Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

495

Caricato da

PECMURUGANCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

495

Caricato da

PECMURUGANCopyright:

Formati disponibili

ASIAN JOURNAL OF CIVIL ENGINEERING (BUILDING AND HOUSING) VOL. 11, NO.

4 (2010)

PAGES 495-507

STRENGTH AND FLEXURAL TOUGHNESS OF CONCRETE

REINFORCED WITH STEEL POLYPROPYLENE HYBRID FIBRES

S.P. Singh

*

, A.P. Singh and V. Bajaj

Department of Civil Engineering, B.R. Ambedkar National Institute of Technology,

J alandhar, India

ABSTRACT

Results of an investigation conducted to evaluate the strength and flexure toughness of

Hybrid Fibre Reinforced Concrete (HyFRC) containing different combinations of steel and

polypropylene fibres are presented. An experimental programme was planned in which

beam specimens of size 100 x 100 x 500 mm were tested under four point static flexural

loading to obtain the flexural strength of HyFRC. In addition, cube specimens of size

150 x 150 x 150 mm were also tested to obtain its compressive strength. The specimens

incorporated steel and polypropylene fibres in the mix proportions of 100-0%, 75-25%,

50-50%, 25-75% and 0-100% by volume at a total volume fraction of 1.0%. The flexural

toughness parameters were obtained using procedure laid down in ASTM C-1018 C, J CI

Method, ASTM 1609/C 1609 M and Post Crack Strength (PCS) Method. The results indicate

that concrete containing a fibre combination of 75% steel fibres +25% polypropylene fibres

can be adjudged as the most appropriate combination to be employed in HyFRC for

compressive strength, flexural strength and flexural toughness.

Keywords: Hybrid fibre reinforced concrete; flexural strength; flexural toughness

1. INTRODUCTION

It is known that concrete is relatively a brittle material and has serious short-coming of poor

toughness. Addition of randomly distributed fibres improves concrete structural

characteristics viz. static flexural strength, ductility and flexural toughness etc., which

depend upon fibre type, size, aspect ratio and volume fractions of the fibres used.

Recent years have seen considerable interest in the fibre hybridization particularly

combinations of metallic and non-metallic fibres. For optimal behaviour, different types of

metallic and non-metallic fibres have been combined. The mechanical properties such as

compressive strength, flexural strength and flexural toughness etc. of Hybrid Fibre

Reinforced Concrete (HyFRC) have been investigated by different investigators. Positive

synergy between the large size steel and small size polypropylene fibres was reported with

*

E-mail address of the corresponding author: spsingh@nitj.ac.in(S.P. Singh)

S.P. Singh, A.P. Singh and V. Bajaj 496

regard to load bearing capacity of concrete by Qian and Stroeven [1]. Influence of fibre type

and combinations on the crack growth resistance of steel and polypropylene fibre reinforced

concrete was reported in another investigation by Banthia and Nandakumar [2]. Mechanical

properties such as compressive strength, splitting tensile strength and flexural strength were

compared for concrete containing different combinations of steel, carbon and polypropylene

fibres at a fibre volume fraction of 0.5% [3]. It was observed concrete reinforced with the

carbon-steel combination achieved highest strength. Various researchers reported the results

of investigations carried out to study the flexural behaviour of concrete containing different

combinations of steel, mesophase pitch based and isotropic pitch based carbon, macro and

micro polypropylene fibres, glass and polyester fibres [4, 5, 6]. The results indicated that

such hybridization indeed is a promising concept. Strain hardening and multiple cracking

behaviour of hybrid fibre reinforced cement composites containing fly ash and different

combinations of steel and polyethylene fibres were investigated [7]. The results suggested

that 50% replacement of cement by fly ash is an optimum replacement for hybrid fibre

composites. Two different types of polypropylene fibres i.e. monofilament and staple fibres

were combined to study the mechanical properties of hybrid fibrous concrete [8]. It has been

shown that the performance of hybrid fibre reinforced concrete is better than mono fibre

concrete mixes. The influence of mixed aspect ratio of steel fibres on the fresh and hardened

properties of fibrous concrete was reported by Mohammadi et al. [9]. The effect of

polypropylene fibres and silica fume on the mechanical properties of lightweight concrete

exposed to high temperature was also investigated and it was observed that the most

effective parameter for the mechanical properties of lightweight fibre reinforced concrete

was degree of heating and the optimum parameters for compressive strength were different

from those for flexural strength [10].

2. RESEARCH SIGNIFICANCE

In the recent past, investigators attempted to enhance the mechanical properties of fibre

reinforced concrete using fibre hybridization. Different types of fibres in different

combinations have been employed with varying sizes of concrete specimens. Though

enhancement in the mechanical properties of HyFRC has been reported through fibre

hybridization, but there exists little understanding of hybrid fibre composites and the

information is still scanty. Hence, this investigation was planned to study the flexural

behaviour of HyFRC containing hybrids of steel and polypropylene fibres. Different

proportions of steel and polypropylene fibres varying from 100% steel fibres to 100%

polypropylene fibres have been investigated to evaluate the mechanical properties of

HyFRC. Tests such as compressive strength and flexural strength have been conducted on

concrete specimens containing different combinations of steel and polypropylene fibres. The

toughness parameters of HyFRC have been evaluated as per ASTM C 1018 C [11], J CI

Method [12], ASTM C 1609 M [13] and a method called Post Crack Strength (PCS) [4, 5].

STRENGTH AND FLEXURAL TOUGHNESS OF CONCRETE REINFORCED... 497

3. EXPERIMENTAL PROGRAMME

The concrete mix proportion used in this investigation for casting the test specimens is

shown in Table 1. Pozzolanic Portland Cement, crushed stone coarse aggregates with

maximum size of 12mm and locally available river sand were used. The materials

conformed to the relevant Indian Standard Specifications. Corrugated steel fibres 35mm

long, 2 mm wide and 0.6 mm in thickness and homo-polymer fibrillated polypropylene

fibres were used in different combinations of 100-0%, 75-25%, 50-50%, 25-75% and

0-100% by volume at a total fibre volume fraction of 1.0%. The specimen used for

compressive strength tests were 150x 150x150mm cubes whereas standard prisms of size

100 x 100 x 500 mm were used for flexural strength tests. Table 2 presents the details of

various fibre concrete mixes used in this investigation.

Table 1: Concrete mix proportion

Water/Cement

ratio

Sand/Cement

ratio

Coarse aggregate/Cement

ratio

0.46 1.52 1.88

Table 2: Fibrous concrete mixes

Fibre mix proportion by volume (%)

Type of fibres

Total volume fraction, V

f

= 1.0%

Steel fibres

(SF)

0 25 50 75 100

Polypropylene

fibres (PPF)

100 75 50 25 0

The specimens were cast in different batches, each batch consisting of nine standard

flexural test specimens and three cubes for determining the 28-day compressive strength of

each mix. The specimens for compressive strength tests were cured in potable water for 28

days, whereas, the specimens for flexural strength tests were cured for 60 days. Appropriate

dose of super-plasticizer was used to maintain workability. In fact, this paper forms a part of

a larger investigation being conducted to investigate the flexural fatigue characteristics of

concrete containing hybrids of steel and polypropylene fibres. Out of each batch of concrete,

three specimens were tested in static flexure and the remaining six specimens were left for

carrying out flexural fatigue tests. This paper reports the results of the static compressive

strength and static flexural strength tests and the results of the flexural fatigue tests shall be

reported in a separate paper.

S.P. Singh, A.P. Singh and V. Bajaj 498

The compressive strength tests were conducted on concrete cubes in a 2000kN Universal

Testing Machine whereas, the flexural strength tests were conducted on a 100 kN servo-

controlled actuator.

4. RESULTS AND DISCUSSION

4.1 Compressive strength test results

The results of the compressive strength test conducted on HyFRC containing different

combinations of steel and polypropylene fibres are presented in Table 3 and Figure 1. The

28 days compressive strength of plain concrete is also shown in Table 3 and Figure 1 for

reference. It is observed that the with the introduction of 100% polypropylene fibres to the

plain concrete, the compressive strength drops to 35.40 MPa from 40.15 MPa resulting in

approximately 13% reduction. Banthia and Soleimani [4] also reported approximately 13%

reduction in compressive strength of concrete containing 100% polypropylene fibres as

compared to that of plain concrete. However, an increase in the compressive strength of

fibrous concrete is observed with the addition of steel fibres to the mix and maximum

compressive strength is obtained for concrete containing 75% steel fibres+25%

polypropylene fibres. In general, there is an increase in compressive strength varying from

6% to 18% on addition of fibres to concrete and the optimum fibre combination is 75% steel

fibres+25% polypropylene fibres for which the maximum increase in compressive strength

of 18% over plain concrete is observed. Further, it can also be seen that the compressive

strength of concrete mix containing 50% steel fibres +50% polypropylene fibres is higher

than that of concrete mix containing 100% steel fibres. The percentage increase/decrease in

compressive strength of HyFRC over plain concrete is presented in Figure 2.

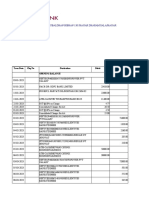

Table 3: Compressive strength test results for HyFRC

28 Days compressive strength (MPa)

*

Fibre mix

proportion by

volume (%)

Cube compression

SF PPF

Fibre

volume

fraction

Batch 1 Batch 2 Batch 3 Average

%Age

increase

-- -- 0.0 39.70 40.50 -- 40.15

#

0

0 100 1.0 35.05 35.55 34.75 35.10 -13

25 75 1.0 37.90 39.60 39.95 39.20 -2

50 50 1.0 45.70 46.20 44.85 45.60 14

75 25 1.0 47.60 49.60 45.05 47.40 18

100 0 1.0 41.40 44.95 41.65 42.65 6

*

Average of Three Specimens

#

Average of Two Batches

STRENGTH AND FLEXURAL TOUGHNESS OF CONCRETE REINFORCED... 499

0

10

20

30

40

50

A

v

e

r

a

g

e

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

(

M

P

a

)

PC

100%PPF

25%SF+75%PPF

50%SF+50%PPF

75%SF+25%PPF

100%SF

Figure 1. Compressive strength of HyFRCfor different fibre combinations

-15

-10

-5

0

5

10

15

20

I

n

c

r

e

a

s

e

i

n

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

(

%

)

100%PPF

25%SF+75%PPF

50%SF+50%PPF

75%SF+25%PPF

100%SF

Figure 2. Percentage increase in compressive strength of HyFRC over that of plain concrete

4.2 Flexural strength test results

The flexural strength results for HyFRC containing different combinations of steel and

polypropylene fibres are presented in Table 4 and Figure 3. The flexural strength of plain

concrete is also listed for reference and comparison. The percentage increase/decrease of

flexural strength of fibrous concrete with respect to plain concrete is presented in Figure 4.

It can be seen that in general, like compressive strength, the flexural strength of concrete

containing 100% polypropylene fibres is less than that of the plain concrete. There is a drop

of approximately 7% in the flexural strength of concrete containing 100% polypropylene

fibres as compared to that of plain concrete. Banthia and Soleimani [4] reported

approximately 11% reduction in flexural strength of concrete containing 100%

polypropylene fibres as compared to that of plain concrete. With gradual replacement of

S.P. Singh, A.P. Singh and V. Bajaj 500

polypropylene fibres with steel fibres, an increase in the flexural strength is observed up to a

fibre combination of 75% steel fibres +25% polypropylene fibres. With further replacement

of polypropylene fibres with steel fibres i.e. for concrete containing 100% steel fibres, a

decrease in flexural strength is observed. The increase in flexural strength taken as average

of three batches of fibrous concrete containing different combinations of steel and

polypropylene fibres varied from 40% to 80%, showing an increase of 42% for HyFRC with

25% steel fibres + 75% polypropylene fibres; 55% for 50% steel fibres + 50%

polypropylene fibres; 80% for concrete containing 75% steel fibres +25% polypropylene

fibres and 40% for concrete containing 100% steel fibres. Thus the optimum fibre

combination for maximum flexural strength is 75% steel fibres+25% polypropylene fibres

as obtained in this investigation.

Table 4: Flexural strength test results for HyFRC

Fibre mix

proportion by

volume (%)

Flexural strength (MPa)

*

SF PPF

Fibre

volume

fraction

Batch 1 Batch 2 Batch 3 Average % Increase

--- --- 0.0 4.20 4.20 --- 4.20 --

0 100 1.0 3.30 3.60 4.80

#

3.90 -7

25 75 1.0 6.05 6.00 5.80 5.95 42

50 50 1.0 6.70 6.40

#

6.50

#

6.50 55

75 25 1.0 7.65 7.40

#

7.70 7.60 80

100 0 1.0 5.60

#

5.60 6.40 5.90 40

*

Average of 3 Specimens

#

Average of 2 Specimens

0

2

4

6

8

A

v

e

r

a

g

e

F

l

e

x

u

r

a

l

S

t

r

e

n

g

t

h

(

M

P

a

)

PC

100%PPF

25%SF+75%PPF

50%SF+50%PPF

75%SF+25%PPF

100%SF

Figure 3. Flexural strength of HyFRC for different fibre combinations

STRENGTH AND FLEXURAL TOUGHNESS OF CONCRETE REINFORCED... 501

-20

0

20

40

60

80

100

I

n

c

r

e

a

s

e

i

n

F

l

e

x

u

r

a

l

S

t

r

e

n

g

t

h

(

%

)

100%PPF

25%SF+75%PPF

50%SF+50%PPF

75%SF+25%PPF

100%SF

Figure 4. Percentage increase in flexural strength of HyFRC over that of plain concrete

Typical load-deflection curves obtained in this investigation for concrete containing

different combinations of fibres are presented in Figure 5. The average peak loads and

corresponding deflections for fibrous concrete with different combinations of both types of

fibres are presented in Table 5. The peak load and corresponding centre point deflection for

plain concrete are also presented for reference. The increase in centre-point deflection

corresponding to peak load as compared to plain concrete varied from 31% to 85% - with an

increase of 31% for 100% polypropylene fibre; 50% for 25% steel +75% polypropylene

fibre; 85% for 50% steel fibre +50% polypropylene fibre; 84% for 75% steel fibre+25%

polypropylene fibre and; 23% for 100% steel fibres. The maximum increase in the value of

centre-point deflection was obtained for 50% steel fibre +50% polypropylene fibres while

the minimum increase in the centre point deflection over plain concrete was for 100% steel

fibres. Figure 6 shows the variation of peak load and first crack load with the percentage of

steel fibres in the concrete mix.

0

3

6

9

12

15

18

0 1 2 3 4 5

Defl ecti on (mm)

L

o

a

d

(

k

N

)

Batch 1

Batch 2

Batch 3

Figure 5. Load-deflection curves for HyFRC, 75% steel fibres+25% polypropylene fibres

S.P. Singh, A.P. Singh and V. Bajaj 502

7.5

10

12.5

15

17.5

0 25 50 75 100

Percentage of Steel Fi bres

L

o

a

d

(

k

N

)

First Crack Load

Peak Load

Figure 6. Average first crack loads and peak loads vs. steel fibre content in concrete mix

Table 5: Average peak loads and corresponding deflections

Fibre mix proportion by

volume (%)

Maximum load and corresponding

deflection

*

SF PPF

Fibre

volume

fraction

Deflection (mm) Load (kN)

--- --- 0 0.402 9.30

0 100 1.0

#

0.528 8.64

25 75 1.0 0.601 13.22

50 50 1.0

&

0.745 14.53

75 25 1.0

#

0.740 16.82

100 0 1.0

#

0.493 13.04

*

Test conducted on 3 batches (3 Samples each)

#

1 batch containing 2 Samples

&

2 batches containing 2 Samples

4.3 Flexural toughness

Concrete due to its brittle behaviour has little ability to resist tensile stresses and strains.

Discontinuous fibres are added to improve energy absorption capacity and to provide

improved resistance to cracking. Thus flexural toughness is an important parameter in

assessing the influence of fibres on the post-peak behaviour of fibre reinforced concrete. A

number of methods have been developed to obtain the flexural toughness and performance of

fibre reinforced concrete. The flexural toughness parameters have been obtained using various

STRENGTH AND FLEXURAL TOUGHNESS OF CONCRETE REINFORCED... 503

methods [11-13]. In addition, a method based on Post Crack Strength (PCS) proposed by

Banthia and Sappakittipakorn [5] has also been used to evaluate the flexural toughness of

fibrous concrete containing different combinations of steel and polypropylene fibres.

Table 6 presents various toughness parameters such as I

5

, I

10,

I

10

/I

5

, R

5, 10

obtained by

ASTM C 1018 and T

J CI

, S

J CI

obtained using J CI method for HyFRC containing different

combinations of steel and polypropylene fibres. The toughness index for plain concrete in

ASTM C 1018 Method is taken as 1.0 because plain concrete flexural test specimens fail

immediately after the formation of first crack. The flexural performance parameters such as

P

600

, P

150

, f

600,

f

150

, T

600

and T

150

for fibrous concrete as obtained using ASTM C 1609/C

1609 M are presented in Table 7 for HyFRC containing different combinations of steel and

polypropylene fibres.

It can be observed from Table 6 that the best performance is given by concrete

containing 75% steel fibres+25% polypropylene fibres. The highest values of T

J CI

and S

J CI

are 31.64 kN-mm and 4.74 MPa respectively for concrete with 75% steel fibres +25%

polypropylene fibres, whereas, the lowest values of 7.57 kN-mm and 1.13 MPa are obtained

for concrete containing 100% polypropylene fibres. Similarly, the highest values of the

parameters obtained using ASTM C 1018 C are for concrete with 75% steel fibres +25%

polypropylene fibres. It can also be concluded from Table 6 that in general, concrete

containing hybrid fibres i.e. combinations of steel and polypropylene fibres gave better

performance as compared to concrete containing single type of fibres be 100% steel or

100% polypropylene fibres. The variation of indices I

5

and I

10

with the increase in

percentage of steel fibres in the concrete mix is shown in Figure 7.

Table 6: Average flexural toughness indices using J CI and ASTM C-1018

Toughness indices

*

Fibre mix

proportion by

volume (%) JCI METHOD ASTM C-1018

SF PPF

Fibre

volume

fraction

T

JCI

(kN-

mm)

S

JCI

(MPa)

T

F.C.

(kN-mm)

I

5

I

10

I

10

/I

5

R

5,10

0 100 1.0

#

7.57 1.13 2.34 2.90 4.78 1.65 37.40

25 75 1.0 20.63 3.09 3.82 3.38 5.22 1.54 37.42

50 50 1.0

&

25.32 3.80 4.49 3.24 5.15 1.59 38.22

75 25 1.0

#

31.62 4.74 5.59 3.84 6.32 1.65 49.65

100 0 1.0

#

22.02 3.30 3.13 3.40 4.96 1.46 31.17

*

Test conducted on 3 batches (3 Samples each)

#

1 batch containing 2 Samples

&

2 batches containing 2 Samples

S.P. Singh, A.P. Singh and V. Bajaj 504

Table 7: Average flexural toughness indices using ASTM C-1609

Toughness indices

*

Fibre Mix

proportion by

volume (%) ASTM C-1609

SF PPF

Fibre

volume

fraction

P

600

(kN)

P

150

(kN)

f

600

(MPa)

f

150

(MPa)

T

600

(Joules)

T

150

(Joules)

0 100 1.0

#

2.91 1.33 1.30 0.60 3.61 7.57

25 75 1.0 10.32 5.37 4.64 2.41 5.30 20.63

50 50 1.0

&

12.23 6.10 5.50 2.74 4.98 25.32

75 25 1.0

#

16.40 8.07 7.38 3.63 6.47 31.62

100 0 1.0

#

12.52 2.93 5.63 1.31 4.04 22.02

*

Test conducted on 3 batches (3 Samples each)

#

1 batch containing 2 Samples

&

2 batches containing 2 Samples

2

3

4

5

6

7

8

0 25 50 75 100

Percentage of Steel Fi bres

V

a

l

u

e

o

f

T

o

u

g

h

n

e

s

s

I

n

d

i

c

e

s

I5

I10

Figure 7. Average values of I

5

and I

10

vs. steel fibre content in concrete mix

As is evident from Table 7, the residual strengths f

600

, f

150

and the toughness parameters

T

600

and T

150

show more or less similar trends as presented by toughness parameters

obtained by the other two methods discussed in the preceding sections. The lowest values of

toughness T

600

and T

150

i.e. 3.61 J oules and 7.57 J oules respectively are shown by concrete

containing 100% polypropylene fibres. As the polypropylene fibres are partially replaced

with steel fibres, an increase in the values of both T

600

and T

150

is observed which continues

up to a fibre combination of 75% steel fibres +25% polypropylene fibres which records

STRENGTH AND FLEXURAL TOUGHNESS OF CONCRETE REINFORCED... 505

highest values of the toughness parameters. Further replacement of polypropylene fibres

with steel fibres i.e. for concrete containing 100% steel fibres, a decrease in the values of

toughness parameters is observed.

The loaddeflection curves as obtained in this investigation for HyFRC containing

different combinations of fibres have also been analysed by Post Crack Strength (PCS)

method as reported by various researchers [4, 5]. It is a method of converting a load-

deflection curve into an equivalent flexural strength curve. The method as demonstrated in

Figure 8, locates the peak load and divides the curve into two regions i.e. pre peak and post

peak. In the post peak region, the points are located corresponding to deflections coinciding

with various fractions of the span. For a beam with width b and depth h, the Post Crack

Strength (PCS) at a deflection L/m is given by the following expression [5]:

|

.

|

\

|

|

.

|

\

|

o

=

2

peak

m , post

bxh

L

x

m

l

E

PCS (1)

Figure 8. Post crack strength (PCS) analysis on a fibrous concrete beam

0

2

4

6

8

10

0.7 1 1.3 1.6 1.9 2.2 2.5 2.8 3.1

L/m (mm)

P

C

S

(

M

P

a

)

100%PPF

25%SF+75%PPF

50%SF+50%PPF

75%SF+25%PPF

100%SF

Figure 9. PCS values for HyFRC containing different combinations of steel and polypropylene fibres

S.P. Singh, A.P. Singh and V. Bajaj 506

The load-deflection curves obtained in this investigation have been analysed using the

said method and a plot of the PCS with respect to L/m ratios for different mix combinations

of fibres used is shown in Figure 9. It is observed from Figure 9 that concrete containing

100% polypropylene fibres showed lowest PCS values. The PCS values increased

significantly with 25% replacement of polypropylene fibres by the steel fibres. Howvere, he

highest PCS values are obtained for concrete containing 75% steel fibres + 25%

polypropylene fibres which appear to be a promising combination.

5. CONCLUSION

Properties, such as compressive strength, flexural strength and flexural toughness of HyFRC

containing different combinations of steel and polypropylene fibres have been investigated.

The flexural toughness indices/parameters were obtained from the load deflection curves

as per procedure laid down in ASTM C 1018, J CI Method and ASTM C 1609/C 1609 M.

The load-deflection curves have also been analysed using PCS technique. A maximum

increase in compressive strength of the order of 18% over plain concrete was observed in

case of concrete containing 75% steel fibres +25% polypropylene fibres. In case of static

flexural strength tests, a maximum increase in flexural strength of the order of 80%, centre

point deflection corresponding to peak load of the order of 84% was observed for HyFRC

with 75% steel fibres +25% polypropylene fibres. The results obtained in this investigation

indicate that, in terms of flexural toughness, concrete with fibre combination of 75% steel

fibres +25% polypropylene fibres gives the best performance. Increase of fibre availability

in the hybrid fibre system due to low density non-metallic fibres in combination of steel

fibres could be the reason for the enhanced flexural toughness of the HyFRC mix.

Acknowledgement: The research work reported is a part of the UKIERI (UK-India

Education and Research Initiative) Collaborative Research Project currently in progress.

The support received from UKIERI and Ministry of Human Resource Development

(MHRD), Government of India is gratefully acknowledged.

REFERENCES

1. Qian CX, Stroeven P. Development of hybrid polypropylene-steel fibre reinforced

concrete, Cement and Concrete Research, 30(2000) 63-9.

2. Banthia N, Nandakumar N. Crack growth resistance of hybrid fiber reinforced cement

composites, Cement and Concrete Composites, 25(2003) 3-9.

3. Yao W, Li J , Wu K. Mechanical properties of hybrid fibre-reinforced concrete at low

fibre volume fraction, Cement and Concrete Research, 33(2003) 23-30.

4. Banthia N, Soleimani SM. Flexural response of hybrid fiber-reinforced cementitious

composites, ACI Materials Journal, 102(2005) 382-9.

5. Banthia N, Sappakittipakorn M. Toughness enhancement in steel fibre reinforced

concrete through fiber hybridization, Cement and Concrete Research, 37(2007) 1366-72.

STRENGTH AND FLEXURAL TOUGHNESS OF CONCRETE REINFORCED... 507

6. Sivakumar A, Santhanam M. Mechanical properties of high strength concrete

reinforced with metallic and non-metallic fibres, Cement and Concrete Composites

29(2007) 603-8.

7. Ahmed SFU, Maalej M, Paramasivam P. Flexural responses of hybrid steel-

polyethylene fibre reinforced cement composites containing high volume fly ash,

Construction and Building Materials, 21(2007) 1088-97.

8. Hsie M, Tu C, Song PS. Mechanical properties of polypropylene hybrid fibre-

reinforced concrete, Material Science and Engineering A, 494(2008) 153-7.

9. Mohammadi Y, Singh SP, Kaushik SK. Properties of steel fibrous concrete containing

mixed fibres in fresh and hardened state, Construction and Building Materials,

22(2008) 956-75.

10. Tanyildizi H. Statistical analysis for mechanical properties of polypropylene fiber

reinforced lightweight concrete containing silica fume exposed to high temperature,

Material and Design, 30(2009) 3252-48.

11. C 1018. Standard Test Method for Flexural Toughness and First-Crack Strength of

Fibre-Reinforced Concrete (Using Ream with Third-Point Loading), Annual Book of

ASTM Standards, ASTM Committee, C-9(1992) 514-20.

12. J CI-SF4. Methods of tests for flexural strength and flexural toughness of fibre

reinforced concrete, 1984, pp. 58-66.

13. C 1609/C 1609M. Standard Test Method for Flexural Performance of Fibre-Reinforced

Concrete (Using Beam with Third-Point Loading), Annual Book of ASTM Standards,

ASTM Committee, C09(2008) 1-9.

Potrebbero piacerti anche

- Combinational Circuit Analysis and DesignDocumento25 pagineCombinational Circuit Analysis and DesignPECMURUGANNessuna valutazione finora

- Digital Signal Processing: b, where (a, b) can be (t t x πDocumento5 pagineDigital Signal Processing: b, where (a, b) can be (t t x πSugan MohanNessuna valutazione finora

- Syllabus: Department of Computer Science & Engineering Lab Manual Digital Lab Class: 2 Yr, 3 SemDocumento104 pagineSyllabus: Department of Computer Science & Engineering Lab Manual Digital Lab Class: 2 Yr, 3 SemPECMURUGANNessuna valutazione finora

- PLDsDocumento25 paginePLDsPECMURUGAN100% (1)

- Combinational Logic Design ProcessDocumento21 pagineCombinational Logic Design ProcessILikeScribd5050Nessuna valutazione finora

- Digital Signal ProcessingDocumento271 pagineDigital Signal ProcessingPECMURUGAN100% (3)

- Combinational Logic1-1Documento9 pagineCombinational Logic1-1PECMURUGANNessuna valutazione finora

- EE101: Digital Circuits (Part 2) : M. B. PatilDocumento68 pagineEE101: Digital Circuits (Part 2) : M. B. PatilSenthil KumarNessuna valutazione finora

- 2-Mod2 CP Impact 2013Documento317 pagine2-Mod2 CP Impact 2013PECMURUGANNessuna valutazione finora

- 7 Segment LedDocumento27 pagine7 Segment LedNikhil BhatiNessuna valutazione finora

- CSE 2 2013R Anna UniversityDocumento11 pagineCSE 2 2013R Anna UniversityBaskyNessuna valutazione finora

- Instructions and RequirementsDocumento4 pagineInstructions and RequirementsPECMURUGANNessuna valutazione finora

- GE 2151 BEEE Question Paper Nov Dec 2011Documento3 pagineGE 2151 BEEE Question Paper Nov Dec 2011PECMURUGANNessuna valutazione finora

- Lec 03 ZCZCDocumento26 pagineLec 03 ZCZCPECMURUGANNessuna valutazione finora

- Ee101 DGTL 3Documento123 pagineEe101 DGTL 3PECMURUGANNessuna valutazione finora

- l2 Combi LogicDocumento27 paginel2 Combi LogicPECMURUGANNessuna valutazione finora

- Chapter 04Documento40 pagineChapter 04瘋橋夜泊Nessuna valutazione finora

- Ee101 DGTL 5Documento150 pagineEe101 DGTL 5Shreeroop AjaykumarNessuna valutazione finora

- GE 2151 BEEE Question Paper Nov Dec 2011Documento3 pagineGE 2151 BEEE Question Paper Nov Dec 2011PECMURUGANNessuna valutazione finora

- KmapDocumento38 pagineKmapPECMURUGANNessuna valutazione finora

- EE101: Digital Circuits (Part 2) : M. B. PatilDocumento68 pagineEE101: Digital Circuits (Part 2) : M. B. PatilSenthil KumarNessuna valutazione finora

- Ee101 DGTL 1Documento152 pagineEe101 DGTL 1PECMURUGANNessuna valutazione finora

- 06668967Documento10 pagine06668967PECMURUGANNessuna valutazione finora

- K MappingDocumento28 pagineK MappingVikrant BhaskarNessuna valutazione finora

- Ee101 DGTL 4Documento116 pagineEe101 DGTL 4PECMURUGANNessuna valutazione finora

- Totally Precast Concrete Bridges: ForwardDocumento27 pagineTotally Precast Concrete Bridges: ForwardPECMURUGANNessuna valutazione finora

- Unit 8: Precast ConcreteDocumento27 pagineUnit 8: Precast ConcreteRemya R. KumarNessuna valutazione finora

- Aasr 2012 3 5 2837 2846Documento10 pagineAasr 2012 3 5 2837 2846PECMURUGANNessuna valutazione finora

- Concreet Tecnologey 7-9-2008Documento23 pagineConcreet Tecnologey 7-9-2008PECMURUGANNessuna valutazione finora

- Precast ConcreteDocumento20 paginePrecast ConcreteMuhammadTareqRasyadJamallulailNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Operator's ManualDocumento110 pagineOperator's ManualAdam0% (1)

- Citrus Information Kit-Update: Reprint - Information Current in 1998Documento53 pagineCitrus Information Kit-Update: Reprint - Information Current in 1998hamsa sewakNessuna valutazione finora

- Science9 Q4 Week2Documento16 pagineScience9 Q4 Week2Maria Josie Lopez TumlosNessuna valutazione finora

- Writing About Graphs, Tables and DiagramsDocumento68 pagineWriting About Graphs, Tables and DiagramsLangers BastasaNessuna valutazione finora

- CryptogrophyDocumento37 pagineCryptogrophyFarah EssidNessuna valutazione finora

- Introduction To Microelectronic Fabrication PDFDocumento332 pagineIntroduction To Microelectronic Fabrication PDFChristy Moore92% (13)

- Earth Science NAME - DATEDocumento3 pagineEarth Science NAME - DATEArlene CalataNessuna valutazione finora

- Class InsectaDocumento4 pagineClass InsectaLittle Miss CeeNessuna valutazione finora

- Present Perfect and Present Perfect ProgressiveDocumento5 paginePresent Perfect and Present Perfect ProgressiveKiara Fajardo matusNessuna valutazione finora

- Swift As A MisanthropeDocumento4 pagineSwift As A MisanthropeindrajitNessuna valutazione finora

- X Lube Bushes PDFDocumento8 pagineX Lube Bushes PDFDavid TurnerNessuna valutazione finora

- Installation of Submarine PE PipesDocumento84 pagineInstallation of Submarine PE Pipeswaseemiqbal133100% (2)

- The Fastest Easiest Way To Secure Your NetworkDocumento9 pagineThe Fastest Easiest Way To Secure Your NetworkMark ShenkNessuna valutazione finora

- Evan Lagueux - H Argument EssayDocumento7 pagineEvan Lagueux - H Argument Essayapi-692561087Nessuna valutazione finora

- P D P: C I D, C M: Design of Coastal RoadsDocumento55 pagineP D P: C I D, C M: Design of Coastal RoadsMohammedNessuna valutazione finora

- FS 1 Episode 2Documento6 pagineFS 1 Episode 2Jayson Garcillan UmipigNessuna valutazione finora

- XXXX96 01 01 2023to28 08 2023Documento18 pagineXXXX96 01 01 2023to28 08 2023dabu choudharyNessuna valutazione finora

- Half Yearly Examination, 2017-18: MathematicsDocumento7 pagineHalf Yearly Examination, 2017-18: MathematicsSusanket DuttaNessuna valutazione finora

- Request For Proposals/quotationsDocumento24 pagineRequest For Proposals/quotationsKarl Anthony Rigoroso MargateNessuna valutazione finora

- KM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)Documento4 pagineKM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)krzysiek1975Nessuna valutazione finora

- Dummy 13 Printable Jointed Figure Beta FilesDocumento9 pagineDummy 13 Printable Jointed Figure Beta FilesArturo GuzmanNessuna valutazione finora

- An Introduction To Routine and Special StainingDocumento13 pagineAn Introduction To Routine and Special StainingBadiu ElenaNessuna valutazione finora

- Chapter 4 Signal Flow GraphDocumento34 pagineChapter 4 Signal Flow GraphAbhishek PattanaikNessuna valutazione finora

- QAI Golden Pass Fact SheetDocumento2 pagineQAI Golden Pass Fact SheetQatar-America InstituteNessuna valutazione finora

- Coating Resins Technical Data SYNOCURE 867S - 60Documento1 paginaCoating Resins Technical Data SYNOCURE 867S - 60Heramb TrifaleyNessuna valutazione finora

- Ass AsDocumento23 pagineAss AsMukesh BishtNessuna valutazione finora

- C103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratoriesDocumento19 pagineC103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratorieshuidhyiuodghNessuna valutazione finora

- The Teacher Research Movement: A Decade Later: Cite This PaperDocumento13 pagineThe Teacher Research Movement: A Decade Later: Cite This PaperAlexandre NecromanteionNessuna valutazione finora

- Assessment - UK Forestry Data ICT THEORY For CAT1Documento13 pagineAssessment - UK Forestry Data ICT THEORY For CAT1Joanna AchemaNessuna valutazione finora

- Rosewood Case AnalysisDocumento5 pagineRosewood Case AnalysisJayant KushwahaNessuna valutazione finora