Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Workshop Safety Rules

Caricato da

Benedict Kamanga BandaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Workshop Safety Rules

Caricato da

Benedict Kamanga BandaCopyright:

Formati disponibili

Workshop Safety Rules

V. Ryan 2003

Before you can use equipment and machines or attempt practical work in a workshop you must understand basic safety rules. These rules will help keep you and others safe in the workshop. Safe Ed (left) always thinks about working safely. On the other hand, Ed the Handyman (right) never considers safety. Not only is he at risk of having an accident but so are those who work near him. They could have an accident because of his reckless behaviour.

Read the safety rules carefully. If you fully understand them you should be able to work safely in a workshop. Do not be like Ed theHandyman !!!!

1. Always listen carefully to the teacher and follow instructions. 2. Do not run in the workshop, you could bump into another pupil and cause an accident. 3. Know where the emergency stop buttons are positioned in the workshop. If you see an accident at the other side of the workshop you can use the emergency stop button to turn off all electrical power to machines. 4. Always wear an apron as it will protect your clothes and hold loose clothing such as ties in place. 5. Wear good strong shoes. training shoes are not suitable. 6. When attempting practical work all stools should be put away. 7. Bags should not be brought into a workshop as people can trip over them. 8. When learning how to use a machine, listen very carefully to all the instructions given by the teacher. Ask questions, especially if you do not fully understand. 9. Do not use a machine if you have not been shown how to operate it safely by the teacher. 10. Always be patient, never rush in the workshop. 11. Always use a guard when working on a machine. 12. Keep hands away from moving/rotating machinery. 13. Use hand tools carefully, keeping both hands behind the cutting edge. 14. Report any damage to machines/equipment as this could cause an accident.

Workshop Safety

What is workshop safety

Safety in the workshop... what exactly does that mean? Does that mean you are unsafe, or prone to accident? Does it mean your shop is unsafe, and prone to accident? The baseline answer to those two questions is you should do something about those problems you are concerned with and fix them. If you have forseeable problems, fix them before they cause an accident. Because they will, and probably when you least expect it. So your shop is safe... why should you use any safety gear? A common mentality is that I'm a safe person, and my shop is a safe place to be, why do I need to wear safety gear? The entire reason for safety gear and practices in the shop is for those things which happen unexpectedly. Those things which you can not predict and compensate for. Like what you ask? How about a piece of a a shattered wood knot bouncing off 3 protective surfaces to hit you in the face? Sure the guards are up, ultra safe, but the unexpected can still occur. If you feel unsafe about something, that is a powerful hint you are giving to yourself. Stop right then don't pass go, don't collect $200, and don't do the one last time. That one last time could be the one that sees your thumb lying next to the tablesaw. A person's mind has some powerful intution, rely on it. Before going on to be more specific, lets look at some of the things we want to protect:

Eyesight. Hearing. Limbs and appendages. Sense of touch. Respiratory System Skin Mortal Life itself. [If you are immortal, it may pay to be safe anyway, since living forever with missing parts may be even worse!] Pleasurable experience.

Philosophy of Safety

People have appendages and other components they hold near and dear. There is a certain amount of redundancy in our bodies systems. However, the fallback on

using those often sucks. Binocular vision with depth perception is way better than vision from a single eye. A thumb makes grasping things easy ... lacking one is most frustrating. Hearing injuries tend to catch up to you later in your life ... and they make themselves heard every minute from then on. Of all the safety items, I think than the phrase Norm Abrams says before every episode of New Yankee Workshop hits it right on the head: There is no more important thing than these -- Safety Glasses . There are some important things to know about safety gear: 1. 2. 3. 4. . The easiest way to use safety gear in your shop is to use it reliably. Make the safety gear the first thing you touch when entering your shop. Make it the last thing that comes off when you leave the shop. Use it whenever you are in your shop, even if you aren't planning on doing anything. Safety glasses on when you enter the shop, and off when you leave. I can not stress that more strongly -- make it an ingrained habit to have those glasses on in the shop. Then think about wearing them for other projects when you get some tools from the shop. One day you may find yourself wearing them while eating lunch out of the shop -- way better than not having them one when you need them. Safety gear must be easily accessible and ubiquitous If your safety gear isn't out and easy to use, you will tend not to use it. Don't make it a big deal to use your safety gear. Have it near to hand to areas where you might need it. Have special places to put your safety gear so it is always easily visible and available for immediate use. Better yet, keep safety gear in multiple places in your shop, such as by individual tools and machines. If there is always safety gear within reach, it will be easy to use, and you will use it. Make sure there is safety gear for shop visitors to use too. Safety gear must be a pleasure to use. If it isn't you won't use it because it is a pain to use. Safety glasses which distort your vision or fog up too easily won't be used. A tablesaw splitter which takes 10 minutes to install isn't one that will be used much. If you want to listen to the radio when you work, get some comfortable hearing protectors with a built-in radio. It is well worth the time to find safety gear that you like to use. THe combined cost of a pair of good safety glasses, a high Safety gear must be used reliably. Safety gear must be easily accessible and ubiquitous. Safety gear must be a pleasure to use. Safety gear must be in good condition.

quality hearing protector, and even a vapor mask is inexpensive compared to a single trip to urgent care or the emergency room. Ultimately you'll have more time and money to spend in the shop too! You need to maintain your safety gear in good working order. If it isn't it may be its own safety hazard. If your safety glasses are crazing, or cracking, don't try to save them. Just throw them away and grab another pair from the safety equipment bin. If they are dirty, clean them so you can see clearly. A microfiber cloth cleans those things almost as good as new, and costs less than a pair of safety glasses. If the splitter on your saw isn't aligned with the blade, take the time to slign it, or order a replacment if it is too bent to fix. Keep spare safety equipment around for when something fails, instead of continuing on with out the safety gear. Oh, yeah, and put the guards back on your tools after you adjust them!

Personal Safety Gear

Now I'll mention some of the personal safety gear, and why you want to have it. This is really obvious, but sometimes you want to think of things which perhaps you don't consider often enough ...

Safety Glasses: Vision is important. Bad things happen by accident. Wear them. Safety glasses also protect your eyes from chemical injury -- remember to use them when cleaning brushes, mixing chemicals together, etc. If you are doing a lot of liquid work, get a pair of the spill-proof chemical style goggles as well. They aren't good for all-around use, they tend to fog up. A full-face shield is another option, especially if working with tools which throw large things, such as a lathe. Hearing Protectors: Many of the power tools in the shop, both small and large, output damaging intensity and frequency of sound. Routers and Tablesaws are the two worst offenders which are popular that come to mind. Exposure to sound tires us just as labor does; using hearing protectors for longer exposure to quieter tools can be a benefit. Push sticks: Keep your fingers away from spinning blades on Saws, Router tables, jointers and other tools. If you can't hold the work with the push-stick... find another way to hold the part. Maybe try a handscrew, so the saw cuts it instead of your hand. Anti-Fatigue & Anti-skid mats: A concrete shop floor can make your legs and back tired sooner. It may not have the greatest footing. These mats keep you safe, and also protect edged tools (or your handplane) that you may drop.

Shop clothes: Why are shop clothes a safety item? They are a safety item because proper shop clothes won't get tangled in your machines. You won't be so worried about bleeding over your shop clothes when you do get hurt. You won't go out of the way to avoid dirtying your good clothes, and put yourself at risk indadvertenly. Long sleeves and pants provide armor which help protect your skin from splinters and from flying debris (shattered knots anyone) from power tools. They protect your skin from chemical splashes. Good boots protect your feet from the dropped razor-sharp chisel, a falling piece of wood, or random sharp trash on the floor. Dust Mask: Cutting wood produces dust, which floats in the air. This dust is collected by our lungs and nasal passages. Some of the wood-dust can be really bad for you. Too much exposure to non-toxic wood dust can be bad for you. Worst case, the exposure to the dust can cause chronic (long term) allergies. Even if you have a dust collector, it doesn't catch all the dust. The worst cases for this I have experienced are sanding, and cutting MDF or particle board. There are some really fancy dust masks, even powered filtered ones available. At the least, you wan't one with a metal nose bridge, so you can form the mask around your nose. THat is one of the more difficult places to seal, and it also prevents moisture from escaping and fogging your safety glasses. Fume Mask: Some solvents and finishes are irritating. Some can even make you loopy (aka affect your consciousness). A sealed fume mask with the proper canisters for the solvents or materials you are using keeps these away from your lungs and bloodstream. You can extend the life of the canisters by keeping them sealed in airtight containers or bags when you aren't using the mask. Keep spare canisters in the shop.

Shop Safety Gear

Dust Collector Dust extractor Table Saw Splitter Push Sticks. Feather boards Fences and Guides Tool Guards and adjusting them. Knowing how to use your tools. No-power and Low-power tests Clamps Fixtures and Jigs.

Quality Tools; sharp blades, et

Workshop rules and safety considerations

School of Architecture and Built Environment Workshop operating rules

Food and drink is not permitted in the workshop. Notify workshop staff on entry to workshop. Always wear the correct protective equipment for the tools you are using. If in doubt ask. All chemicals (eg glues and paints.) MSDS must be checked through chemwatch for use in the workshop. All chemicals must be checked with workshop staff before use. Notify the workshop supervisor of any faulty or broken equipment immediately. Always ask if you are unsure how to use tools safely. Always keep clear of any person operating tools and machinery. Do not talk to anyone operating electrical equipment and machinery. Leads are to be kept up off the floor. Keep your work area tidy and make sure your work piece is fixed securely before work commences. Clean up any spills immediately. Always wash hands after using equipment and materials. Tools of any kind are not to be removed from the workshop without permission. We encourage any suggestions for improving the layout and safety in the workshop. Suggestions can be made to the workshop staff.

Safety in the Workshop

* Students that are affected by drugs or alcohol are not permitted in the Workshop Students with any health problems that may affect workplace safety (eg. medication, epileptic fits) must report this condition to the workshop staff.

Clothing & footwear

All loose clothing (eg shirts hanging out) must be tucked in. Safety boots or enclosed shoes must be worn in the workshop. Do not enter under any circumstances without this footwear. (There are no exceptions to this rule) Long hair has to be tied up including fringes. Some rings are a hazard, preferably do not wear them. Students that wear glasses must be aware that their ordinary glasses are not safety glasses. They are only impact resistant and may shatter.

Common workplace safety

Safety Glasses and Hearing Protection: Every person entering the workshop must collect these items from just inside the door. They must be worn when machinery is being used in the workshop, but as they are forgotten sometimes, preferably worn at all times. It is the responsibility of each student to keep his or her work area clean and tidy. This will be done during and after the completion of your project.

Take care when walking past other students using tools as you may bump them or get tangled in the lead. This could lead to a serious injury to you or the operator of that tool.

When entering workshop

When you enter the workshop, pick up your hearing and eye protectors and immediately report to the workshop supervisor

Machinery usage

Machinery that students are not allowed to operate includes:

Drop Saws Sac Panel Bench Saw Thicknesser Bench Rip Saw Lathes Pressure Testing Machine Milling Machine Plastic Moulder C.N. Router Circular Saws Laser

Tools used only under strict supervision:

* Router and Trimmer All other tools may be used by students as long as they have been inducted into the workshop, and been tested in there capability to use them. Records are kept to which tools each student can operate. Students are not permitted in the office of the workshop. If tools are required, ask the work supervisor.

Behaviour

* Fooling around and practical jokes in the workshop will not be tolerated. These students will be told to leave.

First Aid

All accidents, cuts and abrasions must be reported before leaving the workshop. If an accident does happen, no matter how small, it must be reported to the workshop staff and an Accident Report Form filled out. Filling out this form is imperative for any future complications resulting from this accident.

Fires or other Emergencies

Think before reacting to any emergency in the workshop. It is easier to cope with one victim than two. Do not attempt to fight any fire unless you have been trained to do so.

Operating machinery

When students are operating machinery all other students are to stay clear and not to talk to the operator. If you feel uneasy or unsafe operating any tools or machinery in the workshop, inform the workshop supervisor and help will be provided.

Materials in the Workshop

The University has materials that can be purchased by students. For some major projects the materials are bought to save students time and effort getting them but they do have to be purchased by the student. After major clean ups some materials are suitable for reuse. Always check the Model Assembly Area, as this is where it is stored. There is no charge for this material.

Exiting the Workshop

Before you leave the workshop check that any tools you have been using have been put away in the appropriate spots, cleaned up your work area and have notified the workshop staff.

Workshop safety is everyones responsibility

Potrebbero piacerti anche

- Ice Maker PDFDocumento40 pagineIce Maker PDFmichelNessuna valutazione finora

- Workshop Safety RulesDocumento7 pagineWorkshop Safety RulesSiti Khadijah binti HasimNessuna valutazione finora

- How Automobile Ignition Systems WorkDocumento13 pagineHow Automobile Ignition Systems WorkAbhishek DixitNessuna valutazione finora

- HEMM Dumper24Documento15 pagineHEMM Dumper24miningnova2Nessuna valutazione finora

- Personal Protective EquipmentDocumento14 paginePersonal Protective EquipmentAbhiyan Anala ArvindNessuna valutazione finora

- Health and SafetyDocumento192 pagineHealth and SafetySS100% (1)

- l22 PDFDocumento84 paginel22 PDFRauf HuseynovNessuna valutazione finora

- Electrical Safety PDFDocumento16 pagineElectrical Safety PDFARPITA KUMARINessuna valutazione finora

- 10 Motorcycle Safety 807709Documento8 pagine10 Motorcycle Safety 807709api-309082881Nessuna valutazione finora

- Ergonomics Manual ToolsDocumento4 pagineErgonomics Manual ToolsZeeshan Bajwa100% (1)

- Mechanical Trades SOPDocumento5 pagineMechanical Trades SOPadventmanurungNessuna valutazione finora

- Environment, Health & Safety Management System Manual: Tata Steel Limited Steel Works & CRM Complex-Bara, JamshedpurDocumento54 pagineEnvironment, Health & Safety Management System Manual: Tata Steel Limited Steel Works & CRM Complex-Bara, JamshedpurMonchito AdecerNessuna valutazione finora

- Radiation Protection 2018Documento213 pagineRadiation Protection 2018Ricardo EdanoNessuna valutazione finora

- SafetyDocumento36 pagineSafetymoktarNessuna valutazione finora

- Auto MechanicDocumento34 pagineAuto MechanicRaisul Haque RahatNessuna valutazione finora

- Safety Abrasive WheelDocumento32 pagineSafety Abrasive WheelMohamed Hichem GuesmiNessuna valutazione finora

- Motor Vehicle Workshop Safety RegulationsDocumento2 pagineMotor Vehicle Workshop Safety RegulationstalabiraNessuna valutazione finora

- Mechanical Workshops Health and Safety File W105, W106, W108 - April 2016 - 1Documento152 pagineMechanical Workshops Health and Safety File W105, W106, W108 - April 2016 - 1Shuhaib MDNessuna valutazione finora

- Automotive Workshop SafetyDocumento44 pagineAutomotive Workshop Safetynewairley70% (10)

- INDUSTRIAL SAFETY - HOUSE KEEPING - 113-pDocumento117 pagineINDUSTRIAL SAFETY - HOUSE KEEPING - 113-psandeep100% (1)

- Safety Instrumentation Lecture - 1: DR V S Krushnasamy Associate ProfessorDocumento160 pagineSafety Instrumentation Lecture - 1: DR V S Krushnasamy Associate Professorkrushnasamy subramaniyan100% (1)

- Manual de Operacion Sae 400 11409-Im869 PDFDocumento34 pagineManual de Operacion Sae 400 11409-Im869 PDFLuran JuNessuna valutazione finora

- Electrical SafetyDocumento70 pagineElectrical SafetyRonald Renon QuiranteNessuna valutazione finora

- AUTOMOTIVE SHOP SAFETY TIPSDocumento1 paginaAUTOMOTIVE SHOP SAFETY TIPSJune CostalesNessuna valutazione finora

- Automobile SafetyDocumento23 pagineAutomobile SafetyPrathmeshBhokariNessuna valutazione finora

- Usc Safety Manual EngDocumento169 pagineUsc Safety Manual EngShabana ImranNessuna valutazione finora

- EV Standards Workplan 29 October FinalDocumento45 pagineEV Standards Workplan 29 October FinalAbrar HussainNessuna valutazione finora

- A Guide To Safety: Health & Safety at Work Act 1974Documento18 pagineA Guide To Safety: Health & Safety at Work Act 1974Chanel Maglinao100% (1)

- Osha-TOPIC 1: What Is Occupational Health and Safety?Documento2 pagineOsha-TOPIC 1: What Is Occupational Health and Safety?AimuniMohdIsaNessuna valutazione finora

- Insulect Specification PDFDocumento10 pagineInsulect Specification PDFThuan NguyenNessuna valutazione finora

- Step of Unloading & Loading of FuelDocumento3 pagineStep of Unloading & Loading of FuelMuhammad Tarique Bhatti100% (1)

- Emergency Response Guide-ToyotaDocumento143 pagineEmergency Response Guide-Toyota2791957100% (1)

- The Woman in The Body A Cultural Analysis of ReproductionDocumento299 pagineThe Woman in The Body A Cultural Analysis of ReproductionAndhra Shen100% (5)

- Health Safety in The Workshop TheoryDocumento85 pagineHealth Safety in The Workshop TheoryRustom Janno S. Gersin100% (2)

- Guide To Hot Work Loss PreventionDocumento8 pagineGuide To Hot Work Loss PreventionyatheendravarmaNessuna valutazione finora

- Safety Audit REPORT of Mahindra Two Wheelers SEPTEMBER 2018Documento31 pagineSafety Audit REPORT of Mahindra Two Wheelers SEPTEMBER 2018VarunNessuna valutazione finora

- Discharge Standards For DubaiDocumento6 pagineDischarge Standards For DubaiHRK65Nessuna valutazione finora

- Workshop Inspection Checklist January 2012Documento12 pagineWorkshop Inspection Checklist January 2012Sundara MoorthyNessuna valutazione finora

- Electrical Safety PresentationDocumento19 pagineElectrical Safety PresentationMutahirrasoolNessuna valutazione finora

- Delay Starting MechanismDocumento1 paginaDelay Starting MechanismSaravanan KcNessuna valutazione finora

- Motorola Talkabout T5000 WalkieTalkie MANUALDocumento36 pagineMotorola Talkabout T5000 WalkieTalkie MANUALRich RitterbuschNessuna valutazione finora

- Machine Safety in ConstructionDocumento27 pagineMachine Safety in ConstructionSawyu Nandar100% (1)

- AirFree Ref & Airconditioning ServicesDocumento16 pagineAirFree Ref & Airconditioning ServicesAirFree Ref and Airconditioning ServicesNessuna valutazione finora

- Safety PledgeDocumento3 pagineSafety Pledgeapi-268778235100% (1)

- Working at Height Rescue Training Standard PDFDocumento28 pagineWorking at Height Rescue Training Standard PDFAamir AliNessuna valutazione finora

- HSE Manual Unlimited EnergyDocumento74 pagineHSE Manual Unlimited Energysangar sabirNessuna valutazione finora

- Workplan:: Heavy Equipment Hazards and ControlsDocumento3 pagineWorkplan:: Heavy Equipment Hazards and ControlsRenauld WilsonNessuna valutazione finora

- 11 Electrical SafetyDocumento30 pagine11 Electrical SafetyPrakash RaoNessuna valutazione finora

- OPEX Awareness Dangers in Loading and Unloading Heavy Equipment PDFDocumento2 pagineOPEX Awareness Dangers in Loading and Unloading Heavy Equipment PDFaymenmoatazNessuna valutazione finora

- Catalytic ConverterDocumento11 pagineCatalytic ConverterAJ MukunNessuna valutazione finora

- Indian Standards Ppe 1Documento13 pagineIndian Standards Ppe 1Ramesh Lal BhutianiNessuna valutazione finora

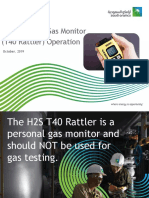

- H2S Personal Gas Monitor Operation GuideDocumento14 pagineH2S Personal Gas Monitor Operation Guidemaher mansiNessuna valutazione finora

- On 4 Months Industrial Training (Quality)Documento22 pagineOn 4 Months Industrial Training (Quality)KingNessuna valutazione finora

- Automobile Safety System: Global Institute of Engineering and TechnologyDocumento18 pagineAutomobile Safety System: Global Institute of Engineering and Technologygajula VenkateshNessuna valutazione finora

- M09 - Preparing and Applying PaintingDocumento171 pagineM09 - Preparing and Applying Paintingtefera getachewNessuna valutazione finora

- Maintenance CultureDocumento7 pagineMaintenance CultureAliaa El-BannaNessuna valutazione finora

- 2 Stroke EngineDocumento24 pagine2 Stroke Enginebrian estriNessuna valutazione finora

- Safe System Of Work A Complete Guide - 2020 EditionDa EverandSafe System Of Work A Complete Guide - 2020 EditionNessuna valutazione finora

- Unit 1-Safety & RegulationDocumento8 pagineUnit 1-Safety & RegulationMyzz Kurchar KarchirNessuna valutazione finora

- DTC Production Design 101.5 - HEALTH & SAFETY - AFDA 2.0Documento17 pagineDTC Production Design 101.5 - HEALTH & SAFETY - AFDA 2.0NatoNessuna valutazione finora

- 50 Reasons Why You Should Put On PPEDocumento13 pagine50 Reasons Why You Should Put On PPEfatmawaticity.safetyNessuna valutazione finora

- Diabetes and Hearing Loss (Pamela Parker MD)Documento2 pagineDiabetes and Hearing Loss (Pamela Parker MD)Sartika Rizky HapsariNessuna valutazione finora

- Run TroopDocumento65 pagineRun TroopRob Colares100% (2)

- Work Authorization Permit.Documento1 paginaWork Authorization Permit.Gabriel TanNessuna valutazione finora

- RecormonDocumento36 pagineRecormonShamal FernandoNessuna valutazione finora

- Dukungan Nutrisi Pra / Pasca BedahDocumento22 pagineDukungan Nutrisi Pra / Pasca BedahAfdhal Putra Restu YendriNessuna valutazione finora

- Phenol Hazards and PrecautionsDocumento3 paginePhenol Hazards and PrecautionsMarnel Roy MayorNessuna valutazione finora

- Drug Study - CiprofloxacinDocumento2 pagineDrug Study - CiprofloxacinryanNessuna valutazione finora

- UntitledDocumento221 pagineUntitledlaljadeff12Nessuna valutazione finora

- MHFL Functional FoodsDocumento24 pagineMHFL Functional FoodsZekel HealthcareNessuna valutazione finora

- Nursing Audit ScheduleDocumento2 pagineNursing Audit ScheduleArvinjohn Gacutan0% (1)

- Abc Sealant SDSDocumento5 pagineAbc Sealant SDSKissa DolautaNessuna valutazione finora

- UWI-Mona 2021-2022 Graduate Fee Schedule (July 2021)Documento15 pagineUWI-Mona 2021-2022 Graduate Fee Schedule (July 2021)Akinlabi HendricksNessuna valutazione finora

- CRS Report: Federal Employee Salaries and Gubernatorial SalariesDocumento54 pagineCRS Report: Federal Employee Salaries and Gubernatorial SalariesChristopher DorobekNessuna valutazione finora

- Referralsystem 161202080450Documento21 pagineReferralsystem 161202080450DRx Sonali Tarei100% (1)

- Study Data Reviewer's Guide: LDCP, Inc. Study LDCP-0242-005Documento16 pagineStudy Data Reviewer's Guide: LDCP, Inc. Study LDCP-0242-005anon_181306460Nessuna valutazione finora

- 2.4 Maxillofacial Trauma (Sia) - Sales&TanDocumento11 pagine2.4 Maxillofacial Trauma (Sia) - Sales&Tanmr dojimamanNessuna valutazione finora

- P3DOC001346 - ISSUE - G MSDS HAFEX EnglishDocumento10 pagineP3DOC001346 - ISSUE - G MSDS HAFEX EnglishOperations AdminNessuna valutazione finora

- Overcoming The Pilot Shortage PDFDocumento16 pagineOvercoming The Pilot Shortage PDFTim ChongNessuna valutazione finora

- Nematode EggsDocumento5 pagineNematode EggsEmilia Antonia Salinas TapiaNessuna valutazione finora

- From Solidarity To Subsidiarity: The Nonprofit Sector in PolandDocumento43 pagineFrom Solidarity To Subsidiarity: The Nonprofit Sector in PolandKarimMonoNessuna valutazione finora

- 1 s2.0 S2214785321052202 MainDocumento4 pagine1 s2.0 S2214785321052202 MainTusher Kumar SahaNessuna valutazione finora

- Debona 2016Documento23 pagineDebona 2016Biomontec Biomontec BiomontecNessuna valutazione finora

- Testing Antibiotics with Disk Diffusion AssayDocumento3 pagineTesting Antibiotics with Disk Diffusion AssayNguyễn Trung KiênNessuna valutazione finora

- PU Exam Cancellation Letter VC, PUDocumento4 paginePU Exam Cancellation Letter VC, PUSanjeevNessuna valutazione finora

- Breast Mass Bilateral To Consider FibroadenomaDocumento5 pagineBreast Mass Bilateral To Consider FibroadenomaYum CNessuna valutazione finora

- Penlon Prima 451 MRI Anaesthetic Machine: Anaesthesia SolutionsDocumento4 paginePenlon Prima 451 MRI Anaesthetic Machine: Anaesthesia SolutionsJuliana Jaramillo LedesNessuna valutazione finora

- Schedule - Topnotch Moonlighting and Pre-Residency Seminar Nov 2022Documento2 pagineSchedule - Topnotch Moonlighting and Pre-Residency Seminar Nov 2022Ala'a Emerald AguamNessuna valutazione finora