Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bulacan State University College of Engineering: Ce 483 Timber Design Types of Stresses For Structural Wood

Caricato da

Sandro SorianoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bulacan State University College of Engineering: Ce 483 Timber Design Types of Stresses For Structural Wood

Caricato da

Sandro SorianoCopyright:

Formati disponibili

Bulacan State University College of Engineering

CE 483 TIMBER DESIGN TYPES OF STRESSES FOR STRUCTURAL WOOD

Prepared By: Kazene Allene F. Zuiga CE 4B

Submitted to: Engr. Vilma Gonzales

TYPES OF STRESSES FOR STRUCTURAL WOOD Bending Stress, Fb When a load is applied to the middle of a beam supported at both ends, it tends to bend the piece, producing bending stresses. But when you look more closely at it, bending is really a combination of compressive, tensile and shear stresses. This is because: the top part of the beam tends to shorten, producing compressive stresses the bottom tends to lengthen, producing tensile stresses the interaction of compressive and tensile stresses produce shear, as the different layers try to slide over each other. When loads are applied, structural members bend, producing tension in the fibers along the face farthest from the applied load, and compression in the fibers along the face nearest to the applied load. This induced stresses are designated as Extreme Fiber Stress in Bending.

Shear Stress, Fv A load which tends to slide one part of a member over an adjacent part produces shear stresses.This can occur in places where a defect in the member might weaken the wood fibres and cause them to split along the grain, such as in the top plate of a wall frame. A force applied causing one section of the piece to shear or slide along the on the other section in a direction parallel to grain. In a loaded beam where the induced stress on the side is compression and on the other side is tension, there is a tendency to create shearing stress parallel to grain. The largest shear parallel to grain stress usually occurs along the neutral axis on the plane at which the induced stress changes from compression to tension.

Tensile Stress, Ft A load which tends to stretch a member produces tensile stresses.This happens to members designed to stop a pulling-apart action,such as a ceiling joist fixed to the foot of two rafters,resisting their tendency to spread apart under the roof load. A force generating tension parallel to grain, creates a tendency to elongate the wood fibers and to cause them to slip by each other. Resistance to tension applied strictly parallel to grain is the highest strength property of wood. This resistance, however, is substantially reduced when the force is applied at an angle to the grain or when the cross section of the piece is reduced by knots or holes.

Tensile Flexural Stress, Ft This are similar to compression parallel to grain in that they act across the full cross section and tend to stretch the member.

Compressive Structural Stress, Fc A load which tends to shorten or crush a member produces compressive stresses. This particularly applies to supporting members such as a post supporting a beam. Applied stresses from this type of loading are generally considered consistent across the entire cross-section of the member, and the fibers are uniformly stressed parallel to the grain along the full length of the member.

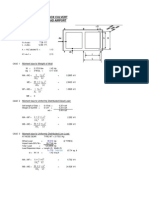

Axial Compressive Stress The working stress in static compression parallel to the grain for green untreated timber piles is determined per ASTM D 2899 using the following equation: C= (S 1.645SD) / 1.88

where :

S = Average small clear crushing strength determined from ASTM D 2555 SD = Standard deviation of small clear crushing strength.

For dynamic stresses (short term stresses due to pile installation), the working stress parallel to the grain is three times the static working stress parallel to the grain for green untreated timber piles. Extreme Fiber Bending Stress The extreme fiber bending stress for timber piles (f) is determined per ASTM D 2899 using the following equation : f = (S 1.645SD) / 2.04 where : S = Average small clear bending strength determined per ASTM D 2555 SD = Standard deviation of small clear bending strength.

For dynamic stresses (short term stresses due to pile installation) the working stress for small clear wood bending strength is three times the static working stress for small clear wood bending strength for green untreated timber piles (f).

Compressive Stress, Fc, Parallel to Grain A force generating compression parallel to grain creates a tendency to compress the wood fibers in lengthwise position. As with tension resistance to compression parallel to grain is affected by the angle of load to grain and by the presence of knots and holes.

Compressive Stress Perpendicular to the Grain The working stress in compression, perpendicular to the grain, for green untreated timber piles is determined per ASTM D 2899 using the following equation: C = S / 1.5 where : S = Average proportional limit stress of small clear specimens determined per ASTM D 2555 A force applied perpendicular to grain, such as the bearing under the ends of a beam, tends to compress the wood at its surface. While the wood becomes more than dense as it is compressed, this action causes slight displacement of the supported member. Thus, limits are placed on loading in bearing perpendicular to grain. For sawn lumber, the compression perpendicular to grain values are based on a deformation limit that has been shown by experience to provide for adequate service in typical wood frame construction. Therefore, stress modifications for duration of load are not applicable to compression perpendicular to grain allowable stresses for sawn lumber.

Shear Stress Perpendicular to the Grain The working stress in horizontal shear perpendicular to the grain for green untreated timber piles () is determined per ASTM D 2899 using the following equation:

= (S 1.645SD) / 5.47 where : S = Average small clear shear strength specimens determined per ASTM D 2555 SD = Standard deviation of small clear shear strength.

Modulus of Elasticity The average small clear modulus of elasticity values determined per ASTM D 2555 shall be taken as the values for timber piles. Elasticity implies that deformation produced by low stresses is completely recoverable after loads are removed. When loaded to higher stress levels, plastic deformation or failure occurs. The three moduli of elasticity, which are denoted by El, Er, and Et, respectively, are the elastic moduli along the longitudinal, radial, and tangential axes of wood.

Modulus of Rigidity, G The modulus of rigidity, also called shear modulus, indicates the resistance to deflection of a member caused by shear stress. The three moduli of rigidity is denoted by Glr, Glt, and Grt are the elastic constants in Lr, Lt and Rt plane, respectively.

Potrebbero piacerti anche

- CEng Career AssessmentDocumento11 pagineCEng Career AssessmentKarthik Dhayalan50% (4)

- Compressive Strength of WoodDocumento6 pagineCompressive Strength of Woodatreu747100% (2)

- API570 Training Book PDFDocumento312 pagineAPI570 Training Book PDFRamziAhmed100% (4)

- CIVE 302 - Lab 1 - Tensile Testing of Steel PDFDocumento9 pagineCIVE 302 - Lab 1 - Tensile Testing of Steel PDFAhmadAliAKbarPhambraNessuna valutazione finora

- Legal Medicine Complete)Documento6 pagineLegal Medicine Complete)Manuel Rodriguez II88% (17)

- Mechanical Design and Stress Analysis of a Distillation ColumnDocumento7 pagineMechanical Design and Stress Analysis of a Distillation ColumnSumant Pilgaonkar100% (1)

- Tension Members DesignDocumento30 pagineTension Members Designrameshbabu_1979Nessuna valutazione finora

- Basic Mechanics Principles Explained</h1Documento20 pagineBasic Mechanics Principles Explained</h1Manoj ReddyNessuna valutazione finora

- File Ms Fox LentDocumento4 pagineFile Ms Fox LentFilthy SoufNessuna valutazione finora

- Elasticity With Lecture 2020Documento5 pagineElasticity With Lecture 2020mean comiaNessuna valutazione finora

- Wood Strength Definitions ExplainedDocumento2 pagineWood Strength Definitions Explainedjoana quiambaoNessuna valutazione finora

- Module3 Design of Tension MembersDocumento33 pagineModule3 Design of Tension MembersPrem KumarNessuna valutazione finora

- STRENGTH OF MATERIALS EQUATIONSDocumento7 pagineSTRENGTH OF MATERIALS EQUATIONSChristianNessuna valutazione finora

- MODULE 1 Introduction and Simple Stresses 2Documento10 pagineMODULE 1 Introduction and Simple Stresses 2Geri LazaroNessuna valutazione finora

- FALLSEM2018-19 MEE1006 ETH TT201 VL2018191005146 Reference Material I Deformation of SoildsDocumento21 pagineFALLSEM2018-19 MEE1006 ETH TT201 VL2018191005146 Reference Material I Deformation of SoildsSHUBHAM KUMARNessuna valutazione finora

- Chapter 1-Stress & StrainDocumento35 pagineChapter 1-Stress & StrainMUHAMMAD HAFIZ KAMAL MOHAMAD KAMALNessuna valutazione finora

- Timber Note 1 Properties of Timber MaterialsDocumento4 pagineTimber Note 1 Properties of Timber MaterialsChiranjaya HulangamuwaNessuna valutazione finora

- CEC 106 Strength of Materials 2020/2021 Session Strength of MaterialsDocumento7 pagineCEC 106 Strength of Materials 2020/2021 Session Strength of MaterialsAbu Muhammad AssalafiyNessuna valutazione finora

- Topic Cover: Stress and StrainDocumento42 pagineTopic Cover: Stress and StrainVinaasha BalakrishnanNessuna valutazione finora

- Nilson-Transformed Area MethodDocumento45 pagineNilson-Transformed Area MethodAhmer MehmoodNessuna valutazione finora

- rc-1 2015-16 Chapter Three 080116Documento28 paginerc-1 2015-16 Chapter Three 080116ABAMELANessuna valutazione finora

- Secondary stresses plate stiffenersDocumento10 pagineSecondary stresses plate stiffenersAnonymous JSHUTpNessuna valutazione finora

- Design of Tension MembersDocumento30 pagineDesign of Tension Memberssharer1Nessuna valutazione finora

- EBB 220/3 Failure in PolymersDocumento58 pagineEBB 220/3 Failure in PolymersespirhalNessuna valutazione finora

- Compendium of SomDocumento13 pagineCompendium of SomVivek BajpaiNessuna valutazione finora

- Line Practice Concrete: Effect of Eccentric Loading of ColumnsDocumento3 pagineLine Practice Concrete: Effect of Eccentric Loading of Columnsgnanasekar007Nessuna valutazione finora

- Strength Failure Modes Sandwich StructuresDocumento6 pagineStrength Failure Modes Sandwich StructuresPrudvi Krishna MaladiNessuna valutazione finora

- Stress and StrainDocumento9 pagineStress and StrainJulian AdamNessuna valutazione finora

- MECHANICAL PROPERTIES OF SOLIDSDocumento40 pagineMECHANICAL PROPERTIES OF SOLIDSfelicia.wNessuna valutazione finora

- Dental Materials Mechanical PropertiesDocumento136 pagineDental Materials Mechanical PropertiesDiksha SolankiNessuna valutazione finora

- Stress and Strain - Class 1Documento21 pagineStress and Strain - Class 1Ahmad AliyuNessuna valutazione finora

- Plastic Behaviour of SteelDocumento16 paginePlastic Behaviour of SteelRøãrîñg GîrîshNessuna valutazione finora

- Structural Materials and Their PropertiesDocumento32 pagineStructural Materials and Their PropertiesChristian Tilia100% (1)

- Wires in OrthodonticsDocumento282 pagineWires in OrthodonticsDr Kiara Kirpalani100% (2)

- Chapter 29Documento66 pagineChapter 29Byron MantheyNessuna valutazione finora

- Leс3Documento22 pagineLeс3PaulNessuna valutazione finora

- Stress and StrainDocumento14 pagineStress and StrainEFRAIM CAMBENessuna valutazione finora

- CHAPTER THREE Fractures - JointDocumento27 pagineCHAPTER THREE Fractures - Jointأمجد هاتف منفي جفالNessuna valutazione finora

- 1 Stress Strain SMDocumento39 pagine1 Stress Strain SMsameerajuvathNessuna valutazione finora

- Basic Properties of Dental MaterialsDocumento17 pagineBasic Properties of Dental MaterialsUmut ASLANNessuna valutazione finora

- Yield Strength, Elastic Limit, and Ultimate StrengthDocumento4 pagineYield Strength, Elastic Limit, and Ultimate StrengthBianca MihalacheNessuna valutazione finora

- Notes/Lect 4 MMTDocumento19 pagineNotes/Lect 4 MMTKeilla Romabiles LeopandoNessuna valutazione finora

- Addis Ababa University Lecture NoteDocumento65 pagineAddis Ababa University Lecture NoteTADY TUBE OWNER100% (9)

- Bolt Joint - The ChallengeDocumento37 pagineBolt Joint - The ChallengeThái Đạo Phạm LêNessuna valutazione finora

- Module-1 Stresses and StrainsDocumento33 pagineModule-1 Stresses and StrainsC.E.M JEFFREYSNessuna valutazione finora

- Assignment No. 5 JJJJJJDocumento9 pagineAssignment No. 5 JJJJJJNicholas Bonn SingNessuna valutazione finora

- Machine Part Stress AnalysisDocumento23 pagineMachine Part Stress AnalysismujtabahassanNessuna valutazione finora

- Strength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsDocumento34 pagineStrength of Materials (15CV 32) : Module 1: Simple Stresses and StrainsAnonymous Qm0zbNkNessuna valutazione finora

- Mechanical Properties PDFDocumento57 pagineMechanical Properties PDFvardhaNessuna valutazione finora

- Design of Steel Structure BeamDocumento17 pagineDesign of Steel Structure BeamShahrah ManNessuna valutazione finora

- Assignment No. 4: Archirectural Representation and DetailingDocumento11 pagineAssignment No. 4: Archirectural Representation and DetailingHritika JagtapNessuna valutazione finora

- Stress-Strain CurveDocumento7 pagineStress-Strain CurveR BNessuna valutazione finora

- Columns: Design and BehaviorDocumento10 pagineColumns: Design and Behavior晓春王Nessuna valutazione finora

- Properties of Materials - Tensile PropertiesDocumento2 pagineProperties of Materials - Tensile PropertiesAamir BugtiNessuna valutazione finora

- Measuring Mechanical Properties of MaterialsDocumento25 pagineMeasuring Mechanical Properties of MaterialsUmesh ChandraNessuna valutazione finora

- Dental Materials Science PDF PDFDocumento257 pagineDental Materials Science PDF PDFIonela MadalinaNessuna valutazione finora

- Trusses How They WorkDocumento7 pagineTrusses How They Workprabhu81Nessuna valutazione finora

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingDa EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNessuna valutazione finora

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Instructions on Modern American Bridge BuildingDa EverandInstructions on Modern American Bridge BuildingNessuna valutazione finora

- Dorotheo Vs CADocumento3 pagineDorotheo Vs CASandro SorianoNessuna valutazione finora

- Land Acquisition OFWs.070605Documento5 pagineLand Acquisition OFWs.070605Jai CarungayNessuna valutazione finora

- Taxation I: General Principles and Nature of TaxationDocumento4 pagineTaxation I: General Principles and Nature of TaxationSandro SorianoNessuna valutazione finora

- Raw File TestDocumento1 paginaRaw File TestSandro SorianoNessuna valutazione finora

- ConflictDocumento8 pagineConflictarcheee2345Nessuna valutazione finora

- Daemon ProcessDocumento6 pagineDaemon ProcessSandro SorianoNessuna valutazione finora

- FormulasDocumento11 pagineFormulasSandro SorianoNessuna valutazione finora

- Defects of TimberDocumento10 pagineDefects of TimberSandro Soriano100% (1)

- Diaz v. Intermediate Appellate CourtDocumento13 pagineDiaz v. Intermediate Appellate CourtSandro SorianoNessuna valutazione finora

- PPL V BustineraDocumento13 paginePPL V BustineraSandro SorianoNessuna valutazione finora

- PPL V TanDocumento9 paginePPL V TanSandro SorianoNessuna valutazione finora

- 2011 NLRC Rules of Procedure Eb 11-12Documento7 pagine2011 NLRC Rules of Procedure Eb 11-12hobbesianstudentNessuna valutazione finora

- 2012 Labor Bar Exam QDocumento29 pagine2012 Labor Bar Exam QClambeauxNessuna valutazione finora

- Draft PunkDocumento6 pagineDraft PunkSandro SorianoNessuna valutazione finora

- ILO Convention 98Documento4 pagineILO Convention 98Mira Ciele Saguinsin BusangilanNessuna valutazione finora

- LTD Case To DigestDocumento75 pagineLTD Case To DigestSandro SorianoNessuna valutazione finora

- ILO Convention 98Documento4 pagineILO Convention 98Mira Ciele Saguinsin BusangilanNessuna valutazione finora

- Adverse ClaimDocumento1 paginaAdverse ClaimSandro SorianoNessuna valutazione finora

- NothingDocumento1 paginaNothingSandro SorianoNessuna valutazione finora

- NothingDocumento1 paginaNothingSandro SorianoNessuna valutazione finora

- NothingDocumento1 paginaNothingSandro SorianoNessuna valutazione finora

- Rules and RegulationsDocumento2 pagineRules and RegulationsSandro SorianoNessuna valutazione finora

- NothingDocumento1 paginaNothingSandro SorianoNessuna valutazione finora

- Timesheet Template with Repeating RowsDocumento2 pagineTimesheet Template with Repeating RowsSandro SorianoNessuna valutazione finora

- Legal Research NotesDocumento5 pagineLegal Research Notespriam gabriel d salidaga100% (11)

- NothingDocumento1 paginaNothingSandro SorianoNessuna valutazione finora

- Horizontal and Vertical CurvesDocumento29 pagineHorizontal and Vertical CurvesSandro SorianoNessuna valutazione finora

- Horizontal and Vertical CurvesDocumento29 pagineHorizontal and Vertical CurvesSandro SorianoNessuna valutazione finora

- Emergency Generator Sizing and Motor Starting Analysis: Mukesh Kumar Kirar, Ganga AgnihotriDocumento6 pagineEmergency Generator Sizing and Motor Starting Analysis: Mukesh Kumar Kirar, Ganga Agnihotribalwant_negi7520Nessuna valutazione finora

- CAT-3500 Upgrade 8-11Documento2 pagineCAT-3500 Upgrade 8-11docrafiNessuna valutazione finora

- Seismic Demand Evaluation For A The Northridge Earthquake 4-Story Steel Frame Structure Damaged inDocumento27 pagineSeismic Demand Evaluation For A The Northridge Earthquake 4-Story Steel Frame Structure Damaged insanh137Nessuna valutazione finora

- Impact TestDocumento4 pagineImpact TestZoHaib JaWedNessuna valutazione finora

- Kumar ResumeDocumento2 pagineKumar ResumePratik KhandelwalNessuna valutazione finora

- Resume - Mark Edison D Fellone - 2014Documento2 pagineResume - Mark Edison D Fellone - 2014api-262936729Nessuna valutazione finora

- Maintenance Instrument Technician CV - Google SearchDocumento26 pagineMaintenance Instrument Technician CV - Google SearchSunket PatelNessuna valutazione finora

- Python Lab Manual r20Documento34 paginePython Lab Manual r20Shanmukh VegiNessuna valutazione finora

- Skyscraper'S Glass Cleaning Automated Robot: Department of Mechanical EngineeringDocumento7 pagineSkyscraper'S Glass Cleaning Automated Robot: Department of Mechanical Engineeringankur raiNessuna valutazione finora

- AS 3735 - Concrete Structures For Retaining LiquidsDocumento27 pagineAS 3735 - Concrete Structures For Retaining LiquidslowiyaunNessuna valutazione finora

- Design of PLC Based Automated Food Processing MachDocumento8 pagineDesign of PLC Based Automated Food Processing MachmaturantnesNessuna valutazione finora

- Electrical/Lighting Design Engineer-CVDocumento3 pagineElectrical/Lighting Design Engineer-CVMohamed67% (6)

- P 192.481 Visually Inspect For Atmospheric Corrosion RevisionsDocumento2 pagineP 192.481 Visually Inspect For Atmospheric Corrosion RevisionsahmadlieNessuna valutazione finora

- ENGINEERING MANAGEMENT Part IDocumento19 pagineENGINEERING MANAGEMENT Part Irtg.chrisNessuna valutazione finora

- Iii - Ii It DPPMDocumento20 pagineIii - Ii It DPPMBalajiNessuna valutazione finora

- Fits & TolerancesDocumento6 pagineFits & Tolerancessuperman92makNessuna valutazione finora

- MECHCON A Corporate ProfileDocumento40 pagineMECHCON A Corporate ProfileMuhammad AzeemNessuna valutazione finora

- Factor of SafetyDocumento12 pagineFactor of SafetyRavi TarunNessuna valutazione finora

- Fundamentals of RoboticsDocumento26 pagineFundamentals of RoboticsRakeshSainiNessuna valutazione finora

- Project CO-PO MappingDocumento4 pagineProject CO-PO MappingAarathi LakshmipathyNessuna valutazione finora

- Two Cell Box CulvertDocumento12 pagineTwo Cell Box CulvertAhmad Arslan Rafique71% (7)

- Glass Block Technical PresentationDocumento16 pagineGlass Block Technical PresentationJothika JothikaNessuna valutazione finora

- NTU SCSE Brochure 2020Documento9 pagineNTU SCSE Brochure 2020AllalannNessuna valutazione finora

- R20 CC Course FileDocumento27 pagineR20 CC Course FileHODCSE RKCENessuna valutazione finora

- Air-Conditioning & RefrigirationDocumento36 pagineAir-Conditioning & RefrigirationMohamed Rizwan100% (1)

- Alloy7055 T7751techsheetDocumento2 pagineAlloy7055 T7751techsheetValerio PeriniNessuna valutazione finora

- TS00E v1.2 Student Noteset PDFDocumento303 pagineTS00E v1.2 Student Noteset PDFpatrick morris100% (1)