Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AISC - Structral Steel Connections

Caricato da

Han KokoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AISC - Structral Steel Connections

Caricato da

Han KokoCopyright:

Formati disponibili

STRUCTURE OF THE EVERYDAY

Title Slide

STRUCTURE OF THE EVERYDAY :

a teaching primer for colleges of architecture

a teaching primer for colleges of architecture

Structural Steel Connections STEEL

S T E E L

American Institute of Steel Construction1

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

PRODUCTION TEAM College of Architecture UNC - Charlotte

Project Director Slide Design & Graphics Modeling & Animations David Thaddeus, AIA Deborah J. Arbes, RA Joe Corsi Dave Mayo Jennifer August Brittany Eaker Kathy Phillips

Production Assistants

IT Coordination Matt Parker Photography David Thaddeus, AIA John Cerny

S T E E L

Software PowerPoint Photoshop Cinema 4D (Mac)

For additional information, please contact: College of Architecture, UNC-Charlotte David Thaddeus, AIA, Associate Professor Thaddeus@email.uncc.edu

Structural Steel Connections | CREDITS

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Acknowledgements

�

This project was made possible through funding from the American Institute of Steel Construction (AISC) with support from the College of Architecture at the University of North Carolina at Charlotte Special thanks to the following people at AISC for their support and help over the duration of the project: Fromy Rosenberg,PE, Director, AISC University Programs Megan Maurer, Coordinator, AISC University Programs The following people have my sincere gratitude for serving on the Focus Group and offering their comments and feedback in the development of this project : Kurt Baumgartner, AIA, JIA, University of Illinois at Urbana Champaign Terri Meyer Boake, Associate Professor, University of Waterloo Thomas Fowler, Associate Professor, California Polytechnic State University Harry Kaufman, PE, NCARB, Professor, Southern Polytechnic State University Kemp Mooney, Kemp Mooney Architects Tim Mrozowski, AIA, Professor, Michigan State University Ryan Smith, Assistant Professor, University of Utah

S T E E L

The following AISC members have provided invaluable insight into the content of this teaching aid: Ron Bruce, PE, President, Builders Steel Company, North Kansas City, MO Lawrence Kruth, PE, Engineering & Safety Manager, Douglas Steel, Lansing, MI David McKenzie, PE, Vice President - Engineering, SP International, North Kansas City, MO

Structural Steel Connections | ACKNOWLEDGEMENTS

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Terms

The American Institute of Steel Construction (AISC) is a non-profit technical institute and trade association established in 1921 to serve the structural steel design community and construction industry in the United States. AISC is offering this teaching aid and learning tool for educational purposes only. The data and information in this presentation is not intended for use in the physical construction of steel structures. The information presented here is considered public information and as such may be distributed or copied. The use of appropriate credit to for images, byline, animations, and content is requested. We hope that you and your students will find this information useful. Please contact Fromy Rosenberg (rosenberg@aisc.org) for further information on AISC or for feedback on this teaching / learning product. Please contact David Thaddeus (thaddeus@email.uncc.edu) for questions or comments on the content of this project.

S T E E L

Structural Steel Connections | TERMS

STRUCTURE OF THE EVERYDAY

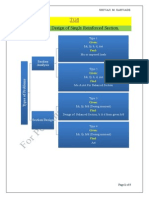

Contents

a teaching primer for colleges of architecture

Structural Steel Connections

Steel to Steel Connections

� Overview

Bolted Connections Welded Connections Comparison

� Shear Connections � Moment Connections � Column Splices � Additional Animations

Roller Connection Curtain Wall to Steel Frame

S T E E L

Module III Contents :

Structural Steel Connections | CONTENTS

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Steel Connections | Overview

� Connections are the glue that

holds a steel structure together. been due to some form of connection failure.

� Historically, most major structural failures have

S T E E L

Connections depend on:

� � � �

Type of loading Strength and stiffness Economy Difficulty or ease of erection

Structural Steel Connections | OVERVIEW

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Steel connections have a direct influence on the cost of the framing system. While a connection may be efficient in the use of material, it may still be very expensive to erect. Repetitive connection design may save costs.

S T E E L

Structural Steel Connections | OVERVIEW

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Most connections have the connecting material (plates,angles, ) attached to one member in the fabrication shop and to the other members in the field. It is a common practice to weld shop attachments and to bolt field attachments. If the supporting girder and a supported beam have the same depth, the supported beam must be double coped. End-plate connections are always shop welded.

� �

S T E E L

Structural Steel Connections | OVERVIEW

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Steel Connections | Bolted Connections

�

Bolting is the preferred method of connecting members on the site. Staggered bolt layout allows easier access for tightening with a pneumatic wrench when a connection is all bolted . High strength bolts may be snug-tightened or slip-critical. Snug-tightened connections are referred to as bearing connections Bolts in a slip-critical connection act like clamps holding the plies of the material together.

S T E E L

Structural Steel Connections | BOLTED CONNECTIONS

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Bearing type connections may have threads included ( Type N ) or excluded ( Type X ) from the shear plane(s). Including the threads in the shear plane reduces the strength of the connection by approximately 25%. Loading along the length of the bolt puts the bolt in axial tension. If tension failure occurs, it usually takes place at the threaded section.

Cy Twombly Gallery. Houston, Texas Renzo Piano

S T E E L

Milwaukee Art Museum. Milwaukee, Wisconsin Santiago Calatrava

Structural Steel Connections | BOLTED CONNECTIONS

10

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Three types of high strength bolts A325, A490 (Hexagonal Head Bolts), and F1852 (Button Head Bolt) A325 may be galvanized A490 bolts must not be galvanized F1852 bolts are mechanically galvanized High strength bolts are most commonly available in 5/8 1 diameters Bolting requires punching or drilling of holes Holes may be standard size holes, oversize holes, short slotted holes, long slotted holes

Slotted holes allow for thermal expansion / contraction

� �

S T E E L

Oversize holes allow for tolerance in assembling the frame

Structural Steel Connections | BOLTED CONNECTIONS

11

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Steel Connections | Welded Connections

�

Due to high costs of labor, extensive field -welding is the most expensive component in a steel frame. Welding should be performed on bare metal. Shop welding is preferred over field welding. The weld material should have a higher strength than the pieces being connected.

� � �

S T E E L

De Menil Collection Museum Houston . Texas Renzo Piano

BCE Place Galleria Toronto . Canada Santiago Calatrava10

Structural Steel Connections | WELDED CONNECTIONS

12

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Single-pass welds are more economical than multi-pass welds. The most economical size weld that may be horizontally deposited in one pass has 5/16. Fillet welds and groove welds make up the majority of all structural welds. The strength of a fillet weld is directly proportional to the welds throat dimension. The capacity of a weld depends on the welds throat dimension and its length

Crown Hall at IIT Campus Chicago . Illinois Ludwig Mies van der Rohe Miller Outdoor Theater Houston . Texas.

S T E E L

Structural Steel Connections | WELDED CONNECTIONS

13

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Steel Connections | Shear Connections

�

Shear connections are the most prevalent type of connections in a steel frame building. Shear connections are called simple connections Since they are assumed not to transfer bending moment, thus allowing end rotation of the member. Shear connections may be made to the web of the supported member while the flanges remain unconnected.

S T E E L

Cantilevered Beam with Shear splice

Shear Connections transfer load from beam web to column flange. No moment transfer occurs since the flanges are free to rotate

Structural Steel Connections | SHEAR CONNECTIONS

14

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

The Corning Museum of Glass Corning . New York Smith - Miller + Hawkinson

The weld material should have a higher strength than the pieces being connected. Seat or hanger connections are the only type of shear connections that connect to the flange of the supported beam.

S T E E L

� �

Angles for shear connections may be attached to supporting members by bolting or welding. Although single plate connections, are the most economical, they must sometimes be evaluated for eccentricity. Single angle connections allow end-rotation for flexible connections. Single angle connections tend to have lower load capacities than double-angle connections.

� �

Structural Steel Connections | SHEAR CONNECTIONS

15

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Steel Connections | Moment Connections

� �

Moment connections are also called rigid connections. Moment connections carry a portion or the full moment capacity of the supported member thus preventing any end-rotation of the member. Moment connections are typically designed to also carry the shear component of the load.

S T E E L

The Royal Ontario Museum Toronto . Canada Daniel Libeskind

Structural Steel Connections | MOMENT CONNECTIONS

16

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Moment connections provide continuity between the supported and supporting members. Relative rotation between the supporting and supported members is negligible. The flanges of the supported member are attached to either a connection element or directly to the supporting member.

S T E E L

The De Menil Collection Museum Houston . Texas Renzo Piano

Structural Steel Connections | MOMENT CONNECTIONS

17

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Steel Connections | Welding vs. Bolting

WELDING Advantages: Eliminates need for punching or drilling. Simplifies complicated joints. Disadvantages: Greater level of skill required for welding than bolting More expensive than bolting. Weld inspection is required and is expensive.

BOLTING Advantages: Easy method of connecting members on the site. Field-bolting is cheaper than field-welding. Disadvantages: Requires drilling or punching through all plies.

S T E E L

Structural Steel Connections | WELDING vs. BOLTING

18

STRUCTURE OF THE EVERYDAY

Shop-Bolted Double Angle | Field-Bolted Beam to Girder or Column

a teaching primer for colleges of architecture

� �

Double angles are shop-bolted to the web of the beam. If the beam and girder have the same depth, then both flanges of the beam are coped to meet flush with the top flange of the girder. of the girder.

� The double angles are then field-bolted to the web � The holes on the beam and the girder may be offset

with respect to each other for ease of fastening.

Some rotation is possible in the gap between the beam flanges and the column web. This happens by the yielding of the connection material (the outstanding angle leg) This is a shear connection since the double angles are fastened to the web, and transfer the load in shear. The bolts on the beam web are in double shear. Those on the girder web are in single shear.

S T E E L

Structural Steel Connections | SHEAR 1

19

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

Shop-Bolted Double Angle | Field-Bolted Beam to Girder or Column

Structural Steel Connections | SHEAR 1

20

STRUCTURE OF THE EVERYDAY

Shop-Welded Double Angle | Field-Bolted Beam to Girder or Column

a teaching primer for colleges of architecture

� Double angles are shop-welded to the web of the beam. � If the beam and girder have different depth, the top flange of the

beam is coped to meet flush with the top flange of the girder.

� The double angles are then field-bolted to the web of the girder. � Some rotation is possible in the gap between the beam flanges and the

column web. This happens by the yielding of the connection material (the outstanding angle leg).

� This is a shear connection since the double angles are fastened to the web,

and transfer the load in shear.

� The bolts on the girder web are in single shear.

S T E E L

Structural Steel Connections | SHEAR 2

21

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

Shop-Welded Double Angle | Field-Bolted Beam to Girder

Structural Steel Connections | SHEAR 2

22

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Shop-Welded Double Angle | Field-Welded Beam to Column Web

�

Double angles are shop-welded to the web of the beam. If the beam flanges are too wide to fit in between the column flanges, the beam flanges will be coped. Some rotation is possible in the gap between the beam flanges and the column web. This happens by the yielding of the connection material (the outstanding angle leg) This is a shear connection since the double angles are fastened to the webs of the beam and column. The vertical segment of the weld transfers the load from the beam web to the column web. Welding all around the outstanding leg will inhibit the flexibility of the connection. The weld at the top is limited to a weld-return. The weld at the bottom is optional.

S T E E L

� �

Structural Steel Connections | SHEAR 3

23

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

Shop-Welded Double Angle | Field-Welded Beam to Column Web

Structural Steel Connections | SHEAR 3

24

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

End Plate Connection | Field-Welded Beam to Girder Web

� � �

End plate is shop-welded to the web of the beam. Holes in the end plate are punched in the shop. Some rotation is possible in the gap between the beam flanges and the column web. This happens by the yielding of the connection material (the outstanding angle leg) The end plate is then field-bolted to the web of the girder. This is a shear connection as the end plate is fastened to the web of the girder (beam flanges are not secured against rotation) The bolts attaching the end plate to the girder web are in single shear.

S T E E L

Structural Steel Connections | SHEAR 4

25

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

End Plate Connection | Shop-Welded Field-Bolted

Structural Steel Connections | SHEAR 4

26

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Unstiffened Seat | Shop-Welded and Field-Bolted

�

The angles are pre-drilled or punched in the shop before they are welded to the girder or column. The bottom angle is called the seat. The seat is where the girder transfers its load to the column in bearing. The top angle provides stability to the girder. The seat angle is larger and thicker since it transfers the load from the girder to the column. Unlike others, this shear connection is not made to the web.

� �

� �

S T E E L

Structural Steel Connections | SHEAR 5

27

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Shop-Welded Seat (Unstiffened) | Field-Bolted to Column Flange

QuickTime and a Cinepak decompressor are needed to see this picture.

S T E E L

Structural Steel Connections | SHEAR 5

28

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Shop-Welded Single Plate | Field-Bolted Plate to Beam or Column

� The single plate is pre-drilled or punched and

then shop-welded to the supporting column or girder web.

� The beam may be swung into place instead of

lowered into place.

� The top flange of the beam is coped to match

the girder elevation.

� This is a shear connection since the single plate

is fastened to the web of the beam.

S T E E L

� The bolts shown are in single shear. � This connection can transfer a small amount of

moment to the supporting member

Structural Steel Connections | SHEAR 6

29

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

Shop-Welded Single Plate | Field-Bolted Plate to Beam Web

Structural Steel Connections | SHEAR 6

30

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Shop-Welded Flange Plates | Field-Bolted Girder to Column

�

The top and bottom flange plates are pre- drilled and then shop-welded to the column. The top and bottom flange plates are field-bolted to the girder flanges. The flange plates are cut to fill the space between the column flanges. The single plate on the girder web transfers shear to the column.

The Corning Museum of Glass Corning . New York Smith - Miller + Hawkinson

� �

The flange plates prevent rotation and thus the transfer of moment forces to the column Allowance for shims must be made. Mill tolerance on beam depth needs to be accommodated

S T E E L

Structural Steel Connections | MOMENT 1

31

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

Shop-Welded Flange Plates | Field-Bolted Girder to Column

Structural Steel Connections | MOMENT 1

32

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Shop-Welded Flange Plates | Field-Bolted Girder to Column

�

The top and bottom flanges are pre-drilled and then shop-welded to the column. The single plate is shop-bolted to the web of the girder. The top and bottom flange plates are field-welded to the girder flanges. The single plate is field-welded to the column web. The flange plates are cut to fill the space between the column flanges. The corners of the flange plates are clipped to eliminate the development of stress concentrations at the re-entrant (back) corners. These corners are left open and are not welded. The single plate on the girder web transfers shear to the column The flange plates prevent rotation and thus the transfer of moment forces to the column, which makes this a moment connection Allowance for shims must be made. Mill tolerance on beam depth needs to be accommodated

Structural Steel Connections | MOMENT 2

� �

� �

S T E E L

� � �

33

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

Shop-Welded Flange Plates | Field-Bolted Girder to Column

Structural Steel Connections | MOMENT 2

34

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Shop-Welded End Plate | Field-Bolted Girder to Column

�

The end plate is pre-drilled and shop-welded to the end of the girder. The corresponding holes in the column flange are pre-drilled. The two transverse stiffener plates are shopwelded to secure the column flanges against the load transferred from the girder flanges. Extended end-plate connections require tight fabrication and erection tolerances. Extended end plate prevents rotation and thus transfers moment forces to the column, which makes this a moment connection.

S T E E L

Structural Steel Connections | MOMENT 3

35

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

Shop-Welded Plate | Field-Bolted Girder to Column

Structural Steel Connections | MOMENT 3

36

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Field-Bolted Moment Splice | Girder to Girder or Column Connection

�

All holes in this connection are pre-drilled in the shop. The web and flanges of each girder are pre-drilled. (2) Shear plates are field-bolted in each side of the webs. The plates that attach the (2) webs to each other are responsible for transferring shear. Pre-drilled flange plates are field-bolted to the top and bottom flanges. The flange plates are responsible for transferring bending moments across the connection. The bolts fastening the web plates are in double shear. The flange plates prohibit any rotation and so this is a moment connection.

The Royal Ontario Museum Toronto . Canada Daniel Libeskind

S T E E L

Structural Steel Connections | MOMENT 4

37

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

Field-Bolted Moment Splice | Girder to Girder or Column Connection

Structural Steel Connections | MOMENT 4

38

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Shop-Welded or Shop Bolted Splice | Connecting Two Different Columns

The plates are pre-punched and then shop-welded to the lower (larger) column. The flange splice plates are field-bolted together. If the two columns have the same depth, but different flange thickness, then a filler plate or shim is used to make up the difference in thickness.

� �

S T E E L

Structural Steel Connections | COLUMN SPLICE 1

39

STRUCTURE OF THE EVERYDAY

Shop-Welded or Shop Bolted Splice | Connecting Two Different Size Columns

a teaching primer for colleges of architecture

S T E E L

Structural Steel Connections | COLUMN SPLICE 1

40

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

Field - Welded Column Splice

�

A temporary plate or erection aid is either welded or bolted to the web and / or flange of the lower (larger) column in the shop. Flange plates may also be required for stability of the column during erection. This plate helps align the upper and lower columns. The upper and lower columns may be of different sizes. The flanges and webs of the two columns are field- welded to each other. This type of weld is called a groove weld.

Groove welds Steel Columns are most economical when they extend over 2 or more stories

S T E E L

Structural Steel Connections | COLUMN SPLICE 2

41

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

Shop-Welded, Field - Bolted Column Splice

Structural Steel Connections | COLUMN SLPICE 2

42

STRUCTURE OF THE EVERYDAY

Thermal Expansion and Contraction for a Highway Girder on a Roller Connection

a teaching primer for colleges of architecture

S T E E L

Structural Steel Connections | Rock & Roll Connection

43

STRUCTURE OF THE EVERYDAY

S T E E L

a teaching primer for colleges of architecture

Curtain Wall Connection to a Steel Frame

Structural Steel Connections | Envelope to Frame

44

STRUCTURE OF THE EVERYDAY

a teaching primer for colleges of architecture

the end

S T E E L

Structural Steel Connections | The American Institute of Steel Construction

45

Potrebbero piacerti anche

- AISC Field Fixes PDFDocumento153 pagineAISC Field Fixes PDFfegenbush93% (15)

- AISC Design Guide 29 - Vertical Bracing Connections PDFDocumento400 pagineAISC Design Guide 29 - Vertical Bracing Connections PDFfzhou60% (5)

- Economical Structural Steel Work 1Documento117 pagineEconomical Structural Steel Work 1James Sabmeethavorn100% (21)

- HSS Connection ManualDocumento34 pagineHSS Connection Manualtylerlhsmith100% (15)

- A Teaching Guide For Structural Steel ConnectionsDocumento85 pagineA Teaching Guide For Structural Steel Connectionsv97% (65)

- Aisc Design Examples v15.0!1!800Documento800 pagineAisc Design Examples v15.0!1!800DavidHmr100% (9)

- Structural Steel Designer's Guide to Common Erection ProblemsDocumento40 pagineStructural Steel Designer's Guide to Common Erection Problemsbanbanio4680% (5)

- Design Gusset Plate LectureDocumento23 pagineDesign Gusset Plate Lecturevijaystructural50% (4)

- AISC Connection Teaching AISC ToolkitDocumento85 pagineAISC Connection Teaching AISC ToolkitoscarNessuna valutazione finora

- Steel StructuresDocumento56 pagineSteel StructuresAwais Safder Malik0% (1)

- Introduction To Connection Design For Steel StructuresDocumento22 pagineIntroduction To Connection Design For Steel StructuresErick Auger100% (6)

- Commercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsDa EverandCommercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsNessuna valutazione finora

- Stress AnalysisDocumento6 pagineStress Analysisapi-3836286100% (4)

- Moment Connections Seismic ApplicationsDocumento46 pagineMoment Connections Seismic Applicationsshak543100% (14)

- Chapter 0 ContentDocumento6 pagineChapter 0 ContentbsitlerNessuna valutazione finora

- AISC Design Guide 33 Curved Member Design 2018Documento166 pagineAISC Design Guide 33 Curved Member Design 2018saital92% (12)

- CIV 413 Structural Steel Design LectureDocumento61 pagineCIV 413 Structural Steel Design LectureحمدةالنهديةNessuna valutazione finora

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Da EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Valutazione: 4 su 5 stelle4/5 (10)

- CO2 Depressurisation OLGADocumento8 pagineCO2 Depressurisation OLGAMaheshNessuna valutazione finora

- Design of Steel-Concrete Composite Structures Using High-Strength MaterialsDa EverandDesign of Steel-Concrete Composite Structures Using High-Strength MaterialsNessuna valutazione finora

- Maintenance of Mining MachineryDocumento22 pagineMaintenance of Mining Machineryjorgeluis2000100% (1)

- Steel Structure ConnectionDocumento6 pagineSteel Structure Connectionntah84Nessuna valutazione finora

- Aisc Bracing Connections 01 PDFDocumento69 pagineAisc Bracing Connections 01 PDFPatrick PolujanNessuna valutazione finora

- Jet Bit Nozzle Size SelectionDocumento46 pagineJet Bit Nozzle Size SelectionBharat BhattaraiNessuna valutazione finora

- E-Notes of Dss - 1 B.Tech 6 SemDocumento183 pagineE-Notes of Dss - 1 B.Tech 6 SemRebel PantherNessuna valutazione finora

- Types of Steel Connections and Their SignificanceDocumento22 pagineTypes of Steel Connections and Their SignificanceAryan KhanNessuna valutazione finora

- Residential Steel Frame Building Case StudyDocumento29 pagineResidential Steel Frame Building Case Studyprajoshi62Nessuna valutazione finora

- Beginner Ansys TutorialDocumento114 pagineBeginner Ansys TutorialNGUYEN92% (12)

- Cold-formed Tubular Members and Connections: Structural Behaviour and DesignDa EverandCold-formed Tubular Members and Connections: Structural Behaviour and DesignValutazione: 5 su 5 stelle5/5 (2)

- Seminar On Steel Plate Shear WallDocumento24 pagineSeminar On Steel Plate Shear WallNilesh Saksena0% (2)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDa EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesValutazione: 4.5 su 5 stelle4.5/5 (16)

- Connections in Steel Structures III: Behaviour, Strength and DesignDa EverandConnections in Steel Structures III: Behaviour, Strength and DesignValutazione: 4 su 5 stelle4/5 (6)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDa EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsValutazione: 4 su 5 stelle4/5 (16)

- Design of Steel Structures: Materials, Connections, and ComponentsDa EverandDesign of Steel Structures: Materials, Connections, and ComponentsNessuna valutazione finora

- How To Design R.C. Flat Slabs Using Finite Element AnalysisDocumento16 pagineHow To Design R.C. Flat Slabs Using Finite Element Analysisocenkt100% (10)

- Connections Teaching ToolkitDocumento85 pagineConnections Teaching Toolkitdfv91Nessuna valutazione finora

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesDa EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNessuna valutazione finora

- Local Checks 1Documento85 pagineLocal Checks 1Alphyl BalasabasNessuna valutazione finora

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsDa EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNessuna valutazione finora

- A First Course in Optimization Theory - ContentDocumento8 pagineA First Course in Optimization Theory - ContentSuraj KumarNessuna valutazione finora

- Weld Symbols PDFDocumento1 paginaWeld Symbols PDFJimmy SanDiego100% (1)

- The Analysis of Irregular Shaped Structures: Wood Diaphragms and Shear Walls, Second EditionDa EverandThe Analysis of Irregular Shaped Structures: Wood Diaphragms and Shear Walls, Second EditionNessuna valutazione finora

- Construction Methods in Industrialized BuildingsDocumento37 pagineConstruction Methods in Industrialized BuildingsJoseph EzekielNessuna valutazione finora

- Aisc-The Material SteelDocumento48 pagineAisc-The Material Steelropin14Nessuna valutazione finora

- Research Papers On Steel StructuresDocumento4 pagineResearch Papers On Steel Structuresjuzel0zupis3100% (1)

- DSS Site Visit ReportDocumento13 pagineDSS Site Visit Report39 - Deep MandokarNessuna valutazione finora

- D.Y. PATIL PRATISHTHANS Steel ConnectionsDocumento28 pagineD.Y. PATIL PRATISHTHANS Steel ConnectionsShad FarasNessuna valutazione finora

- Structural Steel Design FundamentalsDocumento13 pagineStructural Steel Design FundamentalsNiña Criselle PasiaNessuna valutazione finora

- Steel Structure ThesisDocumento8 pagineSteel Structure Thesisdeniseenriquezglendale100% (2)

- AcknowledgementDocumento26 pagineAcknowledgementToniMeloNessuna valutazione finora

- Structural Channel: 1 UsageDocumento2 pagineStructural Channel: 1 UsageRahul ChandraNessuna valutazione finora

- Fundamentals of Steel Part B: Professor Patrick L. GlonDocumento33 pagineFundamentals of Steel Part B: Professor Patrick L. GlonSSNessuna valutazione finora

- Jounal Composite 4Documento11 pagineJounal Composite 4barath kumarNessuna valutazione finora

- Lect 01-02Documento18 pagineLect 01-02thorkhan42Nessuna valutazione finora

- Analysis and Design of Multi-Storeyed Building by Steel Concrete Composite StructureDocumento9 pagineAnalysis and Design of Multi-Storeyed Building by Steel Concrete Composite StructureUsha EngineeringNessuna valutazione finora

- Design of Steel and Concrete Composite StructuresDocumento19 pagineDesign of Steel and Concrete Composite StructuresCristian BlanaruNessuna valutazione finora

- Steel DesignDocumento131 pagineSteel DesignAndrea RamirezNessuna valutazione finora

- NSEL Report 014 Part IIDocumento44 pagineNSEL Report 014 Part IIAllison KeyNessuna valutazione finora

- Experimental Study of Gusset Plate Connections For Tubular BracingDocumento1 paginaExperimental Study of Gusset Plate Connections For Tubular BracingebiNessuna valutazione finora

- Researchpaper Design Model of Built Up Stiffened Column Base Under Large Eccentric LoadDocumento10 pagineResearchpaper Design Model of Built Up Stiffened Column Base Under Large Eccentric LoadNishant GaurNessuna valutazione finora

- CE2352 DSS 2 Marks With AnswerDocumento33 pagineCE2352 DSS 2 Marks With Answerkavithamartin28Nessuna valutazione finora

- Design and Drawing of Steel Steructures (15A01602) : Vemu Institute of TechnologyDocumento95 pagineDesign and Drawing of Steel Steructures (15A01602) : Vemu Institute of Technologysoumyadeba04Nessuna valutazione finora

- Design of Steel Structures Handout 2012-2013Documento3 pagineDesign of Steel Structures Handout 2012-2013Tushar Gupta100% (1)

- J-Bolt Design For StructureDocumento2 pagineJ-Bolt Design For StructureHan KokoNessuna valutazione finora

- Forged Steel ValveDocumento100 pagineForged Steel ValveHan KokoNessuna valutazione finora

- Weekly Eleven Vol 7 No 34Documento44 pagineWeekly Eleven Vol 7 No 34Thit Htoo LwinNessuna valutazione finora

- M04 TemperatureDocumento64 pagineM04 TemperatureLê Văn TrườngNessuna valutazione finora

- Computer Networks Radio Waves: Submitted By: 1.naina Gupta 2.sunidhi Dwivedi Submitted To: Ms. Asha Ma'amDocumento9 pagineComputer Networks Radio Waves: Submitted By: 1.naina Gupta 2.sunidhi Dwivedi Submitted To: Ms. Asha Ma'amsantaNessuna valutazione finora

- Modeling Arterial Blood Flow With Navier-StokesDocumento15 pagineModeling Arterial Blood Flow With Navier-Stokesapi-358127907100% (1)

- Determination of The Diffraction Intensity at Slit and Double Slit SystemsDocumento5 pagineDetermination of The Diffraction Intensity at Slit and Double Slit SystemsJose Galvan100% (1)

- CHE572 Chapter 2 Particle Size Characterization PDFDocumento18 pagineCHE572 Chapter 2 Particle Size Characterization PDFMuhd FahmiNessuna valutazione finora

- AAS 6300 Service ManualDocumento76 pagineAAS 6300 Service Manualfuadye100% (1)

- Renewableand Sustainable Energy ReviewsDocumento9 pagineRenewableand Sustainable Energy Reviewssundeep sNessuna valutazione finora

- LS-DYNA-Intro 14.5 L01 Intro To Exp DynDocumento40 pagineLS-DYNA-Intro 14.5 L01 Intro To Exp DynAnil KumarNessuna valutazione finora

- Teleportation AbstractDocumento2 pagineTeleportation Abstractvishal2988Nessuna valutazione finora

- Lecture2 Semiconductor StatisticsDocumento13 pagineLecture2 Semiconductor StatisticsRakib KhanNessuna valutazione finora

- Structural Health Monitoring: Abin Paul Roll No:4 S7, CE-ADocumento34 pagineStructural Health Monitoring: Abin Paul Roll No:4 S7, CE-AAnjana kpNessuna valutazione finora

- ANSYS Model of A Cylindrical Fused Silica Fibre-01Documento15 pagineANSYS Model of A Cylindrical Fused Silica Fibre-01lamia97Nessuna valutazione finora

- Electrical Engineering BA (B), Analog Electronics, ET065G 6 Credits ET064G 7.5 CreditsDocumento43 pagineElectrical Engineering BA (B), Analog Electronics, ET065G 6 Credits ET064G 7.5 Creditsdev-nullNessuna valutazione finora

- Chapter 2 1 - Linear EquationsDocumento23 pagineChapter 2 1 - Linear Equationsapi-263209117Nessuna valutazione finora

- Catalog Whatman 2018.compressedDocumento214 pagineCatalog Whatman 2018.compressedRakha Milan BachtiarNessuna valutazione finora

- Notes Singly RF BeamDocumento5 pagineNotes Singly RF Beamshivaji_sarvadeNessuna valutazione finora

- Measuring Planck's Constant with LEDsDocumento7 pagineMeasuring Planck's Constant with LEDsAngy100% (1)

- Metodo Epa 18Documento40 pagineMetodo Epa 18Luis TrejoNessuna valutazione finora

- Helm (2008) : Section 32.4: Parabolic PdesDocumento24 pagineHelm (2008) : Section 32.4: Parabolic Pdestarek mahmoudNessuna valutazione finora

- Modeling of Synchronous Generators in Power System Studies: October 2016Documento12 pagineModeling of Synchronous Generators in Power System Studies: October 2016aswardiNessuna valutazione finora

- Four Decades of Research On Thermal Contact, Gap, and Joint Resistance in MicroelectronicsDocumento25 pagineFour Decades of Research On Thermal Contact, Gap, and Joint Resistance in MicroelectronicsDaniel MendesNessuna valutazione finora

- Inline Desilter ManualDocumento18 pagineInline Desilter ManualdesaviniciusNessuna valutazione finora

- Installation Operation Maintenance Manual (Harvest Series)Documento36 pagineInstallation Operation Maintenance Manual (Harvest Series)berkahharianNessuna valutazione finora

- A First Course in Linear Algebra PDFDocumento424 pagineA First Course in Linear Algebra PDFShelvin Naidu100% (1)