Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sizing Heating Coil Insulated Fuel Tank

Caricato da

ypatelsTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sizing Heating Coil Insulated Fuel Tank

Caricato da

ypatelsCopyright:

Formati disponibili

Title of Calculation: Sizing of heating coil for the insulated tank

Client: State Company For Oil Projects (SCOP) Ref doc.: GAD for Fuel Oil Storare Dome Roof Tank Ref Doc no.: 184-TK-13-M-01 Rev A

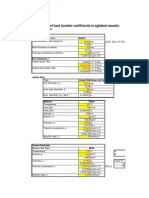

1 (1) INPUT DATA 2 Content of the tank 3 Diameter of Tank 4 Height of the Tank 5 Max height of the liquid 6 Thickness of shell 7 sec-1 tank bottom to 2m 8 sec-2 next 2m 9 sec-3 & 4 next 4 m 10 sec-5 next 2m 11 sec-6 next 2 m 12 Material of the tank 13 Insulation on walls and top 14 SG of fuel oil 15 Ambient temp 16 Final temp of liquid 17 Steam pressure at coil inlet 18 Heatng time allowable 19 (2) ASSUMED DATA 20 Density of Tank material 21 Specific heat of Tank material 22 Specific heat of Fuel Oil in tank 23 (3) CALCULATIONS 24 (i) Heat require for liquid 25 Volume of Fuel oil 26 Mass of Fuel Oil 27 Temperature rise 28 Heating time 29 Heat required 30 (ii) Heat require for Tank material 31 Volume of tank material 32 Mass of tank material 33 Temperature rise 34 Heat required 35 (iii) Heat loss from tank sides+top 36 Mean liquid temperature 37 Temperature diff 38 Heat Transfer Coeff (insulated tank) 39 Total surface area for heat loss 40 Heat loss 41 (iv) Total heat transfer required

VKS VKS VKS

Prep'd by Fuel Oil 34 12 10.5

MSS MSS MSS

App'd by

3 2 1

Rev

m m m mm mm mm mm mm

22 19 15 11 7 Carbon steel 2" thick rockwool 0.96 deg C 20 deg C 100 kg/cm2(g) 7 days 3.0 kg/m3 kJ/kg-C kJ/kg-C 7850 0.5 1.88

m3 kg deg C sec kW m3 kg deg C kW deg C deg C W/m2-C m2 kW kW

9533 9151836 80 259200 5310 19 149251 80 23 60 40 2.3 2190 201 5535

Sizing of steam coil of insulated tank Rev 3

1 of 2

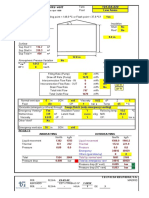

Title of Calculation: Sizing of heating coil for the insulated tank

Client: State Company For Oil Projects (SCOP) Ref doc.: GAD for Fuel Oil Storare Dome Roof Tank Ref Doc no.: 184-TK-13-M-01 Rev A VKS VKS VKS MSS MSS MSS 3 2 1

Prep'd by App'd by Rev 42 (v) Heat transfer area required 43 Steam pressure at coil inlet kg/cm2(g) 7 44 Temp at the steam deg C 169 45 Specific volume of steam m3/kg 0.243904 46 Mean liquid temperature deg C 60 47 Temp difference deg C 109 48 Heat Transfer Coeff for steam coil W/m2-C 100 49 Heat transfer area required m2 508 50 Inclusive of 10 % margin m2 559 559 559 51 Nominal dia of coil pipe inches 2 3 4 52 Sch of pipe mm 80 80 80 3 53 ID of pipe mm 49.2 73.7 97.2 54 Surface area per unit length m2/m 0.189 0.279 0.358 55 Length m 2955 2002 1560 56 (vi) Steam requirment, coil capacity, no. of coils 57 Specific enthalpy of evaporation kJ/kg 2049.8 58 Steam flowrate required kg/hr 9721 9721 9721 59 Max velocity in coil m/s 30 30 30 60 CSA of coil m2 0.0019012 0.004266 0.00742 61 Volumetric flow m3/hr 205 461 801 62 Specific volume of steam m3/kg 0.243904 0.243904 0.243904 63 Max steam possible kg/hr 842 1889 3286 64 No. of different coils required n 11.55 5.15 2.96 3 65 66 (4) CONCLUSION 67 1. Size of the coil - options ND 2" 3" 4" 68 2. No. of coils 12 5 3 69 3. No. of inlets for steam 12 5 3 70 4. No. of outlets for condensed steam 12 5 3 71 5. Length of each coil 246 400 520 72 6. Total length of coils 2952 2000 1560 3 73 74 (5) REMARKS 75 (i) The coil should slope towards outlet i.e. condensate side. 76 (ii) Coil should not be welded with support to allow expansion during start up. 77 (iii) Provide steam trap between control valve and tank inlet. 78

Sizing of steam coil of insulated tank Rev 3

2 of 2

Potrebbero piacerti anche

- Tank coil design thermal calculationsDocumento7 pagineTank coil design thermal calculationsElton Situmeang100% (3)

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFDocumento2 pagineSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1Nessuna valutazione finora

- Heating Coil Sizing For Fuel Oil TankDocumento2 pagineHeating Coil Sizing For Fuel Oil TankAhmed Mujtaba93% (14)

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Documento1 paginaTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456Nessuna valutazione finora

- Internal Coil CalculationDocumento19 pagineInternal Coil CalculationMr Incognito100% (3)

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Documento4 pagineDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanNessuna valutazione finora

- AST Heating Coil Design Calculation Rev 0Documento3 pagineAST Heating Coil Design Calculation Rev 0Pieter Grendel100% (3)

- Sizing For Vaporiser/Flash Vessel: InputsDocumento3 pagineSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNessuna valutazione finora

- Coil Heat CalculationDocumento2 pagineCoil Heat CalculationTarmana Antt100% (1)

- Case D9.03 Storage Tank Heating SystemDocumento3 pagineCase D9.03 Storage Tank Heating SystemBarmar Sbahi0% (1)

- Ael-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilDocumento2 pagineAel-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilbecpavanNessuna valutazione finora

- Half Pipe CalculationDocumento3 pagineHalf Pipe CalculationCaptainTonies0% (1)

- Diameter of Tank Baffle and Coil DimensionsDocumento4 pagineDiameter of Tank Baffle and Coil DimensionsTarmana Antt50% (2)

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Documento16 pagineVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanNessuna valutazione finora

- Heat Transfer in Jacketed VesselDocumento2 pagineHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Documento16 pagineStorage Tank Heat Loss Calcs - Rev.1 31.12.2010Jade GeronimoNessuna valutazione finora

- Rigorous Heat Loss Program for VesselsDocumento2 pagineRigorous Heat Loss Program for VesselsSapariya Hitesh50% (2)

- TankjktDocumento57 pagineTankjktAnonymous 20VAru100% (2)

- Steam Coil SizingDocumento21 pagineSteam Coil SizingMildogg100% (1)

- Half Pipe Coil AgitatedDocumento1 paginaHalf Pipe Coil AgitatedNITINNessuna valutazione finora

- Steam Coil DesignDocumento2 pagineSteam Coil DesignHendri SinagaNessuna valutazione finora

- HFO Bulk Storage Tank Steam Coil SizingDocumento1 paginaHFO Bulk Storage Tank Steam Coil SizingSaeed Rehman100% (1)

- Agitator Vessel Design CostingDocumento20 pagineAgitator Vessel Design CostingneelNessuna valutazione finora

- Design of Limpet Coil as per Appendix EEDocumento10 pagineDesign of Limpet Coil as per Appendix EEmaheshspawar0% (1)

- Steam Coil CalculationDocumento10 pagineSteam Coil CalculationRefqi Kemal Habib100% (2)

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocumento2 pagineDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658Nessuna valutazione finora

- Calculating heat transfer and temperature change in a crude oil storage tankDocumento3 pagineCalculating heat transfer and temperature change in a crude oil storage tankbadelitamariusNessuna valutazione finora

- Condenser DesignDocumento2 pagineCondenser DesignRahul ParmarNessuna valutazione finora

- NT42 Calculation Heat Transfer of Storage Tank Rail TankDocumento2 pagineNT42 Calculation Heat Transfer of Storage Tank Rail TankAnonymous v5uipHNessuna valutazione finora

- Evaporator heat transfer and surface area calculationDocumento4 pagineEvaporator heat transfer and surface area calculationDaniyal HashmiNessuna valutazione finora

- Vapor Liquid Vertical SeparatorDocumento4 pagineVapor Liquid Vertical SeparatorIoana Popescu100% (1)

- Insulation ThicknessDocumento2 pagineInsulation ThicknessShashi Kant KumarNessuna valutazione finora

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDocumento9 pagineHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeNessuna valutazione finora

- Coil DesignDocumento7 pagineCoil DesignSajal Kulshrestha100% (2)

- Maz - Design - Separator Capacity EvaluationDocumento5 pagineMaz - Design - Separator Capacity EvaluationNaeem HussainNessuna valutazione finora

- Calculation Overall Heat TransferDocumento4 pagineCalculation Overall Heat TransferDavid LambertNessuna valutazione finora

- Inlet Flow For Out Breathing: Total Pump in m3/hr 20Documento9 pagineInlet Flow For Out Breathing: Total Pump in m3/hr 20sonaldivNessuna valutazione finora

- Condensate Line SizingDocumento2 pagineCondensate Line SizingAnonymous oVRvsdWzfBNessuna valutazione finora

- Shell and Tube Heat Exchanger SpreadsheetDocumento2 pagineShell and Tube Heat Exchanger SpreadsheetHernan Cardenas Franco100% (1)

- Heat Exchanger Design 1Documento9 pagineHeat Exchanger Design 1Rajeev SaxenaNessuna valutazione finora

- Steam Tracing CalculationDocumento44 pagineSteam Tracing CalculationsafaldNessuna valutazione finora

- Design Calculations - Insulation Thickness REV-1Documento4 pagineDesign Calculations - Insulation Thickness REV-1delMAK100% (1)

- Steam CalculationDocumento27 pagineSteam CalculationRAVI KUMAR CarpenterNessuna valutazione finora

- Tank Coils - Design and UseDocumento7 pagineTank Coils - Design and UseMartin DanzeNessuna valutazione finora

- Venteo API 2000 (Amine)Documento8 pagineVenteo API 2000 (Amine)Produccion VegetalNessuna valutazione finora

- TUBESHEET THICKNESS CALCULATION PER UHX (SECTION VIII DIV 1Documento5 pagineTUBESHEET THICKNESS CALCULATION PER UHX (SECTION VIII DIV 1J.SIVIRA100% (2)

- TEMA Shell & Bundle Entrance and Exit AreasDocumento3 pagineTEMA Shell & Bundle Entrance and Exit Areasnagtummala100% (3)

- Shell Tube Heat Exchanger DesignDocumento7 pagineShell Tube Heat Exchanger DesignMakhdoom Ibad HashmiNessuna valutazione finora

- Rigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00Documento14 pagineRigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00semarasik_651536604100% (1)

- Heating Coil Sizing For Fuel Oil TankDocumento2 pagineHeating Coil Sizing For Fuel Oil TankPouria Sabbagh100% (1)

- Thermal Design of Heat ExchangerDocumento9 pagineThermal Design of Heat ExchangerNaqqash SajidNessuna valutazione finora

- Kalkulasi Steam Trap MFO Rev 00Documento20 pagineKalkulasi Steam Trap MFO Rev 00Rifka AisyahNessuna valutazione finora

- Manual Centrale Termice Pe Lemne Viadrus U22Documento25 pagineManual Centrale Termice Pe Lemne Viadrus U22zamfir92Nessuna valutazione finora

- GB VIADRUS HERCULES U22 P N Navod K Obsluze A Instalaci 7 2011Documento28 pagineGB VIADRUS HERCULES U22 P N Navod K Obsluze A Instalaci 7 2011FlowersOfRomanceNessuna valutazione finora

- Technical DiaryDocumento127 pagineTechnical Diarytushar67100% (1)

- Super Critical Boiler Cycle GuideDocumento32 pagineSuper Critical Boiler Cycle GuideJayaraman Kamaraj100% (1)

- Tech DiaryDocumento51 pagineTech DiarySE ESTNessuna valutazione finora

- Co HenDocumento40 pagineCo HenHiltonNessuna valutazione finora

- Civil Cost EstimateDocumento105 pagineCivil Cost EstimatednbinhNessuna valutazione finora

- Boiler Specification 2Documento3 pagineBoiler Specification 2AbdulBasitNessuna valutazione finora

- The Enchanted Locket: A Tale of Selflessness and RedemptionDocumento2 pagineThe Enchanted Locket: A Tale of Selflessness and RedemptionypatelsNessuna valutazione finora

- The Journey of Redemption: A Boy's Hard-Earned LessonDocumento3 pagineThe Journey of Redemption: A Boy's Hard-Earned LessonypatelsNessuna valutazione finora

- Thames Tragedy: 51 Killed in Collision Between Cruise Boat and DredgerDocumento2 pagineThames Tragedy: 51 Killed in Collision Between Cruise Boat and DredgerypatelsNessuna valutazione finora

- Flex Restraint For HDPE PipeDocumento3 pagineFlex Restraint For HDPE PipeypatelsNessuna valutazione finora

- 57 80Documento3 pagine57 80husamNessuna valutazione finora

- Trials and Tribulation of Cheating ScribdDocumento3 pagineTrials and Tribulation of Cheating ScribdypatelsNessuna valutazione finora

- Curvature of Ellipsoids and Other Surfaces: W. F. HarrisDocumento5 pagineCurvature of Ellipsoids and Other Surfaces: W. F. HarrisypatelsNessuna valutazione finora

- AVK STEM CAPS FOR GATE VALVESDocumento2 pagineAVK STEM CAPS FOR GATE VALVESypatelsNessuna valutazione finora

- 57 80Documento3 pagine57 80husamNessuna valutazione finora

- Mystery Behind This DocumentDocumento4 pagineMystery Behind This DocumentypatelsNessuna valutazione finora

- Flex Restraint For HDPE PipeDocumento3 pagineFlex Restraint For HDPE PipeypatelsNessuna valutazione finora

- Flex Restraint For HDPE PipeDocumento3 pagineFlex Restraint For HDPE PipeypatelsNessuna valutazione finora

- Immersion PDFDocumento164 pagineImmersion PDFCarlos SopasNessuna valutazione finora

- Flex Restraint For HDPE PipesDocumento1 paginaFlex Restraint For HDPE PipesypatelsNessuna valutazione finora

- How To Waste Your TimeDocumento2 pagineHow To Waste Your TimeypatelsNessuna valutazione finora

- How To Waste Your TimeDocumento2 pagineHow To Waste Your TimeypatelsNessuna valutazione finora

- Typing PracticeDocumento1 paginaTyping PracticeypatelsNessuna valutazione finora

- GibberishDocumento1 paginaGibberishypatelsNessuna valutazione finora

- Typing PracticeDocumento1 paginaTyping PracticeypatelsNessuna valutazione finora

- Typing PractiveDocumento1 paginaTyping PractiveypatelsNessuna valutazione finora

- General Overview Boilers and FlowDocumento22 pagineGeneral Overview Boilers and FlowLiam MoylanNessuna valutazione finora

- Budget PlannerDocumento12 pagineBudget PlannerypatelsNessuna valutazione finora

- Budget PlannerDocumento12 pagineBudget PlannerypatelsNessuna valutazione finora

- PhaseI Phy L2 Push&PullDocumento58 paginePhaseI Phy L2 Push&PullypatelsNessuna valutazione finora

- 1 214 BoilerSafetyValveRegulationsDocumento18 pagine1 214 BoilerSafetyValveRegulationsypatelsNessuna valutazione finora

- Mobile BroadbandDocumento1 paginaMobile BroadbandypatelsNessuna valutazione finora

- Wall Thickness CalculatorDocumento7 pagineWall Thickness CalculatorypatelsNessuna valutazione finora

- 1 214 BoilerSafetyValveRegulationsDocumento18 pagine1 214 BoilerSafetyValveRegulationsypatelsNessuna valutazione finora

- Microsoft CEO Satya NadellaDocumento3 pagineMicrosoft CEO Satya NadellaypatelsNessuna valutazione finora

- PenDocumento2 paginePenypatelsNessuna valutazione finora

- Guia de Diagramas de Turbina SolarDocumento102 pagineGuia de Diagramas de Turbina SolarbillitusNessuna valutazione finora

- Combinepdf - 2023-05-15T135221.088Documento2 pagineCombinepdf - 2023-05-15T135221.088JKI JakartaNessuna valutazione finora

- Boles Lecture Notes Thermodynamics Chapter 10Documento15 pagineBoles Lecture Notes Thermodynamics Chapter 10prince assiriNessuna valutazione finora

- Schematics of A Refrigeration Cycle: Air ConditionerDocumento1 paginaSchematics of A Refrigeration Cycle: Air ConditionerAndre EinsteinNessuna valutazione finora

- 07 - System of Particles and Rotational MotionDocumento20 pagine07 - System of Particles and Rotational Motionᴍᴏᴊᴏ JOJONessuna valutazione finora

- Attachment 15. Study Report On Heating Blanket Sizing On Flare BootDocumento24 pagineAttachment 15. Study Report On Heating Blanket Sizing On Flare BootYusufNessuna valutazione finora

- ATI 390 User Manual Completed Version - 20180410Documento128 pagineATI 390 User Manual Completed Version - 20180410williamppNessuna valutazione finora

- Ss49e Sensor EfectohallDocumento4 pagineSs49e Sensor EfectohallKenzo CórdovaNessuna valutazione finora

- Terminal Markings ConnectionsDocumento9 pagineTerminal Markings ConnectionsMuhammad Haris Baig100% (1)

- Emi Unit 4Documento2 pagineEmi Unit 4Murali KrishnaNessuna valutazione finora

- Virtual Work Analysis of Mechanical Systems in EquilibriumDocumento20 pagineVirtual Work Analysis of Mechanical Systems in EquilibriumarslansaeedarslanNessuna valutazione finora

- Review Sheet For Newton's Laws Test 15Documento3 pagineReview Sheet For Newton's Laws Test 15api-237866679Nessuna valutazione finora

- 4023 Nov 2022 QP P2Documento13 pagine4023 Nov 2022 QP P2mariah jabesiNessuna valutazione finora

- SRT Power Point Presentation 1Documento17 pagineSRT Power Point Presentation 1lehulaNessuna valutazione finora

- W4 PotentialDocumento10 pagineW4 PotentialAshraf YusofNessuna valutazione finora

- EEE 241 EEE 241 Analog Electronics 1 Tutorial Tutorial DR Norlaili Mohd NohDocumento42 pagineEEE 241 EEE 241 Analog Electronics 1 Tutorial Tutorial DR Norlaili Mohd NohMd Anwar HossainNessuna valutazione finora

- Physrevd.13.191 Hawking RadDocumento7 paginePhysrevd.13.191 Hawking RadSteven ChapmanNessuna valutazione finora

- Power Plant OperationDocumento5 paginePower Plant OperationAthira NairNessuna valutazione finora

- Infineon-Application Note Design of A 600 W HB LLC Converter Using CoolMOS - P6-AN-v01 - 00-ENDocumento42 pagineInfineon-Application Note Design of A 600 W HB LLC Converter Using CoolMOS - P6-AN-v01 - 00-ENигорь сидоренкоNessuna valutazione finora

- Lecture01 P2 PDFDocumento23 pagineLecture01 P2 PDFNguyen Luan100% (1)

- KEY Math 115-009 Calculus 1 Circle One: Grade My Work / Answers Exam 2Documento3 pagineKEY Math 115-009 Calculus 1 Circle One: Grade My Work / Answers Exam 2mantaray_09Nessuna valutazione finora

- Chapter 3 Momentum EquationDocumento27 pagineChapter 3 Momentum EquationFattihiEkhmal100% (1)

- Calculation of Safe Bearing Capacity as per IS 6403 - 1981Documento11 pagineCalculation of Safe Bearing Capacity as per IS 6403 - 1981navneet3bawaNessuna valutazione finora

- 400A Diesel Welding MachineDocumento3 pagine400A Diesel Welding MachineSuristiono WidjayaNessuna valutazione finora

- Centrifugal PumpsDocumento42 pagineCentrifugal PumpsMalaku HaileNessuna valutazione finora

- Technical Data: 1300 Series Edi 1306C-E87Tag4Documento8 pagineTechnical Data: 1300 Series Edi 1306C-E87Tag4mahmoud khtaNessuna valutazione finora

- Physics KinematicsDocumento11 paginePhysics KinematicsRichmond CarrilloNessuna valutazione finora

- LM-K5530X (SM)Documento61 pagineLM-K5530X (SM)Robert 2005Nessuna valutazione finora

- Electrical - Apgenco 2012 Paper & KeyDocumento4 pagineElectrical - Apgenco 2012 Paper & KeyGsn Reddy100% (1)

- Department of Electronics and Communication Engineering Faculty of Engineering and Technology, SRM UniversityDocumento6 pagineDepartment of Electronics and Communication Engineering Faculty of Engineering and Technology, SRM UniversityShubham Kumar GuptaNessuna valutazione finora