Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

01 Spring02 Optimization Tack

Caricato da

Priyesh SaxenaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

01 Spring02 Optimization Tack

Caricato da

Priyesh SaxenaCopyright:

Formati disponibili

c2r-fila automation

5/9/02

10:46 AM

Page 15

T H E

A R T

O F

I N N O V A T I O N

Optimization: Taking a Different Tack

A slick design and the use of new materials make the Fila sailboat a force to contend with on the competitive boat racing circuit.

By Beverly A. Beckert

Sailboat racing requires safe, fast, easyto-handle boats. Just ask Jean-Marie Finot, renowned for building such highperformance vessels. His French company, Groupe Finot, has been in business more than 30 years. During this time, he has constructed all types of boats, including those that compete in extreme races. One such sailboat, the Fila, typifies advancements made in boat design: this 60-ft., open yacht features the use of new materials and components refined through the use of computer simulation.

The Fila sailboat, designed by naval architect Jean-Marie Finot, competes in extreme races. It features the use of new materials and components refined through the use of computer simulation.

Concept To Reality

15

Spring 2002

c2r-fila automation

5/9/02

10:46 AM

Page 16

The Altair OptiStruct optimization software enabled engineers to redesign the keel of the Fila sailboat (left). The optimized keel, using extra high-strength and ultra-highstrength steels, was 100 kg lighter than the original (right).

A New World

Thirty years ago, technology hardly played a role in the design of racing sailboats. Today, everything has changed. Computer technology is used not only to design boat components from the mast to the hull but also to finetune them. Groupe Finot reports it introduced computeraided design (CAD) technology in 1972. Today, Finot engineers use computer technology in virtual product prototyping, optimizing the shape of the hull and refining boat lines. According to Finot, Hulls, structures, ballasts and rudders, sail sets and other elements are studied and improved by these methods. In addition, the company notes it is tapping computer tools for laminate calculations, which are essential for the optimization of planking sampling and crossbeams. This extremely valuable tool, according to Groupe Finot, has enabled us to increase working capacity and quality, giving us 10 times more options to play with and allowing a large number of fast alterations. It is used for both races and sea and testing tank trials.

Groupe Finot says it devotes a minimum of 30% of its time to new research, registering patents and using new techniques and materials. The company is always on the lookout for any new opportunities to improve its boat design concepts.

In Ship-Shape

It came as no surprise, then, that work began on a project to improve the performance of the Finotdesigned Fila after Italian sailor Giovanni Soldini piloted it to victory in the Around Alone race in the fall of 1999 (see Soldini to the Rescue). Soldini invited Altair Engineerings Italian office in Lecce to optimize the design of the sailboats keel the foundational structure of the ship. The Fila features a hydraulic canting keel which plays a crucial role in sailboat racing. Its job is to re-right

Antonio Del Prete and his design team devoted approximately 3,500 man-hours to testing different keel conditions. Engineers used OptiStruct to evaluate the sailboats flow resistance and analyze the structural loads and stresses on the keel.

Concept To Reality

16

Spring 2002

c2r-fila automation

5/9/02

10:47 AM

Page 17

T H E

A R T

O F

I N N O V A T I O N

S oldini to the Rescue

the boat when the wind tips the boat to one side or even capsizes it. When the boat lists to one side, there is more wetted surface area and friction as the boat cuts through the water, resulting in reduced speed. The canting keel, which rotates around the boat, increases the stability and speed of the boat by keeping it upright with the sails in the wind. Altairs Antonio Del Prete, mechanical engineer and project manager, explains that the goal of the Altair engineering team was to optimize the internal structure of the keel. Engineers focused on reducing the keels weight, lowering its center of gravity and attaining the maximum rigidity. The team began by assessing the design of the keel, which was made of extra-high-strength steel. Altair collaborated with steel manufacturers SSAB Tunnplt and SSAB Oxelsund to increase the use of extra-highstrength and ultra-high-strength steels in the new keel.

Giovanni Soldini is something of a national hero in Italy. Although his roots are in landlocked Milan, he has long been considered to be among the best solo sailors. Since the tender age of 16, he has made a profession of challenging winds and waves that we mortals only see in our nightmares. During the Around Alone race in 1999, Soldini gained worldwide repute after saving the life of Frenchwoman Isabelle Autissier when her boat sank. She was not the only one to face problems many other boats fell victim to the rough weather in that race. But Soldini rode out the storm and won the race. It was during the third leg of the event that Autissier experienced problems with the boats autopilot, which malfunctioned and resulted

in the boat capsizing. At the time, she led the overall race. Soldini heard the news and informed race headquarters that he would alter his course to search for Autissier. With the assistance of meteorologist Pierre Lasnier, he honed in on her approximate location. After several hours, he found the capsized boat but did not see Autissier. Soldini circled her boat a couple of times. Then, on the third pass, he hit the boat with a hammer. Autissier emerged, got into her lifeboat and Soldini tossed her a line. Soon, she was safely onboard the Fila, and the racing adventure resumed. Piloting the Fila, Soldini captured victory in 116 days, 20 hrs., 7 min. and 59 sec. His performance set a record in its class. Contributed by Hkan Johansson, Ahrena Media AB

Keel Calculations

Del Prete explains that the keel consists of a bulb at the bottom and the fin, which attaches to the hull. Thanks to simulation software that evaluated the new materials and a new shape, engineers were able to transfer weight from the fin to the bulb, increasing the

boats righting moment in the process. By the end of the project, the optimized keel was 100 kg lighter. The Altair team relied on Altair OptiStruct software to optimize the design of the keel. The program determines the best design based upon required structural parameters for a given package volume. According to Del Prete, We devoted approximately

Concept To Reality

17

Spring 2002

c2r-fila automation

5/9/02

10:47 AM

Page 18

T H E

A R T

O F

I N N O V A T I O N

B uilding Better Boats

Altair Engineering is no stranger to unique projects. In 1995 and again in 2000, the company dove into optimization projects connected with the Americas Cup race. Jeff Brennan, Altairs vice president of Commercial Software, explains that, in 1995, Altair helped the PACT95 Americas Cup team optimize the strength and weight ratios of the hull and appendages for its Young America entry. We used our OptiStruct software, says Brennan, to predict the optimal load paths for the boats structural weight and mass. If you look at the inside of the hull, we determined the best placement for the ring plates and bulkheads. We developed a design that looked like a spider web of trusses. Virtual testing proved its feasibility. He adds that the hull is the only part of the boats design that is secret from competitors:

optimizing it, then, can provide a team with a competitive advantage. Although the yacht was defeated by New Zealand in the finals, its technical superiority prompted three American syndicates to approach Altair for help in designing entries for the 2000 race. Altair chose to collaborate with the AmericaOne team. According to Brennan, On this project, we again performed structural optimization of the load paths inside the hull. Our goal was to use as little material as possible to support the loading conditions, take the mass saved from the hull, put it in the lead keel bulb to lower the center of gravity and improve performance. Brennan adds that Altair Engineerings product design consultants used an array of analysis software and their knowledge of materials and composites in the process. Paul Cayard, skipper and CEO of AmericaOne, says, Technology plays an

increasingly important role in the Americas Cup design and design optimization process, particularly the structural design and performance of the boats. Altair Engineerings optimization services were readily and seamlessly integrated into our design environment and provided our team with some unique insights for improving the structural efficiency of the hull, resulting in a stiffer, lighter and faster boat. OptiStruct, notes Bruce Nelson, chief designer of the AmericaOne, saved us countless hours of investigating nonoptimal solutions and focused our engineers on the best distribution of material. It also allowed us to develop an extremely optimized, lightweight and rigid structural framework. What about the upcoming Americas Cup race? Brennan says that Altair is being courted by several U.S. campaigns and will soon decide on a partner.

3,500 man-hours to test different keel conditions. The software evaluated worst-case conditions as well as the affordability of the solution. He explained that engineers tested the Filas flow resistance and also analyzed the structural loads and stresses on the keel. The keel, says Del Prete, is hollow inside. In order to ensure its stability and high performance, we needed a lighter structure and the right reinforcements to guarantee stiffness. Engineers ran the simulations on a Hewlett-Packard UNIX server with eight processors. Because Altair OptiStruct is parallelized, problems were distributed across the processors, enabling engineers to run them faster and to try more variations. According to Del Prete, work on the project began in July 2000. By March 2001, final drawings were delivered.

The Right Results

The Altair Engineering team set up an initial meeting with Finot, Soldini and the keel manufacturer to present the results for the optimized keel. Soldini,

an expert sailor, offered suggestions on how to simplify the assembly operation of the keel, so Altair made some minor modifications in its design. In the final meeting, Del Prete reports that Finot was impressed with the new shape of the keel and said it was the best he had seen. This was high praise coming from a naval architect of his stature. For us, says Del Prete, the redesign of the keel was a challenging yet exciting project. We are not keel experts. Yet, Altair OptiStruct enabled us to converge on the right design. Del Prete adds that he and his team were able to draw on the experience of Altairs involvement in optimizing the inner hull structure of AmericaOne, which competed in the last Americas Cup race (see Building Better Boats). Optimization technology, concludes Del Prete, can be used in a range of applications, including boat design. It helps good minds develop even better solutions. Beverly A. Beckert is Editorial Director of Concept To Reality.

Concept To Reality

18

Spring 2002

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 01a-3.6 - Dry DockingDocumento14 pagine01a-3.6 - Dry DockingRajiv VigNessuna valutazione finora

- Installation: B Aquamatic DPH, DPR Volvo Penta IPS InboardDocumento236 pagineInstallation: B Aquamatic DPH, DPR Volvo Penta IPS InboardPriyesh Saxena100% (2)

- ShippingDocumento226 pagineShippingamu_more44Nessuna valutazione finora

- Shipping Cost & Charter PartyDocumento29 pagineShipping Cost & Charter PartyHimanshu Kathuria100% (3)

- The United States Navy Vs The Third World SubmarineDocumento40 pagineThe United States Navy Vs The Third World Submarine547Nessuna valutazione finora

- LNG Pilot Study - Trinidad and Tobago - Final ReportDocumento109 pagineLNG Pilot Study - Trinidad and Tobago - Final Reportjohn kokarakisNessuna valutazione finora

- Letter of CreditDocumento5 pagineLetter of CreditSujith PSNessuna valutazione finora

- Vacuum Bagging TechniquesDocumento56 pagineVacuum Bagging TechniquesPriyesh SaxenaNessuna valutazione finora

- Beks Gemi Isletmeciligi Ve Ticaret A.SDocumento1 paginaBeks Gemi Isletmeciligi Ve Ticaret A.SOnur ÖksüzoğluNessuna valutazione finora

- RMR Request FormDocumento1 paginaRMR Request FormPriyesh SaxenaNessuna valutazione finora

- Liquid Bulk Cargo ShipsDocumento48 pagineLiquid Bulk Cargo ShipskarlaNessuna valutazione finora

- Various Stresses in Ships StructureDocumento5 pagineVarious Stresses in Ships Structuremeghbrishty50% (2)

- Nautical Flags and Their MeaningDocumento8 pagineNautical Flags and Their MeaningMary- Ann RamosNessuna valutazione finora

- Bridge Resource Management GuideDocumento4 pagineBridge Resource Management GuideDnv Bailey100% (7)

- SHIPASSGNDocumento1 paginaSHIPASSGNPriyesh SaxenaNessuna valutazione finora

- Microsoft Project: Cadd CentreDocumento66 pagineMicrosoft Project: Cadd CentrePriyesh SaxenaNessuna valutazione finora

- Reference SOLAS/46CFR160.050 Guideline 160.150 - Specification For Lifebuoys, SOLAS 160.150-1 Incorporation by ReferenceDocumento11 pagineReference SOLAS/46CFR160.050 Guideline 160.150 - Specification For Lifebuoys, SOLAS 160.150-1 Incorporation by ReferencePriyesh SaxenaNessuna valutazione finora

- 0002 LB02 MAS Lit Book Web - 15892Documento116 pagine0002 LB02 MAS Lit Book Web - 15892Priyesh SaxenaNessuna valutazione finora

- P 06Documento23 pagineP 06Priyesh SaxenaNessuna valutazione finora

- P 06Documento23 pagineP 06Priyesh SaxenaNessuna valutazione finora

- Rhino Dot Net CrashDocumento1 paginaRhino Dot Net CrashPriyesh SaxenaNessuna valutazione finora

- t32 CFC Info - New 2014Documento1 paginat32 CFC Info - New 2014Priyesh SaxenaNessuna valutazione finora

- SCT User GuideDocumento18 pagineSCT User GuidePriyesh SaxenaNessuna valutazione finora

- Img-D10!30!2013T5-01-25AM-Information of Pre Bid Meeting Clarifications Security BoatDocumento1 paginaImg-D10!30!2013T5-01-25AM-Information of Pre Bid Meeting Clarifications Security BoatPriyesh SaxenaNessuna valutazione finora

- Read FirstDocumento1 paginaRead FirstPriyesh SaxenaNessuna valutazione finora

- Non Disclosure Agreement5Documento7 pagineNon Disclosure Agreement5Isha PatelNessuna valutazione finora

- Hand LayupDocumento1 paginaHand Layupkumar4cimNessuna valutazione finora

- 340712a.f BRO Gelcoat Chop RS GunDocumento8 pagine340712a.f BRO Gelcoat Chop RS GunPriyesh SaxenaNessuna valutazione finora

- Guidelines For Chartering of Foreign Flag VesselsDocumento17 pagineGuidelines For Chartering of Foreign Flag Vesselsrohitqwerty123Nessuna valutazione finora

- Container Handling InnovationDocumento2 pagineContainer Handling InnovationenderikuNessuna valutazione finora

- 33-Loading, Discharging & TrimDocumento32 pagine33-Loading, Discharging & Trimoleksandr100% (2)

- HTTP WWW - Maib.gov - Uk Cms Resources - CFM File Yeoman Bontrup SynopsisDocumento1 paginaHTTP WWW - Maib.gov - Uk Cms Resources - CFM File Yeoman Bontrup SynopsisIoana PetcuNessuna valutazione finora

- Ass3ssment Test RadiocomunicationsDocumento11 pagineAss3ssment Test RadiocomunicationsPatricia CottonNessuna valutazione finora

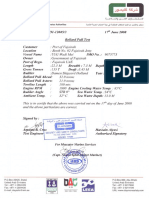

- 12 Bollard Pull Test CertificateDocumento1 pagina12 Bollard Pull Test CertificateMaan MrabetNessuna valutazione finora

- Curriculum Vitae: I. Personal DataDocumento1 paginaCurriculum Vitae: I. Personal DataMuhammad FathirNessuna valutazione finora

- Preparing Cargo Plans PDFDocumento5 paginePreparing Cargo Plans PDFHasan CiçinNessuna valutazione finora

- 1739130-Sea Ghost and Other VesselsDocumento6 pagine1739130-Sea Ghost and Other VesselsKacperNessuna valutazione finora

- C N F All FinalDocumento86 pagineC N F All FinalMd AlaminNessuna valutazione finora

- Corectii (NM 1652)Documento3 pagineCorectii (NM 1652)Vitalie FricatelNessuna valutazione finora

- Hallmark 6000 ReviewDocumento6 pagineHallmark 6000 ReviewA Jeff ButlerNessuna valutazione finora

- Complaint Affiidavit and Witness AffidavitDocumento4 pagineComplaint Affiidavit and Witness AffidavitREJFREEFALLNessuna valutazione finora

- Working On Deck in Heavy WeatherDocumento2 pagineWorking On Deck in Heavy WeatherCan Yigit DincNessuna valutazione finora

- Points of The Compass - WikipediaDocumento19 paginePoints of The Compass - WikipediaAmador De LemosNessuna valutazione finora

- RESUME Ed Wi AdDocumento3 pagineRESUME Ed Wi Admaspul lamuruprintNessuna valutazione finora

- VR Tour Cruise Yachts RivagestmartinDocumento4 pagineVR Tour Cruise Yachts RivagestmartinFranklin Dirk Peter WenurNessuna valutazione finora

- Application Form: Chief Officer Kulyuk YuriyDocumento2 pagineApplication Form: Chief Officer Kulyuk YuriyLazaros KarapouNessuna valutazione finora

- V.O. Chidambaranar Port TrustDocumento2 pagineV.O. Chidambaranar Port TrustSasidharan RajendranNessuna valutazione finora