Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Baytron - Coatingguide 2014

Caricato da

Bala SingamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Baytron - Coatingguide 2014

Caricato da

Bala SingamCopyright:

Formati disponibili

100-020/09.

00

BAYTRONCoating Guide

Issue 10/2002 The use of BAYTRON P can generally be recommended as preferable in most applications.

Introduction

Generally speaking, polymers are insulators. However there is a special class of polymers the intrinsically conductive polymers that have conductivity levels between those of semiconductors and metals (up to 102 - 103 S/cm) The combination of metallic and polymeric properties opens completely new opportunities in numerous applications, particularly in the electronics industry, which were previously not possible. With poly(3,4-ethylenedioxythiophene) or briefly named PEDT or PEDOT available under the trade name BAYTRON - H.C. Starck has developed the latest generation of conductive polymers which are characterized by outstanding properties: High conductivity High transparency High stability Easy processing

R [Ohms/sqr]

2. Coating with BAYTRON P

BAYTRON P is a waterborne dispersion of the polymer complex poly(3,4-ethylenedioxythiophene)/ polystyrene sulfonate (PEDT/PSS). The dispersion consists of submicrometer sized gel particles which upon drying form a continous film which is conductive and transparent. BAYTRON P is typically considered a raw material and is most often formulated by end users into a coating for plastics, glass and other substrates. To assist customers in their formulation work with BAYTRON P, we have developed several coating formulations that contain BAYTRON P. These coating formulations have been optimized for individual substrates, such as PVC, polycarbonate,

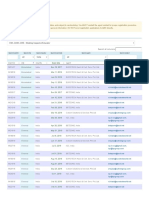

1E+9 1E+8 1E+7 1E+6 1E+5 1E+4 1E+3 1E+2 0,00 0,25 0,50 0,75 1,00 1,25 1,50

CPP 105D (low binder content) CPP 103D (high binder content)

1. Coating with BAYTRON

BAYTRON allows plastics, especially films, and glass to be coated with a conductive, transparent and durable PEDT layer (see Figs .1 and 2).

100 90 80 Transmission [%] 70 60 50 40 30 20 10 0

300 400 500 600 700 800

Layer Thickness :

Dry film thickness [m]

Fig. 2 Surface resistance vs. layer thickness glass, etc. at different wet film thicknesses and surface resistivities. The coatings may be applied by conventional coating methods such as brushing, spin-coating, printing processes, spraying, dipping, and roller-coating techniques. Other binding agents may be added. For more information about different formulations that were developed by H.C. Starck to assist the customer, please see the Guide Formulations (see section 6). The coatings are physically dried in an oven at temperatures between 80 to 200 C. The drying time depends on coating thickness, temperature and air humidity and should be determined by appropriate application tests. The minimum drying time is limited by the evaporation rate of water from the polymer gel to about 30 to 60 s under practical conditions. 1

50 nm 100 nm 200 nm 500 nm 1000 nm

Wavelength [nm]

Fig. 1 Transmission of light vs. PEDT/PSS dry layer thickness In most applications, surface conductivity can be achieved using very thin films (< 1 m) of BAYTRON conductive polymers (cp. Fig. 2). The PEDT layer can be applied by using the aqueous polymer dispersion BAYTRON P or by direct (in-situ) polymerization of the monomer BAYTRON M with the oxidizer BAYTRON C.

100-020/09.00

2. Direct polymerization of BAYTRON M

BAYTRON M is 3,4-ethylenedioxythiophene (EDT). It is mixed in solution with iron (III)toluene sulfonate, BAYTRON C, in organic solvents such as isopropanol, and ethanol. To this solution can be added binding agents such as polyvinylacetate or adhesion promoters for glass such as epoxysilanes. Details are described in EP Patent 339340 (or US Patent 5035926). This solution can be used for some hours at room temperature before PEDT is precipitated. EDT starts to polymerize in the coatings as the solvent evaporates. After the end of polymerization the iron salt must be removed from the coating by washing with water.

Typical applications for BAYTRON-based coating on glass: Monitors and TV screens (antistatic effect, shielding) Glass apparatus in explosion-hazard areas By combining BAYTRON with silanes, e.g. tetraethoxysilane, high hardness, scratch resistance, and surface resistance can be obtained. For achieving optimum hardness curing temperatures of about 180C are required. Scratch-resistant antistatic coating Guide formulation CPG 130.6 allows the application of antistatic coatings with goodscratch resistance. Surface resistance: < 106 Ohm/ Pencil hardness: 9H Quantity of BAYTRON P used per m2: approx. 2g (spray application) Highly conductive coatings Higher conductivity can be achieved by using guide formulation CPP 105D. The hardness of the coating is, however, lower than when using guide formulation CPG 130.6. Surface resistance: < 103 Ohm/ Quantity of BAYTRON P used per m2: approx 6g The BAYTRON coatings can be either applied by spraying or the spin-coating method.

3. Antistatic Coating of Plastics

Static charge on plastic surfaces leads to numerous problems. Coating with BAYTRON permits plastic surfaces to be given an antistatic finish. Virtually all plastics can be coated with PEDT, including polycarbonate, polyethylene, polyethylene terephthalate, polyamide, and polypropylene. A surface activiation like Corona treatment should be performed prior to coating in the case of PET and polyolefins to enhance adhesion to the substrate. Typical applications for BAYTRON-based antistatic and static dissipative coatings on plastic surfaces: Electronic packaging (carrier tapes, bags, boxes) Plastic electronic component housings and windows Clean-room packaging Thermoformable coatings can be obtained by using soft binders e.g. contained in CPP 4531 type guide formulations (see section 6). Such coatings can be stretched by more than 200% during deep drawing. By this the initial surface resistance is increased by one or two orders of magnitude only.

5. Electrostatic Coatings

As a rule, plastic components cannot be coated electrostatically as their surfaces are not electrically conductive. Coating with BAYTRON generates the necessary surface conductivity. Possible coating methods: Powder coating Electrostatic spray coating (wet) Suitable formulations based on our recommendations permit good adhesion and conductivity of the primer coats on many plastic substrates (e.g. polyurethane, polypropylene). Advantages over carbon black-filles primers and plastics: The necessary surface conductivity can be attained with very thin films. 2

4. Coating of Glass

It is also possible to produce transparent, conductive coatings on glass using BAYTRON.

100-020/09.00

The transparency of BAYTRON allows the use of light brilliant coatings. There are no negative effects on the mechanical properties of the plastic.

CPP 135D: For alcohol-resistant transparent dissipative coatings with good adhesion properties on polycarbonate or PVC plastic surfaces. CPP 141D: For the application of clear, hard, alcohol-resistant, antistatic coatings with good adhesion properties on aluminum, polycarbonate, and PVC surfaces. CPP 4531II: For thermoformable coatings with good adhesion properties on many plastic surfaces. CPP 4531E3D: For conductive coatings on plastic surfaces as pretreatment for electrostatic coating. Also especially suited for coatings on corona-treated polyethylene and/or polypropylene. CPG 130.6: For scratch-resistant antistatic coatings with good adhesion properties on glass surfaces.

We recommend guide formulation CPP 4531 E3D for the conductive coating of plastics as pretreatment for electrostatic coating. Wet film thickness: 2-4 m Surface resistance: < 107 Ohm/ Quantity of BAYTRON P coating per m2: approx. 0.75 to 1.5 g Other BAYTRON coating formulations may also be used as electrostatic primer coatings. For more information, see below.

6. BAYTRON Coating Guide Formulations

To assist customers in their formulation work with BAYTRON conductive polymers, we have developed several coating formulations that contain BAYTRON P. These coating formulations have been optimized for individual substrates, such as PVC, polycarbonate, glass, etc. at different wet film thicknesses and surface resistivities and are mainly used for dissipation of static surface charges on various substrates. The coatings may be applied by conventional coating methods such as brushing, spin-coating, printing processes, spraying, dipping, and roller-coating techniques. BAYTRON Guide Formulations include: CPP 103D: For antistatic coatings with good adhesion properties on many plastic surfaces. CPP 105D: For antistatic coatings with higher conductivity, good adhesion properties on plastic and glass surfaces, and resistance to both aliphatic and aromatic hydrocarbon solvents. CPP 116.6D: For antistatic coatings with good adhesion properties on polycarbonate or PVC plastic surfaces. CPP 134.18D: For highly transparent static dissipative coatings with good adhesion properties on polycarbonate or PVC plastic surfaces. Good for dip-coating applications.

100-020/09.00

BAYTRON Coating Guide Formulation CPP 103D

For the application of clear antistatic coatings with good adhesion properties on plastic surfaces. Wet film thickness: Quantity of BAYTRON P used per m2: Surface resistivity: Properties of the dispersion: Solid content: Viscosity: pH value: Density: 6 m 1.5 g 107-108 Ohm/ 12 % 60 mPa.s 8 0.979 g/cm3

Above values are approximate

COMPONENT BAYTRON P Dimethylaminoethanol, 50% in water A B U710 N-Methyl-2-pyrrolidinone Silquest A 187 Isopropanol Dynol 604 Total

% BY WEIGHT 25.86 0.12 38.79 9.05 0.26 25.62 0.30 100.00

Notes All components must be mixed in the above order under constant agitation. The coating can be applied by conventional coating methods such as brushing, spin-coating, printing, spraying, and roller-coating. Corona treatment should be performed prior to coating polypropylene or polyethylene substrates. Coating should be cured at approximately 80-120C for a minimum of three to five minutes. Surface resistivity measurements made according to IEC Standard 93 (VDE 0303, Part 30) or ASTM D 257.

The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. This application-specific analysis at least must include testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by H.C. Starck. All information is given without warranty or guarantee. It is expressly understood and agreed that the customer assumes and hereby expressly releases H.C. Starck from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical assistance and information. Any statement or recommendation not contained herein is unauthorized and shall not bind H.C. Starck. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. No license is implied or in fact granted under the claims of any patent. In case of order please refer to issue number of the respective product data sheet. All deliveries are based on the latest issue of the product data sheet and the latest version of our General Conditions of Sale and Delivery.

100-020/09.00

BAYTRON Coating Guide Formulation CPP 105D

For the application of antistatic coatings with higher conductivity, good adhesion properties on plastic and glass surfaces, and resistance to both aliphatic and aromatic hydrocarbon solvents. on plastic Wet film thickness Surface resistivity Quantity of BAYTRON P used per m2 Properties of the dispersion: Solid content: Viscosity: pH value: Density: 6 m < 104 Ohm/ 2.6 g on glass 12 m < 103 Ohm/ 5.2 g

1.2 % 30 mPa.s 2.8 0.900 g/cm3

Above values are approximate.

COMPONENT BAYTRON P N-Methyl-2-pyrrolidinone Silquest A 187 Isopropanol Dynol 604 Total

% BY WEIGHT 42.92 2.58 0.86 53.34 0.30 100.00

Notes All components must be mixed in the above order under constant agitation. The coating can be applied by conventional coating methods such as brushing, spin-coating, printing, spraying, and roller-coating. Corona treatment should be performed prior to coating polypropylene or polyethylene substrates. Coating should be cured at approximately 80-120C for a minimum of three to five minutes. Surface resistivity measurements made according to IEC Standard 93 (VDE 0303, Part 30) or ASTM D 257.

The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. This application-specific analysis at least must include testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by H.C. Starck. All information is given without warranty or guarantee. It is expressly understood and agreed that the customer assumes and hereby expressly releases H.C. Starck from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical assistance and information. Any statement or recommendation not contained herein is unauthorized and shall not bind H.C. Starck. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. No license is implied or in fact granted under the claims of any patent. In case of order please refer to issue number of the respective product data sheet. All deliveries are based on the latest issue of the product data sheet and the latest version of our General Conditions of Sale and Delivery.

100-020/09.00

BAYTRON Coating Guide Formulation CPP 116.6D

For the application of antistatic coatings with good adhesion properties on polycarbonate or PVC plastic surfaces. Wet film thickness Surface resistivity 6 m 5 x 105 Ohm/ 12 m 2 x 105 Ohm/ 2.8 g

Above values are approximate.

18 m 5 x 104 Ohm/ 4.3 g

Quantity of BAYTRON P used per m2 1.4 g

COMPONENT BAYTRON P Dimethylaminoethanol, 50% in water Sancure 825 Silquest A 187 Deionized water Isopropanol n-Butanol Dynol 604 Total

% BY WEIGHT 23.90 0.18 17.90 0.24 19.89 29.90 7.89 0.10 100.00

Notes All components must be mixed in the above order under constant agitation. The coating can be applied by conventional coating methods such as printing, pourcoating, or dip-coating. The coated film/sheet should be dried at approximately 80-120 C for at least 3 to 5 minutes. Surface resistivity measurements made according to IEC Standard 93 (VDE 0303, Part 30) or ASTM D 257.

The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. This application-specific analysis at least must include testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by H.C. Starck. All information is given without warranty or guarantee. It is expressly understood and agreed that the customer assumes and hereby expressly releases H.C. Starck from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical assistance and information. Any statement or recommendation not contained herein is unauthorized and shall not bind H.C. Starck. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. No license is implied or in fact granted under the claims of any patent. In case of order please refer to issue number of the respective product data sheet. All deliveries are based on the latest issue of the product data sheet and the latest version of our General Conditions of Sale and Delivery.

100-020/09.00

BAYTRON Coating Guide Formulation CPP 134.18D

For the application of highly transparent static dissipative coatings with good adhesion properties on polycarbonate or PVC plastic surfaces. This formulation has been used to dip coat irregularly shaped plastic articles. Wet film thickness Surface resistivity Quantity of BAYTRON P used per m2 Properties of the dispersion: Solid content: Viscosity: pH value: Density: 20 m 1 x 106 Ohm/ 1.7 g 2.2 % 10 mPa.s 8 0.926 g/cm3

Above values are approximate.

COMPONENT BAYTRON P Dimethylaminoethanol, 50% in water Deionized water Isopropanol Sancure 825 n-Butanol Silquest A 187 Dynol 604 Total

% BY WEIGHT 8.62 0.02 41.67 41.58 6.47 1.50 0.04 0.10 100.00

Notes All components must be mixed in the above order under constant agitation. The coating can be applied by conventional coating methods such as printing, pour-coating, or dip-coating. The coated film/sheet or plastic article should be dried at approximately 80 120C for at least 3 to 5 minutes. Surface resistivity measurements made according to IEC Standard 93 (VDE 0303, Part 30) or ASTM D 257.

The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. This application-specific analysis at least must include testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by H.C. Starck. All information is given without warranty or guarantee. It is expressly understood and agreed that the customer assumes and hereby expressly releases H.C. Starck from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical assistance and information. Any statement or recommendation not contained herein is unauthorized and shall not bind H.C. Starck. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. No license is implied or in fact granted under the claims of any patent. In case of order please refer to issue number of the respective product data sheet. All deliveries are based on the latest issue of the product data sheet and the latest version of our General Conditions of Sale and Delivery.

100-020/09.00

BAYTRON Coating Guide Formulation CPP 135D

For the application of alcohol-resistant transparent static dissipative coatings with good adhesion properties on polycarbonate or PVC plastic surfaces. Wet film thickness Surface resistivity Quantity of BAYTRON P used per m2 Properties of the dispersion: Solid content: Viscosity: pH value: Density: COMPONENT BAYTRON P Dimethylaminoethanol, 50% in water NeoRez R986 Silquest A 187 Deionized water Isopropanol N-Methyl-2-pyrrolidinone Dynol 604 Total

6 m 5 x 105 Ohm/ 1.5 g 8% 25 mPa.s 8 0.959 g/cm3

18 m 5 x 104 Ohm/ 4.5 g

Above values are approximate.

% BY WEIGHT 24.20 0.11 20.20 0.25 20.90 30.30 3.93 0.11 100.00

Notes All components must be mixed in the above order under constant agitation. The coating mixture should be filtered through a 3 or 5 micron filter twice before using: once directly after mixing and again six hours later. The coating can be applied by conventional coating methods such as printing, pour-coating, or dip-coating. Spray coating has not yet been tested. The coated film/sheet should be dried at approximately 80-120 C for at least 3 to 5 minutes. Surface resistivity measurements made according to IEC Standard 93 (VDE 0303, Part 30) or ASTM D 257.

The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. This application-specific analysis at least must include testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by H.C. Starck. All information is given without warranty or guarantee. It is expressly understood and agreed that the customer assumes and hereby expressly releases H.C. Starck from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical assistance and information. Any statement or recommendation not contained herein is unauthorized and shall not bind H.C. Starck. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. No license is implied or in fact granted under the claims of any patent. In case of order please refer to issue number of the respective product data sheet. All deliveries are based on the latest issue of the product data sheet and the latest version of our General Conditions of Sale and Delivery.

100-020/09.00

BAYTRON Coating Guide Formulation CPP 141D

For the application of clear, hard, alcohol-resistant, antistatic coatings with good adhesion properties on aluminum, polycarbonate, and PVC surfaces. Wet film thickness Surface Resistivity Transmission at 550 nm Quantity of BAYTRON P used per m2 4 to 6 m 106 Ohm/ > 95% [for 4 to 12 m wet film thicknesses] 2.1 to 3.2 g

Properties of the dispersion: Solid content: 18 % Viscosity: 25 mPa.s pH value: 8

Above values are approximate.

COMPONENT BAYTRON P Dimethylaminoethanol, 50% in water NeoRez R986 Eastek 1200-02-30% Isopropanol N-Methyl-2-pyrrolidinone Dynol 604 Total

% BY WEIGHT 52.6 0.3 31.4 10.5 2.0 3.1 0.1 100.00

Notes All components must be mixed in the above order under constant agitation. The coating can be applied by conventional coating methods such as printing, pour-coating, dip-coating, and spray coating. The coated film/sheet should be dried at approximately 80-120C for at least 3 to 5 minutes. Surface resistivity measurements made according to IEC Standard 93 (VDE 0303, Part 30) or ASTM D 257.

The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. This application-specific analysis at least must include testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by H.C. Starck. All information is given without warranty or guarantee. It is expressly understood and agreed that the customer assumes and hereby expressly releases H.C. Starck from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical assistance and information. Any statement or recommendation not contained herein is unauthorized and shall not bind H.C. Starck. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. No license is implied or in fact granted under the claims of any patent. In case of order please refer to issue number of the respective product data sheet. All deliveries are based on the latest issue of the product data sheet and the latest version of our General Conditions of Sale and Delivery.

100-020/09.00

BAYTRON Coating Guide Formulation CPP 4531II

For the application of thermoformable coatings with good adhesion properties on plastic surfaces. Even after thermoforming, the PEDT coating is still conductive enough to guarantee an antistatic effect. Wet film thickness: 4 m Surface resistivity: < 105 Ohm/ Quantity of BAYTRON P used in coating: 2.3 g/m2 Properties of the dispersion: Solid content: Viscosity: pH value: 8% 70 mPa.s 2

Above values are approximate.

6 m 3.0 x 104 Ohm/ 3.45 g/m2

24 m 9.0 x 103 Ohm/ 13.8 g/m2

COMPONENT BAYTRON P Bayderm Finish 85UD N-Methyl-2-pyrrolidinone Isopropanol Total

% BY WEIGHT 57.65 15.63 3.48 23.24 100.00

Notes All components must be mixed in the above order under constant agitation. The coating can be applied by conventional coating methods such as brushing, spincoating, printing, spraying, and roller-coating. Corona treatment should be performed prior to coating polypropylene or polyethylene substrates. Coating should be cured at approximately 80-120C for a minimum of three to five minutes. Surface resistivity measurements made according to IEC Standard 93 (VDE 0303, Part 30) or ASTM D 257.

The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. This application-specific analysis at least must include testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by H.C. Starck. All information is given without warranty or guarantee. It is expressly understood and agreed that the customer assumes and hereby expressly releases H.C. Starck from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical assistance and information. Any statement or recommendation not contained herein is unauthorized and shall not bind H.C. Starck. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. No license is implied or in fact granted under the claims of any patent. In case of order please refer to issue number of the respective product data sheet. All deliveries are based on the latest issue of the product data sheet and the latest version of our General Conditions of Sale and Delivery.

10

100-020/09.00

BAYTRON Coating Guide Formulation CPP 4531 E3D

For the application of conductive coatings on plastic surfaces as pretreatment for electrostatic coating. For the application of conductive coatings with good adhesion to corona-treated polyethylene surfaces.

Wet film thickness 2 m 4 m Surface resistivity < 107 Ohm/ < 107 Ohm/ Quantity of BAYTRON P used in coating 0.8 g/m2 1.7 g/m2 6 m 5.0 x 104 Ohm/ 2.5 g/m2 24 m 1.4 x 104 Ohm/ 10.2 g/m2

Properties of the dispersion: Solid content: Viscosity: pH value: Density COMPONENT BAYTRON P Bayderm Finish 85UD N-Methyl-2-pyrrolidinone Isopropanol Dynol 604 Silquest A 187 Total

4.5 % 50 mPa.s 2.4 0.911 g/cm3

Above values are approximate.

% BY WEIGHT 38.36 10.40 2.32 48.58 0.20 0.14 100.00

Notes All components must be mixed in the above order under constant agitation and filtered through a 10 micron filter prior to using or storing. The coating can be applied by conventional coating methods such as brushing, spin-coating, printing, spraying, and roller-coating. Organic binders such as polyurethane dispersions or polyvinyl acetate can be added to the BAYTRON P polymer dispersion to improve the adhesive properties. Coating should be cured at approximately 80-120C for a minimum of three to five minutes. Surface resistivity measurements made according to IEC Standard 93 (VDE 0303, Part 30) or ASTM D 257.

The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. This application-specific analysis at least must include testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by H.C. Starck. All information is given without warranty or guarantee. It is expressly understood and agreed that the customer assumes and hereby expressly releases H.C. Starck from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical assistance and information. Any statement or recommendation not contained herein is unauthorized and shall not bind H.C. Starck. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. No license is implied or in fact granted under the claims of any patent. In case of order please refer to issue number of the respective product data sheet. All deliveries are based on the latest issue of the product data sheet and the latest version of our General Conditions of Sale and Delivery.

11

100-020/09.00

BAYTRON Coating Guide Formulation CPG 130.6

For the application of scratch-resistant antistatic coatings with good adhesion properties on glass surfaces.

Surface Resistivity Pencil Hardness Quantity of BAYTRON P used per m2 < 106 Ohm/ 9H 2 g (spray application)

Above values are approximate.

COMPONENT BAYTRON P Isopropanol Ethylene glycol Tetraethoxysilane Acetic acid (100%) Total

% BY WEIGHT 31.70 39.70 15.90 11.90 0.80 100.00

Notes All components must be mixed in the above order under constant agitation. The coating can be applied by conventional spray-coating or spin-coating methods. Coated substrates should preferably be dried for 10 minutes at 50C. Evaporation of the solvent is followed by post-curing for 30 minutes at 180C. Surface resistivity measurements made according to IEC Standard 93 (VDE 0303, Part 30) or ASTM D 257. Refractive index of coating CPG 130.6 on glass was found to be nD = 1.4565 at 589.3 nm.

The conditions of your use and application of our products, technical assistance and information (whether verbal, written or by way of production evaluations), including any suggested formulations and recommendations, are beyond our control. Therefore, it is imperative that you test our products, technical assistance and information to determine to your own satisfaction whether they are suitable for your intended uses and applications. This application-specific analysis at least must include testing to determine suitability from a technical as well as health, safety, and environmental standpoint. Such testing has not necessarily been done by H.C. Starck. All information is given without warranty or guarantee. It is expressly understood and agreed that the customer assumes and hereby expressly releases H.C. Starck from all liability, in tort, contract or otherwise, incurred in connection with the use of our products, technical assistance and information. Any statement or recommendation not contained herein is unauthorized and shall not bind H.C. Starck. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. No license is implied or in fact granted under the claims of any patent. In case of order please refer to issue number of the respective product data sheet. All deliveries are based on the latest issue of the product data sheet and the latest version of our General Conditions of Sale and Delivery.

12

Potrebbero piacerti anche

- Polyken 936 TapeDocumento2 paginePolyken 936 TapeKyaw Kyaw AungNessuna valutazione finora

- Epocoat 111 PDFDocumento3 pagineEpocoat 111 PDFjunaid112Nessuna valutazione finora

- Cafco Sprayfilm WB3 - DSDocumento6 pagineCafco Sprayfilm WB3 - DSSiva GsNessuna valutazione finora

- Retrowrap HD Specifications (2014)Documento15 pagineRetrowrap HD Specifications (2014)Alfredo Solorzano MaloNessuna valutazione finora

- A&M of PCs For Concrete - 1Documento8 pagineA&M of PCs For Concrete - 1nimalranasinghe2505Nessuna valutazione finora

- Brochure Coating Raw Materials For Building Protection 14-06-2011 EDocumento32 pagineBrochure Coating Raw Materials For Building Protection 14-06-2011 EΣταύρος ΒουγιουκλίδηςNessuna valutazione finora

- iKOTE AC 40 (DEC-2023) V1.3Documento2 pagineiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNessuna valutazione finora

- The Polyurea Revolution: Protective Coatings For The 21st CenturyDocumento4 pagineThe Polyurea Revolution: Protective Coatings For The 21st CenturyMihaela LetNessuna valutazione finora

- Fosroc Nukote ST: Constructive SolutionsDocumento4 pagineFosroc Nukote ST: Constructive SolutionsRaj PatelNessuna valutazione finora

- Specification GlassFiberDocumento6 pagineSpecification GlassFiberMukesh MaharjanNessuna valutazione finora

- POLYCHEM PLC Transparent Conductive Coating #JN0313-2-BDocumento2 paginePOLYCHEM PLC Transparent Conductive Coating #JN0313-2-BNguyen Ho Hoang HaiNessuna valutazione finora

- Vacuum Metallizing Plastic Parts - 2Documento7 pagineVacuum Metallizing Plastic Parts - 2Dede SyaechudinNessuna valutazione finora

- Ecoshield PBDocumento2 pagineEcoshield PBBaugh Graphic DesignNessuna valutazione finora

- Boscoseal Torch OnDocumento3 pagineBoscoseal Torch OnjbonvierNessuna valutazione finora

- 5 - FilmsDocumento3 pagine5 - FilmsGloria GonzálezNessuna valutazione finora

- 8756087914559863Documento28 pagine8756087914559863Lucas Del PretteNessuna valutazione finora

- Fosroc Waterproofing B2R-BOQ (Revised 24th)Documento38 pagineFosroc Waterproofing B2R-BOQ (Revised 24th)폴로 쥰 차67% (3)

- Jining QiangkeDocumento35 pagineJining QiangkeCobu LamNessuna valutazione finora

- Aestheitic of Rigid FoamDocumento13 pagineAestheitic of Rigid FoamMuhammad SaadNessuna valutazione finora

- 2007 Penetron BrochureDocumento14 pagine2007 Penetron Brochurekdee075Nessuna valutazione finora

- Modern Technology Assignment FinalDocumento15 pagineModern Technology Assignment FinalchuchuNessuna valutazione finora

- PolyimidesDocumento2 paginePolyimidesthinnnhNessuna valutazione finora

- iKOTE CM 30R (TDS) 02-APRIL-2024Documento2 pagineiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNessuna valutazione finora

- Ch-27.8 PlasticsDocumento108 pagineCh-27.8 PlasticsgUDYFiydfNessuna valutazione finora

- POLYCELL PU 510WB 22sDocumento2 paginePOLYCELL PU 510WB 22snorlailiNessuna valutazione finora

- Polycell Pu510 TdsDocumento3 paginePolycell Pu510 TdsnorlailiNessuna valutazione finora

- Extrusion Coating & LaminationDocumento24 pagineExtrusion Coating & Laminationzus2012100% (1)

- Brochure-Advantex Generic UKDocumento6 pagineBrochure-Advantex Generic UKcentaur150Nessuna valutazione finora

- DESMOFLEX TOP COΑΤ v2 ENDocumento3 pagineDESMOFLEX TOP COΑΤ v2 ENprestigebuild888Nessuna valutazione finora

- BR Polyken Rev11 Sep10Documento8 pagineBR Polyken Rev11 Sep10diaccessltd_17172961Nessuna valutazione finora

- Corrocoat Product GuideDocumento6 pagineCorrocoat Product Guidedosetiadi100% (1)

- B Stage EpoxyDocumento2 pagineB Stage Epoxywinowino100% (1)

- CEILCOTE 505 Coroline.Documento2 pagineCEILCOTE 505 Coroline.stuart3962Nessuna valutazione finora

- Material Properties of PEDocumento12 pagineMaterial Properties of PEIgnatius SamrajNessuna valutazione finora

- Nitoseal 290Documento4 pagineNitoseal 290Venkata RaoNessuna valutazione finora

- Dictionary of Plastic Industry TermsDocumento8 pagineDictionary of Plastic Industry TermsAriel CacciaNessuna valutazione finora

- Composites: Part B: Cheng-Ho Chen, Jun-Jie Wang, Fu-Su YenDocumento4 pagineComposites: Part B: Cheng-Ho Chen, Jun-Jie Wang, Fu-Su YenMazurchevici Andrei DănuţNessuna valutazione finora

- 0400GF Amerlock 400 GF PDSMay 08Documento2 pagine0400GF Amerlock 400 GF PDSMay 08amadan64Nessuna valutazione finora

- Corrocoat - Polyglass VE Pipe Grade - 2016Documento2 pagineCorrocoat - Polyglass VE Pipe Grade - 2016Victor PomboNessuna valutazione finora

- TDS en Tecnocoat CP 2049Documento7 pagineTDS en Tecnocoat CP 2049recep kablanNessuna valutazione finora

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocumento2 pagineRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNessuna valutazione finora

- TDS Chemflake Glass Flake SuggestedDocumento5 pagineTDS Chemflake Glass Flake SuggestedShankar Pl GowdaNessuna valutazione finora

- MesamollDocumento3 pagineMesamollKiên PhùngNessuna valutazione finora

- 100% Solids Polyurethane Coatings Technology For Corrosion Protection in Water and Wastewater SystemsDocumento0 pagine100% Solids Polyurethane Coatings Technology For Corrosion Protection in Water and Wastewater SystemsAkbar KamalNessuna valutazione finora

- 3 LayerDocumento4 pagine3 LayerArya Raditya100% (1)

- Photographic Applications of PolymersDocumento12 paginePhotographic Applications of Polymersvinit singhNessuna valutazione finora

- A6dd4 Dr. Fixit Unilastic 811 TdsDocumento3 pagineA6dd4 Dr. Fixit Unilastic 811 TdsANKIT SINGH-DMNessuna valutazione finora

- Datasheet BONDiT B-4XDocumento7 pagineDatasheet BONDiT B-4XEnrico959Nessuna valutazione finora

- Thermoplastic Carbonate Groups ToughDocumento3 pagineThermoplastic Carbonate Groups ToughAnish KumarNessuna valutazione finora

- BITUSTICK - XL-Tecnical Data SheetDocumento2 pagineBITUSTICK - XL-Tecnical Data Sheetaldred_chezka100% (1)

- 100% Polyurethane - IndiaDocumento9 pagine100% Polyurethane - Indiaeric paglinawanNessuna valutazione finora

- Bitustick XLSDocumento2 pagineBitustick XLSAbed DaherNessuna valutazione finora

- 09875Documento10 pagine09875sethu1091Nessuna valutazione finora

- 6 2 1 2 7 Bitustick PDocumento2 pagine6 2 1 2 7 Bitustick PRobin Denkins PaulNessuna valutazione finora

- MarineDocumento4 pagineMarineVlad DzemgyNessuna valutazione finora

- Mea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaDocumento2 pagineMea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaMuhammad hussainNessuna valutazione finora

- Chemflake SpecialDocumento5 pagineChemflake Specialmajmor-1Nessuna valutazione finora

- UV Coating Flooring - Radtech 2003 - D. Bontinck M. IdacageDocumento6 pagineUV Coating Flooring - Radtech 2003 - D. Bontinck M. IdacageJuan Antonio Tito Esp CalNessuna valutazione finora

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionDa EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNessuna valutazione finora

- Calibration Block - BIGPROBEDocumento19 pagineCalibration Block - BIGPROBEBala SingamNessuna valutazione finora

- This Domain Is Registered at NamecheapDocumento3 pagineThis Domain Is Registered at NamecheapBala SingamNessuna valutazione finora

- Hha Brochure Pmi Master SmartDocumento5 pagineHha Brochure Pmi Master SmartBala SingamNessuna valutazione finora

- Muffle FurnaceDocumento2 pagineMuffle FurnaceBala SingamNessuna valutazione finora

- Vickers 30kg ManualDocumento12 pagineVickers 30kg ManualBala SingamNessuna valutazione finora

- 1 Indeed Public ViewDocumento4 pagine1 Indeed Public ViewBala SingamNessuna valutazione finora

- Dumond Smart Strip SdsDocumento7 pagineDumond Smart Strip SdsBala SingamNessuna valutazione finora

- AC Coupon TM GuideDocumento4 pagineAC Coupon TM GuideBala SingamNessuna valutazione finora

- ThiruvarutpaDocumento19 pagineThiruvarutpaBala SingamNessuna valutazione finora

- Industrial Building For Sale/Lease: Asking Price: $4,650,000Documento3 pagineIndustrial Building For Sale/Lease: Asking Price: $4,650,000Bala SingamNessuna valutazione finora

- Multi Channel IndicatorDocumento1 paginaMulti Channel IndicatorBala SingamNessuna valutazione finora

- Session 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowDocumento48 pagineSession 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowBala SingamNessuna valutazione finora

- Canadian DRIP List - Canadian DRIP PrimerDocumento6 pagineCanadian DRIP List - Canadian DRIP PrimerBala SingamNessuna valutazione finora

- AI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsDocumento15 pagineAI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsBala SingamNessuna valutazione finora

- Replica Metallography and Penetrant TestingDocumento14 pagineReplica Metallography and Penetrant TestingBala Singam100% (1)

- Choose Event Type To View Schedules: CWI, CAWI, CWE - Welding Inspector/EducatorDocumento2 pagineChoose Event Type To View Schedules: CWI, CAWI, CWE - Welding Inspector/EducatorBala SingamNessuna valutazione finora

- Proth Psgs Manual PDFDocumento106 pagineProth Psgs Manual PDFBala SingamNessuna valutazione finora

- AI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsDocumento15 pagineAI-702M/704M/706M High Performance Intelligent Multi-Channel IndicatorsBala SingamNessuna valutazione finora

- PDF Catalogue PDFDocumento42 paginePDF Catalogue PDFBala SingamNessuna valutazione finora

- P45 To P45 PQR CertifiedDocumento7 pagineP45 To P45 PQR CertifiedBala SingamNessuna valutazione finora

- Supervisor: Job/Location: Date: Work To Be Done: Task LocationDocumento1 paginaSupervisor: Job/Location: Date: Work To Be Done: Task LocationBala SingamNessuna valutazione finora

- Hardness Test TrainingDocumento18 pagineHardness Test TrainingBala SingamNessuna valutazione finora

- Prorod Spec SheetDocumento2 pagineProrod Spec SheetBala SingamNessuna valutazione finora

- X-Ray Pipeline CrawlerDocumento4 pagineX-Ray Pipeline CrawlerBala SingamNessuna valutazione finora

- Manual Spirax Sarco Sx80Documento106 pagineManual Spirax Sarco Sx80armani_crupierNessuna valutazione finora

- CPD 120asDocumento42 pagineCPD 120aspcbjuanNessuna valutazione finora

- MT7636 DS-EN - Rev1.30Documento9 pagineMT7636 DS-EN - Rev1.30Vishal dtuNessuna valutazione finora

- Wej Electronic Co.,Ltd: BC846AW, BW BC847AW, BW, CW BC848AW, BW, CWDocumento4 pagineWej Electronic Co.,Ltd: BC846AW, BW BC847AW, BW, CW BC848AW, BW, CWserver hostNessuna valutazione finora

- Manual M258 PDFDocumento160 pagineManual M258 PDFdinojr2010Nessuna valutazione finora

- 1 s2.0 S1369702116302917 MainDocumento15 pagine1 s2.0 S1369702116302917 MainAkrithi AkrithiNessuna valutazione finora

- Seminar ReportDocumento26 pagineSeminar Reportmeghna100% (4)

- Tda 6508 AddDocumento43 pagineTda 6508 AddMukesh ThakkarNessuna valutazione finora

- Vernier Delay Line 1Documento8 pagineVernier Delay Line 1Shibnath BhattacharjeeNessuna valutazione finora

- Basic Tube Power SuppliesDocumento21 pagineBasic Tube Power SuppliesElaine MoratoNessuna valutazione finora

- McIntosh MC250 Service Manual 23C48+ PDFDocumento9 pagineMcIntosh MC250 Service Manual 23C48+ PDFViorel AldeaNessuna valutazione finora

- Audio Oscillator Circuit Based On ICL8038. Square, Triangle and Sine Wave Forms. 20Hz To 20KHz Frequency ReangeDocumento1 paginaAudio Oscillator Circuit Based On ICL8038. Square, Triangle and Sine Wave Forms. 20Hz To 20KHz Frequency ReangeMohamed ShaganNessuna valutazione finora

- Assembly Features: Front ViewDocumento4 pagineAssembly Features: Front ViewTaQuangDucNessuna valutazione finora

- U II Device Modeling 19-9-16Documento17 pagineU II Device Modeling 19-9-16Parag ParandkarNessuna valutazione finora

- New Microwave Lab ManualDocumento35 pagineNew Microwave Lab ManualRadhikaNessuna valutazione finora

- TDA25410 If Amplifier With Demodulator and AfcDocumento8 pagineTDA25410 If Amplifier With Demodulator and Afcspam0000Nessuna valutazione finora

- Design and Construction of A Smart Streetlight SystemDocumento51 pagineDesign and Construction of A Smart Streetlight SystemJerry Joseph100% (1)

- Operation of The Classical CMOS SchmittDocumento5 pagineOperation of The Classical CMOS SchmittAakash ChandraNessuna valutazione finora

- Transmisor de Presión PXTKDocumento4 pagineTransmisor de Presión PXTKNicolii RamonNessuna valutazione finora

- DDPSMVol 2Documento22 pagineDDPSMVol 2LawrieNessuna valutazione finora

- Transformador de 3 EnrolamentosDocumento5 pagineTransformador de 3 EnrolamentosrobertoseniorNessuna valutazione finora

- LD7530M/LD7530N: Green-Mode PWM Controller With Programmable OLP Delay Time and Integrated ProtectionsDocumento20 pagineLD7530M/LD7530N: Green-Mode PWM Controller With Programmable OLP Delay Time and Integrated Protectionsmauricio alfonsoNessuna valutazione finora

- Generator ProtectionDocumento62 pagineGenerator ProtectionMohammad Ibnul Hossain100% (5)

- Unit I - MCQs (Bank 2)Documento5 pagineUnit I - MCQs (Bank 2)AbhijeetNessuna valutazione finora

- Assignment EE 4202Documento10 pagineAssignment EE 4202Chanki P PyrbotNessuna valutazione finora

- Fuses-Medium Voltage 9.0-1: September 2011Documento12 pagineFuses-Medium Voltage 9.0-1: September 2011Fredelito Dela CruzNessuna valutazione finora

- Experimental Demonstration of 4 Light Communication Using A Commercial CCD Image SensorDocumento5 pagineExperimental Demonstration of 4 Light Communication Using A Commercial CCD Image SensorazharNessuna valutazione finora

- VarshaDocumento46 pagineVarshavarshaNessuna valutazione finora

- Tapless LibraryDocumento4 pagineTapless Libraryresource hubNessuna valutazione finora