Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

F Technology Story

Caricato da

Tufail MemonDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

F Technology Story

Caricato da

Tufail MemonCopyright:

Formati disponibili

g

GER-3950C

GE Power Systems

The F Technology Experience Story

Eric Gebhardt GE Power Systems Atlanta, GA

The F Technology Experience Story

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 MS7001F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 MS9001F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Design Enhancements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 MS6001FA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Operational Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Compressor Issues and Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Tie Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 15th Stage Wheel Cracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 17th Stage Fillet Cracking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Turbine Rotor Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Turbine 2-3 Spacer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Third Stage Subassembly Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Uprates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Future Evolution of the F/FA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Compressor Capability Offers Further Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

GE Power Systems GER-3950C (10/00)

I I

The F Technology Experience Story

GE Power Systems GER-3950C (10/00)

I I

ii

The F Technology Experience Story

Introduction

Prior to 1987, the largest gas turbines (both 50 Hz and 60 Hz) operated at firing temperatures in the neighborhood of 2012F(1100C). Combined Cycle plants were operating at efficiencies upwards of 45%. Reliability/Availabilty had begun to reflect the maturing of the gas turbine in base load service, with fleet availability between 85% and 95% depending on turbine model and manufacturer. In June 1987, GE introduced a new generation of gas turbine the MS7001F. The introduction of the MS7001F was driven by the demand for higher efficiency plants with lower emissions and lower cost (per KW/Hr). When the MS7001F was first introduced projections were made that the unit would obtain 200 MW and 50% efficiency in a Combined Cycle Duty Application. Since that time the numbers of GE "F" Technology units in the world has grown to 146 that were in operation at the end of 1999. It is estimated that there will be 239 in operation by the end of 2000 (See Figure 1).

History

Gas turbines were first used for power generation in the 1950s, and were used almost exclusively for peaking duty. For this mode of service, designs were required which featured low specific cost and good starting reliability. Through the 1960s and early 1970s, continuing advances in gas-turbine efficiency, reliability, and availability facilitated a wider range of applications for gas turbines. As operating hours increased, fuel cost assumed greater significance in optimizing machine design. The importance of this factor grew dramatically with the rapid rise in fuel prices following the oil crises of the 1970s. As operating (fuel) cost became more important in gas-turbine economics, technology development was focused on improving efficiency, primarily through increasing firing temperature. In 1981 the MS7001F program began, planners realized that the larger gas turbine size would mean lower power plant specific cost, and a higher firing temperature would result in higher combined cycle efficiency.

300

Number of Units

3500 3000

250

Hours of Operation

200 150

2000 1500 100 50 0

1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000

1000 500 0

Figure 1. Cumulative number of units and hours in operation each year. 2000 values are estimated based on sales and units in manufacturing.

GE Power Systems GER-3950C (10/00)

I I

Hours of Operation

Number of Units

2500

The F Technology Experience Story

In order to achieve the higher firing temperatures many changes would be required to the unit to ensure no adverse affects on maintenance intervals. Key technologies had been developed which would allow for this new design. These included new compressor airfoil designs which would allow for a higher inlet mass flow, as well as new methods for large superalloy castings which would allow for more efficient cooling of the buckets and nozzles. The one major factor against significant advancement was the power generation industry was in downturn. GE made the decision to continue with the design despite the status of the industry at the time. which were closely followed by the MS6001F (which would be gear driven at 50 Hz or 60 Hz) (See Figure 2). The heart of the F Technology came from the First stage compressor aerodynamic design, higher temperature capable materials and more sophisticated hot gas path component cooling circuit.

MS7001F

From the beginning, the MS7001F development program contained an extensive series of tests. These were grouped into three phases: (See Figure 2) I First were component and technology validation tests. These tests included combustor operation, bucket and compressor blade vibration tests, heat transfer coefficient measurement and many others. I Second was the factory test under load with test points at full firing temperature. An axial flow compressor was used for the factory-loaded tests.

Design

Prevailing economic factors resulted in the decision to introduce the first F machine configured to serve the 60 Hz market (MS7001F), then follow with a 50 Hz product (MS9001F), and finally flowing the technology to a size demanded by industrial cogeneration and district heating (MS6001F). The MS7001F (60 Hz) and MS9001F (50 Hz) programs were integrated and had overlapping development cycles

MS7001F and MS9001F Engineering Test and Product Introduction Schedule

Year

7F No-Load Test 7F Loaded Test 7F Comm. Shtp. 7F Power Plant Constr. 7F CC Operation 9F Rotor Ships (GVL) 9F Comb. Ships (GVL) 9F Comm. Shtp. (EGT) 9F Test - France 9F Comm. Op. - France GE Prime 9F Test (GVL) GE Prime 9F Ships (GVL)

1987

1988

1989

1990

1991

1992

1993

GT 25511A

Figure 2. Schedule of key milestones GE Power Systems GER-3950C (10/00)

I I

The F Technology Experience Story

I Third in the series was the field test, where full flow and full temperature could be simultaneously achieved. Additional changes were also decided on to support drive in industry for increased Reliability and Availability. These changes were: I Dedicated accessory base skids that were arranged for easy access and powered by individual electric motors. This design was to minimize downtime associated with all types of maintenance. I Axial exhaust was designed to reduce the losses between the gas turbine exit and the heat recovery steam generator (HRSG). I Cold end generator drive configuration. I Two bearing design was adopted similar to steam turbines and MS6001B/MS5001 gas turbines. The Greenville test confirmed the predicted compressor performance, efficiency, and operational functionality. During disassembly following the Greenville test, slight cracking was observed on four compressor vanes. Analysis was performed and a resolution was implemented prior to the unit being placed in operation. The heavily instrumented unit from Belfort experienced dynamic excitation on stages 14, 15 and 16 stators during startup and acceleration from cold conditions. Although a modified start-up procedure eliminated the condition, changes were made in blade profiles to completely eliminate the possibility of vibration problems on future units. All blades put in service were of the modified design.

Design Enhancements

The most significant impact which test data had on the appearance of the F family of gas turbines was the choice of a rotor designed with IN706 material rather than the lower-strength, M152. The design team recognized that ductility of M152 could be reduced by exposure to the environments of a turbine with high pressure ratio and high gas path temperature. As the effect of exposure of iron-based wheel alloys to turbine environments was more fully understood, the decision was made to increase the robustness of the rotor by applying a material far less sensitive to exposure to high temperature. So the rotor was redesigned with lighter, yet stronger, wheels and spacers. In the process, the total depth of bolt holes in the rotor was reduced, hence the multiple-bolt construction, much like the MS5001 turbine rotor, in place of the through-bolting used on the MS7001E and similar machines.

MS9001F

The MS9001F was introduced in 1989 and was designed using aerodynamic scaling from the MS7001F. Fundamental component configurations can be based on this scaling technique. However, some phenomena are known not to scale. Their effects were investigated by the same thorough analysis used in the preceding design, and the necessary adjustments were made. Initially there were two MS9001F units built practically simultaneously. A unit with minimal instrumentation was operated at no load in the Greenville factory, and a fully instrumented unit was assembled in the Belfort factory. The instrumented unit later underwent fully-loaded testing in simple-cycle operation.

GE Power Systems GER-3950C (10/00)

I I

The F Technology Experience Story

The outcome of the testing of the machines resulted in tuning of other portions of the design. These changes would result in better overall life of the units. The first rotating blade of the compressor (stage zero) was re-tuned to raise a natural frequency. Blade clearances were adjusted to reduce the level of rubbing during transients. The solidity of compressor stator stage 17 was increased to eliminate a high vibratory stress due to flow separation under some operating conditions. In order to ensure that the units would meet life predictions temperatures were measured to confirm calculations. Data from the testing confirmed the calculations that were performed and thus verified our parts life estimates that were made early in the design. bility for all gas turbine products. Interim steps resulted in systems capable of 42 ppm and 25 ppm. The F technology, because of high specific output, brings an additional benefit to the environment. Because of the higher specific output of high firing temperature machines, less NOx and CO are emitted per unit of power produced for the same exhaust concentrations. Because of the increased efficiency, less fuel is required for a given level of power production; hence, F technology machines emit less CO2. Figure 3 illustrates the benefits of F technology given fixed emission standards.

Operational Issues

After more than five years of essentially troublefree service and more than 150,000 fleet operating hours, a number of GE F class gas turbines experienced compressor or turbine rotor distress beginning in mid-1994. Ultimately, most of the operating units were affected to some extent by these issues. Root cause was identified, resolutions were designed and implemented throughout the fleet in a manner designed to minimize the unavailablity to the operators. The issues encountered during this period did impact customers operations, but these observations are important in assessing the implications to advancing technology: I F Technology Fundamentals were not root cause of issues. F Technology Fundamentals include high firing temperature and associated high temperature materials, advanced cooling or high mass flow compressor stages. I Issues were associated with features and processes applied to single machines or a limited population. Turbine Rotor flexibility had fleet-wide implications.

MS6001FA

Conceptual design of an MS6001F gear driven version began in 1991. The objective was to bring the benefits of F technology to the market segment traditionally served by the MS5001 and the MS6001B. An output in the range of 60 MW to 70 MW would represent a proportional increase in output beyond the MS6001B similar to the increase of the MS6001B relative to the MS5001. Since the MS6001FA was to be a geardriven machine, the grid frequency of the application was irrelevant in selecting scale factor. The MS6001FA is a 2/3 scale of the MS7001FA. The design program began in 1993 and the first unit was assembled in late 1995.

Emissions

Due to environmental concerns with the exhaust of the heavy duty gas turbine emissions criteria commonly specify a maximum concentration of NOx in the exhaust. During the F programs, a parallel program delivered lowemission combustors for the GE product line. The goal was to develop single-digit NOx capaGE Power Systems GER-3950C (10/00)

I I

The F Technology Experience Story

(F)

Figure 3. Emissions versus firing temperature I The components that were affected were limited to a few internal rotor components. I Because of the efforts made to advance the reliability of gas turbines, particularly in the controls and diagnostics, in most cases, the problems were detected before any damage occurred. I Resolutions for all of the issues that were encountered have been implemented and have been completely successful. question was disqualified. Bolts tensioning procedures were also revised to reduce mean stress level variation. Standardization and control of bolt and nut details realize similar improvements in stress level. Continued reliable operation of the units assembled with the now-standard parts and procedures in both MS7001F and MS9001F sizes validates the design.

15th Stage Wheel Cracking

During disassembly of the units to replace compressor through bolts a crack was found on the 15th stage wheel web area where the rotor blades were staked in place. The RCA for web cracking discovered that there were two factors that caused this. One was the thickness of the material and second was the procedure used to stake the blades in place. Dovetail area distress and the effect of dovetail proc-essing on blade dynamics resulted in thickening of the rim area and standardized staking practice on future units. No substantive changes in the basic compressor design were required. Configuration details and assembly practices of the current production units increase the rotors robustness.

Compressor Issues and Resolution

Tie Bolts

Several early production MS9001F units experienced cracking of compressor rotor through bolts. All cracked compressor bolts were traced to one particular supplier. Root cause was determined to be vendor methods for production of the bolts, which were outside of GEs specifications. No MS7001F units were not affected nor were any of the US built MS9001F units. Compressor rotor bolts were standardized in the methods of production and the vendor in

GE Power Systems GER-3950C (10/00)

I I

The F Technology Experience Story

17th Stage Fillet Cracking

Early in 1997 a unit was removed from service due to vibrations which were beyond balance abilities. Shortly thereafter another unit was removed with similar characteristics. After many weeks and rigorous analysis it was found that the cause of the vibrations was a crack in the fillet region of the 17th stage of the compressor. The RCA showed two key contributing factors. First factor was unit specific operational parameters had led to cracking in this area. Second factor was impact damage that was caused during assembly of the compressor rotors. Maintenance factors for startup, operations and shutdown were implemented. The steam turbine industry recognized this fact in the 1950 to 1970 time frame when the growth of the industry led to larger steam turbines. This is also true of gas turbines, as the size of the unit increases there is a larger requirement for maintenance factors. Disassembly procedures were reviewed and revised with additional precautions to be taken to ensure there was no impact between the windage nut on the compressor through bolts and fillet radius of the 17th stage. (See figure 4).

Turbine Rotor Issues

Turbine 2-3 Spacer

The design of all early turbine rotors contained features which caused sufficient rubbing between the 2-3 spacer rim and the 3rd stage wheel seal land to cause portions of the land to break away. In some instances, rotor balance was affected. The same rolling motion caused flexing of the 2-3 spacer. During the cooldown cycle on some units, the spacer cooled sufficiently faster than the mating wheels to cause the rabbet fit to become disengaged. The stresses in the web of the 2-3 spacer were high enough in this condition to cause cracking, and this cracking was observed in a few rotors removed from service. Rim distress is avoided by cutting back the aft flange of the 2-3 spacer. This has been done on several units already operating. Along with this change, the operating conditions leading to light rabbet loads are eliminated by lowering the rotor fast cool down cranking speed. Current production spacers are of a new design that prevents the rim engagement, the disengagement of the rabbet, and high flexing stress. The issue has not occurred in units with the

15th Stage Through Bolts

17th Stage Fillet

Figure 4. Cross section of compressor rotor showing locations of components GE Power Systems GER-3950C (10/00)

I I

The F Technology Experience Story

new spacer, or in units with field modifications and cooldown cycle modifications. base, from whatever gas turbine product it comes, can benefit multiple product lines. Figure 7 shows the incremental evolution of the E class machine. As the E class matured, a decision was made to introduce the F class machinesthe 7F and its scaled versions, the 9F and the 6F. Many factors drove this decision, but once the F machines were introduced, technology advancement or operating experience on the F product line has helped drive further evolution on the older E class machines, albeit in more gradual steps. Design improvements for the F product line are made incrementally, and based on proven materials, extensive laboratory or engine testing, and operating experience. When the F technology was announced, uprate potential was projected. Immediately upon completion of the prototype testing at the Greenville factory, these uprates began. One of the projections made was that the combined cycle efficiency would be increased from the 50% cited in the introduction paper, to 55%. The 55% level was achieved in 1994 with the testing a MS7001F unit in combined-cycle mode. Uprates continue, as the technology becomes available and as experience on the high temperature components of the F fleet remains favorable. Table 1 shows the evolution of the MS7001F machine. Each uprate has been achieved without reducing inspection intervals below those established by the original design. The first uprate of the MS7001F simply took advantage of the better than expected performance observed in testing. Firing-temperature upgrades involved modifications to component cooling and pressure ratio. These include improved clearance and leakage control achieved with the help of honeycomb seals - which have been used now for years in the MS9001E and MS7001EA machines. Figure 8

Third Stage Subassembly Bolts

Two MS9001F and three MS7001F units experienced cracking of the forward end of the third stage subassembly bolts. Root cause analysis was performed and it was found that under certain operating conditions combined with low elongations on the bolts that the bolts would relax causing high cycle fatigue. Conclusion of the RCA was to revise the elongation process to reduce variability and to change the bolts to a different material to increase margin to event. (See figure 5).

Availability

At the beginning of the F Program, GE and an industry advisory board set product availability goals which were higher than had yet attained by any gas turbine. As can be seen in Figure 6, availability of the F units has followed the mature proven units.

Uprates

Gas turbine designers are obliged to pursue opportunities for improving efficiency, reliability, and maintenance cost, in such ways as to not invalidate the experience base. This experience

2-3 Spacer Third Stage Subassemble

Figure 5. Cross section view of the turbine rotor showing affected components

GE Power Systems GER-3950C (10/00)

I I

The F Technology Experience Story

100 95 90 85

7B-E Fleet

80 75 70

6B 7F/FA

Years in Operation

Figure 6. F Technology following proven technology

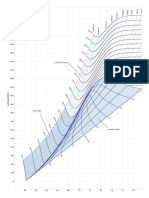

60% Combined Cycle Efficiency

CC Efficiency Firing Temp

H

Future Potential Upgrades

Firing Temp (F) 2600

55%

F

50%

2400

2200

E

45%

2000 1800

40% 1970 1975 1980 1985 1990 1995 2000 2005 Year of Shipment

Figure 7. Incremental evolutions of E and F technology shows the evolution of the PG7231FA to the PG7241FA, illustrating the incremental enhancements that were incorporated recently into the 7F product line. ing of H and other technologies; and, a recent F compressor mapping test are all key factors that will be carefully weighed.

Future Evolution of the F/FA

As GE looks forward to the next steps in the continued evolution of the F/FA product line, a range of factors is being considered. The continuing improvement in F reliability and growing experience base; the development and testGE Power Systems GER-3950C (10/00)

I I

Compressor Capability Offers Further Options

In 1998 a compressor test was run to revalidate the operating surge limit for the F/FA compressor. The results of this test indicated there was significant additional capability in the compressor. Figure 9 shows how this development 8

The F Technology Experience Story

PG7191(F) 150 MW 9880 BTU/kWh 13.5:1 2300F 1991 PG7221(FA) 159 MW 9500 BTU/kWh 15.1:1 2350F 1993 PG7231(FA) 167.8 MW 9380 BTU/kWh 14.9:1 2400F 1997 PG7241(FA) 171.7 MW 9360 BTU/kWh 15.5:1 2420F 1999

Output Heat Rate (LHV) Pressure Ratio Firing Temp. Introduction

Table 1. Evolution from PG7191(F) to PG7241(FA+e)

9PPM 2.6 Combustor DLN 2.6 DLN Combustor

EGV Arrangement New EGV Arrangement

New EGV Arrangement

9PPM DLN 2.6 Combustor Flexible Seals Flexible Seals

Stage 2 Bucket Stage 2 Bucket 2 Bucket Stage Scalloped Shroud Scalloped Shroud Mod Cooling Mod Cooling Hole Pattern Hole Pattern

HGP Gas SealingPath Hot

Hot Gas PathSealing Improved Improved Sealing

Tapered Struts

Tapered Struts

Compressor Rotor

Robust Compressor

Rotor Robust Compressor Rotor

Honeycomb HPPS 3300 Series Bentley Probes #1 & #2 Series Bearings 3300 Bentley Probes

#1 & #2 Bearings

Honeycomb HPPS Tie Bolt and Marriage Flange Cooling Honeycomb HPPS Tie Bolt & Marriage Flange Cooling

Monitoring/Diagnostics Monitoring/Diagnostics Added Combustor Tuning Kit Added Combustor Tuning Kit

Tie Bolt & Marriage Flange Cooling

Double Wall Cone Cone Double Walled Double Walled Cone Improved Sealing Improved Sealing Reduced Flow Reduced Flow

Stage Nozzle, Bucket, Shroud Stage 1 1Nozzle, Bucket, Shroud Stage HGP TBC1 Coating Thermal Barrier Coating Thermal Barrier Coating Reduced Cooling Air Reduced Cooling Air

Figure 8. Transition from PG7231 to PG7241 gas turbine illustrates incremental improvement philosophy

59

7191 2300F

7221 2350F

7231 2400F

7241FA 2420F

7251FB 2500+F

7FB PR=18.5 7FB NOx 25

57 7FA PR=15 7FA 9 NOx 2700 2600 2500 2400 2300 2200 2100 1984 1986 1988 1990 1992 1994 1996 1998 2000 2002 2004 2006

Net CC Efficiency

55

7FA

53

51

ature mper ing te r fi T G

FA Compressor Test Completed

Year

Figure 9. Evolution of the MS7001F GE Power Systems GER-3950C (10/00)

I I

Firing Temperature (F)

ncy cie effi C C

7FB

The F Technology Experience Story

opens up additional options for the next step in F evolution to continue on a gradual incremental change in pressure ratio and temperature or take a more aggressive path and take advantage of the results of the 1998 compressor test. As these options are examined, significant technical tradeoffs must be analyzed.

References

1. Miller, H.E., F Technology - The First Half Million Operating Hours GER3950B 2. Eldrid, R., Marks, P., Continuing Evolution of F Technology Dec 1999.

GE Power Systems GER-3950C (10/00)

I I

10

The F Technology Experience Story

List of Figures

1. Cumulative number of units and hours in operation each year. 2000 values are estimated based on sales and units in manufacturing. 2. Schedule of key milestones 3. Emissions versus firing temperature 4. Cross section of compressor rotor showing locations of components 5. Cross section view of the turbine rotor showing affected components 6. F Technology following proven technology 7. Incremental evolutions of E and F technology 8. Transition from PG7231 to PG7241 gas turbine illustrates incremental improvement philosophy 9. Evolution of the MS7001F

List of Tables

1. Evolution from PG7191(F) to PG7241(FA+e)

GE Power Systems GER-3950C (10/00)

I I

11

The F Technology Experience Story

GE Power Systems GER-3950C (10/00)

I I

12

Potrebbero piacerti anche

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDocumento4 pagineList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZNessuna valutazione finora

- Thermal Peaking PDFDocumento26 pagineThermal Peaking PDFkhozaqiNessuna valutazione finora

- Technical Information Letter: Ge Power TIL 2445 Product ServiceDocumento4 pagineTechnical Information Letter: Ge Power TIL 2445 Product ServiceMinhajur Rahman100% (1)

- 1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesDocumento8 pagine1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesArgenomSaubiNessuna valutazione finora

- Gas TurbineDocumento14 pagineGas TurbineMowaten Masry100% (1)

- SGT800 Verification ReportDocumento58 pagineSGT800 Verification ReportThanapaet RittirutNessuna valutazione finora

- SBLM2500 Ind 217Documento5 pagineSBLM2500 Ind 217Daniil SerovNessuna valutazione finora

- Gea32081a LM6000 - Pa - Us - R1 - LRDocumento1 paginaGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNessuna valutazione finora

- Generator VOL 8ADocumento18 pagineGenerator VOL 8AEmadAlhosien AlhosienNessuna valutazione finora

- SGT6-5000F PAC - LowRes PDFDocumento18 pagineSGT6-5000F PAC - LowRes PDFmyegnrNessuna valutazione finora

- General Electric - Inlet Air RecommendationDocumento28 pagineGeneral Electric - Inlet Air Recommendationhussain mominNessuna valutazione finora

- Ger 3751 ADocumento28 pagineGer 3751 Ahbh123456Nessuna valutazione finora

- Alstom Gen TOPAIR PDFDocumento6 pagineAlstom Gen TOPAIR PDFcynaidu100% (1)

- 9FA Enhancement Brochure - GEA17570Documento8 pagine9FA Enhancement Brochure - GEA17570Peter_Phee_341Nessuna valutazione finora

- LM TM2500 Upgrade Solutions PDFDocumento2 pagineLM TM2500 Upgrade Solutions PDFLibyanManNessuna valutazione finora

- T48 SpreadDocumento1 paginaT48 SpreadKarim MuhammedNessuna valutazione finora

- GEA31503e PGP Product E-Catalog 2015 R10Documento47 pagineGEA31503e PGP Product E-Catalog 2015 R10juagamsar100% (1)

- GER3620L Nov 3 09b 1Documento60 pagineGER3620L Nov 3 09b 1rafieeNessuna valutazione finora

- 4 - Inspection - Interval - Extension W5015DA PDFDocumento12 pagine4 - Inspection - Interval - Extension W5015DA PDFEDBNessuna valutazione finora

- GE LM6000 1275-GryDocumento1 paginaGE LM6000 1275-GryuzairmughalNessuna valutazione finora

- F646 CompleteSampleDocumento36 pagineF646 CompleteSampleraj4523Nessuna valutazione finora

- Fact Sheet Variable Inlet Guide VaneDocumento1 paginaFact Sheet Variable Inlet Guide VaneDarioNessuna valutazione finora

- GE 9HA Gas TurbineDocumento4 pagineGE 9HA Gas TurbinejparmarNessuna valutazione finora

- TIL 1304 3 - 9th Stage Stator Casing Hook Fit CrackingDocumento4 pagineTIL 1304 3 - 9th Stage Stator Casing Hook Fit CrackinghernangNessuna valutazione finora

- Alstom GT KA-26 Overview PDFDocumento35 pagineAlstom GT KA-26 Overview PDFCyrix.One100% (1)

- Rotating Diodes Exciter Having Competitive Performance For Nuclear PlantDocumento9 pagineRotating Diodes Exciter Having Competitive Performance For Nuclear PlantR0B0T2013Nessuna valutazione finora

- Fuel NozzlesDocumento3 pagineFuel Nozzlesfrancisco_navas4479100% (1)

- Til 1539Documento13 pagineTil 1539Michael JordanNessuna valutazione finora

- 9FA Recommended Parts ListingDocumento1 pagina9FA Recommended Parts Listingalexandr_popov_2Nessuna valutazione finora

- TIL 1880 Trip Risk When Liquid Fuel Recirculation Is Turned Off While Running On Gas PDFDocumento5 pagineTIL 1880 Trip Risk When Liquid Fuel Recirculation Is Turned Off While Running On Gas PDFManuel L LombarderoNessuna valutazione finora

- APA DOC No. 2014 PDFDocumento67 pagineAPA DOC No. 2014 PDFThanapaet RittirutNessuna valutazione finora

- Til 1236-R2Documento5 pagineTil 1236-R2makarov.olegNessuna valutazione finora

- EngDocumento44 pagineEngzomglolzscribdNessuna valutazione finora

- 9fa ProbsDocumento12 pagine9fa ProbsMarbz Al MonteNessuna valutazione finora

- GT13E2 Infographic - Final - PDFDocumento1 paginaGT13E2 Infographic - Final - PDFGregory StockNessuna valutazione finora

- NIC - 07-37 - Rev-01 Technical Updates Web Portal GEDocumento47 pagineNIC - 07-37 - Rev-01 Technical Updates Web Portal GEManuel L LombarderoNessuna valutazione finora

- GT Gas Fuel and Air FlowDocumento38 pagineGT Gas Fuel and Air FlowhinaNessuna valutazione finora

- MOU (06std) - HDGT Auxiliary Systems LDocumento80 pagineMOU (06std) - HDGT Auxiliary Systems Lalaeddine chahdane100% (1)

- GE Aeroderivative Vietnam Sep 22 FinalDocumento36 pagineGE Aeroderivative Vietnam Sep 22 Finaltuanpham100% (1)

- Siemens 1 GTX 100 TurbineDocumento16 pagineSiemens 1 GTX 100 TurbinejparmarNessuna valutazione finora

- 11 Electrabel Maxima Power PlantDocumento29 pagine11 Electrabel Maxima Power Plantpartha6789Nessuna valutazione finora

- Performance and Reliability Improvements For The Ms5001 Gas TurbinesDocumento39 paginePerformance and Reliability Improvements For The Ms5001 Gas TurbinesMuhammad Irfan AnwarNessuna valutazione finora

- Til 1755-R3 Lci Water - Cooled Bus LeaksDocumento8 pagineTil 1755-R3 Lci Water - Cooled Bus LeaksMichael SanchezNessuna valutazione finora

- Nic 13.05Documento14 pagineNic 13.05BouazzaNessuna valutazione finora

- Psib 20130524aDocumento1 paginaPsib 20130524aLéandre Ettekri NdriNessuna valutazione finora

- Ger 3928c Uprate Options Ms9001 Heavy Duty Gas TurbineDocumento58 pagineGer 3928c Uprate Options Ms9001 Heavy Duty Gas Turbineamir moniriNessuna valutazione finora

- Mxl2 For Gt26Documento4 pagineMxl2 For Gt26Mai DangNessuna valutazione finora

- Psib 20150212Documento10 paginePsib 20150212Léandre Ettekri NdriNessuna valutazione finora

- Pivot Arm Turning GearDocumento24 paginePivot Arm Turning Gearoom_tgw100% (1)

- 7HA Gas Turbine: World's Largest, Most Efficient Gas Turbine in Its ClassDocumento4 pagine7HA Gas Turbine: World's Largest, Most Efficient Gas Turbine in Its Classjparmar100% (2)

- Applicability Guide PDFDocumento2 pagineApplicability Guide PDFtriplbingaziNessuna valutazione finora

- Technical Specifications, Fuel Nozzle GR 127 PDFDocumento8 pagineTechnical Specifications, Fuel Nozzle GR 127 PDFMadhan KumarNessuna valutazione finora

- Illustrated Parts Breakdown (GEK 50336)Documento1.072 pagineIllustrated Parts Breakdown (GEK 50336)Yeison DazaNessuna valutazione finora

- Ger 4207Documento16 pagineGer 4207XXXNessuna valutazione finora

- The F Technology Experience Story: GE Power SystemsDocumento16 pagineThe F Technology Experience Story: GE Power SystemsManarFikry100% (1)

- GE Steam Bypass System Ger4201Documento18 pagineGE Steam Bypass System Ger4201Utku Kepcen100% (1)

- Ger 4217 ADocumento30 pagineGer 4217 Atehranqom100% (2)

- GE's Next 7FA Gas Turbine "Test and Validation"Documento20 pagineGE's Next 7FA Gas Turbine "Test and Validation"JJ100% (1)

- GEA18457ADocumento20 pagineGEA18457AEdGouramiNessuna valutazione finora

- Essentials of Anatomy and PhysiologyDocumento31 pagineEssentials of Anatomy and PhysiologyTufail MemonNessuna valutazione finora

- T-Icb-06: 2.1 To Study The Existing Systern To Acquisition Sysrem Das-100 System Imake Yokogawa, Japan)Documento1 paginaT-Icb-06: 2.1 To Study The Existing Systern To Acquisition Sysrem Das-100 System Imake Yokogawa, Japan)Tufail MemonNessuna valutazione finora

- Group Leader Training Program: Centeral Power Generation Co. LTD PakistanDocumento1 paginaGroup Leader Training Program: Centeral Power Generation Co. LTD PakistanTufail MemonNessuna valutazione finora

- Wonders of ComputersDocumento27 pagineWonders of ComputersTufail MemonNessuna valutazione finora

- Case StudyDocumento10 pagineCase StudyVintage ArtNessuna valutazione finora

- Computational Neuroscience CW1 (Bristol)Documento3 pagineComputational Neuroscience CW1 (Bristol)libannfNessuna valutazione finora

- DelhiDocumento44 pagineDelhiIndia TreadingNessuna valutazione finora

- 417 Model E Alarm Check ValvesDocumento4 pagine417 Model E Alarm Check ValvesM Kumar MarimuthuNessuna valutazione finora

- SC431 Lecture No. 4 Economic Comparisons (Continued)Documento51 pagineSC431 Lecture No. 4 Economic Comparisons (Continued)Joseph BaruhiyeNessuna valutazione finora

- Jazz Piano VoicingsDocumento19 pagineJazz Piano Voicingskeybiank86% (58)

- UMTS Optimization GuidelineDocumento84 pagineUMTS Optimization GuidelineEvelio Sotolongo100% (3)

- GTP For 1CX300sqmmDocumento4 pagineGTP For 1CX300sqmmpriyanka236Nessuna valutazione finora

- TOFD Dead Zone CalculatorDocumento4 pagineTOFD Dead Zone CalculatorWill SmithNessuna valutazione finora

- Lexium 23 Plus - BCH0802O12A1CDocumento4 pagineLexium 23 Plus - BCH0802O12A1Cagungch100% (1)

- Ant CabDocumento93 pagineAnt CabZubair MinhasNessuna valutazione finora

- Review Paper - Evolution of CMOS Ring OscillatorDocumento10 pagineReview Paper - Evolution of CMOS Ring OscillatorNor Samida YaacobNessuna valutazione finora

- ML Observability Build Vs Buy Download Guide 1689038317Documento31 pagineML Observability Build Vs Buy Download Guide 1689038317rastrol7Nessuna valutazione finora

- Psychometric Development and Validation of GaslightingDocumento15 paginePsychometric Development and Validation of GaslightingYang ZhangNessuna valutazione finora

- Switching Power Supply DesignDocumento21 pagineSwitching Power Supply DesignSamuel mutindaNessuna valutazione finora

- Semi Conductors: The Start of Information AgeDocumento15 pagineSemi Conductors: The Start of Information AgeMarvin LabajoNessuna valutazione finora

- Nidhi ResumeDocumento2 pagineNidhi ResumeabhiNessuna valutazione finora

- Chapter - Four Soil Permeability and SeepageDocumento19 pagineChapter - Four Soil Permeability and SeepageBefkadu KurtaileNessuna valutazione finora

- Mollier Enthalpy Entropy Chart For Steam - US UnitsDocumento1 paginaMollier Enthalpy Entropy Chart For Steam - US Unitslin tongNessuna valutazione finora

- Introduction To DatabasesDocumento33 pagineIntroduction To Databases米皮皮Nessuna valutazione finora

- Fahad H. Ahmad (+92 323 509 4443) : Kinetic Particle Theory (5070 Multiple Choice Questions)Documento51 pagineFahad H. Ahmad (+92 323 509 4443) : Kinetic Particle Theory (5070 Multiple Choice Questions)Ali AshrafNessuna valutazione finora

- en Product OverviewDocumento81 pagineen Product OverviewShakeel AhmedNessuna valutazione finora

- A334 Carino, Patricia Andrea Assignment On ForecastingDocumento3 pagineA334 Carino, Patricia Andrea Assignment On ForecastingPatricia Andrea CariñoNessuna valutazione finora

- Form in MusicDocumento8 pagineForm in MusicAndri KurniawanNessuna valutazione finora

- Surface Mount Multilayer Varistor: SC0805ML - SC2220ML SeriesDocumento8 pagineSurface Mount Multilayer Varistor: SC0805ML - SC2220ML SeriesTalebNessuna valutazione finora

- HST TrainingDocumento11 pagineHST TrainingRamesh BabuNessuna valutazione finora

- 20CB PDFDocumento59 pagine20CB PDFChidiebere Samuel OkogwuNessuna valutazione finora

- Beam Design: BackgroundDocumento2 pagineBeam Design: BackgroundolomizanaNessuna valutazione finora

- Elecon GearboxDocumento19 pagineElecon GearboxShirley Farrace100% (3)

- App NandDocumento30 pagineApp NandRajesh MedampudiNessuna valutazione finora