Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

US Legal Document Establishes ASTM Standard for Steel Bolts

Caricato da

rensieovi0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

216 visualizzazioni7 pagineThis document summarizes an American National Standard that specifies requirements for quenched and tempered steel bolts and studs up to 3 inches in diameter. It details chemical and mechanical property requirements, dimensions, testing methods, and sampling procedures to ensure bolts and studs meet the standard's specifications for strength and quality. Compliance with this standard helps ensure bolts and studs can withstand the loads they are designed to carry.

Descrizione originale:

astm.a449.1978

Titolo originale

astm.a449.1978

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document summarizes an American National Standard that specifies requirements for quenched and tempered steel bolts and studs up to 3 inches in diameter. It details chemical and mechanical property requirements, dimensions, testing methods, and sampling procedures to ensure bolts and studs meet the standard's specifications for strength and quality. Compliance with this standard helps ensure bolts and studs can withstand the loads they are designed to carry.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

216 visualizzazioni7 pagineUS Legal Document Establishes ASTM Standard for Steel Bolts

Caricato da

rensieoviThis document summarizes an American National Standard that specifies requirements for quenched and tempered steel bolts and studs up to 3 inches in diameter. It details chemical and mechanical property requirements, dimensions, testing methods, and sampling procedures to ensure bolts and studs meet the standard's specifications for strength and quality. Compliance with this standard helps ensure bolts and studs can withstand the loads they are designed to carry.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

By Authority Of

THE UNITED STATES OF AMERICA

Legally Binding Document

By the Authority Vested By Part 5 of the United States Code 552(a) and

Part 1 of the Code of Regulations 51 the attached document has been duly

INCORPORATED BY REFERENCE and shall be considered legally

binding upon all citizens and residents of the United States of America.

HEED THIS NOTICE: Criminal penalties may apply for noncompliance.

Official Incorporator:

THE EXECUTIVE DIRECTOR

OFFICE OF THE FEDERAL REGISTER

WASHINGTON, D.C.

Document Name:

CFR Section(s):

Standards Body:

e

ASTM A449: Quenched and Tempered Steel Bolts

and Studs

24 CFR 200, Subpart S

American Society for Testing and Materials

AMERICAN NATIONAL ,ANSI/ASTM A 449 - 78a

STANDARD '

: , ,.

If.!.

I,'"

Standard, ,Specification for

QUENCHED AND"TEMPEREI)'STEEL BOLTS AND STUDS

1

, "'I

This standard is issued under .l"lxed designiiionA 449; the number'inunediateiy following the designatiori indIcates the

year of original adoption or, in the case of revision, the year oflast revision. A number in parentheses indicates the yeiu"oflast

reapproval. ; , " ' ',', "',

1. Scope

1.1 This specification covers the chemical

and mechanical requirements for quenched

and tempered, medium carbon steel bolts and

studs 3 in. and under in diameter for general

applications where ,highs,trength is required.'

1.2 Suitable nuts larecoveted ,in Specifica- ,

tion A 563. Unless otherwise 'specified, the

a,nctstyle ofn,ut shall be ,as fo}1ows,:,

Fastener Size and Surface Finish

Nut Grade and',

Style4-

y. to f.im./plaiittorwiih a coating of B, hex

, ,\ thickness to require over-

l., tapped nuts) '

over I to 3 in" plain (or with a coating A, heavy hex

of insufficient thickness to require

over-tapped nuts)

v.. to 3 in., galvanized (or with a coating C, heavy hex

thickness requiring over-tapped nuts)

A Nuts of other grades and styles having specified proof

load stresses (Specification A 563, Table 3) greater than the

specified grade and style of nut are suitable.

NOTE I-The values stated in inch-pound units

are to be regarded as the standard.

2. Applicable Documents

2.1 ASTM Standards:

A 153 Specification for Zinc Coating (Hot-

Dip) on Iron and Steel Hardware

2

A 370 Methods and DefInitions for Mechan-

ical Testing of Steel Products.

3

A 563 Specification for Carbon and Alloy

Steel Nuts

4

2.2 American National Standards:

5

ANSI B 1.1 Unified Screw Threads

ANSI B 18.2.1 Square and Hex Bolts and

Screws .

3. Material and Manufacture

3.1 Steel for bolts and studs shall be made

by the open-hearth, basic-oxygen, or electric-

furnace process.

....

3.2 The bolts and studs shall be heat treated

by quenching in 'a'liquid medium froma1;Jpve

the, transformation, temperature ana then ,tem-

pering by re4ellting t9 a temperature of n9t1ess

than 800F '(427C). ,

3.3 rIueads of bolts and studs shall, be

rolled, 'cut;!of'ground. ' "

'"3:4Whtin specified, galvaIliied 'fasteners

shall be hot-dip galvanized in with

of.

A 153. When specified by the purchaser to,he

mechanically galvanized, fasteners covered by

specific.atibn':shali: oe iliechilIllcallYZW,C-

cmlted,anci the coating \to -re-

quirements for Class 50 of Specification B 454,

or to the coating thickness, adherence, and

quality requirements for Class C of Specifica-

tion A 153.

NOTE 2-When the intended application requires

that assembled tension exceeds 50 % of minimum

bolt or stud proofload, an anti-galling lubricant may

be needed, Application of such a lubricant to nuts

and a test of the lubricant efficiency are provided in

Supplementary Requirement Sl of Specification

A 563 and should be specified when required.

4. Chemical Requirements

4.1 The bolts and studs shall conform to

requirements as to the chemical composition

specified in Table 1.

4.2 Product analyses may be made by the

I This specification is under the jurisdiction of ASTM

Committee F-16 on Fasteners, and is the direct responsibility

of Subcommittee F 16.02 on Steel Bolting.

Current edition approved Sept. 29, and Oct. 27, 1978.

Published December 1978. Originally published as A 449 -

63 T. Last previous edition A 449 - 77.

2 Annual Book of ASTM Standards, Part 3.

a Annual Book of ASTM Standards, Parts I to 5 and 10.

4 Annual Book of ASTM Standards, Parts I and 4.

, May be obtained from American National Standards

Institute, Inc., 1430 Broadway, New York, NY 10018,

398

purchaser from fmished material representing

each lot. The chemical composition thus deter-

mined shall conform to the requirements pre-

scribed for product analysis in Table 1.

4.3 Application of heats of steel to which

bismuth, selenium, tellurium, or lead has been

intentionally added shall not be permitted.

5. Mechanical Requirements

5.1 Bolts and studs shall not exceed the max-

imum hardness specified in Table 2. Bolts less

than three diameters in length and studs less

than four diameters in length shall have hard-

ness values not less than the minimum nor

more than the maximum hardness limits re-

quired in Table 2, as hardness is the only

requirement.

5.2 Bolts and studs 1% in. in diameter or

less, other than those excepted in 4.1, shall be

tested full size and shall conform to the tensile

strength and either the proof load or yield

strength requirements specified in Tables 3 and

4.

5.3 Bolts and studs larger than 1% in. in

diameter as above, other than those excepted

in 5.1, shall preferably be tested full size and

when so tested, shall conform to the tensile

strength and either the proof load or yield

strength requirements specified in Tables 3 or

4 respectively. When equipment of sufficient

capacity for full-size testing is not available, or

when the length of the bolt or stud makes full-

size testing impractical, machined specimens

shall be tested and shall conform to the require-

ments of Table 5. In the event that bolts are

tested by both full size and by the machined

test specimen methods, the full-size test shall

govern if a controversy between the two meth-

ods exists.

5.4 For bolts and studs on which both hard-

ness and tension tests are performed, accept-

ance based on tensile requirements shall take

precedence over low readings of hardness tests.

6. Dimensions

6.1 Unless otherwise specified, the bolts

shall be fmished hexagon head with dimensions

conforming to the latest issue of ANSI BI8.2.1.

6.2 Studs shall have dimensions conforming

to those specified by the purchaser.

6.3 Unless otherwise specified, threads shall

be Coarse Thread Series as specified in the

399

A 449

latest issue of ANSI B 1.1, and shall have Class

2A tolerances.

6.4 Unless otherwise specified, bolts to be

used with nuts or tapped holes that have been

tapped oversize, in accordance with Specifica-

tion A 563, shall have Class 2A threads before

hot dip or mechanical galvanizing. After gal-

vanizing, the maximum limit of pitch and ma-

jor diameter may exceed the Class 2A limit by

the following amount:

Diameter, in.

Up to 'Vi" inel

Over '/16 to I, incl

Over I

Oversize Limit, in. (mm)A

0.016(0.41)

0.021(0.53)

0.031(0.79)

A These values are the same as the minimum overlapping

required for galvanized nuts in Specification A 563.

6.5 The gaging Ihnit for bolts shall be veri-

fied during manufacture or use by assembly of

a nut tapped as nearly as practical to the

amount oversize shown above. In case of dis-

pute, a calibrated thread ring gage of that same

size (Class X tolerance, gage tolerance plus) is

to be used. Assembly of the gage, or the nut

described above, must be possible with hand

effort following application oflight machine oil

to prevent galling and damage to the gage.

These inspections, when performed to resolve

disputes, are to be performed at the frequency

and quality described in Table 6.

7. Test Methods

7.1 Bolts and studs shall be tested in accord-

ance with Supplement III of Methods A 370.

7.2 The wedge test shall be applicable only

to square and hexagon head bolts.

7.3 Studs shall be tested by the Axial Ten-

sion Method as described in SI1.1.3.1, Supple-

ment III of Methods A 370.

8. Number of Tests and Retests

8.1 The requirements of this specification

shall be met in continuous mass production for

stock, and the manufacturer shall make sample

inspections to ensure that the product conforms

to the specified requirements. Additional tests

of individual shipments of material are not

ordinarily contemplated. Individual heats of

steel are not identified in the fmished product.

8.2 When specified in the order, the manu-

facturer shall furnish a test report certified to

be the last completed set of mechanical tests for

each stock size in each shipment.

8;3, When testing on a lot basis is specified

on the purchase order, a lot, for purposes of

'selecting test samples; shall (:onsist of allma-

; terial'of,one:.type; that is, bolts or studs having

the, same nominal diameter and length offered

fot mspection :at one time. From each lot; the

number of tests for' each .specified property

shall be 'as follows: ;,i

Number of Pieces in Lot

800 and less

Over 800 to 8 bob, incl

Over 8 000 to 22 000, inel

Over 22000

Number of

Sam.ples

, I

'2

3

5

8.4 Should any sample fail to meet the re-

quirements of a specified test, double the opg-

inal number of samples from the same lot shall

be retested for the requiremetit(s), iIJ. which it

failetl. All the additibiialsamples shall conform

'tt) the specification or the lot shal1be

, 8.5 If any test shows defective ma-

chming, it may be discarded and another spec-

imen substituted.

9. Workmanship

- 9.1 The bolts.-and studs shall be comriJ.er-

cially smooth and free from burrs, laps; seams,

cracks, arid 'Other; injurious material or manu-

facturing defects which would make them un-

suitable for theiritended application.

10. Marking

10.1 Bolt heads shall be marked with 3 :radial

," .'

TABLE 1 Chemical Requirements

"

Carbon

Manganese, min

Phosphorus, max

Sulfur, max '

, % '

Heat

0.28-0.55

0,.60.

6.040

0.050

".-.,

.i'

Product,

Analysis

0.25-0.58

0.57

0.048

0.058

04.449

lines 120 deg apart and with a symbol idenV-

'>Tying' the. manufacturer, Markings may be

raised or depressed atthe option of the manu-

facturer.: .. - , . " :

; 'i1: . inspei!ti?D. :"

11.1 Ii in 8.2 is

required by the it, shall pe specified

in the inquiry and c;011,tra<:t 'Or, :' .

11,2 The inspeCtor representing pur-

chaser shall have free entry, at all times while

work on the contract is being

. performed, to all parts works

that concern the manufacture and testing ofthe

material The, shall af-

ford the inspector all reasonable facilities, with-

<;lut ch8;rge, to 4im the material is

.' furnished ,in accordance. with this speci-

'fication. All (except product analysis),

shall be made at the place of man-

ufactur!'l prior to unless

specified, and shall be so conducted as not to

interfere with the of

the works. ' . "

i '.

12. Rejection .'

12.1 Rejections based

'ifi.ed herein shall be reponed. to the manufac-

hirer within30 days after teceip(c,fmaterial oy

the purchaser. "

TABLE2 Hardness Require'iltents

,Bolt or Stud Diameter; in.

v.. to I, incl

Oyer I to 1 2, iiicl'

Over I t1! to 3, incl.

, . ,"/. ..

, Hardness,

Brinell

Hardness

Number

255 to 321

223 (0285

183 to 235

25 to 34

19 to 30

\ J

400

~ ~ ~ A 449

TABLE 3 Tensile Requirements for Coarse-Thread Fuil-Size Bolts and Studs

Proof Load, Length

Alternative Proof

Bolt or Stud Threads per S.tress Area, Tensile Load, Load, Yield Strength

Diameter, in. inch

A 28

min,lbf

c Measurement

Method (0.2 % Off- ill.

Method, lbf

c

set),lbf

c

Column 1 Column 2 Column 3 Column 4 Column 5 Column 6

y,

20 0.0318 3 800 2700 2900

0/16 18 0.0524 6 300 4450 4 800

% . 16 0.0775 9 300 6 600. 7 100

%6 14 0.1063 12750 9 050 9 800

V. 13 0.1419 17 050 12 050 13 050

0/16 12 0.182 21 850 15 450 16750

0/, 11 0.226 27 100 19 200 20 800

% 10 0.334 40 100 28 400 30700

'Va 9 00462 55 450 39 250 42 500

8 0.606 72 700 51 500 55 750

IVa 7 0.763 80 100 56450 61 800

IV. 7 0.969 101 700 71 700 78 500

10/, 6 1.155 121 300 85 450 93 550

IY, 6 10405 147 500 104 000 113 800

lo/4 5 1.90 171 000 104 500 110 200

2 41'2 2.50 225 000 137 500 145 000

2V. 4Y, 3.25 292 500 178 750 188 500

2Y, 4 4.00 360 000 220 000 232 000

2% 4 4.93 443 700 271 150 286 000

3 4 5.97 537 300 328 350 346 200

A For 8 threads per inch in sizes I y, to I y, in., incl, stresses of 105,000 psi (725 MPa), 74,000 psi (510 MPa), and 81,000 psi

(560 MPa) shall be used for calculating the values in columns 4, 5, and 6 respectively.

B Stress area calculated from the formula:

A, = 0.7854 [D - 0.9743/n)]'

where:

A, = stress area,

D = nominal diameter, and

n = threads per inch.

C Values tabulated are based on the following:

Bolt Size, in. Column 4, psi (MPa)

V. to I, incl 120 000 (825)

I y, to m, inel 105 000 (725)

1% to 3, incl 90 000 (620)

401

Column 5, psi (MPa)

85 000 (585)

74 000 (510)

55 000 (380)

Column 6, psi (MPa)

92 000 (635)

81 000 (560)

58 000 (400)

:rABLE 4

Bolt or Stud Threads per

Diameter; In. inch

Colul!\ll L Column 2

14 28

0/1. 24

% 24

'VI. 20

V. 20

'fl.. 18

% 18

0/4 16

'VB 14

12

IV. 12

m 12

1% 12

IV. 12

A See foolnote

B

below Table 3.

B See foolnoleo below Table 3.

A 449

Tensile Requirements (or Bolts and Studs

Proof Load, Length

Alternative Proof

Stress Area, Tensile .Load, Load, Yield Stre)lgth

2A

min; Ibf

B Measurement

Method (0.2 % Off m.

Method, IbfB

set), min, IbfB

Column 3 Column 4 ,Column 5 Column 6

0.0364 4350 3 100 3 500

0.0580 6 950 4950 5 350

0.0878 10 550 7 450 8 100

0.1187 14500 10 100 10 900

0.1599 19 200 13 600 14700

0.203 24350 17 250 18 700

0.256 30700 21 750 23 500

0.373 44 750 31 700

. ,

34300

0.509 61 100 43 250 46 800

0.663 79550 56 350 61 000

0.856 89 900 63 350 69 350

1.073 112 650 79400 86 900

1.315 138 100 .97 300 106 500

1.581 166 000 117 000 128 000

TABLE 5 rensile Requirements Machined from Bolts and Studs

Bolt or Stud Diameter, in.

14 to 1, illcl

1 t(\ 1 v.,. inel

Over 1 V2 to 3, incl

Tensile Strength,

min, psi (MPa)

'120 000 (825)

105 , 000 (725)

90 0,00 .

Yield Strength, min,

psi (MPa)

92 000 (635)

81. 000 (560)

58 000 (400)

Elongation in

4Dmin, %

14

14

14

TABLE 6 Sample Sizes and Acceptance Numbers for

Inspection of Hot Dip or Mechanically Galvanized Threads

Lot Size SampleSizeA, B

Acceptance

NumberA

2 to 90 13 1

91 to 150 20 2

151 to 280 32 3

281 to 500 50 5

501 to 1 200 80 7

1 201 to 3 200 .125 10

3201 to 10 000 206 14

10 00 I and over 315 21

A Sample sizes of acceptance numbers are extracted from

"Single Sampling Plan for Normal Inspection" Table IIA,

MILSTD105D,

B Inspect aU bolts in the lot if the lot size is less than the

sample size,

Reduction of

Area, min, %

35

35

35

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in

connection with any item mentionea in this standard. Users oj this standard are expressly advised that determination of the

validity of any such patent rights, and the risk of infringement of such rights, is entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five

years and if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or

for additional standards and should be addressed to ASTM Headquarters. Your comments will receive careful consideration

at a meeting of the responsible technical committee, which you may attend. If you feel that your comments have not received

afair hearing you should make your views known to the ASTM Committee on Standards, 1916 Race St., Philadelphia, Po.

19103, which will schedule a further hearing regarding your comments. Failing satisfaction there, you may appeal to the

ASTM Board of Directors.

402

Potrebbero piacerti anche

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Da EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Valutazione: 5 su 5 stelle5/5 (1)

- High-Carbon Anti-Friction Bearing Steel: Standard Specification ForDocumento4 pagineHigh-Carbon Anti-Friction Bearing Steel: Standard Specification ForTriveni Forge QCNessuna valutazione finora

- Astm b85 1984Documento7 pagineAstm b85 1984Siddhi Sharma100% (1)

- A1018Documento5 pagineA1018Aleksei AvilaNessuna valutazione finora

- ASTM-A449: Licensed by Information Handling Services Licensed by Information Handling ServicesDocumento7 pagineASTM-A449: Licensed by Information Handling Services Licensed by Information Handling ServicesRoland CepedaNessuna valutazione finora

- Astm A311 - 2015 - ObsoletoDocumento4 pagineAstm A311 - 2015 - ObsoletoRicardo Ricardo100% (1)

- Astm b162Documento9 pagineAstm b162Johan ConradieNessuna valutazione finora

- F879MDocumento6 pagineF879MmsbarretosNessuna valutazione finora

- ASME B18 8 100M 2000 Spring PinsDocumento57 pagineASME B18 8 100M 2000 Spring Pinshcsharma1967Nessuna valutazione finora

- Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements ForDocumento31 pagineSteel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements Foralucard375Nessuna valutazione finora

- Steel Bars, Alloys, For NitridingDocumento2 pagineSteel Bars, Alloys, For Nitridingruben carcamoNessuna valutazione finora

- F1136F1136M 11Documento3 pagineF1136F1136M 11Manuel Antonio Santos Vargas0% (1)

- Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements ForDocumento9 pagineSteel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements FormuhammadNessuna valutazione finora

- Astm A838Documento4 pagineAstm A838RATHNAKUMARANessuna valutazione finora

- A675/A675MDocumento5 pagineA675/A675Mpavan_joshi_5100% (1)

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocumento4 pagineSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsSriniramu SriniramuNessuna valutazione finora

- Free-Machining Stainless Steel Bars: Standard Specification ForDocumento4 pagineFree-Machining Stainless Steel Bars: Standard Specification ForLuciano Grassi KuyvenNessuna valutazione finora

- A829Documento4 pagineA829Deepak GovindanNessuna valutazione finora

- A 607 PDFDocumento4 pagineA 607 PDFGustavo Suarez100% (1)

- A449-14 Standard Specification For Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120 - 105 - 90 Ksi Minimum Tensile Strength, General UseDocumento7 pagineA449-14 Standard Specification For Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120 - 105 - 90 Ksi Minimum Tensile Strength, General UseislamakthamNessuna valutazione finora

- Stainless Steel Socket Button and Flat Countersunk Head Cap ScrewsDocumento7 pagineStainless Steel Socket Button and Flat Countersunk Head Cap ScrewsDanZel DanNessuna valutazione finora

- Astm b169Documento4 pagineAstm b169ANIL100% (1)

- Astm A582 - A582m-22Documento4 pagineAstm A582 - A582m-221965karanfil6Nessuna valutazione finora

- Astm A646 A646mDocumento5 pagineAstm A646 A646mJosé de Paula MoreiraNessuna valutazione finora

- A299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFDocumento2 pagineA299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFGagan SinghNessuna valutazione finora

- Cold-Drawn, Stress-Relieved Carbon Steel Bars Subject To Mechanical Property RequirementsDocumento4 pagineCold-Drawn, Stress-Relieved Carbon Steel Bars Subject To Mechanical Property Requirementssharon blushteinNessuna valutazione finora

- Astm b108-Aluminium-Alloy Permanent Mold CastingsDocumento18 pagineAstm b108-Aluminium-Alloy Permanent Mold CastingsEldennisNessuna valutazione finora

- Astm A321Documento2 pagineAstm A321clevercog0% (1)

- ASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricDocumento14 pagineASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricSinan Chen100% (1)

- A 1018 - A 1018M - 16aDocumento8 pagineA 1018 - A 1018M - 16aJose Anisio Silva0% (1)

- A 1070 - 16Documento8 pagineA 1070 - 16Nguyễn Như ThếNessuna valutazione finora

- SAEDocumento8 pagineSAEEnriqueGDNessuna valutazione finora

- B26B26MDocumento14 pagineB26B26MAbraham MallisaNessuna valutazione finora

- ASTM A563 - 07 Standard Specification For Carbon and Alloy Steel NutsDocumento8 pagineASTM A563 - 07 Standard Specification For Carbon and Alloy Steel NutsDagoberto AguilarNessuna valutazione finora

- Brass Rod, Bar, and Shapes: Standard Specification ForDocumento7 pagineBrass Rod, Bar, and Shapes: Standard Specification ForMuthuswamyNessuna valutazione finora

- ASTM A580 2006 Standard Specification For Stainless Steel WireDocumento5 pagineASTM A580 2006 Standard Specification For Stainless Steel WireEidrish Shaikh100% (2)

- Stainless Steel Bars and Shapes: Standard Specification ForDocumento7 pagineStainless Steel Bars and Shapes: Standard Specification ForMarcelo Santos100% (1)

- Sae Ams-H-6875b-2010Documento22 pagineSae Ams-H-6875b-2010dmt1905100% (1)

- Astm A506Documento4 pagineAstm A506Fabio SegattoNessuna valutazione finora

- Astm A484-A484m-00Documento12 pagineAstm A484-A484m-00Razvan Andrei GiuscaNessuna valutazione finora

- B 21 - B 21M - 14Documento8 pagineB 21 - B 21M - 14Ahmed BilalNessuna valutazione finora

- Stainless Steel Socket Head Cap Screws: Standard Specification ForDocumento8 pagineStainless Steel Socket Head Cap Screws: Standard Specification ForMarcelo BarretosNessuna valutazione finora

- Astm A108Documento4 pagineAstm A108scriptd_ozd3n100% (3)

- Ionic Technologies Aerospace Heat Treatment and Nitriding ServicesDocumento3 pagineIonic Technologies Aerospace Heat Treatment and Nitriding ServicesSinan YıldızNessuna valutazione finora

- Astm A747Documento4 pagineAstm A747Srinivasan KrishnamoorthyNessuna valutazione finora

- Astm A293-2022Documento10 pagineAstm A293-2022CarlosNessuna valutazione finora

- Astm A564Documento10 pagineAstm A564chetan_thakur4278100% (1)

- Astm A314 PDFDocumento3 pagineAstm A314 PDFMatyash MatyashNessuna valutazione finora

- QQ N 290aDocumento17 pagineQQ N 290aBryan MartinezNessuna valutazione finora

- WSS M1P94 ADocumento9 pagineWSS M1P94 AAleks SenaNessuna valutazione finora

- Astm A574Documento9 pagineAstm A574Jose Angel RodriguezNessuna valutazione finora

- Astm A1008 12aDocumento9 pagineAstm A1008 12aAleks SenaNessuna valutazione finora

- Sae J429Documento8 pagineSae J429David Lay IINessuna valutazione finora

- A322Documento4 pagineA322rgi178Nessuna valutazione finora

- Astm F 835 PDFDocumento6 pagineAstm F 835 PDFDan Dela Peña100% (1)

- Astm A307 1978 PDFDocumento6 pagineAstm A307 1978 PDFalvaedison00Nessuna valutazione finora

- Sa 307Documento8 pagineSa 307Web LogueandoNessuna valutazione finora

- A307 PDFDocumento6 pagineA307 PDFmuthunayakeNessuna valutazione finora

- A 307 - 02 - Qtmwny0wmgDocumento6 pagineA 307 - 02 - Qtmwny0wmgvhenriquezmNessuna valutazione finora

- Astm A-449Documento8 pagineAstm A-449Anonymous GhPzn1x100% (2)

- Calculating Caloric ExpenditureDocumento2 pagineCalculating Caloric ExpenditurerensieoviNessuna valutazione finora

- Rivets Stainless Steel DomeDocumento1 paginaRivets Stainless Steel DomerensieoviNessuna valutazione finora

- Engineering & Piping DesignDocumento36 pagineEngineering & Piping DesignkumarkumaeNessuna valutazione finora

- Stress Analysis of Piping SystemsDocumento108 pagineStress Analysis of Piping SystemsShijumon KpNessuna valutazione finora

- Design For CreepDocumento437 pagineDesign For Creeprensieovi100% (1)

- Ati 316ti Tds en v1Documento5 pagineAti 316ti Tds en v1rensieoviNessuna valutazione finora

- Piping Specifications HarrisDocumento27 paginePiping Specifications Harrisrensieovi100% (2)

- Astm A82 1979Documento6 pagineAstm A82 1979rensieoviNessuna valutazione finora

- Astm A391 1965Documento6 pagineAstm A391 1965rensieoviNessuna valutazione finora

- Astm b858 1995Documento6 pagineAstm b858 1995rensieoviNessuna valutazione finora

- Stress Concentrations From Mechanical Design - An Integrated Approach - Ansel C UguralDocumento7 pagineStress Concentrations From Mechanical Design - An Integrated Approach - Ansel C Uguralmarkbnichols_scribdNessuna valutazione finora

- 149 Atzori - Manara - Meneg ITALY Paper FINALDocumento8 pagine149 Atzori - Manara - Meneg ITALY Paper FINALrensieoviNessuna valutazione finora

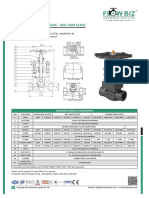

- FlowBiz Forged Steel Globe Valve 1500 ClassDocumento2 pagineFlowBiz Forged Steel Globe Valve 1500 ClassFlowBiz Exports Pvt. Ltd.Nessuna valutazione finora

- Materials Guideline Update: Preliminary Survey ResultsDocumento44 pagineMaterials Guideline Update: Preliminary Survey ResultsmrinalkantibhaduriNessuna valutazione finora

- Deformation of Solids: 1-Nov 01-Q/5Documento3 pagineDeformation of Solids: 1-Nov 01-Q/5Coolman PoonNessuna valutazione finora

- 1 s2.0 0043164895900322 Main PDFDocumento5 pagine1 s2.0 0043164895900322 Main PDFMaría MGNessuna valutazione finora

- Technical Specification of ABC Cable - Ergon EnergyDocumento61 pagineTechnical Specification of ABC Cable - Ergon EnergySatyaNessuna valutazione finora

- Meta Lab ManualDocumento66 pagineMeta Lab Manualharshal wasnik100% (1)

- Sae SymbolDocumento1 paginaSae Symbolnate anantathatNessuna valutazione finora

- Seismic Design Coefficients From ASCE 7-10-2Documento5 pagineSeismic Design Coefficients From ASCE 7-10-2Bunkun15Nessuna valutazione finora

- Air HorseDocumento8 pagineAir HorseLasitha ChathurangaNessuna valutazione finora

- Radiography Interpretation PDFDocumento220 pagineRadiography Interpretation PDFVijay Kumar100% (1)

- Soal Senyawa Kimia PDFDocumento4 pagineSoal Senyawa Kimia PDFLewi Petrik HorayosNessuna valutazione finora

- New From Kennedy Valve: The Vintage Hydrant The Patriot Hydrant Check ValveDocumento14 pagineNew From Kennedy Valve: The Vintage Hydrant The Patriot Hydrant Check ValveM Kumar MarimuthuNessuna valutazione finora

- New Fashioned BillycartDocumento2 pagineNew Fashioned BillycartAntônio CastroNessuna valutazione finora

- Saej 524 V 002Documento5 pagineSaej 524 V 002Marcos Verissimo Juca de PaulaNessuna valutazione finora

- Powell Gate ValvesDocumento3 paginePowell Gate Valveszguy360Nessuna valutazione finora

- Structural Behaviour of Bolted Moment Connections in Cold-Formed Steel Beam-Column Sub-FramesDocumento22 pagineStructural Behaviour of Bolted Moment Connections in Cold-Formed Steel Beam-Column Sub-FramesAniket DubeNessuna valutazione finora

- Powerpoint Templates: Metallic Materials Constraints for SpacecraftDocumento71 paginePowerpoint Templates: Metallic Materials Constraints for Spacecraftleila hanjani hanantoNessuna valutazione finora

- Mikrotest Op ManualDocumento4 pagineMikrotest Op ManualmgmqroNessuna valutazione finora

- Pedrollo Submersible Vortex Pump - VXDocumento2 paginePedrollo Submersible Vortex Pump - VXGeorge CobraNessuna valutazione finora

- API 571 Damage MechanismsDocumento42 pagineAPI 571 Damage MechanismsIsmail Jamaluddin100% (1)

- Creep TestDocumento18 pagineCreep Testdeemi75Nessuna valutazione finora

- AccumulatorsDocumento9 pagineAccumulatorsBaldo CastilloNessuna valutazione finora

- Champion Dual Disc Wafer Check ValvesDocumento8 pagineChampion Dual Disc Wafer Check ValvesShanghai koko ValvesNessuna valutazione finora

- Agar PedaDocumento8 pagineAgar PedaSuresh JeevaNessuna valutazione finora

- Crosby ShacklesDocumento1 paginaCrosby Shacklesroy sihalohoNessuna valutazione finora

- Compression Spring Design InfoDocumento4 pagineCompression Spring Design Infomprabhu4youNessuna valutazione finora

- INFORME MetalografiaDocumento9 pagineINFORME MetalografiaRhaiNessuna valutazione finora

- Transmission OPGW Fittings ClosuresDocumento20 pagineTransmission OPGW Fittings ClosuresARCC2030Nessuna valutazione finora

- Sheet MetalDocumento11 pagineSheet Metalshah_faizan123Nessuna valutazione finora