Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1 s2.0 S1359431111006727 Main

Caricato da

Delian KurniawanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1 s2.0 S1359431111006727 Main

Caricato da

Delian KurniawanCopyright:

Formati disponibili

Applied Thermal Engineering 50 (2013) 1576e1581

Contents lists available at SciVerse ScienceDirect

Applied Thermal Engineering

journal homepage: www.elsevier.com/locate/apthermeng

Regeneration characteristics of desiccant rotor with microwave and hot-air heating

Mitsuhiro Kubota*, Takuya Hanada, Satoshi Yabe, Hitoki Matsuda

Department of Energy Engineering and Science, Graduate School of Engineering, Nagoya University, Furo-cho, Chikusa-ku, Nagoya-shi, Aichi 464-8603, Japan

a r t i c l e i n f o

Article history: Received 15 March 2011 Accepted 22 November 2011 Available online 30 November 2011 Keywords: Microwave irradiation Hot-air heating Desiccant rotor Regeneration Zeolite

a b s t r a c t

Microwave heating, because of its advantages of direct and rapid heating of materials, has the potential to be employed as a novel regeneration method of desiccant rotors in humidity conditioners. We proposed a combined regeneration process, which combines microwave heating and conventional hot-air heating. The system is expected to achieve high heating rate during an initial regeneration period by assisting water desorption using the additional energy of the microwave. In this study, the regeneration characteristics of a desiccant rotor were experimentally investigated under conditions of microwave heating, hot-air heating, and combined heating at various microwave powers and hot-air temperatures. The effectiveness of the combined regeneration was evaluated in terms of the regeneration ratio, the initial regeneration rate, the temperature distribution in the rotor, and nally in terms of the energy consumption. It was demonstrated that combined heating was effective at leveling non-uniform temperature distribution in the rotor. Combined heating achieved higher ratios and initial rates in regeneration compared to just microwave and hot-air heating. This result was obviously attributed to the additional input of microwave energy, resulting that average rotor temperature increased by microwave absorption of rotor. Moreover, it was also effective for enhancement of regeneration to level the temperature distribution in the rotor by combination of two heating methods with different heating mechanisms. Both the initial regeneration rate and the equilibrium regeneration ratio for combined heating were found to increase as the microwave power increased. A linear relationship was observed with respect to microwave power. From the viewpoint of energy consumption, it may be possible to apply combined and microwave heating to humidity control systems that switch between adsorption and regeneration in short cycle times, if the conversion and absorption efciencies of the microwave are signicantly improved. 2011 Elsevier Ltd. All rights reserved.

1. Introduction Desiccant humidity conditioners, which make use of adsorption/desorption features of porous material, have attracted considerable attention as environmentally friendly humidity control systems. These systems have potential to reduce energy consumption for humidity control by utilizing low-temperature waste heat, compared to conventional compression refrigeration devices. Moreover, sensible and latent cooling loads can be controlled independently [1e6]. We have attempted to improve the regeneration process of the system in order to develop a highly efcient desiccant humidity conditioner. In solid desiccant systems, hot air is usually employed as a heating medium for regeneration of the rotor. However, hot-air

* Corresponding author. Tel.: 81 52 789 5597; fax: 81 52 789 3842. E-mail address: kubota@nuce.nagoya-u.ac.jp (M. Kubota). 1359-4311/$ e see front matter 2011 Elsevier Ltd. All rights reserved. doi:10.1016/j.applthermaleng.2011.11.044

heating requires a long time to heat the entire desiccant rotor, because thermal energy is indirectly transferred from hot air to the rotor. Moreover, it is well known that lowering the regeneration temperature, especially below 353 K, leads to a signicant decrease in humidity control performance due to insufcient water desorption. In order to overcome these problems, we have focused on microwave (MW) heating as a regeneration energy source. Microwave irradiation supplies energy to the whole material body, allowing the materials to produce thermal energy. As a consequence, the temperature of the materials rises rapidly.Based on the merits of microwave irradiation, we have proposed a novel hybrid regeneration process, combining microwave and conventional hotair (HA) heating. Combination of both heating methods is expected to achieve higher regeneration rate due to direct and rapid heating by microwave irradiation in addition to indirect heating by hot-air ow. The hybrid system also promotes lower heat utilization, as the additional microwave energy assists in water desorption.

M. Kubota et al. / Applied Thermal Engineering 50 (2013) 1576e1581

1577

We have experimentally investigated desorption behaviors of water from the adsorbent particle bed [7] and the desiccant rotor [8] under microwave irradiation. In our previous study, regeneration experiments were conducted using a practical desiccant rotor coated with zeolite in the microwave power ranging from 200 to 800 W and having a rotor length of 60e180 mm [8]. We observed that both the desorption ratio in the equilibrium state and the initial desorption rate increased linearly with the microwave power. In addition, the initial desorption rate and desorption ratio at 600 s also increased with rotor length. However, experimentally determined desorption ratio in a desorption equilibrium was much lower than the theoretically calculated value, which was estimated from changes in relative humidity brought about by the increase in temperature of the rotor. It was concluded that a noticeable temperature distribution in the rotor was the main reason for the decrease in the desorption ratio. Based on the above-mentioned results, in this study, we have experimentally investigated the regeneration characteristics of a zeolite desiccant rotor using a combination of heating under various microwave powers (200e800 W) and hot-air temperatures (313e373 K). For purposes of comparison, regeneration experiments of the rotor were also performed using only hot-air ow. The combination of microwave and hot-air heating was evaluated in terms of the equilibrium desorption ratio, the initial desorption rate, temperature distributions in the rotor, and energy consumption by comparing the results obtained for microwave heating and hot-air heating individually. 2. Experimental 2.1. Apparatus A schematic diagram of the apparatus is shown in Fig. 1. The experimental apparatus was almost the same as that used in our previous study. Details of the apparatus have been described elsewhere [8]. The setup mainly consisted of a microwave irradiator (IDX Co., Ltd.), circular waveguide, microwave dummy load, desiccant rotor, electric heater, and temperature/humidity controlling room. In this experiment, a desiccant rotor coated with synthesized zeolite (100 mm I.D., 120 mm length, channel pitch of honeycomb matrix: 3.7 mm width 2.2 mm height) was used and installed inside the aluminum waveguide. Microwave energy was supplied from an irradiator through a horizontal circular waveguide, and was nally absorbed by circulating water own in the dummy load at 303 K. Humidity and temperature transmitters with accuracies of

1 %RH and 0.2 K (HUMICAP HMT333, Vaisala Corp.) were mounted at the inlet and outlet of the waveguide. The air ow rate was monitored using a thermal mass owmeter with an accuracy of 1% of full scale (TF1050-A12G-115A, Oval Corp.). Outlet air temperature at a position of 20 mm behind the rotor in the direction of irradiation was also recorded using an optical ber thermometer (AMOTH FL-2000, Anritsu-Meter Co., Ltd.) at the center of the waveguide along the radial direction. 2.2. Procedure Prior to the regeneration experiment, humid air at 303 K and with an absolute humidity, AH, of 16 g/kg-DA (60 %RH) was introduced into the waveguide at a ow rate of 7.9 103 m3/s (face velocity, u, was 1 m/s) until the outlet dew point of humid air became equal to the inlet dew point of the air (Adsorption process). After the desiccant rotor attained water adsorption equilibrium, the regeneration experiment was performed. For hot-air heating, humid air maintained at AH 16 g/kg-DA was heated to the predetermined temperature by an electric heater and supplied to the desiccant rotor. The hot air was controlled in the regeneration temperature ranges of 313e373 K, resulting in a decrease in the relative pressure of air from 60 % to 34.5e2.5%. In the combined heating, microwave energy of 2.45 GHz was irradiated to the desiccant rotor under hot-air ow at the temperatures of 313e353 K. The microwave power, P, was varied from 200 to 800 W. During combined regeneration, the owing air was maintained at the same conditions of humidity as described for the adsorption process; i.e., the absolute humidity of inlet air was 16 g/kg-DA. In the regeneration process, changes in absolute humidity of air at the inlet and outlet of the rotor and the outlet air temperature were measured throughout the experiment by humidity and temperature transmitters and an optical ber thermometer, respectively. The amount of desorbed water, q [gH2O], was calculated by the following equation.

Zq q

0

_ AHout AHin dq m

(1)

_ is mass ow rate of air [kg-DA/s]; AHin and AHout are the where m absolute humidity at the inlet and outlet of the desiccant rotor [gH2O/kg-DA], respectively; and q denotes time [s]. The reproducibility of the experiment with respect to the amount of desorbed water, q, was 4%. 3. Results and discussion 3.1. Effect of hot-air heating on regeneration behavior of desiccant rotor Figs. 2 and 3 show changes in the outlet air temperature and regeneration ratio, q/qE, with time for hot-air heating at inlet hotair temperatures of 313e373 K. Experimental data for microwave heating at P 600 W is also plotted in these gures for comparison. In Fig. 3, the regeneration ratio, q/qE, was dened as the ratio of the amount of desorbed water, q, to the equilibrium amount of adsorbed water in the adsorption process, qE. The total amount of water adsorbed in an equilibrium state, qE, was estimated on the basis of a water adsorption isotherm measured at 303 K by a volumetric gas adsorption apparatus (BELSORP18, Bel Japan, Inc.). In the case of hot-air heating, the temperature of outlet air gradually increased with time and attained a constant temperature corresponding to the inlet air temperature. For all hot-air heating

Fig. 1. Schematic diagram of experimental apparatus.

1578

M. Kubota et al. / Applied Thermal Engineering 50 (2013) 1576e1581

383

Outlet air temperature, T a, out [ K ]

373 363 353 343 333

373 K MW-600 W 353 K

below 353 K up to 90 s, and there might be possibility for the application of microwave regeneration to practical humidity conditioning system. 3.2. Effect of combination of microwave and hot-air heating on regeneration behavior of desiccant rotor Fig. 4 shows regeneration characteristics of the rotor for a combination of microwave irradiation and hot-air heating. The microwave power was varied from 200 to 800 W under a hot-air ow at 333 K. It was observed that combined heating achieved higher regeneration ratios than hot-air heating alone. Both the initial regeneration rate and the equilibrium regeneration ratio for combined heating increased as the microwave power increased. We have previously reported a similar trend for microwave heating [8]. The temperature of humid air at the outlet also increased with microwave power; e.g. a steady temperature of 372 K was obtained at 1200 s for P 800 W, but 346 K for P 200 W. Consequently, the high ratio and the initial rate of regeneration were attributed to the rise in temperatures of the desiccant rotor and humid air caused by microwave absorption by the rotor. More specically, when humid air and rotor temperatures increased, the relative pressure in the regeneration process decreased, resulting in a lower water adsorptivity of zeolite. Fig. 5 shows the effect of microwave power on the initial regeneration rate and regeneration ratio in the equilibrium state for microwave, hot-air, and combined heating. As reported in our previous work [8], concerning microwave heating, the initial regeneration rate and nal regeneration ratio were found to linearly increase with increasing microwave power. Polaert et al. also observed the tendency of the regeneration rate to increase linearly with the absorbed microwave power [9]. In Fig. 5, it can be seen that linear relationship was obtained for combined heating, and also for microwave irradiation. The slopes obtained for combined heating and microwave heating are similar, indicating that microwave irradiation had more or less the same effect on water desorption even though the temperature of the hot-air owing through the rotor varied within this experimental range. 3.3. Heating characteristics of desiccant rotor by different heating methods In order to explain the difference in water desorption between the various regeneration methods, the heating characteristics of the

333 K

323 313 303 0 300 600 900

313 K

1200

Time, [ s ]

Fig. 2. Change in outlet air temperature with time at various inlet hot-air temperatures.

0.7

Regeneration ratio, q / qE [ -]

0.6 0.5 0.4 0.3

373 K

Typical operation range of desiccant dehumidifier

353 K MW-600 W

0.2

333 K

0.1 0 0 300 600 900

313 K

1200

Time, [ s ]

Fig. 3. Change in regeneration ratio, q/qE, with time at various inlet hot-air temperatures.

experiments, a small temperature rise in the rate of outlet air for an initial period was observed when compared to microwave heating at P 600 W. This result indicates that microwave irradiation is very effective for rapid heating of the desiccant rotor in the initial regeneration period. Regarding the regeneration ratio for hot-air heating, the adsorbed water desorbed rapidly with time up to around 300 s, and subsequently, a desorption equilibrium was achieved after 900 s with a slower regeneration rate. In an equilibrium state, it was demonstrated that the experimental desorption ratio approximately corresponded with theoretically calculations based on change in relative pressure accompanied by hot-air ow. Moreover, as is well known for hot-air regeneration, both the initial regeneration rate and the equilibrium regeneration ratio increased with temperature of hot air. When comparing microwave and hot-air heating, it can be seen that the regeneration ratio in the equilibrium state for microwave irradiation was much lower than that for hot-air at 353 K, although the outlet air temperature for microwave irradiation attained a value of 353 K. Desiccant humidity conditioners are normally operated with a regeneration time of 90e180 s under typical running conditions of rotor rotation speed of 10e20 rph, with the regeneration zone occupying half the rotor area. In Fig. 3, the regeneration rate of microwave regeneration was comparable to that of hot-air heating

0.6

Regeneration ratio, q/qE [ - ]

0.5 0.4 0.3 0.2

L = 120 mm u = 1.0 m/s

800W+333K 600W+333K 400W+333K 200W+333K 333K

0.1 0 0 300 600 Time, [ s ] 900 1200

Fig. 4. Effect of combined heating on regeneration ratio at microwave powers of 200e800 W under a hot-air ow at 333 K.

M. Kubota et al. / Applied Thermal Engineering 50 (2013) 1576e1581

1579

dq/d (q/qE)e [kg/s] [-]

Initial regeneration rate, dq/d [kg/s]

10-3

0.12 0.1 0.08

0.5 0.4 0.3

0.06 0.04 0.02 0 0 200 400 600 800

L = 120 mm u = 1.0 m/s

0.2 0.1 0 1000

Microwave power, P [W]

Fig. 5. Relationship between initial regeneration rate, dq/dq, equilibrium regeneration ratio (q/qE)e, and MW power.

rotor under microwave irradiation, hot-air ow, and combined heating were investigated by measuring the temperature distribution in the rotor using optical ber thermometers. The thermometers were installed at fteen points inside the desiccant rotor. They were positioned every 20 mm from the inlet of rotor in the axial direction (20, 40, 60, 80, and 100 mm) and also located every 20 mm from the center (0, 20, and 40 mm) in the radial direction. Fig. 6 is an isothermal diagram of the rotor at 45 s (initial state of regeneration) and 1200 s (equilibrium state), heated by hot air at an inlet temperature of 333 K, by microwave irradiation at P 600 W, and by a combination of hot air at 333 K and microwave at P 600 W, respectively. At a heating time of 45 s, the radial temperature gradient was observed for microwave and combined heating methods, and the temperature at an outer position near the waveguide was lower than that at the center of the rotor. This result was attributed to the fact that the electric eld intensity of the cylindrical waveguide decreased with increasing radius, in addition to heat loss and sensible heat of the waveguide. However, for combined heating, temperature difference between the center and the outer of rotor was less than that observed for microwave due to uniform heating in the radial direction by hot-air ow. Meanwhile, a slight temperature rise was observed for the axial temperature distribution around inlet of the rotor in the case of hot-air heating. The heating of the desiccant rotor proceeded from the upstream to the downstream of air ow. In conventional air heating, thermal energy supplied to the rotor by air gradually decreased due to heat exchange between the rotor and air, and consequently the rise in temperature diminished with increasing axial distance of the rotor. Meanwhile, for microwave heating, higher temperatures were recorded at the downstream of the rotor in spite of the fact that the microwave was irradiated from upstream of the rotor. This phenomenon has been described in detail in our previous paper [8]. For combined heating, a temperature gradient was leveled out in the axial direction compared to microwave heating. In particular, the temperature around the rotor inlet for combined heating was higher than that for microwave heating, since the rotor was heated from an upstream position by hot air ow. When the uniformity of temperature rise in the whole rotor was quantitatively evaluated with standard deviation, the standard deviation of measured rotor temperatures was 8.6 K for microwave heating. Meanwhile, the value for combined heating

Equilibrium regeneration ratio, (q/q )e [-]

0.14

MW HA (333K) MW+HA

0.6

Fig. 6. Temperature distributions in the desiccant rotor for hot-air, microwave, and combined heating at 45 s and 1200 s.

was 7.8 K, indicating that combined heating achieved more uniformly temperature rise than microwave heating. Once a regeneration equilibrium state was attained at 1200 s, the rotor was uniformly heated to that of the inlet air temperature of 333 K for hot-air heating. In the case of microwave heating, a temperature gradient was observed in both axial and radial directions even at a steady state. The standard deviation of rotor temperatures became 13.1 K, although average rotor temperature attained 333 K for microwave heating. It is concluded that the low regeneration ratio was caused by a temperature gradient in the rotor, although the outlet air and average rotor temperatures were sufciently high to promote water desorption. In contrast, for combined heating, a non-uniform temperature distribution was observed around the inlet of rotor even after 1200 s, but the standard deviation was improved to 8.5 K compared to microwave heating, resulting that the entire rotor relatively attained a uniform temperature compared to microwave heating. Moreover, higher average rotor temperatures of 352.2 K was achieved than hot-air at 333 K and microwave irradiation at 600 W alone by combination of

1580

M. Kubota et al. / Applied Thermal Engineering 50 (2013) 1576e1581

both heating methods. From these results, it was demonstrated that a combination of microwave irradiation and hot-air ow can be applied to level temperature distributions in the rotor. As a result, higher regeneration ratio and initial regeneration rates were achieved for combined heating, because both higher and uniform rotor temperature led to enhancement of regeneration of the rotor due to lowering the relative pressure in the regeneration process.

regeneration in short cycle times. However, this conclusion does not take into account conversion efciencies from electricity to microwave nor thermal energy and the microwave absorption efciency of the rotor. Further research is required to signicantly improve these efciencies with the aim of realizing the application of combined heating in humidity conditioners. 4. Conclusions

3.4. Energy consumption for regeneration of the rotor for various heating methods The effectiveness of combined heating was evaluated in terms of energy consumption for regeneration of the rotor. In this paper, the effective energy, Q [kJ], was dened by the following equation.

Q uArCp DT q

(2)

where u is face velocity of air [kg/s], A denotes the cross-sectional area [m2], r and Cp are the density [kg/m3] and the specic heat capacity [J/(kg/K)] of air, respectively For hot-air heating, the effective energy, Q, indicates the sensible heat required to rise air temperature to a predetermined value; i.e. DT is the temperature difference of air between hot-air during regeneration (313e373 K) and air ow during adsorption (303 K). Under microwave heating, the effective energy, Q, describes thermal energy generated from the desiccant rotor and adsorbed water by absorbing microwave energy. Consequently, DT is the difference in temperature of humid air between the inlet and the outlet of the rotor under conditions of regeneration equilibrium, because thermal energy generated by rotor and water became equal to that absorbed by owing air in that state. For combined heating, the effective energy can be dened as the sum of the effective energies of hot-air ow and microwave irradiation. In Eq. (2), q denotes the time required to obtain the predetermined amount of desorbed water. Table 1 shows the relationship between effective energy consumption and amount of desorbed water under different heating methods. Making the assumption that humid air is treated with this system and that the absolute humidity of the air is reduced from 16 g/kg-DA to 10 g/kgDA during the adsorption process, the regeneration rate needs to be greater than 0.053 103 kg/s. Under these conditions, when the regeneration process was performed for 90 s, about 5 g of water was desorbed. The blank entries in Table 1 indicate that regeneration was unable to promote the required level of water desorption and/ or the rate could not be maintained over 0.053 103 kg/s throughout regeneration. Either or these two scenarios demonstrate that the heating method may not be suitable for practical applications. It was found that microwave heating achieved the minimum effective energy consumption when desorbed water below 5 g. Combined heating was effective at regeneration of the rotor over a desorbed water range of 5e7 g. From these results, it was concluded on the basis of energy consumption that it may be possible to apply either combined or microwave heating to humidity control systems that switch between adsorption and

In order to obtain fundamental ndings of regeneration characteristics of combined heating using microwave and hot-air, regeneration experiments were performed using a zeolite-coated desiccant rotor under conditions of hot-air heating and combined heating. The regeneration experiments were conducted in the microwave power, P, range of 200e800 W and hot-air temperatures of 313e373 K. Furthermore, the temperature distribution in the desiccant rotor was also measured using optical ber thermometers in order to investigate heating characteristics of the rotor. It was demonstrated that combined heating was effective at leveling non-uniform temperature distribution by heating the rotor inlet using hot air and heating the rotor outlet using microwaves. With the higher temperature rise and the leveling of the temperature distribution of the rotor, combined heating achieved a higher regeneration ratio compared to hot-air and microwave heating separately. Furthermore, both the initial regeneration rate and equilibrium regeneration ratio under combined heating increased with microwave power, and a linear relationship was observed with respect to microwave power. From the viewpoint of energy consumption, it may be possible to apply combined and microwave heating to humidity control systems that switch between adsorption and regeneration in short cycle times. For this to become a reality both the conversion and absorption efciencies of the microwave need to be signicantly improved. Nomenclature

A AH Cp _ m P q qE Q u

DT r q

cross-sectional area of rotor, m2 absolute humidity of air, gH2O/kg-DA specic heat of air, J/(kg K) mass ow rate of air, kg-DA/s microwave power, W amount of desorbed water from the rotor, gH2O total amount of adsorbed water in an equilibrium state, gH2O effective energy, kJ face velocity of air, m/s temperature difference in humid air between inlet and outlet of the rotor, K density of air, kg/m3 time, s

References

[1] C.R. Ruivo, J.J. Costa, A.R. Figueiredo, Numerical study of the inuence of the atmospheric pressure on the heat and mass transfer rates of desiccant wheels, Int. J. Heat Mass Trans. 54 (2011) 1331e1339. [2] A. Kodama, Cross-contamination test of an enthalpy wheel loading a strong acidic cation ion-exchange resin or 3A zeolite as a desiccant material, J. Chem. Eng.Jpn. 43 (10) (2010) 901e905. [3] M. Beccali, P. Finocchiaro, B. Nocke, Energy and economic assessment of desiccant cooling systems coupled with single glazed air and hybrid PV/thermal solar collectors for applications in hot and humid climate, Sol. Energy 83 (2009) 1828e1846. [4] S.S. Elsayed, T. Miyazaki, Y. Hamamoto, A. Akisawa, T. Kashiwagi, Performance analysis of air cycle refrigerator integrated desiccant system for cooling and dehumidifying warehouse, Int. J. Refrig. 31 (2008) 189e196. [5] T.S. Ge, Y.J. Dai, R.Z. Wang, Y. Li, Experimental investigation on a one-rotor twostage rotary desiccant cooling system, Energy 33 (2008) 1807e1815.

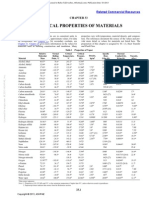

Table 1 Effective energy consumption, Q [kJ], for regeneration of the desiccant rotor for various amounts of desorbed water. Heating methods and conditions Amount of desorbed water [g] 3 MW HA MW HA 373 K 800 W 800W 333 K 600W 353 K 600W 333 K 37 23 33 41 36 4 47 32 41 52 48 5 56 52 64 61 6 67 64 81 7 79 79 95 8 93 101 116 10 124

M. Kubota et al. / Applied Thermal Engineering 50 (2013) 1576e1581 [6] A.E. Kabeel, Solar powered air conditioning system using rotary honeycomb desiccant wheel, Renew. Energy 32 (2007) 1842e1857. [7] M. Saitake, M. Kubota, F. Watanabe, H. Matsuda, Enhancement of water desorption from zeolite by microwave irradiation, Kagaku Kogaku Ronbunshu, J. Chem. Eng. 33 (1) (2007) 53e58 (in Japanese).

1581

[8] M. Kubota, T. Hanada, S. Yabe, H. Matsuda, Water desorption behavior of desiccant rotor under microwave irradiation, Appl. Therm. Eng. 31 (2011) 1482e1486. [9] I. Polaert, A. Ledoux, L. Estel, R. Huyghe, M. Thomas, Microwave assisted regeneration of zeolite, Int. J. Chem. Reactor Eng. 5 (2007) A117.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- April 2014Documento86 pagineApril 2014Delian KurniawanNessuna valutazione finora

- Si - f13 - ch33 (Physical Properties of Materials)Documento4 pagineSi - f13 - ch33 (Physical Properties of Materials)Delian KurniawanNessuna valutazione finora

- International Journal of Thermal Sciences: Jonathan Dallaire, Louis Gosselin, Alexandre K. Da SilvaDocumento9 pagineInternational Journal of Thermal Sciences: Jonathan Dallaire, Louis Gosselin, Alexandre K. Da SilvaDelian KurniawanNessuna valutazione finora

- Tes Penalaran Angka - V3Documento0 pagineTes Penalaran Angka - V3Delian KurniawanNessuna valutazione finora

- Monthly ReportDocumento20 pagineMonthly ReportDelian KurniawanNessuna valutazione finora

- 6400 PartsDocumento3 pagine6400 PartsDelian KurniawanNessuna valutazione finora

- (Kelly S. Graham) Fundamentals of Mechanical Vibra PDFDocumento359 pagine(Kelly S. Graham) Fundamentals of Mechanical Vibra PDFDelian KurniawanNessuna valutazione finora

- Conditional Sent PDFDocumento2 pagineConditional Sent PDFDelian KurniawanNessuna valutazione finora

- CATIA IntroDocumento26 pagineCATIA IntroDelian Kurniawan100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Entry Test - 2 (JEE Eklavya 2023-Earlybird)Documento45 pagineEntry Test - 2 (JEE Eklavya 2023-Earlybird)vwxyz technologyNessuna valutazione finora

- TE Chemical LeachingDocumento25 pagineTE Chemical LeachingevemillyNessuna valutazione finora

- Environmentally Friendly Corrosion Inhibitors PDFDocumento36 pagineEnvironmentally Friendly Corrosion Inhibitors PDFMekon-Engineering MkeNessuna valutazione finora

- Reduction Preg RobbingDocumento8 pagineReduction Preg RobbingAde SatriaNessuna valutazione finora

- Astm D 4179Documento5 pagineAstm D 4179Alvaro HernandezNessuna valutazione finora

- Sattler PDFDocumento232 pagineSattler PDFRodrigo Mazzarella100% (1)

- Drier Manual PDFDocumento261 pagineDrier Manual PDFoluwatoke segunNessuna valutazione finora

- Volhard PDFDocumento4 pagineVolhard PDFAdrian Murgoci33% (3)

- Silica Gel Blue DescriptionDocumento5 pagineSilica Gel Blue DescriptionAnggriani Dwi PutriNessuna valutazione finora

- (Fundamental Materials Research) S.B. McCullen, J.C. Vartuli, C.T. Kresge, W.J. Roth, J.S. Beck, K.D. Schmitt (Auth.), Thomas J. Pinnavaia, M. F. Thorpe (Eds.) - Access in Nanoporous Materials-SpringeDocumento436 pagine(Fundamental Materials Research) S.B. McCullen, J.C. Vartuli, C.T. Kresge, W.J. Roth, J.S. Beck, K.D. Schmitt (Auth.), Thomas J. Pinnavaia, M. F. Thorpe (Eds.) - Access in Nanoporous Materials-SpringeKamilo Arciniegaz100% (1)

- Adsorption, Ion Exchange, Chromatography, and ElectrophoresisDocumento39 pagineAdsorption, Ion Exchange, Chromatography, and ElectrophoresisAntonioAravenaNessuna valutazione finora

- Vanadio NMRDocumento7 pagineVanadio NMRsergioodin4851Nessuna valutazione finora

- Filtration of Apple Juice by Nylon Nanofibrous MembranesDocumento7 pagineFiltration of Apple Juice by Nylon Nanofibrous MembranesDavid CamargoNessuna valutazione finora

- Estimating The Remaining GAC Removal CapacityDocumento73 pagineEstimating The Remaining GAC Removal Capacityfenda2Nessuna valutazione finora

- Materials Studio Technical Specifications - v2Documento7 pagineMaterials Studio Technical Specifications - v2Rahul BorseNessuna valutazione finora

- 235 Spanish Chemistry TermsDocumento28 pagine235 Spanish Chemistry TermsHugh Fox IIINessuna valutazione finora

- Environmental PollutionDocumento10 pagineEnvironmental PollutionPragya AgrahariNessuna valutazione finora

- Pharmaceutics McqsDocumento78 paginePharmaceutics McqsakramuddaulaNessuna valutazione finora

- UIL Cehemical MediaDocumento5 pagineUIL Cehemical MediaSujiono SujionoNessuna valutazione finora

- Che 305: Mass Transfer Ii: Dr. Syeda Sultana RaziaDocumento17 pagineChe 305: Mass Transfer Ii: Dr. Syeda Sultana RaziaMohaiminNessuna valutazione finora

- 25.leather I ViiifDocumento174 pagine25.leather I Viiifrs8395422Nessuna valutazione finora

- 13 NpartiDocumento223 pagine13 NpartijennimuruganNessuna valutazione finora

- Carbon Black Production, Properties and Uses Production, Properties and UsesDocumento308 pagineCarbon Black Production, Properties and Uses Production, Properties and UsesJapan Polymers Analytical and Research LabNessuna valutazione finora

- Application of Gas Separation MembranesDocumento47 pagineApplication of Gas Separation Membranesscribduserme123Nessuna valutazione finora

- CECA (ARKEMA) - Acticarbone White PaperDocumento10 pagineCECA (ARKEMA) - Acticarbone White Paperatom_1971Nessuna valutazione finora

- A Reticular Chemistry Guide For THR Design of Periodic SolidDocumento22 pagineA Reticular Chemistry Guide For THR Design of Periodic Solidsatyajit beheraNessuna valutazione finora

- Biochar-Based Adsorbents For Carbon Dioxide Capture - A Critical ReviewDocumento14 pagineBiochar-Based Adsorbents For Carbon Dioxide Capture - A Critical ReviewZackkNessuna valutazione finora

- Sulfrex 1Documento36 pagineSulfrex 1skeckdy100% (1)

- A Critical Review of The Use of Surfactant-Coated Nanoparticles in Nanomedicine and Food NanotechnologyDocumento63 pagineA Critical Review of The Use of Surfactant-Coated Nanoparticles in Nanomedicine and Food NanotechnologyMartin MaguNessuna valutazione finora

- Strainer-Separable TiO2 On Halloysite Nanocomposite-Embedded Alginate Capsules With Enhanced Photocatalytic Activity For Degradation of Organic DyesDocumento11 pagineStrainer-Separable TiO2 On Halloysite Nanocomposite-Embedded Alginate Capsules With Enhanced Photocatalytic Activity For Degradation of Organic DyesBachi NanoNessuna valutazione finora