Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Honeywell 393690 Inlet Outlet Flange Kits 69-0256

Caricato da

Alfredo Castro FernándezDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Honeywell 393690 Inlet Outlet Flange Kits 69-0256

Caricato da

Alfredo Castro FernándezCopyright:

Formati disponibili

393690 Inlet/outlet Flange Kits

INSTALLATION INSTRUCTIONS

APPLICATION

These inlet/outlet flanges are used for modifying the VR82 Series family of combination gas controls for use with different pipe sizes and piping configurations. Flanges (PART NO. 393690) are available for 3/8 in., 1/2 in. and 3/4 in. straight and angle (elbow) connections. All elbow flanges are 90 degrees. All flange kits include one flange with attached O-ring and four mounting screws. TRADELINE kits also include a 9/64 in. hex wrench. See Table 1.

WARNING

To avoid dangerous accumulation of fuel gas, turn off gas supply at the appliance service valve before starting installation, and perform Gas Leak Test after completion of installation.

IMPORTANT Gas controls are shipped with protective seals over inlet and outlet tappings. Do not remove seals until ready to connect flange and piping.

Table 1. Inlet/Outlet Flanges for VR8200 Family of Combination Gas Controls Part No. Inlet/Outlet Pipe Size 3/8 in. NPT 1/2 in. NPT 3/4 in. NPT

aElbow

Flange Type Straight Elbowa Straight Elbow Elbow

a

Less Hex Wrench 393690-2 393690-6 393690-3 393690-4 393690-5

With Hex Wrench 393690-11

393690-13 393690-15

OUTLET RIGHT 9/64 IN. HEX SCREWS

Straight

a

flanges cannot be used on the inlet end of standing pilot models if the ECO connector is used.

INSTALLATION

When installing this product... 1. 2. 3. 4. Read these instructions carefully. Failure to follow them could damage the product or cause a hazardous condition. Check the ratings given in the instructions and on the product to make sure the product is suitable for your application. Installer must be a trained, experienced service technician. After installation is complete, check out product operation as provided in gas control instructions.

OUTLET UP

OUTLET LEFT

OUTLET DOWN

M32873A

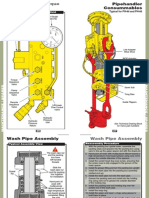

Fig. 1. Fasten flange to gas control using 25 inch-pounds torque.

Put Bar Code Here

69-0256-03

393690 INLET/OUTLET FLANGE KITS

Install flange on control

Choose the appropriate flanges for your application. Follow the appropriate installation steps outlined below. See Fig. 1. 1. 2. 3. Remove seal over control inlet or outlet. Check to insure that the O-ring is fitted in the groove of the flange. If O-ring is not attached or is missing, do not install flange. With O-ring facing control, line up the screw holes on the control with the holes in the flange. Insert and tighten the hex screws provided with the flange. Tighten screws to 25 inch-pounds torque to provide a gas tight seal. Complete installation following instructions provided with the control. If a wrench is used on the control after flanges are mounted, apply the wrench to the flange, not the control. See Fig. 2.

WHEN FLANGE IS NOT USED

Using flanges to solve swing radius problems

In some field service applications, it is difficult or impossible to thread the control onto the gas supply pipe because of space limitations. This problem can be resolved in many instances through the use of a flange. The flange is installed on the end of the supply pipe in place of the gas control, following the same precautions and instructions that are used for installing the gas control. After the flange is installed, the gas control is attached to the flange as outlined above. Note that use of the flange increases the overall length of the gas control.

4.

WHEN FLANGE IS USED

APPLY WRENCH FROM TOP OR BOTTOM OF GAS CONTROL TO EITHER SHADED AREA

APPLY WRENCH TO FLANGE ONLY

M3079B

Fig. 2. Proper use of wrench on gas control with and without flanges.

CHECKOUT

After all system piping is complete, perform Gas Leak Test, making sure to test joint between flanges and gas control.

WARNING

Perform the gas leak test any time work is done on a gas system to avoid the possibility of fire or explosion with property damage, personal injury or loss of life.

The Gas Leak Test is performed as follows: Paint pipe connections upstream of gas control with a rich soap and water solution to test for leaks before operating main burner. Bubbles indicate gas leak. To stop leak, tighten pipe connections. After piping connections are checked, turn on main burner. Stand clear while lighting pilot or while main burner ignites to prevent injury caused from hidden leaks which could cause flashback in the appliance vestibule. With main burner in operation, paint pipe joints (including flanges), pilot gas tubing connections and control inlet and outlet with rich soap and water solution. Bubbles indicate gas leak. To stop leak, tighten flange screws, joints and pipe connections. Replace part if leak can't be stopped.

Automation and Control Solutions

Honeywell International Inc. 1985 Douglas Drive North Golden Valley, MN 55422 customer.honeywell.com

U.S. Registered Trademark 2011 Honeywell International Inc. 69-025603 M.S. Rev. 08-11 Printed in United States

Potrebbero piacerti anche

- Holley Carb AdjustmentsDocumento8 pagineHolley Carb AdjustmentsAaron SteeleNessuna valutazione finora

- ConfrontoDocumento6 pagineConfrontosgarrozzoNessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- Women in CombatDocumento16 pagineWomen in CombatArina PredaNessuna valutazione finora

- Engine Fuel System Troubleshooting GuideDocumento19 pagineEngine Fuel System Troubleshooting GuidePablo Rojas Valenzuela100% (1)

- 199R7948 5rev5 PDFDocumento16 pagine199R7948 5rev5 PDFbatman2054Nessuna valutazione finora

- Counterstrain PointsDocumento7 pagineCounterstrain PointsHamza100% (2)

- 1KR-FE Emission ControlDocumento105 pagine1KR-FE Emission ControlChristina Smith100% (3)

- Compressor WabcoDocumento6 pagineCompressor Wabcoruben_cruz_34Nessuna valutazione finora

- Weber ManualDocumento28 pagineWeber ManualMedardo SilvaNessuna valutazione finora

- 3306 Industrial Engine 64Z05381-UP (SEBP1989 - 33) - Sistemas y ComponentesDocumento15 pagine3306 Industrial Engine 64Z05381-UP (SEBP1989 - 33) - Sistemas y ComponentesLynda Carroll100% (2)

- Dragon Keeper Chap 21-24questionsDocumento9 pagineDragon Keeper Chap 21-24questionsapi-2328088250% (2)

- Objective - To Familiarization Students With Regulation and Guidelines in Place To Prevent Accident With LifeboatsDocumento31 pagineObjective - To Familiarization Students With Regulation and Guidelines in Place To Prevent Accident With LifeboatsOladokun Sulaiman Olanrewaju100% (9)

- Surgical InstrumentsDocumento4 pagineSurgical InstrumentsGlaizalyn Fabella TagoonNessuna valutazione finora

- Denervation of Hand JointsDocumento42 pagineDenervation of Hand JointsHand SurgeryNessuna valutazione finora

- Shoulder Joint Anatomy GunaDocumento65 pagineShoulder Joint Anatomy Gunakaradi2000Nessuna valutazione finora

- Rotator CuffDocumento46 pagineRotator CuffLiza Perez- Pagatpatan100% (2)

- Manual Valvula PCVDocumento16 pagineManual Valvula PCVzamirgothNessuna valutazione finora

- Worksafe Manual HandlingDocumento18 pagineWorksafe Manual HandlingtahseenhassantirmiziNessuna valutazione finora

- 1NZ-FE Fuel Injector RemovalDocumento47 pagine1NZ-FE Fuel Injector RemovalJulien Daulon63% (8)

- Kato Traction Alternator ManualDocumento30 pagineKato Traction Alternator ManualsupriNessuna valutazione finora

- CAT 3412 Air Inlet and Exhaust SystemDocumento8 pagineCAT 3412 Air Inlet and Exhaust SystemCEVegaO100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Instruction Manual Air CompressorDocumento13 pagineInstruction Manual Air Compressornguyenvanhai1903198156% (9)

- Mobility Nursing Diagnosis GuideDocumento3 pagineMobility Nursing Diagnosis GuideYan ReyesNessuna valutazione finora

- Emergency Nursing Priorities/TITLEDocumento8 pagineEmergency Nursing Priorities/TITLECharisse TaylanNessuna valutazione finora

- LPG Carbon Dioxide Fire Suppression System Installation Manual .Documento50 pagineLPG Carbon Dioxide Fire Suppression System Installation Manual .hrhgk100% (1)

- Lipke Second EditionDocumento194 pagineLipke Second EditionDavid Wrobel100% (7)

- Gas Booster 5 0.75 Series Models AG AGD AGT S PDFDocumento16 pagineGas Booster 5 0.75 Series Models AG AGD AGT S PDFu2006262918100% (1)

- Handbook of RefractoryDocumento331 pagineHandbook of RefractoryAamirMalikNessuna valutazione finora

- Troubleshooting The Divider Block SystemDocumento3 pagineTroubleshooting The Divider Block SystemMarcus MorganNessuna valutazione finora

- Operation Manual Horizontal Split CaseDocumento24 pagineOperation Manual Horizontal Split CaseadiNessuna valutazione finora

- SIT630 Installation InstructionsDocumento2 pagineSIT630 Installation Instructionsmelisa63Nessuna valutazione finora

- vr8305 Direct Ignition Combination Gas Control ManualDocumento15 paginevr8305 Direct Ignition Combination Gas Control ManualJulio GnzlzNessuna valutazione finora

- Warning: Installation Instructions For Level MaintainersDocumento4 pagineWarning: Installation Instructions For Level MaintainersDiego Fernando Pedroza UribeNessuna valutazione finora

- Operating Manual: Altronic Gas Control Valve, 690210Documento12 pagineOperating Manual: Altronic Gas Control Valve, 690210Esau Jose PabloNessuna valutazione finora

- 3306B MrhernadezDocumento108 pagine3306B MrhernadezAnderson SalazarNessuna valutazione finora

- V776-561-004S Air Dryer CheckDocumento4 pagineV776-561-004S Air Dryer CheckWilson BuenoNessuna valutazione finora

- XB 13 InstallDocumento8 pagineXB 13 InstalljbozakNessuna valutazione finora

- Convertidor Neumatico Y695ADocumento8 pagineConvertidor Neumatico Y695AALBERTONessuna valutazione finora

- Trinity & Matrix: Natural To LP Conversion InstructionsDocumento4 pagineTrinity & Matrix: Natural To LP Conversion InstructionsFREDNessuna valutazione finora

- Ball Valve BrochureDocumento6 pagineBall Valve BrochureRohith GrandhiNessuna valutazione finora

- Accelerator Control, Fuel & Exhaust Systems: Go To Table of Contents Go To Quick Reference IndexDocumento5 pagineAccelerator Control, Fuel & Exhaust Systems: Go To Table of Contents Go To Quick Reference IndexLevin Tan HtNessuna valutazione finora

- Automatic Gas Manifolds Installation, Operation & Maintenance ManualDocumento20 pagineAutomatic Gas Manifolds Installation, Operation & Maintenance ManualtaibkNessuna valutazione finora

- Inst Manual Outdoor252 450CDocumento12 pagineInst Manual Outdoor252 450CAgustin CesanNessuna valutazione finora

- VR8205 & VR4205 Spec - PDF INSTALLDocumento8 pagineVR8205 & VR4205 Spec - PDF INSTALLAlejandro ObregonNessuna valutazione finora

- General Instructions For Safe Operation of High Pressure CompressorsDocumento6 pagineGeneral Instructions For Safe Operation of High Pressure CompressorsTansu MavunacıNessuna valutazione finora

- Maintenance Working Hours Flow For Gas TurbineDocumento7 pagineMaintenance Working Hours Flow For Gas TurbineHilmi HanoinNessuna valutazione finora

- 1063 Forged Brass Spring Check ValveDocumento5 pagine1063 Forged Brass Spring Check ValveSyed FazluNessuna valutazione finora

- Operating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasDocumento20 pagineOperating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasCarlos RondonNessuna valutazione finora

- CVS Pressure Controller ManualDocumento12 pagineCVS Pressure Controller ManualOghale B. E. OmuaborNessuna valutazione finora

- Bomba Primaria e CombustibleDocumento8 pagineBomba Primaria e CombustibleoscarNessuna valutazione finora

- Sno 450 XRDocumento20 pagineSno 450 XRMelvin HrsNessuna valutazione finora

- SB388CDocumento13 pagineSB388CBenjamin LeedsNessuna valutazione finora

- 189 010 - en 15.710057 V3.0Documento12 pagine189 010 - en 15.710057 V3.0balzac191Nessuna valutazione finora

- Compressed Gas Regulators v2 0Documento12 pagineCompressed Gas Regulators v2 0RajanbabuNessuna valutazione finora

- Megafire ManualDocumento6 pagineMegafire ManualBehnam NoorizadehNessuna valutazione finora

- Harris Regulator ManualDocumento12 pagineHarris Regulator ManualButton DavidsonNessuna valutazione finora

- Engine reassembly step-by-step guideDocumento5 pagineEngine reassembly step-by-step guidepatrick barruetaNessuna valutazione finora

- Induction Module Assembly 9.5: GeneralDocumento10 pagineInduction Module Assembly 9.5: Generalvette512Nessuna valutazione finora

- Series RM Rate-Master Flowmeters: Specifications - Installation and Operating InstructionsDocumento2 pagineSeries RM Rate-Master Flowmeters: Specifications - Installation and Operating InstructionsDJoko Trend RedsNessuna valutazione finora

- Fill Rite Fuel MeterDocumento12 pagineFill Rite Fuel MeterriobmNessuna valutazione finora

- Cylinder Change PurgingDocumento16 pagineCylinder Change Purgingengg_mech77Nessuna valutazione finora

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDocumento4 pagineAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangNessuna valutazione finora

- Multistage Vertical Inline Pumps PM1, PM3, PM5 Series: Specifications Information and Repair Parts ManualDocumento12 pagineMultistage Vertical Inline Pumps PM1, PM3, PM5 Series: Specifications Information and Repair Parts ManualAnibal QuezadaNessuna valutazione finora

- Torque TDS4 Pocket Guide-2 PDFDocumento5 pagineTorque TDS4 Pocket Guide-2 PDFHaridev50% (2)

- AIB - GVS - 20 Bomba de VacioDocumento11 pagineAIB - GVS - 20 Bomba de VacioRico GonzalezNessuna valutazione finora

- Iron Balancing Valves IOM For Hattersley ColourDocumento8 pagineIron Balancing Valves IOM For Hattersley ColourMuhammad ElbarbaryNessuna valutazione finora

- Sum-Carb InstrDocumento14 pagineSum-Carb InstrbobNessuna valutazione finora

- Checks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlDocumento4 pagineChecks To Be Carried Out On Receipt of The Actuator: ! - #$ Flow ControlSyko GuyNessuna valutazione finora

- I PM380-125 07 05 enDocumento8 pagineI PM380-125 07 05 enOmprakash_janaNessuna valutazione finora

- 3.4.3 Process Connections: Liquid Service Gas Service Steam ServiceDocumento1 pagina3.4.3 Process Connections: Liquid Service Gas Service Steam ServiceTanuTiganuNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SDa EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNessuna valutazione finora

- Fisher LP-Gas Regulators and Equipment Application Guide d450104t012Documento87 pagineFisher LP-Gas Regulators and Equipment Application Guide d450104t012Alfredo Castro FernándezNessuna valutazione finora

- 30 LED ProjectsDocumento37 pagine30 LED ProjectsMohamed Farag MostafaNessuna valutazione finora

- Spectronic 20 DatasheetDocumento4 pagineSpectronic 20 DatasheetAlfredo Castro FernándezNessuna valutazione finora

- Localization of Brain Stem LesionsDocumento35 pagineLocalization of Brain Stem LesionsHrishikesh Jha0% (1)

- Pionjar 120Documento40 paginePionjar 120Igor Halterbeck HalterbeckNessuna valutazione finora

- Fractures and SplintingDocumento20 pagineFractures and Splintingapi-19867248Nessuna valutazione finora

- Section A (Compulsory) (5x8 40) Answer The Following: I) Name The FollowingDocumento5 pagineSection A (Compulsory) (5x8 40) Answer The Following: I) Name The FollowingDebaditya ChakrabortyNessuna valutazione finora

- 11 (2) Effectiveness of Therapeutic Ultrasound and Kinesiotape in Treatment of Tennis Elbow (Jusmaniar) IIDocumento9 pagine11 (2) Effectiveness of Therapeutic Ultrasound and Kinesiotape in Treatment of Tennis Elbow (Jusmaniar) IIainunNessuna valutazione finora

- PREPAREDNESS PLANNING AND RISK ASSESSMENTDocumento4 paginePREPAREDNESS PLANNING AND RISK ASSESSMENTanita theresiaNessuna valutazione finora

- Blood Supply of Head and NeckDocumento29 pagineBlood Supply of Head and NeckBM mugalNessuna valutazione finora

- Practice Final ExamDocumento8 paginePractice Final ExamMaria Jeorgia SalinasNessuna valutazione finora

- DNA TESTING REVEALS CRIMINAL JUSTICE EXAMDocumento7 pagineDNA TESTING REVEALS CRIMINAL JUSTICE EXAMJobelle Badrina Javier - SalacNessuna valutazione finora

- Med Surg Sensory Sample PDFDocumento30 pagineMed Surg Sensory Sample PDFShucipto DwiNessuna valutazione finora

- Severity Assessment and Scoring For Neurosurgical Models in RodentsDocumento11 pagineSeverity Assessment and Scoring For Neurosurgical Models in RodentsKazhi SujudNessuna valutazione finora

- Forensic BallisticDocumento12 pagineForensic BallisticYash GuptaNessuna valutazione finora

- Overcoming Shoulder Dystocia in an Emergency SituationDocumento20 pagineOvercoming Shoulder Dystocia in an Emergency Situationfarhan fauziNessuna valutazione finora

- II.2.Diaphragm (M.diaphragma Thoracoabdominalis)Documento2 pagineII.2.Diaphragm (M.diaphragma Thoracoabdominalis)alllexissssNessuna valutazione finora

- Health Week 4 - 3rd QuarterDocumento5 pagineHealth Week 4 - 3rd QuarterNoemelyn VecinaNessuna valutazione finora

- Grammar For Corporate WorkersDocumento146 pagineGrammar For Corporate WorkersVictor RodriguesNessuna valutazione finora