF LEARNING OUTCOMES: Upon completion of this module the students will be able to: LO 1. Identify appropriate sealant/adhesive LO 2. Prepare surface for sealant/adhesive LO 3. Apply sealant/adhesive evenly LO 4. Store/dispose sealant/adhesive

22

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Identify appropriate sealant/adhesive ASSESSMENT CRITERIA: 1. Sealant/adhesive is selected in line with job requirements and manufacturers specification. 2. Sealant/adhesive checking is performed to ensure that product is fit for use. CONTENT: 1. Types of sealant/adhesive 2. Uses of sealant/adhesive CONDITIONS: The following resources are needed: Materials Sealant Adhesives Body filler Epoxy base Hardener Learning Materials Service Manuals Related references METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

23

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Prepare surface for sealant/adhesive ASSESSMENT CRITERIA: 1. Surface materials are identified as per construction. 2. Surface is cleared and free from moisture, dust and other foreign matters to ensure maximum adhesive or seal. CONTENT: 1. Types of surface materials 2. Procedure in preparing surface materials. CONDITIONS: The following resources are needed: Tools Scraper Steel brush

Materials Sealants/Adhesive Rags Sandpaper Cleaning solvent

METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Written exam

24

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 3. Apply Sealant/Adhesive Evenly ASSESSMENT CRITERIA: 1. Sealant/adhesive is applied evenly on the surface in line with manufacturers specification. 2. Excess sealant/adhesive is removed by sanding or scrapping. 3. Tools and equipment used to apply sealant/adhesive are appropriate to job requirements. 4. Safety is observed and Personal Protective Equipment (PPE) are worn in accordance with industry SOP. 5. Hazards associated with the use of sealant/adhesive are identified CONTENT: 1. 2. 3. 4. 5. Procedure in applying sealant/adhesive Removing of excess sealant/adhesive Proper usage of tools Safety measures in applying sealant/adhesive Identify health hazards associated in handling sealant/adhesives

CONDITIONS: The following resources are needed: Tool Scraper Equipment PPE Materials Sealants/Adhesive Rags Sand paper METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning

25

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 4. Store/Dispose Sealant/Adhesive ASSESSMENT CRITERIA: 1. Sealant/adhesive is stored as per prescribed procedure. 2. Waste is disposed as per workshop standard operating procedure (SOP). CONTENT: 1. Proper storage/disposal of sealant/adhesive 2. Waste disposal system CONDITIONS: The following resources are needed: Equipment PPE Store cabinet Garbage container Materials Rags Cleaning solution Learning Materials Module Related references METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning

26

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY MODULE TITLE NOMINAL DURATION MODULE DESCRIPTION

: : : :

USE AND APPLY LUBRICANT/COOLANTS USING AND APPLYING LUBRICANTS/COOLANTS 50 hours This module covers the knowledge, skills and attitudes required in using and applying lubricants/coolants

SUMMARY OF LEARNING OUTCOMES: Upon completion of this module the students will be able to: LO 1. Identify types of lubricants/coolants LO 2. Use and apply lubricants/coolants LO 3. Perform housekeeping activities

27

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Identify types of lubricants/coolants ASSESSMENT CRITERIA: 1. Correct information on lubrication schedule is assessed and interpreted from appropriate manufacturers specification. 2. Type and quantity of lubricant/coolant are identified as per job requirement. CONTENT: 1. 2. 3. 4. Importance of lubricants/coolants Types of lubricants Interpret product specifications Safety measures in handling lubricants

CONDITIONS: The following resources are needed: Lubricants Personal Preventive Equipment (PPE) Special Service Tools (SST) Simulated work place Manufacturers specification manual Vehicle

METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Written test

28

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Use and Apply Lubricants ASSESSMENT CRITERIA: 1. Correct procedure for change of lubricant is identified following manufacturers specification or information manual data. 2. Correct tools and equipment are selected and used in line with job requirements 3. Existing lubricants are removed and replaced with specified type and quantity of new materials in line with manufacturers specifications 4. Safety procedure and use of PPE are observed when removing or replacing lubricant 5. Used lubricants are disposed in accordance with environmental guidelines 6. Work is checked in line with company SOP. CONTENT: 1. Correct procedures in changing or applying lubricants 2. Safety precautions in applying lubricants. CONDITIONS: The following resources are needed: Lubricants Personal Preventive Equipment (PPE) Special Service Tools (SST) Simulated work place Manufacturers specification manual Vehicle Service manual Periodic maintenance manual

METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Direct Observation Oral questioning Written test

29

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 3. Perform Housekeeping Services ASSESSMENT CRITERIA: 1. Tools, equipment and materials are properly stored as per companys Special Office Procedure (SOP). 2. Workplace is free from waste materials. CONTENTS: 1. 2. 3. 4. 5 S Housekeeping Procedures Environmental Requirements Safety signs and symbols Work process

CONDITIONS: The following resources are needed: Cleaning materials Personal Protective Equipment (PPE) Tools, equipment and materials Simulated work place METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Written test

30

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY MODULE TITLE NOMINAL DURATION MODULE DESCRIPTION

: : : :

MOVE AND POSITION VEHICLE MOVING AND POSITIONING VEHICLE 100 hours This module covers the knowledge, skills and attitudes required to prepare vehicle for driving, moving and positioning and checking of vehicle.

SUMMARY OF LEARNING OUTCOMES: Upon completion of this module the students will be able to: LO 1. Prepare vehicle for driving LO 2. Move and position vehicle

31

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Prepare Vehicle for driving ASSESSMENT CRITERIA: 1. Correct check-up procedures are performed based on vehicle manufacturers standard. 2. Vehicles running gears are checked in accordance with work place procedure. 3. Brake, Light, Oil, Water, Air & Fuel (BLOWAF) are checked as per specifications. CONTENT: 1. Prepare vehicle for driving 2. Safety measures in driving vehicle 3. Check-up procedures include the following: Oil level Brake fluid Coolant level Battery (electrolyte) Tire pressure Position of driving gear Lighting and devices Position of side mirror CONDITIONS: The following resources are needed: Equipment Vehicle Learning materials Driving Manual METHODOLOGIES Lecture/discussion Demonstration (actual driving)

ASSESSMENT METHOD Practical demonstration

32

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Move and Position Vehicle ASSESSMENT CRITERIA: 1. Work area is checked from obstructions before moving the vehicle. 2. Vehicle is moved to the designated work area. 3. Vehicle is checked. CONTENT: CONDITIONS: The following resources are needed: Equipment Vehicle Learning material Driving Manual Cleaning Materials METHODOLOGIES Lecture/discussion Demonstration Principles of driving and techniques Safety measures in driving vehicle Procedures in checking vehicle BLOWAF (Brake, Lights, Oil, Water, Air, Fuel)

ASSESSMENT METHOD Practical demonstration (actual driving)

33

Competency-Based Curriculum for Public Tech-Voc High Schools

THIRD YEAR 1st Grading Unit of Competency Service Automotive battery 100 100 2nd Grading Test and repair wiring lighting system 100 100 3rd Grading Test and repair wiring and lighting system 100 100 4th Grading Service ignition system 100 100

No. of hours TOTAL HOURS

Note: (OPTIONAL) ON THE JOB TRAINING AFTER COMPLETION THIRD YEAR = 120 HOURS

34

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY MODULE TITLE NOMINAL DURATION MODULE DESCRIPTION

: : : :

SERVICE AUTOMOTIVE BATTERY SERVICING AUTOMOTIVE BATTERY 100 hours This module covers the knowledge, skills and attitudes required in servicing automotive battery such as: testing battery, interpreting information on battery, using appropriate instruments, finding and analyzing results.

SUMMARY OF LEARNING OUTCOMES: Upon completion of this module the students will be able to: LO 1. Test automotive battery LO 2. Remove and replace batteries LO 3. Service and charge batteries LO 4. Jump start vehicle

35

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Test Automotive Battery ASSESSMENT CRITERIA 1. Battery is tested to avoid damage to any workplace property or vehicle. 2. Correct information is assessed and interpreted based on manufacturers specification. 3. Appropriate test equipment and instrument are selected 4. Test results are analyzed and interpreted 5. Findings are reported to automotive teacher/trainor. CONTENTS Parts and functions of automotive battery Types of automotive battery Test procedures Interpretation of manufacturers specification and manual Proper usage of tools and equipment Safety measures in handling automotive battery

CONDITIONS The following resources are needed: Equipment TV monitor with VCD/DVD player and CDs PC set Personal protective equipment (PPE) Battery Materials Learning Material Modules Automotive battery manufacturers manual Other related references Rags Distilled water

METHODOLOGIES Lecture/Discussion Demonstration Video Lesson

ASSESSMENT METHODS Observation Oral questioning Written Test Practical demonstration Performance test using scoring rubrics 36

Competency-Based Curriculum for Public Tech-Voc High Schools

LO2. Remove and Replace Batteries ASSESSMENT CRITERIA: 1. Battery is removed and replaced to avoid damage to any workplace property or vehicle. 2. Appropriate tools and equipment are selected. 3. Extra care is taken to prevent loss of vehicles electronic memory (if applicable). CONTENTS Correct procedures in removing and replacing battery Interpretation of manufacturers specification and manual Proper usage of tools and equipment Safety measures in removing and replacing battery

CONDITIONS The following resources are needed: Battery Box wrench (12x13 mm) Personal protective equipment (PPE) Automotive battery manufacturers manual and related references Simulated workplace Vehicle METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical Demonstration Performance test using scoring rubrics

37

Competency-Based Curriculum for Public Tech-Voc High Schools

LO3. Service and Charge Battery ASSESSMENT CRITERIA: 1. Battery is charged using the appropriate battery charger. 2. Electrolyte levels are checked and topped up. 3. Battery and its terminals are cleaned. CONTENTS Correct procedure in charging the battery Interpretation of charging rate Safety measures in servicing and charging the battery

CONDITIONS: The following resources are needed: Battery Battery charger Personal protective equipment (PPE) Automotive battery manufacturers manual Simulated workplace Steel brush Tap water Distilled water Hydrometer tester Cell tester METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT MTHODS Observation Oral questioning Practical demonstration

38

Competency-Based Curriculum for Public Tech-Voc High Schools

LO4. Jump Start Vehicle ASSESSMENT CRITERIA: 1. Vehicle is jump started to avoid damage to any workplace property or vehicle. 2. Jumper leads are selected and used to ensure spark protection which is employed when necessary. 3. Leads are connected / disconnected correctly according to sequence and polarity. CONTENTS: Correct procedure in connecting battery Use the specific size of jumper leads/wires Safety measures in connecting and disconnecting jumper leads

CONDITIONS: The following resources are needed: Battery Jumper leads Personal protective equipment (PPE) Simulated work place Vehicle METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

39

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY : TEST AND REPAIR WIRING/LIGHTING SYSTEM MODULE TITLE NOMINAL DURATION : TESTING AND REPAIRING WIRING/LIGHTING SYSTEM : 200 hours

MODULE DESCRIPTION : This module covers the knowledge, skills and attitudes required in testing and repairing wiring/lighting systems. It includes the basic electrical and electronics circuit. SUMMARY OF LEARNING OUTCOMES: Upon completion of this module the students will be able to: LO 1. Test electrical systems LO 2. Repair electrical systems LO 3. Test and repair starting system

40

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Test Electrical System ASSESSMENT CRITERIA: 1. Correct information is assessed and interpreted from appropriate manufacturers specifications. 2. Tests are carried out to determine faults using appropriate tools and techniques. 3. Faults are identified and preferred action is determined. 4. Tests are completed without causing damage to the workplace property or vehicle. CONTENTS: Testing Purpose of wiring/lighting circuit Component parts of wiring/lighting circuit wiring/lighting circuit Interpretation of test results Safety measures in testing wiring/lighting circuit CONDITONS: The following resources are needed: Tools /Equipment Pliers Set of screwdrivers Bow wrench Test lamp Lighting system mock-up Voltmeter tester Multi-tester Learning Materials Module Service manual

METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration Written test

41

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Repair Electrical Systems ASSESSMENT CRITERIA: 1. Correct information is assessed and interpreted using appropriate tools and equipment. 2. Necessary repairs are carried out using appropriate tools, techniques and materials. 3. Electrical system is repaired without causing damage to the work place, property or vehicle. CONTENTS: Interpretation of manufacturers specification Safety measures in repairing electrical circuit Repair/replacement of faulty parts Adaptation of appropriate techniques in repairing electrical circuit

CONDITIONS: The following resources are needed: Tools Electrical pliers Box wrench Set of screwdrivers Soldering iron Equipment Materials Electrical tapes Wire terminals Automotive wires Sand paper Leads Electrical mock-up

Learning Materials Module Service manual

METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

42

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 3. Test and repair starting system ASSESSMENT CRITERIA: 1. Tests are carried out to determine faults using appropriate tools and techniques. 2. Faults are identified and preferred repair action determined. 3. Starting systems are repaired without causing damage to any workplace property or vehicle 4. Information is assessed and interpreted from appropriate manufacturers specification CONTENTS:

Interpretation of manufacturers specification Starting system service caution Testing starting system Parts of starter motor Procedure in removing, disassembling, testing, repairing/replacing, assembling and mounting starting motor.

CONDITIONS: The following resources are needed: Tools/Equipment Starting motor Battery Set of screwdrivers Mock-up Simulated work place Open/close wrench Multi-tester Soldering iron Vernier caliper Materials Steel brush Soldering lead/paste Automotive wires Sand paper Gasoline

43

Competency-Based Curriculum for Public Tech-Voc High Schools

Learning Materials Module Service manual

METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

44

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY MODULAR TITLE NOMINAL DURATION MODULE DESCRIPTION

: SERVICE IGNITION SYSTEM : SERVICING IGNITION SYSTEM : 100 hours : This module covers the knowledge, skills and attitudes required in servicing ignition system such as checking and conducting test on ignition component. It also includes repairing the ignition system components.

SUMMARY OF LEARNING OUTCOMES: Upon completion of this module the students will be able to: LO 1. Check ignition system LO 2. Perform spark test LO 3. Check ignition coil resistance LO 4. Check ballast resistor LO 5. Adjust contact point clearance (if any) Lo 6. Perform ignition wiring installation LO 7. Perform ignition timing LO 8. Repair non-electronic ignition system and/or components

45

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Check Ignition System ASSESSMENT CRITERIA: 1. Spark plug is checked and inspected in accordance with standard testing procedure. 2. Ignition distributor and associated parts are checked/evaluated according to standard procedure. 3. Ignition system harness is checked and inspected. CONTENTS: Functions of the ignition system Types of ignition system Parts of the ignition system Operating principles of the ignition system Safety measures in checking ignition system Servicing ignition system components

CONDITIONS: The following resources are needed: Tools Spark plug cleaner Spark plug wrench Set of screwdriver Equipment Materials Rags Wire brush Sandpaper Air compressor Engine mock-up Multi-tester

METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Questioning Practical demonstration

46

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Perform Spark Test ASSESSMENT CRITERIA: 1. Engine is started as per standard operating procedures. 2. Spark test is conducted in accordance with standard testing procedures. 3. Safety measures are applied in accordance with standard testing procedure. CONTENTS: Procedures for spark testing Performing spark test Safety measures in spark test/triggering test Determining and analyzing electric spark

CONDITIONS: The following resources are needed: Tools Insulated pliers Screwdriver Equipment Materials Sand paper Rags Engine mock-up

METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

47

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 3. Check Ignition Coil Resistance ASSESSMENT CRITERIA: 1. Coil terminal of ignition coil is disconnected. 2. Ignition coil resistance is checked. CONTENTS: Functions of ignition coil Parts of ignition coil Interpreting secondary and primary circuit Checking and interpreting ignition coil resistance

CONDITIONS: The following resources are needed: Tools Plier Multi-tester Equipment Materials Ball pen/pencil Bond paper Engine mock-up

Learning Materials Module Service Manual Related references METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

48

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 4. Check Ballast Resistor ASSESSMENT CRITERIA: 1. Ballast resistor is checked as per requirement. CONTENTS: Procedures in checking ballast resistor Analysis of resistance test results

CONDITIONS: The following resources are needed: Tools Box wrench Screwdriver VOM Multi-tester Equipment Materials Ball pen/pencil Bond paper Ignition mock-up

Learning Materials Module Service manual METHODOLOGIES Demonstration Discussion

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

49

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 5. Adjust Contact Point Clearance ASSESSMENT CRITERIA: 1. Contact point is adjusted per service manual specification. 2. Contact point adjustment is analyzed and interpreted. CONTENTS: CONDITIONS: The following resources are needed: Tools Set of screwdriver Feeler gauge Set of Wrench Equipment Materials Sand paper Rags Grease Ignition mock-up Correct procedures in adjusting contact points Safety measures in adjusting contact points

Learning Materials Module Related references METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT MTEHODS Observation Oral questioning Practical demonstration

50

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 6. Perform Ignition Wiring Installation ASSESSMENT CRITERIA: 1. Tools and ignition wiring materials are checked and evaluated per standard specifications. 2. Ignition wirings are installed based on a required diagram. 3. Safety measures are applied in installing wirings of the ignition system in accordance with OHS policy. CONTENTS: Procedure in checking ignition system components Performing wiring installation of ignition system Safety measures in wiring installation

CONDITONS: The following resources are needed: Tools Electrical pliers Set of screwdriver Wire stripper Soldering iron Equipment Materials Soldering leads Automotive wires Wire terminals Electrical tape Engine mock-up

Learning Materials Module Related references METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration Performance test using scoring rubrics

51

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 7. Perform Ignition Timing ASSESSMENT CRITERIA: 1. Ignition Timing procedure is applied per engine requirement. 2. Ignition timing is checked per ignition specifications. 3. Safety measures are applied. CONTENTS: Interpreting ignition timing procedures Adjusting ignition timing CONDITIONS: The following resources are needed: Tools Box wrench Set of screw driver Equipment Engine mock-up Ignition timing light Dwell meter Materials Rags White chalk

Learning materials Module Related references METHODOLOGIES Lecture/discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

52

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 8. Repair Non-electronic Ignition System and/or Component ASSESSMENT CRITERIA: 1. Parts and components of non-electronic ignition system are identified and located. 2. Ignition system/components are repaired without causing any damage on them. CONTENTS: Repair ignition system components Diagnosing non-electronic ignition components Safety measures in repairing ignition component parts

CONDITIONS: The following resources are needed: Tools Set of box wrench Set of screw drivers Pliers Voltmeter Soldering iron Equipment Materials Ignition system mock-up Rags Paint brush Soldering lead Wire

Learning materials Module Service manual METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Practical demonstration

53

Competency-Based Curriculum for Public Tech-Voc High Schools

FOURTH YEAR 1st Grading Unit of Competency Perform gas engine 2nd Grading Perform diesel engine 3RD Grading Perform underchassis preventive maintenance 100 100 4th Grading Perform underchassis preventive maintenance 100 100

No. of hours TOTAL HOURS

100 100

100 100

54

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY : PERFORM GAS ENGINE TUNE UP MODULE TITLE NOMINAL DURATION : PERFORMING GAS ENGINE TUNE UP : 100 hours

MODULE DESCRIPTION : This module covers the knowledge, skills and attitudes required in performing gas engine tune up such as checking/adjusting valve clearance, analyzing spark plug condition, replacing filters, replacing contact point and condenser, adjusting dwell angle, conducting compression test, and setting and adjusting ignition timing.

SUMMARY OF LEARING OUTCOMES: Upon completion of this module the students will be able to: LO 1. Check / adjust valve clearance LO 2. Inspect / test spark plug LO 3. Check / replace fuel filter and air cleaned LO 4. Inspect / replace contact point and condenser LO 5. Test / adjust dwell angle and ignition setting LO 6. Adjust engine idle speed and mixture LO 7. Check advance mechanism and adjust ignition timing LO 8. Conduct compression testing

55

Competency-Based Curriculum for Public Tech-Voc High Schools

LO1. Check/Adjust Valve Clearance ASSESSMENT CRITERIA: 1. Valve tappet clearance is set in accordance with standard specifications. 2. Valve clearance is checked and adjusted. CONTENTS: Principle of engine operation Using relevant tools and equipment Interpreting manufacturers specification manual Procedures in adjusting valve tappet clearance Safety measures in adjusting valve tappet clearance

CONDITONS: Students must be provided with the following: The following resources are needed: Tools Box wrench (12mm x 13mm, 14mm x 15mm, 18mm x 9mm) Set of screwdriver Feeler gauge Equipment Material Rags Learning materials Manufacturers manual Module VCD METHODOLOGIES Lecture / Discussion Demonstration Video lesson Engine mock-up, TV, VCD/DVD player

ASSESSMENT METHODS Observation Oral questioning Demonstration

56

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Inspect/Test Spark Plug ASSESSMENT CRITERIA: 1. Spark plug clearance is adjusted as per job requirement. 2. Spark plug is tested. 3. Spark plug test result is analyzed and appropriate recommendations to check deviations are prescribed according to SOP. CONTENTS: Cleaning methods and materials Applying maintenance procedure Safety measures in testing spark plug

CONDITONS: The following resources are needed: Tools Torque wrench Spark plug wrench Feeler gauge Equipment Materials Rags Sand paper Engine mock-up

Learning material Module METHODOLOGIES Lecture / Discussion Demonstrative

ASSESSMENT METHODS Observation Oral questioning Performance assessment using scoring rubrics

57

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 3. Check/Replace Fuel Filter and Air Cleaner ASSSESSMENT CRITERIA: 1. Fuel filter and air cleaner are replaced as per job requirements. 2. Fuel filter is freed from sediments and impurities following SOP. CONTENTS: Procedures in checking/replacing fuel filter and air cleaner Applying maintenance procedures Safety measures in checking fuel filter and air cleaner

CONDITONS: The following resources are needed: Tools Box wrench 10x11 mm Box wrecnh12x13 mm Pliers Set of screwdriver (- +) Equipment Materials Air cleaner Fuel filter Rags Fuel line clamps Hose clip Engine mock-up

Learning materials Module METHODOLOGIES Lecture / Discussion Demonstration

ASSSESSMENT Observation Oral questioning Performance assessment using scoring rubrics

58

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 4. Inspect/Replace Contact Points/Condenser ASSESSMENT CRITERIA: 1. Contact points gap is inspected as per job requirement. 2. Procedure in checking / testing the condenser is correctly applied CONTENTS: Checking of contact points Procedures in checking / testing condenser Applying maintenance procedure

CONDITIONS: The following resources are needed: Tools Set of screwdriver (- +) Box wrench (8x9mm) Feeler Gauge Materials Sand paper Contact points Condenser Learning materials Module and related references METHODOLOGIES Lecture / Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Performance assessment using scoring rubrics

59

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 5. Adjust Engine Idle Speed and Mixture ASSESSMENT CRITERIA: 1. Engine Speed Revolution Per Minute (RPM) is checked 2. Adjustment on the carburetor is performed based on the required performance standard. CONTENTS: Adjusting procedures Safety measures on adjustments

CONDITIONS: The following resources are needed: Tools/equipment Equipped vehicle engine mock up Tachometer Screwdriver SUPPLIES: Fuel Rags

Learning material Module METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Performance assessment using scoring rubrics

60

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 6. Test/Adjust Dwell Angle and Ignition Setting ASSESSMENT CRITERIA: 1. Dwell angle is adjusted per engine requirements. 2. Ignition timing is set per manual specifications. CONTENTS: Procedure in adjusting dwell angle Setting ignition timing CONDITONS: The following resources are needed: Tools Set of screwdriver Box wrench (12mm x 13mm, 14mm x 15mm) Equipment Materials Engine mock-up Dwell Meter Timing Light Rags

Learning materials Module and automotive books METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Demonstration Performance Assessment using Scoring Rubrics

61

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 7. Check Advance Mechanism and Adjust Ignition Timing ASSESSMENT CRITERIA: 1. Ignition timing is adjusted in accordance with standard specifications. 2. Safety in using equipment is observed per OHS policy. 3. Advance timing is checked per SOP. CONTENTS: Using relevant tools and equipment safely Assessing, interpreting and applying technical information Adjusting the ignition timing with the vehicles specification CONDITIONS: The following resources are needed: Tools / equipment Vehicle Timing light Box wrench 12mmx13mm TV, VCD, DVD player and CDs Learning material Module Service manual Related reference METHODOLOGIES Lecture/Discussion Video lesson Demonstration

ASSESSMENT METHODS Observation Oral questioning Demonstration Performance assessment using scoring rubrics

62

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 8. Conduct Compression Test ASSESSMENT CRITERIA 1. Compression test is conducted as required. 2. Test is conducted to avoid damage or injury to person or property 3. Compression test result is interpreted and appropriate recommendations are prescribed CONTENTS: Procedure in compression testing Perform compression testing Interpreting and analyzing compression test results CONDITIONS: The following resources are needed: Tool Sparkplug wrench Equipment Engine mock-up Compression tester (gasoline) Materials Rags Learning Material Modules Service manual Related references METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Demonstration Performance assessment using Rubrics

63

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY MODULE TITLE NOMINAL DURATION MODULE DESCRIPTION

: : : :

PERFORM DIESEL ENGINE TUNE-UP PERFORMING DIESEL ENGINE TUNE-UP 100 hours This module covers the knowledge, skills and attitudes required in performing diesel engine tune-up such as timing the injection system, installing injection pump, bleeding process, engine compression testing and using appropriate tools.

SUMMARY OF LEARNING OUTCOMES: Upon completion of this module the students will be able to: LO 1. Install injection pump to the engine following correct timing LO 2. Bleed injection fuel pump LO 3. Conduct compression testing per job specification

64

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Install Injection Pump Following the Correct Timing ASSESSMENT CRITERIA 1. Injection timing is set as per engine specification. 2. Required injection pump installation process is set-up as SOP requirement. 3. Mounting bolts are tightened as per specifications and torque sequence. CONTENTS: Interpretation of timing marks Procedures in setting fuel injection timing Proper usage of special tools in setting injection timing Safety measures in installing injection pump to the engine

CONDITIONS: The following resources are needed: Tools Set of Special service tool Equipment Engine Injection system mock-up TV monitor with VCD/DVD player Materials CD Bond paper Board marker Whiteboard Learning Materials Manuscripts Text book about diesel engine METHODOLOGIES Lecture/Discussion Demonstration Video Lesson

ASSESSMENT METHODS Direct observation Oral questioning Demonstration Performance assessment using scoring rubrics

65

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Bleed Injecting Fuel System ASSESSEMENT CRITERIA 1. Fuel level, line leakage and fuel strainer/filter are checked. 2. Air lock free fuel system is determined. 3. Screw and primer pumps are bled. CONTENTS: Bleeding Diesel fuel injection pump. Safety measures in bleeding.

CONDITIONS: The following resources are needed: Tools Open wrench Box wrench Screwdriver (Flat) Equipment TV monitor with VCD/DVD player Materials Diesel fuel Rags Container Learning Materials Manuscript Testing Data Module VCD METHODOLOGIES Lecture/Discussion Demonstration Video Lesson

ASSESSMENT METHODS Direct observation Oral questioning Performance assessment using scoring rubrics

66

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 3. Conduct Compression Testing ASSESSMENT CRITERIA 1. Engine requirement in compression testing is determined. 2. Specification compression test result is read and interpreted per SOP. 3. Corresponding recommendation/prescription is given based on the test result. CONTENTS: Compression testing procedure and precaution Interpretation of results from compression testing Recommendations are given based on the results interpreted

CONDITIONS: The following resources are needed: Tools Compression tester (Diesel) Set of Open end wrench Adjustable wrench Equipment Diesel engine mock-up TV/VCD/DVD player and CDs Materials Ball pen/pencil Bond paper Learning Material Module Manuscript METHODOLOGIES Lecture/Discussion Demonstration Video lesson

ASSESSMENT METHODS Observation Oral questioning Performance assessment using scoring rubrics

67

Competency-Based Curriculum for Public Tech-Voc High Schools

UNIT OF COMPETENCY MODULE TITLE NOMINAL DURATION MODULE DESCRIPTION

: : : :

PERFORM UNDERCHASSIS PREVENTIVE MAINTENANCE PERFORMING UNDERCHASSIS PREVENTIVE MAINTENANCE 200 hours This module covers the knowledge, skills and attitudes required in performing underchassis preventive maintenance such as: checking clutch fluid and lines, inspecting brake system, inspecting/changing transmission and different gear oil, inspecting/replacing power steering fluid, checking/re-filling transmission fluid, inspecting/bleeding air tank checking tires and tires preserver, checking under-chassis body bolts and nuts.

SUMMARY OF LEARNING OUTCOMES: Upon completion of this module the students will be able to: LO 1. Check clutch fluid and lines. LO 2. Inspect brake system LO 3. Inspect/change transmission/differential gear oil LO 4. Inspect /replace power steering fluid LO 5. Check/re-fill automatic transmission fluid LO 6. Inspect bleed air tank LO 7. Check tires and tire pressures LO 8. Check under-chassis body bolts and nuts

68

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 1. Check Fluids and Lines ASSESSMENT CRITERIA: 1. Clutch fluid level is checked and maintained between minimum and maximum as per SOP. 2. Clutch lines are checked for twist and bends. 3. Clutch cover is fitted in the cap. 4. Clutch fluid is used. CONTENTS: Functions of the clutch Types of clutch Parts of the clutch Operation of the clutch Checking procedures Safety measures in handling clutch fluid Maintenance procedure manual

CONDITIONS: The following resources are needed: Equipment Personal Protective Equipment (PPE) Vehicle Supplies and Materials Brake fluid Learning Materials Module Service Manual METHODOLOGIES ASSESSMENT Lecture/Discussion Self-paced learning METHODS Observation Oral questioning Practical demonstration using rubrics

69

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 2. Inspect Brake System ASSESSMENT CRITERIA: 1. Brake fluid level is checked and maintained between the minimum and maximum. 2. Brake lines or hoses are checked and freed from twist and bends. 3. Brake pedal free play is specified. 4. Brake operation is checked and tested as per SOP. 5. Hydraulic fluid is used/changed without spillage and at the specified level. 6. Brake pedal height/free-play is checked and adjusted. 7. Hydraulic brake system is bleed in accordance with brake standards. 8. Emergency brake function is checked. 9. Points for adjustment of emergency brake are identified. CONTENTS: Purpose of the brake system Types of brake Parts of the brake system Procedure in bleeding hydraulic brake system Procedure in adjusting pedal height/free-play Interpretation of manufacturers specification and manuals Safety measures in working on brake system Maintenance procedure manual Positive work values

CONDITIONS: The following resources are needed: Tools Box wrench (12mm x 13mm) Open-end wrench (9mm x 10mm) Tire wrench Equipment TV monitor, VCD/DVD player Materials Brake fluid Empty container Rags Hose Learning Materials Module Service Manual VCD

70

Competency-Based Curriculum for Public Tech-Voc High Schools

METHODOLOGIES Lecture/Discussion Demonstration Video Lesson

ASSESSMENT METHODS Observation Oral questioning Written test Demonstration using Scoring Rubrics

71

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 3. Check / Change Manual Transmission Gear Oil ASSESSMENT CRITERIA: 1. Gear oil is inspected as per SOP. 2. The vehicle is positioned. 3. Transmission gear is selected and used, cleared and not diluted. 4. Grade/classification and level of gear oil used in accordance with manufacturers specification. 5. SOP is followed in the process of inspection/changing transmission, differential and gear oil. CONTENTS: Purpose of gear oil Procedure in inspecting and changing gear oil Proper use of tools and equipment Safety measures in changing transmission/differential gear oil Oil grade (Society Automotive Engineers 90 - 140) CONDITIONS: The following resources are needed: Tools Box wrench (16mm x 17mm, 22mm x 24mm, 18mmx19mm) Equipment Personal protective equipment (PPE) Oil station Vehicle TV monitor, VCD/DVD player Materials Gear oil (SAE-90) Rags Sealant/Teflon tape Learning Materials Module Service manual VCD METHODOLOGIES Lecture/Discussion Demonstration Video Lesson

ASSESSMENT METHODS Observation Oral questioning Written test Performance Assessment using Scoring Rubrics 72

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 4. Inspect/Replace Power Steering Fluid ASSESSMENT CRITERIA 1. Power steering linkages and corrections are inspected. 2. Power steering performance is checked at engine idle speed. 3. Fluid is inspected/replaced per prescribed specifications. CONTENTS: Advantages of power steering system Power steering component parts, function and operation Classification of power steering fluid Safety measures in replacing power steering fluid Maintenance procedure manual Positive work values CONDITIONS: The following resources are needed: Tools Box wrench/Open wrench (16mm x 17mm) Personal protective equipment (PPE) Tools and materials Equipment Vehicle Material Power steering fluid Learning Materials Module Service Manual METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Written test Performance Assessment using Scoring Rubrics

73

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 5. Check/Re-fill Automatic Transmission Fluid ASSESSMENT CRITERIA: 1. Automatic Transmission Fluid (ATF) is checked and replenished at required level. CONTENTS: Product instructions and specification of Automatic Transmission Fluid (ATF) Safety measures in replacing automatic transmission fluid Positive work values CONDITIONS: The following resources are needed: Tools Special Service Tools (SST) Simulated work place Equipment Personal protective equipment (PPE) Vehicle Material Automatic transmission fluid Learning Materials Module Service Manual METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning

74

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 6. Inspect and Bleed Air Tank ASSESSMENT CRITERIA 1. Air tank is inspected as per SOP. 2. Procedure in bleeding air tank is followed per job specifications. 3. Safety measures are applied in bleeding air tank in accordance with OHS policy. CONTENTS: Purpose of the air tank Location of air tank Parts of the air tank Correct air pressure Bleeding procedure CONDITIONS: The following resources are needed: Tools Box wrench Wire stripper Equipment Vehicle Materials Container Rags Learning Materials Module Service Manual METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral/Written test

75

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 7. Check Tires and Tire Pressure ASSESSMENT CRITERIA 1. Tires are inspected for damage or deformities and are freed from solid objects. 2. Tire pressure is checked and maintained as per SOP. 3. Tire rotation is performed per required performance standard. CONTENTS: Functions of tire Types of tire Checking procedure Interpretation of manufacturers specification and manual Proper use of tools and equipment Safety measures in handling tires Maintenance procedure manual Positive work values Tire troubles and diagnosis The following resources are needed: Tools Tire wrench Tire pressure gauge Equipment Vehicle TC monitor, VCD/DVD player and CDs Computer Hydraulic jack Air compressor Materials Spare tire Rags Learning Materials Module Service Manual METHODOLOGIES Lecture/Discussion Demonstration Video lesson

ASSESSMENT METHODS Observation Oral questioning Written test Practical Demonstration using Scoring Rubrics 76

Competency-Based Curriculum for Public Tech-Voc High Schools

LO 8. Check Under-chassis Body Parts, Bolts and Nuts ASSESSMENT CRITERIA 1. Bolts/nuts including tire studs, bolts/nuts are checked as per SOP. 2. Body bolts/nuts torque are checked and maintained. 3. Checking procedure is done according to manufacturers specifications. 4. Tightness of the bolts is determined per torque specifications. CONTENTS: Purpose of bolts and nuts Interpretation of manufacturers specification Proper use of tools Safety measures Maintenance Procedure Manual Positive work values CONDITIONS: The following resources are needed: Tools Set of box wrench Set of socket wrench Equipment Vehicle Personal Protective Equipment (PPE) Material Rags Learning Materials Module Service Manual METHODOLOGIES Lecture/Discussion Demonstration

ASSESSMENT METHODS Observation Oral questioning Written test Performance assessment using Scoring Rubrics

77

Competency-Based Curriculum for Public Tech-Voc High Schools

ACNOWLEDGEMENT The Department of Education (DepEd), Central Office through Technical Vocational Task Force, wishes to extend its gratitude and appreciation to the Technical Education and Skills Development Authority (TESDA) and all the curriculum writers for sharing their time and expertise in the development of a Competency-Based Curriculum for Strengthening Technical Vocational Education Program of the country.

Writers: NELSON M. ARISGA Malvar National High School Malvar, Batangas, Region 4A, CALABARZON ROBERT S. DOMINGO AFG Bernardino Memorial Trade School Marilao, Bulacan, Region 3 ELIGIO B. ESCOBAR Sanchez Mira School of Arts and Trades Sanchez Mira Cagayan Region 3 CHONA C. BUNDOC Muntinlupa Business High School Muntinlupa City, NCR PURITA S. SIMANGAN Solona Freshwater Fisheries School Iraga, Solona, CAgayan, Region 3 MARIA VENA N. NIERVO Glan School of Arts and Trades Glan, Saranggani Province, Region 12 Facilitator: EXSUPERIO G. JACINTO Southern Isabela College of Arts and Trades Santiago City, Isabela, Region 3

78

Competency-Based Curriculum for Public Tech-Voc High Schools

Writers: NELSON C. SENEDO Tagum National Trade School Apokon, Tagum City Region XI JOHN M. DIEGO Isabela School of Arts and Trades DepEd Ilagan, Isabela, Region II LORNA A. MALABAD Isabela School of Arts and Trades DepEd BELEN L. TADO Tagum National Trade School Apokon, Tagum City Region XI LENILYN R. BAGAS AFG Bernardino Memorial Trade School Marilao, Bulacan Region III Facilitator: ABEL B. ELPEDES TESDA Taguig City, MM

79

Competency-Based Curriculum for Public Tech-Voc High Schools

Potrebbero piacerti anche

- Servicing Clutch SystemDocumento76 pagineServicing Clutch SystemTesda Ptc Malilipot67% (3)

- Competency Based Learning Material: Servicing BrakesDocumento33 pagineCompetency Based Learning Material: Servicing BrakesMelvy de la Torre100% (2)

- 4th-Yr Cblm-AutomotiveDocumento218 pagine4th-Yr Cblm-Automotiveapi-24026514885% (20)

- Module 2-Test & Repair FinalDocumento24 pagineModule 2-Test & Repair FinalCharmaine Mae RetizaNessuna valutazione finora

- Automotive CBC PDFDocumento82 pagineAutomotive CBC PDFClifford FloresNessuna valutazione finora

- 2-2 Testing and Repairing WiringElectrical SystemDocumento44 pagine2-2 Testing and Repairing WiringElectrical SystemJayson CayabyabNessuna valutazione finora

- Service BatteriesDocumento91 pagineService BatteriesEduard Pascual AlipNessuna valutazione finora

- CBLM Service Ignition System For TraineeDocumento75 pagineCBLM Service Ignition System For TraineeCedric Vlog & GamesNessuna valutazione finora

- SC SystemDocumento80 pagineSC Systemgillian marbebe0% (1)

- Suspension Lesson PlanDocumento6 pagineSuspension Lesson PlanShahebaz WandrickNessuna valutazione finora

- Pulling Out Manual TransmissionDocumento66 paginePulling Out Manual TransmissionTesda Ptc Malilipot100% (1)

- 1 Perform Pre Delivery InspectionDocumento48 pagine1 Perform Pre Delivery InspectionCharity AnneNessuna valutazione finora

- Module Perform-Pre-Delivery-InspectionDocumento56 pagineModule Perform-Pre-Delivery-InspectionRonaldo CruzNessuna valutazione finora

- CBLM Servicing Automotive BatteryDocumento62 pagineCBLM Servicing Automotive BatteryJayson CayabyabNessuna valutazione finora

- Gasoline Engine Tune - UpDocumento44 pagineGasoline Engine Tune - UpNomer PacilanNessuna valutazione finora

- AT 111 - Module 6 Servicing Automotive BatteryDocumento28 pagineAT 111 - Module 6 Servicing Automotive BatteryJeffrey Segarra NicomedesNessuna valutazione finora

- Service Cooling SystemDocumento121 pagineService Cooling Systemgillian marbebe100% (1)

- Grade 9 AutoDocumento10 pagineGrade 9 AutoKariza PugalNessuna valutazione finora

- Servicing Differential & Front AxleDocumento39 pagineServicing Differential & Front AxleTesda Ptc Malilipot86% (7)

- Auto Servicing NC II (Combined)Documento101 pagineAuto Servicing NC II (Combined)Michael V. Magallano100% (5)

- Q1 Mod 3 TVL Automotive Servicing Grade 12 For StudentDocumento17 pagineQ1 Mod 3 TVL Automotive Servicing Grade 12 For StudentDarey Reyes100% (1)

- 2 1 Servicing Automotive Battery 1Documento52 pagine2 1 Servicing Automotive Battery 1Jayson Cayabyab100% (3)

- Automotive Battery Servicing (CBLM)Documento3 pagineAutomotive Battery Servicing (CBLM)MARY JOY AGMIT100% (8)

- 1 Perform Diesel Engine Tune Up 1Documento29 pagine1 Perform Diesel Engine Tune Up 1Jheng Delos Reyes Pantoja100% (2)

- Periodic Maintenance Automotive EngineDocumento13 paginePeriodic Maintenance Automotive EngineJANE MAE100% (1)

- Service Ignition SystemDocumento38 pagineService Ignition SystemAlex J RoblesNessuna valutazione finora

- Competency Based Learning Material: Technical Education and Skills Development AuthorityDocumento33 pagineCompetency Based Learning Material: Technical Education and Skills Development AuthorityCharis Abad0% (2)

- Evidence Plan Automotive Servicing NC II Service Automotive BatteryDocumento7 pagineEvidence Plan Automotive Servicing NC II Service Automotive BatteryMELANIE IBARDALOZANessuna valutazione finora

- Automotive Servicing Grade 12: TVL/Industrial ArtsDocumento15 pagineAutomotive Servicing Grade 12: TVL/Industrial ArtsNereo Reoliquio100% (1)

- Check Ignition SystemDocumento33 pagineCheck Ignition SystemZoeAnneFranchezkaMiranda50% (4)

- 2-week-10-LO1 and 2 Removing and Replacing Electrical UnitsDocumento14 pagine2-week-10-LO1 and 2 Removing and Replacing Electrical UnitsJheng Delos Reyes Pantoja100% (4)

- 1 3 Reading Interpreting and Applying Specifications and ManualDocumento17 pagine1 3 Reading Interpreting and Applying Specifications and ManualEZRAMAE TINGCANG100% (1)

- Automotive Servicing NC 1 Service Automotive Battery Servicing Automotive BatteryDocumento166 pagineAutomotive Servicing NC 1 Service Automotive Battery Servicing Automotive BatteryMax DomonNessuna valutazione finora

- Christian - Detailed - Lesson - PlanDocumento9 pagineChristian - Detailed - Lesson - PlanChristian MelgarNessuna valutazione finora

- CBLM Automotive CORE Servicing Suspension System NC IIDocumento98 pagineCBLM Automotive CORE Servicing Suspension System NC IIRichard Chaneco86% (7)

- Servicing Brake SystemDocumento31 pagineServicing Brake SystemFrancis Martinez100% (1)

- Competency Based Learning Material: Servicing Diesel Fuel InjectorDocumento26 pagineCompetency Based Learning Material: Servicing Diesel Fuel Injectorgillian marbebeNessuna valutazione finora

- TVL-IA-Automotive11 Quarter2 Module 2Documento26 pagineTVL-IA-Automotive11 Quarter2 Module 2Mclin Jhon Marave Mabalot100% (1)

- Starting SystemDocumento21 pagineStarting SystemNikunj Yagnik100% (1)

- TR Automotive Electrical Assembly-NC IIDocumento73 pagineTR Automotive Electrical Assembly-NC IIMichael V. Magallano100% (1)

- TR Motorcycle Small Engine Servicing NC IIDocumento102 pagineTR Motorcycle Small Engine Servicing NC IIJericho LaboneteNessuna valutazione finora

- Servicing BrakesDocumento33 pagineServicing BrakesJoe Vane Niñal AntifuestoNessuna valutazione finora

- AUTOMOTIVE SERVICING NC-I (Training Plan)Documento9 pagineAUTOMOTIVE SERVICING NC-I (Training Plan)Amor BayawaNessuna valutazione finora

- 6-Automotive UnderchassisDocumento3 pagine6-Automotive UnderchassisGODNessuna valutazione finora

- 19 Performing Underchassis Preventive PDFDocumento124 pagine19 Performing Underchassis Preventive PDFMujeres Virglius PabliusNessuna valutazione finora

- Preview PDFDocumento62 paginePreview PDFlembert casinilloNessuna valutazione finora

- 1 2 Performing Mensuration and CalculationDocumento35 pagine1 2 Performing Mensuration and CalculationJohn Edward Raagas100% (1)

- SHS Automotive ServicingDocumento88 pagineSHS Automotive ServicingJaylordPalattao100% (1)

- 1 Perform Pre Delivery InspectionDocumento48 pagine1 Perform Pre Delivery InspectionjovenalNessuna valutazione finora

- Competency Based Learning Material-AutomotiveDocumento7 pagineCompetency Based Learning Material-AutomotiveMarx Engel Monreal Juntado100% (1)

- Automotive Servicing NC II CGDocumento36 pagineAutomotive Servicing NC II CGChristine Grace Espallardo JungcoNessuna valutazione finora

- CBLM Gas NC IDocumento77 pagineCBLM Gas NC ICoach Jimmy Garage100% (1)

- Enhanced Module On Applying Appropriate Sealant or AdhesiveDocumento53 pagineEnhanced Module On Applying Appropriate Sealant or AdhesiveClayton Mark CadampogNessuna valutazione finora

- Automotive Servicing Teachers Guide PDFDocumento21 pagineAutomotive Servicing Teachers Guide PDFallan lariosa100% (4)

- Performing Under Chassis Preventive MaintenanceDocumento103 paginePerforming Under Chassis Preventive MaintenanceJean Ann Ramos100% (6)

- Assembling and Testing Manual TransmissionDocumento64 pagineAssembling and Testing Manual TransmissionJoong-won Roa Jang100% (3)

- 305 MhexmodDocumento37 pagine305 Mhexmodnamduong368100% (6)

- Auto MechanicDocumento34 pagineAuto MechanicRaisul Haque RahatNessuna valutazione finora

- 2006 Us Army Lessonplans b01 Hyex Pmcs 23pDocumento23 pagine2006 Us Army Lessonplans b01 Hyex Pmcs 23pLo Shun FatNessuna valutazione finora

- SYL Mechanic Motor Vehicle 08-06-14Documento43 pagineSYL Mechanic Motor Vehicle 08-06-14swami061009Nessuna valutazione finora

- SBM Level of Practice ClaveriaRVS 300450Documento4 pagineSBM Level of Practice ClaveriaRVS 300450Allan TomasNessuna valutazione finora

- Module3 PPST1 5 2Documento32 pagineModule3 PPST1 5 2Jhonabie Suligan Cadeliña100% (2)

- LO3. Saving and SharingDocumento13 pagineLO3. Saving and SharingAllan TomasNessuna valutazione finora

- How To TAG SHS Learners in The LISDocumento6 pagineHow To TAG SHS Learners in The LISAllan TomasNessuna valutazione finora

- Major Aa Worksheet and InstructionsDocumento4 pagineMajor Aa Worksheet and InstructionsAllan TomasNessuna valutazione finora

- Ipcrf-Development PlanDocumento1 paginaIpcrf-Development PlanAllan TomasNessuna valutazione finora

- Tomas - LG 2.1.1 - Graded AssessmentDocumento1 paginaTomas - LG 2.1.1 - Graded AssessmentAllan TomasNessuna valutazione finora

- DM PHROD 2021 0010 Guidelines On The Implementation of RPMS For SY2020 2021 - SignedDocumento48 pagineDM PHROD 2021 0010 Guidelines On The Implementation of RPMS For SY2020 2021 - SignedIris Rivera-Perez100% (8)

- COT RPMS Rating Sheet For MT I IV For SY 2020 2021 in The Time of COVID 19Documento1 paginaCOT RPMS Rating Sheet For MT I IV For SY 2020 2021 in The Time of COVID 19Josefina Llamado100% (15)

- COT RPMS Rating Sheet For MT I IV For SY 2020 2021 in The Time of COVID 19Documento1 paginaCOT RPMS Rating Sheet For MT I IV For SY 2020 2021 in The Time of COVID 19Josefina Llamado100% (15)

- COT-RPMS Observation Notes FormDocumento1 paginaCOT-RPMS Observation Notes FormRodelMiniano67% (3)

- Performance Monitoring and Coaching FormDocumento1 paginaPerformance Monitoring and Coaching FormAllan TomasNessuna valutazione finora

- Setting Up Peer To Peer NetworkingDocumento1 paginaSetting Up Peer To Peer NetworkingAllan TomasNessuna valutazione finora

- COT-RPMS Observation Notes FormDocumento1 paginaCOT-RPMS Observation Notes FormRodelMiniano67% (3)

- Performance Test in Creating A Worksheet 2018Documento2 paginePerformance Test in Creating A Worksheet 2018Allan TomasNessuna valutazione finora

- How To Reset Inkpad Using Epson Adjustment ProgramDocumento7 pagineHow To Reset Inkpad Using Epson Adjustment ProgramAllan TomasNessuna valutazione finora

- Creating SECRET FolderDocumento2 pagineCreating SECRET FolderAllan TomasNessuna valutazione finora

- Optical IllusionDocumento1 paginaOptical IllusionAllan TomasNessuna valutazione finora

- Strengths and Weaknesses of Online LearningDocumento6 pagineStrengths and Weaknesses of Online LearningAllan TomasNessuna valutazione finora

- Handout in ICF I - Windows 7.pptx-Black & WhiteDocumento19 pagineHandout in ICF I - Windows 7.pptx-Black & WhiteAllan TomasNessuna valutazione finora

- Hand Out in Excel-Compressed FinalDocumento11 pagineHand Out in Excel-Compressed FinalAllan TomasNessuna valutazione finora

- Lec1 Occupational Health and Safety ProceduresDocumento14 pagineLec1 Occupational Health and Safety ProceduresAllan TomasNessuna valutazione finora

- Mailmerge: ST ND RDDocumento1 paginaMailmerge: ST ND RDAllan TomasNessuna valutazione finora

- Performance Test in Creating A Worksheet 2018Documento2 paginePerformance Test in Creating A Worksheet 2018Allan TomasNessuna valutazione finora

- CRVS Brigada Form 1.1Documento4 pagineCRVS Brigada Form 1.1Allan TomasNessuna valutazione finora

- MULTIMEDIADocumento1 paginaMULTIMEDIAAllan TomasNessuna valutazione finora

- Oath of MembershipDocumento2 pagineOath of MembershipAllan TomasNessuna valutazione finora

- Oath of MembershipDocumento2 pagineOath of MembershipAllan TomasNessuna valutazione finora

- Zipgrade Scored PaperDocumento1 paginaZipgrade Scored PaperAllan TomasNessuna valutazione finora

- CSS ReviewerDocumento2 pagineCSS ReviewerLeo SindolNessuna valutazione finora

- Dr. Thein Lwin Language Article (English) 15thoct11Documento17 pagineDr. Thein Lwin Language Article (English) 15thoct11Bayu Smada50% (2)

- Vedic Maths PDFDocumento2 pagineVedic Maths PDFbikash chandra haldarNessuna valutazione finora

- 2nd Q MATHDocumento5 pagine2nd Q MATHCELESTIA VILLANessuna valutazione finora

- CALL (Computer-Assisted Language Learning) and Distance LearningDocumento6 pagineCALL (Computer-Assisted Language Learning) and Distance LearningMourad DiouriNessuna valutazione finora

- Creative LibrarianDocumento13 pagineCreative LibrarianulorNessuna valutazione finora

- A Final Project: By: Yani Ika Apriwulan NPMDocumento28 pagineA Final Project: By: Yani Ika Apriwulan NPMIwanHariyantoNessuna valutazione finora

- DLL DemoDocumento6 pagineDLL DemoRhissan Bongalosa AcebucheNessuna valutazione finora

- Culturally Relevant UsaDocumento14 pagineCulturally Relevant UsaNitin BhardwajNessuna valutazione finora

- Incorporate The Multiple IntelligenceDocumento3 pagineIncorporate The Multiple IntelligenceNuraihan HashimNessuna valutazione finora

- 7 (F) - OECS Learning Standards MathematicsDocumento123 pagine7 (F) - OECS Learning Standards MathematicsJolette ScottNessuna valutazione finora

- TKT ActivitiesDocumento17 pagineTKT ActivitiesGuadalupe GódlenNessuna valutazione finora

- Neuman TheoryDocumento10 pagineNeuman Theorypreeti19987Nessuna valutazione finora

- Prospectus Med MDocumento62 pagineProspectus Med MYOGESH MUNEJANessuna valutazione finora

- CD 3380Documento24 pagineCD 3380mallupatil_2011Nessuna valutazione finora

- DREYFUS, Hubert L. Heidegger, Authenticity and Modernity - Essays in Honor of Hubert L. Dreyfus V1Documento424 pagineDREYFUS, Hubert L. Heidegger, Authenticity and Modernity - Essays in Honor of Hubert L. Dreyfus V1Guilherme Pereira100% (5)

- Module 3 Ed3Documento6 pagineModule 3 Ed3Tea Sheanley Malunes CastillonNessuna valutazione finora

- Sample Demo Lesson Plan in Principles and Methods of TeachingDocumento3 pagineSample Demo Lesson Plan in Principles and Methods of TeachingJun PontiNessuna valutazione finora

- A Glimpse On K To 12 Program in The PhilippinesDocumento71 pagineA Glimpse On K To 12 Program in The PhilippinesErnie Cerado100% (1)

- Worksheet Activity 1Documento3 pagineWorksheet Activity 1Florencito RivasNessuna valutazione finora

- DLL Template A4 LandscapeDocumento1 paginaDLL Template A4 LandscapeLeoben GalimaNessuna valutazione finora