Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Optimize Cyclone Separator Efficiency

Caricato da

FDLTLSDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Optimize Cyclone Separator Efficiency

Caricato da

FDLTLSCopyright:

Formati disponibili

2

2.1

Static separators:

Cyclones

2.1.1 Introduction: - In cement manufacturing industries, large-sized cyclone separators are used as main process equipments in significant numbers for handling high volumetric flow rates of dust-laden gases. - The cyclone is a simple mechanical device commonly used in the grinding circuits to remove relatively large particles from gas streams. - Cyclones are often used as precleaners to remove more than 80% of the particles greater than 20m in diameter. Smaller particles that escape the cyclones can then be collected by more efficient control equipment like bag filters and electroprecipitators. - Cyclones are relatively inexpensive since they have no moving parts and they are easy to operate. - The most common type of cyclone is known as reverse flow cyclone separator 2.1.2 Advantages of cyclones: - Low capital cost - Ability to operate at high temperatures and pressures - Low maintenance requirements because no moving parts - Constant pressure drop - Can separate both solid and liquid particles, sometimes both simultaneously 2.1.3 Disadvantages of cyclones: - Low efficiency especially for very small particles - High operating costs in case of high pressure drop - Subject to erosion or clogging if abrasive solids are processed. 2.1.4 Principle of operation: - The spiral pattern of gas flow is developed by the manner in which the gas is introduced. It enters along the side of the

cyclone body wall and turns a number of times to spiral down (external vortex) to the bottom. Particles in the gas are subjected to centrifugal forces which move them radially outwards, against the inward flow of gas and towards the inside surface of the cyclone. When the gas reaches the bottom of the cyclone, it reverses direction and flows up the center of the tube, also in a spiral fashion. This spiral fashion is also called inner vortex and fine particles are carried with the air and leave the cyclone through the immersion tube. Solids at the wall are pushed downwards by the outer vortex and out of the solids exit. - Gravity has been shown to have little effect on the cyclone's operation. See the figures on the right side and below.

2.1.5 Forces affecting the particles - We consider a reverse flow cyclone with a cylindrical section of radius R. Particles entering the cyclone with the gas stream are forced into a circular motion. - The forces acting on a particle following a circular path are drag, buoyancy and centrifugal force (Fd, Fb and Fc). - The balance between these forces determines the equilibrium orbit adopted by the particle. - The drag force is caused by the inward flow of gas part the particle and acts radially inwards. Considering a particle of diameter x and density

p following an orbit of radius r in a gas of density f and viscosity ,

We have the tangential velocity of the particle be U and the radial inward velocity of the gas be Ur. If we assume that the Stokes law applies under these conditions then the drag force is given by:

- The centrifugal and buoyancy forces acting on the particle moving with a tangential velocity component U at radius r are,

We can neglect the buoyancy force. - And at a steady state, we have:

2.1.6 Flow Characteristics - The rotational flow in the forced vortex within the cyclone body gives rise to a radial pressure gradient. - This pressure gradient, combined with the frictional pressure losses at the gas inlet and outlet and losses due to changes in flow direction, make up the total pressure drop. - The pressure drop, measured between the inlet and gas outlet, is usually proportional to the square of gas flow rate through the cyclone. - A resistance coefficient, the Euler number Eu, relates the cyclone pressure drop p to a characteristic velocity:

Where

f is the gas density

- The velocity v is based on the cross-section of the cylindrical body of the cyclone:

Where Q is the gas flow rate and D is the cyclone inside diameter

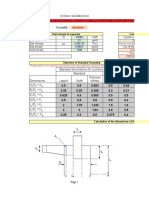

- The Euler number represents the ratio of pressure forces to the inertial forces acting on a fluid element. - Value is practically constant for a given cyclone geometry, independent of the cyclone body diameter. 2.1.7 Mechanical parts: - Tangential inlet volute - Cylindrical section - Immersion tube - Conical section - Discharge (rotary valve, pendulum flap) 2.1.8 Cyclones families: - Conventional - High efficiency - High capacity See the figure on the right: 2.1.9 Design of the cyclones: - Dimensions: a = Height of tangential inlet b = Width of tangential inlet De = Diameter of air outlet tube S = Immersion length of outlet tube D = Cyclone diameter h = Length of cylindrical section z = Length of conical section H = Cyclone length B = Diameter of material outlet - On the sheet below, we can have a good idea of the standard cyclone dimensions for each family:

- Regardless of the configuration selected, we must follow the following recommendations: a S to avoid the by-pass of the particules from the input section directly to the tube exit b (D-De)/2 to avoid an excessive pressure drop H 3D to keep the tip of the vortex formed by the gases inside the conical section of the cyclone The inclination angle of the cone of the cyclone should be 7-8 to ensure a quick slide of the powder De/D 0,4-0,5, H/De 8-10 and s/De 1 to ensure the operation with the maximum efficiency 2.1.10 Cyclones scale-up: - The scale-up of cyclones is based on a dimensionless parameter, the Stokes number,which characterizes the separation performance of a family of geometricallysimilar cyclones. The Stokes number (Stk50) is dened as:

- It is interesting to find that, for well-designed and well-known cyclones, there is a direct correlation between Eu and Stk50:

- For Stairmand high-efficiency cyclones: Stk50 = 1,4/10000 and Eu = 320 - For Stairmand high-capacity cyclones: Stk50 = 6/1000 and Eu = 46 2.1.11 Cyclone's efficiency: - A model widely accepted is use for determining the efficiency of a cyclone. - In this model, Ne is the number of revolutions the gas falling in the outer vortex. The equation is:

See the "Design of cyclones" section to know the parameters - With the model of Lapple (1951) which is an empirical relationship in order to calculate the cut size (50% of efficiency), we have:

Where:

Vi is gas inlet velocity in m/h (range in m/sec: 15-30 m/sec) and

is the air viscosity in kg/m.h b is the width of the tangential inlet in m

p is the solid density in kg/m3 f is the air density in kg/m3 The efficiency (i) of any size of particle is given by the following formula:

Where Di is the particle of reference of a range - The overall efficiency of the cyclone is a weighted average of the collection efficiencies for the various size ranges and is given by:

Where mi is the mass of particles in a certain range and

M is the total mass of particles

This efficiency can be undervalued with the concentration of solid particles in the air flow rate. Then, when the concentration is higher than 2 gr/m3, a correction is applied:

where 1 is the efficiency found,

C1 is 2 (gr/m3), 2 is the new efficiency and C2 is the concentration in dust

2.1.12 Cyclone's pressure drop: - In the evaluation of a cyclone design, pressure drop is a primary consideration. Because it is directly proportional to the energy requirement, under any circumstance, knowledge of pressure drop through a cyclone is essential in designing a fan system. - Many models have been developed to determine the cyclone pressure drop but one of the well accepted is the model of Shepherd and Lapple (1939). The formula of p is:

K is a constant: K = 16 for tangential inlet without neutral inlet vane

K = 7,5 if tangential inlet with neutral inlet vane and large cyclones It is better to keep a pressure drop lower than 2,5 kPa. 2.1.13 Design modifications and consequences:

2.1.14 General methodology for the design of cyclones - 1. Select a configuration (conventional, high efficiency or high capacity) - 2. Select a speed at inlet (15-30 m/sec) - 3. In function of the flow rate importance, it is useful to have a 1st estimation of the cyclones number - 4. Calculate the diameter of the cylindrical section of the cyclone D - 5. Calculate the other dimensions of the cyclone on the basis of the table for the selected configuration - 6. Calculate the pressure drop - 7. To analyze if D and p are excessively large. Analyze the possibility of using various cyclones in parallel. For nc cyclones in parallel repeat items 2 and 3 using the value of Q/nc in place - 8. Calculate efficiencies for fractions and the total - 9. Compare the calculated efficiency with desired. If you do not achieve the desired value, use a larger value of speed inlet - 10. Estimate the cost of the cyclone

2.1.15 Example of calculation: - We want to install cyclone(s) with following data: - ventilation flow rate: 160 000 m3/h - temperature: 90 C - altitude: 1 000 m - dust concentration: 80 gr/m3 - dust density: 1 600 kg/m3 - desired pressure loss: 150 mmWG - Space restriction: maximum height of cyclone: 9 m - Typical feed of the cyclone: Dimension 1 2 5 10 16 32 45 63 90 140 % residue cumulated 99 96 91 85 71 59 35 20 8 1 size intervals 01 12 25 510 1016 1632 3245 4563 6390 90140 > 140 mass in gr 2,2 6,6 11 13,2 30,8 26,4 52,8 33 26,4 17,6 0 220 - Calculate: - number of cyclones and cyclones dimensions % residue partial 1 3 5 6 14 12 24 15 12 8 0 100

- pressure drop - efficiency - check if all is OK - Calculation of air density: - pressure (ph) at 1000m over the sea level with the formula:

- air density (f) with the formula:

where t is the gas temperature in C

Following the methodology: 1 Configuration: We choose: High Capacity Stairmand

2 Speed inlet: We choose: 20 m/sec 3 Cyclones number first estimation: At the moment, we choose: 1 cyclone Then, the flow rate for calculation is: 160 000 m3/h or 44,444 m3/sec 4 Cyclone diameter calculation: With the formula:

5 Other dimensions of the cyclone:

6 Pressure drop calculation: With the formula:

Note: we selected K = 16 in this case 7 Check if diameter and pressure drop are OK: Pressure drop is Ok because 1380,1 Pa = 140,7 mmWG < 150 mmWG There is a problem with the height of the cyclone: 11,280 m > 9 m Then we calculate again for 2 cyclones, Q becomes 160 000 m3/h divided by 2 = 80 000 m3/h = 22,222 m3/sec Using the same formula, we will have:

Note, the pressure drop is the same because dimension parameters are of the same configuration! Now, it is OK. The cyclone have a height of 8 m < max. 9m 8 Efficiencies calculation:

and:

where = 0,0765 kg/m.h Then, we use the equation:

where Di is the average size of each interval size intervals 01 12 25 510 1016 1632 3245 Average size 0,5 1,5 3,5 7,5 13 24 38,5

4563 6390 90140 For example, we have for 0,5 :

54 76,5 115

Results for all sizes:

size intervals 01 12 25 510 1016 1632 3245 4563 6390 90140

Average size 0,5 1,5 3,5 7,5 13 24 38,5 54 76,5 115

0,00128302177287949 0,0114298777003086 0,0592209424589986 0,22423535743116 0,464793283874561 0,747467079330783 0,883947753305672 0,937438968817134 0,967817554669971 0,985498639024517

The next step is to multiply i by the partial residue of the interval (or mass), and to make the sum for all sizes in order to have the total efficiency:

size intervals 01 12 25 510 1016 1632 3245 4563 6390 90140

Average size 0,5 1,5 3,5 7,5 13 24 38,5 54 76,5 115

0,00128302177287949 0,0114298777003086 0,0592209424589986 0,22423535743116 0,464793283874561 0,747467079330783 0,883947753305672 0,937438968817134 0,967817554669971 0,985498639024517

i X mi % residue partial 1 0,00128302177287949 3 0,0342896331009258 5 0,296104712294993 6 1,34541214458696 14 6,50710597424385

12 24 15 12 8 8,9696049519694 21,2147460793361 14,061584532257 11,6138106560397 7,88398911219613 71,93 %

As we have a concentration of 80 gr/m3 in the inlet of the cyclone, we modify the efficiency with:

Conclusion, the efficiency is 85,66% 9 Checking of the efficiency: If it is not enough, we have to recalculate with a higher inlet velocity

Potrebbero piacerti anche

- Cyclone Spreadsheet AC080120Documento10 pagineCyclone Spreadsheet AC080120Azba ZuggishNessuna valutazione finora

- Ejector vs Eductor - What's the DifferenceDocumento2 pagineEjector vs Eductor - What's the DifferencePierre NorrisNessuna valutazione finora

- Spreadsheet Heat Loss from a PipeDocumento1 paginaSpreadsheet Heat Loss from a PipeJogender DhayalNessuna valutazione finora

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDa EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNessuna valutazione finora

- XCELDocumento2 pagineXCELridanormaNessuna valutazione finora

- Replacement of Chiller SystemDocumento71 pagineReplacement of Chiller Systemmoejamal80Nessuna valutazione finora

- Cyclone SeparatorsDocumento46 pagineCyclone SeparatorsRahul Patel100% (1)

- Cyclone PDFDocumento34 pagineCyclone PDFRodrigo Florindo100% (1)

- Tupia - 17 Molduras Com 3 BitsDocumento5 pagineTupia - 17 Molduras Com 3 Bitsleocadio_01100% (1)

- Machine Design: Stress Concentration FactorsDocumento30 pagineMachine Design: Stress Concentration FactorsM.HNessuna valutazione finora

- Rectangular Concrete Beam, Column Analysis and DesignDocumento17 pagineRectangular Concrete Beam, Column Analysis and DesignRohit Khandelwal100% (3)

- Folding Bench and Picnic Table Combo 8pagesDocumento8 pagineFolding Bench and Picnic Table Combo 8pagesannymentges100% (1)

- Module # 5: Separation EquipmentsDocumento34 pagineModule # 5: Separation EquipmentsManojMauryaNessuna valutazione finora

- Baterlle Two CurveDocumento20 pagineBaterlle Two CurveAdam ThomsonNessuna valutazione finora

- SizingAndSelectionOfHydrocyclones Rev2Documento43 pagineSizingAndSelectionOfHydrocyclones Rev2RAVI1972100% (2)

- Steel DesignDocumento180 pagineSteel DesignAndrick Alvarez100% (2)

- FPI FiberglassbookDocumento164 pagineFPI FiberglassbookA_ValsamisNessuna valutazione finora

- Hydro Cyclone Thesis 2007Documento239 pagineHydro Cyclone Thesis 2007wyma01100% (1)

- Size ReductionDocumento24 pagineSize ReductionKarynne Bernardine Gerona SiclotNessuna valutazione finora

- Modeling Cyclone PerformanceDocumento4 pagineModeling Cyclone PerformancesergioNessuna valutazione finora

- Powder transfer rate and vacuum system sizingDocumento3 paginePowder transfer rate and vacuum system sizingm_nassifNessuna valutazione finora

- 9 Transport of Particles by FluidsDocumento8 pagine9 Transport of Particles by FluidsArun AppaduraiNessuna valutazione finora

- Decanter DesignDocumento3 pagineDecanter DesignFiza Nnazlan100% (5)

- Spray tower: countercurrent gas-liquid contactorDocumento6 pagineSpray tower: countercurrent gas-liquid contactorihllhm100% (1)

- ScrubberDocumento68 pagineScrubberPitiporn Hasuankwan100% (1)

- Cyclone Design - Stairmand MethodDocumento4 pagineCyclone Design - Stairmand MethodFaizan AhmedNessuna valutazione finora

- Thermal design of a 2-effect forward-feed evaporatorDocumento4 pagineThermal design of a 2-effect forward-feed evaporatorAristya KurniawanNessuna valutazione finora

- 7 Quencher DesignDocumento8 pagine7 Quencher DesignJozsef Acs100% (1)

- Cyclone CalculatorDocumento19 pagineCyclone CalculatornarsingrameshNessuna valutazione finora

- Coal Calculation 2Documento2 pagineCoal Calculation 2Hanuman TripathiNessuna valutazione finora

- Cyclone Design Calculation Tool SimplifiedDocumento6 pagineCyclone Design Calculation Tool SimplifiedKevin WilliamNessuna valutazione finora

- Design of Shell & Tube HXDocumento62 pagineDesign of Shell & Tube HXUmirahRashidahNessuna valutazione finora

- Burner CalculationDocumento9 pagineBurner CalculationAbul QasimNessuna valutazione finora

- A Venturi Scrubber Used To Clean Gasifier Syngas Results in PDFDocumento5 pagineA Venturi Scrubber Used To Clean Gasifier Syngas Results in PDFPaoLa MonTañoNessuna valutazione finora

- Energy BalanceDocumento11 pagineEnergy BalanceBharat VaajNessuna valutazione finora

- Cyclone Performance and Design PDFDocumento23 pagineCyclone Performance and Design PDFIstván SzékelyNessuna valutazione finora

- Cyclone Separator Design: The Optimum Velocity of Separator Range Is 10-20 M/secDocumento7 pagineCyclone Separator Design: The Optimum Velocity of Separator Range Is 10-20 M/secmohsinziaNessuna valutazione finora

- Bag FilterDocumento27 pagineBag FiltermkpqNessuna valutazione finora

- Data Sheet CyclonesDocumento1 paginaData Sheet Cycloneslatif.deNessuna valutazione finora

- Design of Trombone Cooler For GassesDocumento2 pagineDesign of Trombone Cooler For GassesFahad Bin Ali100% (2)

- Coal Gasifier ProcessesDocumento28 pagineCoal Gasifier ProcessesH Janardan PrabhuNessuna valutazione finora

- Bag Filter CalculationDocumento3 pagineBag Filter CalculationJag KhadseNessuna valutazione finora

- Ventury Scrubber Design MethodDocumento3 pagineVentury Scrubber Design MethodPukhraj DagaNessuna valutazione finora

- Wetscrubber VenturiDocumento10 pagineWetscrubber Venturiakifah100% (1)

- PV Wet ScrubberDocumento7 paginePV Wet ScrubberCepi Sindang KamulanNessuna valutazione finora

- Nozzle CriteriaDocumento2 pagineNozzle CriteriaKhalil LasferNessuna valutazione finora

- The Hydrocyclone: International Series of Monographs in Chemical EngineeringDa EverandThe Hydrocyclone: International Series of Monographs in Chemical EngineeringValutazione: 5 su 5 stelle5/5 (3)

- Cyclone SeparatorDocumento1 paginaCyclone SeparatorDan Toader100% (1)

- Vertical Spray Tower For Gas ScrubbingDocumento2 pagineVertical Spray Tower For Gas ScrubbingJag Khadse100% (1)

- TEMA E shell and tubes heat exchanger calculationDocumento9 pagineTEMA E shell and tubes heat exchanger calculationjnmanivannanNessuna valutazione finora

- Venturi Scrubber Theory & ExperimentDocumento6 pagineVenturi Scrubber Theory & ExperimentTian Fung Wang100% (1)

- Wet scrubber technology for air pollution controlDocumento3 pagineWet scrubber technology for air pollution controlRoger FernandezNessuna valutazione finora

- Cyclone Excel Calculation - Google SearchDocumento2 pagineCyclone Excel Calculation - Google SearchFucKerWengieNessuna valutazione finora

- Assignment (Air Pollution)Documento7 pagineAssignment (Air Pollution)Durga Prasad Murmu0% (1)

- Test Cyclone ExcelDocumento16 pagineTest Cyclone Excelvivek mishraNessuna valutazione finora

- Ball Mill Design - CompressDocumento6 pagineBall Mill Design - CompressSuresh VedalaNessuna valutazione finora

- Cyclone Separator Press DropDocumento2 pagineCyclone Separator Press DropCristian MartínezNessuna valutazione finora

- Vapor Line Sizing-Mpp6Documento10 pagineVapor Line Sizing-Mpp6Nitin KurupNessuna valutazione finora

- Cyclone Design Calculation Tool SimplifiedDocumento6 pagineCyclone Design Calculation Tool SimplifieddadNessuna valutazione finora

- Sly Venturi ScrubberDocumento2 pagineSly Venturi Scrubberzguy360Nessuna valutazione finora

- MEDIACalculator (Raw Mill2)Documento4 pagineMEDIACalculator (Raw Mill2)irfanNessuna valutazione finora

- Specifying Venturi Scrubber Throat Length For PDFDocumento5 pagineSpecifying Venturi Scrubber Throat Length For PDFChristopher LloydNessuna valutazione finora

- Ecway Technologies: Design and Fabrication of Cyclone Seperator Using Vane PumpDocumento9 pagineEcway Technologies: Design and Fabrication of Cyclone Seperator Using Vane Pumpieee4mybusinessonly100% (1)

- Ammonium 2520sulphate Material 2520balance.Documento9 pagineAmmonium 2520sulphate Material 2520balance.AgadmatorNessuna valutazione finora

- MP305 PDFDocumento40 pagineMP305 PDFrichardstormNessuna valutazione finora

- Chlorine: International Thermodynamic Tables of the Fluid StateDa EverandChlorine: International Thermodynamic Tables of the Fluid StateNessuna valutazione finora

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- Logosophy - The Need For Balance When Judging ValuesDocumento8 pagineLogosophy - The Need For Balance When Judging ValuesFDLTLSNessuna valutazione finora

- OKI C910 User GuideDocumento112 pagineOKI C910 User GuideFDLTLSNessuna valutazione finora

- Logosophy - Haste As The Denial of TimeDocumento4 pagineLogosophy - Haste As The Denial of TimeFDLTLSNessuna valutazione finora

- Hydro Impulse Turbine Speed RegulationDocumento3 pagineHydro Impulse Turbine Speed RegulationFDLTLSNessuna valutazione finora

- Logosophy - Focusing On Objective RealitiesDocumento4 pagineLogosophy - Focusing On Objective RealitiesFDLTLSNessuna valutazione finora

- Best Weekend ProjectsDocumento196 pagineBest Weekend ProjectsFDLTLS100% (3)

- Logosophy - Orientation For The YoungDocumento4 pagineLogosophy - Orientation For The YoungFDLTLSNessuna valutazione finora

- Logosophy - Fundamental Questions On Human LifeDocumento7 pagineLogosophy - Fundamental Questions On Human LifeFDLTLSNessuna valutazione finora

- JazzBass - Eletric Layout1 PDFDocumento1 paginaJazzBass - Eletric Layout1 PDFFDLTLSNessuna valutazione finora

- 12Documento23 pagine12FDLTLSNessuna valutazione finora

- 12Documento23 pagine12FDLTLSNessuna valutazione finora

- FEM9.512 EnglDocumento12 pagineFEM9.512 EnglFDLTLSNessuna valutazione finora

- WaterPower&Dam - Nov09Documento44 pagineWaterPower&Dam - Nov09FDLTLS100% (1)

- Best Practice Guide Impulse Lines For Differential-Pressure FlowmetersDocumento22 pagineBest Practice Guide Impulse Lines For Differential-Pressure FlowmetersamietkolteNessuna valutazione finora

- Definition, types and analysis of statically determinate and indeterminate beamsDocumento47 pagineDefinition, types and analysis of statically determinate and indeterminate beamsJack PresadoNessuna valutazione finora

- Python 5Documento5 paginePython 5sasdffgNessuna valutazione finora

- Conduction HTDocumento25 pagineConduction HTRamaneish SivarajNessuna valutazione finora

- 1345 3539 1 SMDocumento10 pagine1345 3539 1 SMYoga PrasytioNessuna valutazione finora

- Determining The Velocity of Sound in The Air Using Resonance TubeDocumento12 pagineDetermining The Velocity of Sound in The Air Using Resonance TubeRara Aisyah RamadhanyNessuna valutazione finora

- Annurev FL 26 010194 000323Documento41 pagineAnnurev FL 26 010194 000323henkNessuna valutazione finora

- Seismic Isolation Product Line-UpDocumento9 pagineSeismic Isolation Product Line-UpSyafrul MubaraqNessuna valutazione finora

- Electronics CoolingDocumento31 pagineElectronics Coolingvicky3000Nessuna valutazione finora

- MM658 HandoutDocumento1 paginaMM658 Handoutmanojpatel2410Nessuna valutazione finora

- 3 - Absolute, Effective and Relative PermeabilitiesDocumento34 pagine3 - Absolute, Effective and Relative PermeabilitiesAhmad MammadovNessuna valutazione finora

- PHYS 20 - Chapter 4 - Work, Energy and PowerDocumento22 paginePHYS 20 - Chapter 4 - Work, Energy and PowerbuicoandrieNessuna valutazione finora

- Ind PDFDocumento33 pagineInd PDFGlory Frans Jane BesañesNessuna valutazione finora

- Heat Transfer Coefficient of Composite WallsDocumento14 pagineHeat Transfer Coefficient of Composite WallsbonnieNessuna valutazione finora

- Natural Gas Homework2Documento42 pagineNatural Gas Homework2Khanz KhanNessuna valutazione finora

- Simulation of Viscoelastic Materials in AbaqusDocumento5 pagineSimulation of Viscoelastic Materials in AbaqusRahulprabhakaran VannostranNessuna valutazione finora

- Route Selection and Deepwater Pipeline DesignDocumento19 pagineRoute Selection and Deepwater Pipeline DesignSampurnanand PandeyNessuna valutazione finora

- Article JAS Cyclone Revised R2 PDFDocumento24 pagineArticle JAS Cyclone Revised R2 PDFAinaNessuna valutazione finora

- Gas Dynamics Report ValidationDocumento8 pagineGas Dynamics Report ValidationM.t. HabibiNessuna valutazione finora

- Ressa Reslope and MsewDocumento2 pagineRessa Reslope and Msewchehalis0% (1)

- In Situ Tests and The Pre-Failure Deformation Behaviour of SoilsDocumento6 pagineIn Situ Tests and The Pre-Failure Deformation Behaviour of SoilsLTE002Nessuna valutazione finora

- Convection vs. Conduction: Newton's Law of CoolingDocumento2 pagineConvection vs. Conduction: Newton's Law of CoolingAriel GonzalesNessuna valutazione finora

- Muranga Ees 201 Tut 1Documento3 pagineMuranga Ees 201 Tut 1jonathan otienoNessuna valutazione finora

- SATURATION NUCLEATE POOL BOILING - A SIMPLE CORRELATIONDocumento9 pagineSATURATION NUCLEATE POOL BOILING - A SIMPLE CORRELATIONForcus on100% (1)