Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

00-10-008 - Jul.1998

Caricato da

Levi Murdok0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

56 visualizzazioni0 pagineINITIAL SAMPLE VALIDATION FOR PARTS MADE OF POLYMER MATERIALS D.I.MAT INTERVENTION Service 65830 Section Normes et Cahiers des Charges VISA RESPONSABLE(s) RENAULT 1999 Page 2 / 8 this document is to be considered as a whole the parts of which shall not be separated.

Descrizione originale:

Titolo originale

00-10-008--- Jul.1998

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoINITIAL SAMPLE VALIDATION FOR PARTS MADE OF POLYMER MATERIALS D.I.MAT INTERVENTION Service 65830 Section Normes et Cahiers des Charges VISA RESPONSABLE(s) RENAULT 1999 Page 2 / 8 this document is to be considered as a whole the parts of which shall not be separated.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

56 visualizzazioni0 pagine00-10-008 - Jul.1998

Caricato da

Levi MurdokINITIAL SAMPLE VALIDATION FOR PARTS MADE OF POLYMER MATERIALS D.I.MAT INTERVENTION Service 65830 Section Normes et Cahiers des Charges VISA RESPONSABLE(s) RENAULT 1999 Page 2 / 8 this document is to be considered as a whole the parts of which shall not be separated.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 0

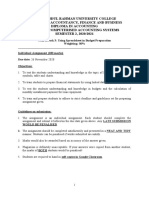

STANDARD

Classement prvu : 00 - 10 - 008 / - - - Sce NTl

Responsable du document A.T. NCC 60201 7XXXX

Pilote(s) technique(s) PILOTE 99999 99999

Date de mise jour :

Normalisation Renault Automobiles

00 - 10 - 008 / - - -

INITIAL SAMPLE VALIDATION

FOR PARTS MADE OF POLYMER MATERIALS

D.I.MAT INTERVENTION

Service 65830

Section Normes et Cahiers des Charges

VISA RESPONSABLE(S)

SIGNATURE :

NOM :

SERVICE :

DATE :

XX/XX/XXXX

RENAULT 00 - 10 - 008 / - - -

RENAULT 1999 Page 2/8

This document is to be considered as a whole the parts of which shall not be separated.

RENAULT 1999.

No duplication permitted without the consent of the issuing department.

No circulation permitted without the consent of RENAULT.

DATE OF ISSUE

July 1998 - - - This issue originates from Draft NC 97 217 / - - A.

REVISION

REFERENCED DOCUMENTS

Standard : 00-10-003.

Quality Rules : Q00 10 A 20, Q00 10 A 21.

RENAULT 00 - 10 - 008 / - - -

RENAULT 1999 Page 3/8

CONTENTS

Page

1. SCOPE AND FIELD OF APPLICATION 4

2. PRINCIPLE 4

3. DI.Mat MATERIAUX POLYMERES ET MISE EN OEUVRE DEPARTMENT COMMITMENT 4

4. D.I.Mat INTERVENTION LEVELS 5

5. SUPPLIER PENALTIES 6

ANNEX 1 - POSSIBLE D.I.Mat INTERVENTION LEVELS 7

ANNEX 2 - NOTE TO BE USED IN CASE OF MALFUNCTION 8

RENAULT 00 - 10 - 008 / - - -

RENAULT 1999 Page 4/8

1. SCOPE AND FIELD OF APPLICATION

The purpose of this standard is to describe the intervention process of the D.I.Mat (Direction de

l'Ingnierie des Matriaux: "Ingnirie des Matriaux" Department) for initial sample validation. It

applies to parts and products for which polymer materials are mostly used.

2. PRINCIPLE

A procedure aimed at making the Suppliers responsible is started; it consists in transferring the part

approval responsibility to them using the "laboratory" criteria of the product specifications for the

delivered part in compliance with:

- either Quality Rule Q00 10 A 20 "Assurance Qualit Produit Processus (AQPP) POE Vhicules",

- or Quality Rule Q00 10 A 21 "Assurance Qualit Produit Processus (AQPP) POE Mcanique".

The audit and crossed test procedure applied according to Standard 00-10-003 "Part and product

laboratory self approval" is used to evaluate the Laboratory Self-Approval ability of a Supplier for a

specified part or product. This audit procedure is based on two consecutive and complementary

aspects, i.e.:

- Detailed estimation of the Supplier's evaluation, verification, and test facilities by the D.I.Mat to

complement that performed during the EAQF (Evaluation d'Aptitude Qualit Fournisseur:

supplier quality capability assessment).

- Checking that the results obtained by the Supplier and those obtained by the D.I.Mat laboratory

match according to all the test methods mentioned in the corresponding normative documents.

3. D.I.MAT MATERIAUX POLYMERES ET MISE EN OEUVRE DEPARTMENT COMMITMENT

The Matriaux polymres et mise en oeuvre Department of the D.I.Mat commits itself:

- To organize its interventions within the framework of AQPP by defining three intervention levels

described in paragraph 4. and schematized in annex 1.

- To define the level it wants to apply and make it known from step 1 of the AQPP after having

indicated the product/process/validation criticity level to the Engineering Centre and the

Purchasing sector concerned.

Reminder: The "Achats" Department shall:

. Claim from the Supplier who was found capable of Laboratory Self-Approval by the

D.I.Mat for a given part or product a formal commitment acknowledgement according to

which he acknowledges to bear the entire validation responsibility for the part or product

concerned (see model in Standard 00-10-003, annex 5).

. Organize a penalty system with three seriousness levels towards Suppliers not fulfilling

their commitments.

RENAULT 00 - 10 - 008 / - - -

RENAULT 1999 Page 5/8

4. D.I.MAT INTERVENTION LEVELS

The Supplier systematically transmits to the D.I.Mat a copy of each approval file sent to the AQPP

pilot (GFE (Groupe Fonction Elmentaire: elementary function group) pilot for the bodywork; SQF

(Section Qualit Fournisseur: supplier quality section) pilot for the mechanics) accompanied by one or

several parts so that the D.I.Mat may carry out its mission.

The D.I.Mat intervention process in the initial sample validation which is formalized by an internal

procedure is explained below according to three risk levels:

- LEVEL "A" :

The AQPP pilot makes a decision on the part compliance with respect to the "laboratory" tests of

the product specifications just reading the Supplier's conclusion in the approval file.

The approval file for a part or product is drawn up from the validation plan prepared during step 1

of the AQPP.

In the normal case of supplies from Suppliers having received Laboratory Self-Approval

notification for the part or product, who are therefore capable of performing all the tests of the

product specifications, the intervention level is "A".

In the case where the Supplier declared to have received "Laboratory Self-Approval notification"

for the part or product cannot exceptionally perform such or such test of the product

specifications, it is agreed that he subcontracts the test performance to a laboratory approved by

RENAULT at his expense and under his responsibility. He is obliged to give an approval file

including the results of these tests to the AQPP pilot.

When the Supplier's class is level "A", the opinion of the D.I.Mat is not required during

step 4 of the AQPP.

On the contrary, the D.I.Mat may randomly audit files, even carry out a complete or partial

counter-expertise for the part or product.

If this file audit gives negative results, the opinion of the D.I.Mat transmitted to the AQPP pilot

results in part or product K10 (or K50) quotation.

Any failure or delay preventing the D.I.Mat from performing a possible audit is regarded as a

Supplier's malfunction and penalized according to the rules specified in paragraph 5.

- LEVEL "B" :

The D.I.Mat expects "laboratory" criteria validation for the part or product from the analysis of the

approval file presented by the Supplier.

The D.I.Mat declares part or product approval within a week from the time when the Supplier's

file is received.

In this case, an approval note from the D.I.Mat is required for step 4 of the AQPP.

RENAULT 00 - 10 - 008 / - - -

RENAULT 1999 Page 6/8

Level "B" applies, for instance, in the following cases:

. To a Supplier suspended from his Laboratory Self-Approval capability owing to malfunction

which resulted in the application of a seriousness level 2 penalty by the "Achats"

Department without necessary systematic performance of counter-expertise tests by the

D.I.Mat.

. In the case of supplies from Suppliers found to be reliable enough with respect to the part

quality risks, but without starting or concluding the Laboratory Self-Approval capability

procedure for all that (audit + crossed tests).

. In the case of supplies from Suppliers found to be reliable enough with respect to the part

quality risks, but for which the D.I.Mat wants to read the approval file on the occasion of the

introduction of new tests in the product specifications.

- LEVEL "C" :

The D.I.Mat performs counter-expertises for all or part of the tests specified in the validation

plan. For this purpose, the Supplier is obliged to send the parts subjected to approval

accompanied by a file including the results of the validation tests it has performed.

Level "C" relates to parts from Suppliers not recognized as having received the "Laboratory Self-

Approval notification" for the functions concerned.

In this case, an approval note from the D.I.Mat is required for step 4 of the AQPP.

5. SUPPLIER PENALTIES

In the event of malfunction in the D.I.Mat intervention process owing to the Supplier, an operational

note is sent to the "Achats" Department according to the model given in annex 2.

A penalty system with three seriousness levels is applied by the "Achats" Department towards

Suppliers not fulfilling their commitments.

- Seriousness level 3

It applies to a simple administrative malfunction, and results in the sending of mail to the

Supplier by the "Achats" Department for him to present his corrective action plan.

- Seriousness level 2

It applies to a serious Supplier's malfunction with customer quality repercussions or during

repeated seriousness level 3 incidents.

The Supplier is summoned by the "Achats" Department manager to be "Admonished", with the

threat to be excluded as an Expert Supplier for the part under consideration if a repeated

malfunction is noticed.

The Laboratory Self-Approval capability notification may be challenged.

- Seriousness level 1

It applies to characterized deception or during repeated seriousness level 2 incidents.

The Supplier is summoned by the "Achats" Department manager to be notified:

. his exclusion as an Expert Supplier for future parts for the function under

consideration,

. the cancellation of his Laboratory Self-Approval capability.

RENAULT 00 - 10 - 008 / - - -

RENAULT 1999 Page 7/8

ANNEX 1

POSSIBLE D.I.Mat INTERVENTION LEVELS

(decision expressed in the validation plan)

In all the cases, mandatory sending of the parts and files demanded by the D.I.Mat in the

validation plan within the time specified.

Engagement Fournisseur

sur conformit pice

directement pris en

compte par l'AQPP

A

Analyse par la D.I.Mat du

dossier de validation du

Fournisseur

B

Essais D.I.Mat de

contre-expertise

sur pice

C

Audits alatoires de

dossiers par la D.I.Mat

Si dossier non valable

droit de veto D.I.Mat

Etape 4 de l'AQPP

Agrment D.I.Mat

obligatoire pour l'tape 4

de l'AQPP

Cas normal des pices issues de

Fournisseurs en Self-Agrment

Laboratoire

Normal case of parts from

Laboratory Self-Approval Suppliers

Supplier commitment

to part compliance

directly considered by AQPP

D.I.Mat analysis of

Supplier's validation file

D.I.Mat counter-expertise

tests

on part

Mandatory D.I.Mat

approval for step 4

in AQPP

Random file audits

by D.I.Mat

If invalid file

D.I.Mat right of veto

Step 4 in AQPP

RENAULT 00 - 10 - 008 / - - -

RENAULT 1999 Page 8/8

ANNEX 2

NOTE TO BE USED IN THE EVENT OF MALFUNCTION

OPERATIONAL NOTE No 60154 - 9x - xxxx

LABORATORY SELF-APPROVAL MALFUNCTION

ACTION REQUEST to SUPPLIER

IDENTIFICATION (part and file)

- Vehicle / mechanical component:

- Part designation:

- Part No:

- Supplier:

- Laboratory Self-Approval capability for the function notified on:

- Date and reference of the approval file concerned:

- Supplier's laboratory having drawn up this file:

MALFUNCTION NATURE

Problem statement and malfunction consequences:

Reference of the documents in which the problem is explained:

SERIOUSNESS LEVEL (1 more serious than 3 )

K 1 K 2 K 3

PARTICULAR D.I.Mat EXPECTATIONS

Since the malfunction described above justifies an action with the Supplier, we require the

"Achats" Department concerned to start the operation and associate it with us.

"Matriaux polymres et Mise en Oeuvre" Department manager

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Final Test 1 Grade 10Documento4 pagineFinal Test 1 Grade 10Hường NgôNessuna valutazione finora

- 23-12-22 National ConferenceDocumento4 pagine23-12-22 National ConferenceNIKITA CHAUHANNessuna valutazione finora

- Chapter 8: ETHICS: Mores Laws Morality and EthicsDocumento3 pagineChapter 8: ETHICS: Mores Laws Morality and EthicsJohn Rey BandongNessuna valutazione finora

- IMMI S257a (s40) Requirement To Provide PIDsDocumento4 pagineIMMI S257a (s40) Requirement To Provide PIDsAshish AshishNessuna valutazione finora

- Just Design Healthy Prisons and The Architecture of Hope (Y.Jewkes, 2012)Documento20 pagineJust Design Healthy Prisons and The Architecture of Hope (Y.Jewkes, 2012)Razi MahriNessuna valutazione finora

- Projections GuideDocumento28 pagineProjections GuidemkmattaNessuna valutazione finora

- Annamalai University: Accounting For Managerial DecisionsDocumento307 pagineAnnamalai University: Accounting For Managerial DecisionsMALU_BOBBYNessuna valutazione finora

- EDUC - 115 D - Fall2018 - Kathryn GauthierDocumento7 pagineEDUC - 115 D - Fall2018 - Kathryn Gauthierdocs4me_nowNessuna valutazione finora

- Managing A Person With ADHD - Team Skills FromDocumento7 pagineManaging A Person With ADHD - Team Skills FromHieu PhanNessuna valutazione finora

- Climate Change (B Ok - CC)Documento481 pagineClimate Change (B Ok - CC)Rashid LatiefNessuna valutazione finora

- Lease FinancingDocumento17 pagineLease FinancingPoonam Sharma100% (2)

- Pip Assessment GuideDocumento155 paginePip Assessment Guideb0bsp4mNessuna valutazione finora

- GCTADocumento5 pagineGCTAPatty CabañaNessuna valutazione finora

- 2018 Vaccine Services enDocumento200 pagine2018 Vaccine Services enCiprian BalcanNessuna valutazione finora

- Quiz On Cash and Cash EquivalentDocumento5 pagineQuiz On Cash and Cash EquivalentJomel BaptistaNessuna valutazione finora

- Managerial Accounting 15Th Edition Garrison Test Bank Full Chapter PDFDocumento67 pagineManagerial Accounting 15Th Edition Garrison Test Bank Full Chapter PDFNicoleTuckeroajx100% (13)

- Case StudyDocumento2 pagineCase StudyRahul DhingraNessuna valutazione finora

- Women's Heart HealthDocumento3 pagineWomen's Heart HealthMatt ThielkeNessuna valutazione finora

- Differences Between Old and New GenerationDocumento7 pagineDifferences Between Old and New GenerationJopie ArandaNessuna valutazione finora

- Metaphysics Aristotle Comm Aquinas PDFDocumento778 pagineMetaphysics Aristotle Comm Aquinas PDFhsynmnt100% (1)

- Islam and PatriarchyDocumento21 pagineIslam and PatriarchycarolinasclifosNessuna valutazione finora

- IJHSS - A Penetrating Evaluation of Jibanananda Das' Sensibilities A Calm Anguished Vision - 3Documento10 pagineIJHSS - A Penetrating Evaluation of Jibanananda Das' Sensibilities A Calm Anguished Vision - 3iaset123Nessuna valutazione finora

- Ikea ReportDocumento48 pagineIkea ReportPulkit Puri100% (3)

- Binder PI T4 Weber July 2017Documento63 pagineBinder PI T4 Weber July 2017Nilesh GaikwadNessuna valutazione finora

- EA FRM HR 01 03 JobApplicationDocumento6 pagineEA FRM HR 01 03 JobApplicationBatyNessuna valutazione finora

- Sample TRF For Master TeacherDocumento10 pagineSample TRF For Master TeacherBernard TerrayoNessuna valutazione finora

- Cw3 - Excel - 30Documento4 pagineCw3 - Excel - 30VineeNessuna valutazione finora

- Marketing Chapter001Documento22 pagineMarketing Chapter001Reham MohamedNessuna valutazione finora

- Simao Toko Reincarnated Black JesusDocumento25 pagineSimao Toko Reincarnated Black JesusMartin konoNessuna valutazione finora

- Basavaraju Reservation Under The Constitution of India Issues and PerspectivesDocumento9 pagineBasavaraju Reservation Under The Constitution of India Issues and PerspectivesK ThirunavukkarasuNessuna valutazione finora