Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3011 Newest PG2

Caricato da

ccglobalincTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3011 Newest PG2

Caricato da

ccglobalincCopyright:

Formati disponibili

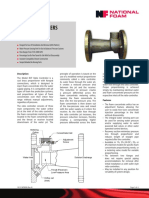

BLANKET GAS REGULATORS

OPTIMUM PROTECTION

For optimum protection of a tank

and to meet regulatory require-

ments, each tank should be

protected by 1) a properly-sized

blanket gas regulator, to maintain

the vapor pressure in the tank, 2) a

properly-sized pressure/vacuum

relief valve or pilot operated valve,

to release the vapor during pump-in Pressure Vacuum Relief Valve BLANKET GAS REGULATOR

or thermal expansion, and 3) a MODELS MODELS

Emergency Relief Valve 1200, 1220, 1460, 1660, 3011L/H –3041L/H

properly-sized emergency relief MODELS 8800, 8820, 8860 From 200 psig to 0.5" WC

valve to protect against pressure 2500, 2400, 2300, 2000 0.87" WC to +15 psig/ or 200 psig to -8" WC

+0.87" WC to +15 psig -0.87" WC to -12 psig with one regulator

rise due to external fire. Tank

protection systems can be

combined across multiple tanks, but blanket gas regulator models and Flow Capacity

careful consideration must be given specifications.

1. Determine the set pressure of Required flow capacity should be

to provide adequate relief and input

the tank determined by using API 2000 or

capacity and to prevent fouling or

2. Determine the pressure of the the relevant sizing standard. Groth

clogging of system piping. Consult

blanket gas supply Corporation’s “Cal-Q-Size” will size

Groth Corporation for assistance in

3. Select the appropriate model your valve and regulator applica-

these situations.

number from Table 1, Product tions in accordance with API 2000.

A Groth blanket gas regulator Selection Guide To find the rated capacity for your

prevents evaporation or contam- 4. Determine the flow capacity application, please refer to Table 2,

ination in a tank and prevents a from Table 2, Flow Capacity Flow Capacity. Capacity is listed as

flammable or explosive environment 5. Select the appropriate spring a function of supply pressure for

in the tank vapor space. A Groth range from Table 3, Spring four typical blanket gases: carbon

pressure/ vacuum relief valve or Ranges dioxide, nitrogen, natural gas, and

pilot operated valve with vacuum 6. Configure the proper model air.

relief will maintain a bubble-tight number and select soft goods

seal to prevent vapor from escaping and connection type from How

into the atmosphere until the set to Order Standard Blanket Gas

pressure is exceeded, and provide Regulators on page 4.

vacuum protection in case of a gas

supply failure. The emergency relief Table 1 — PRODUCT SELECTION GUIDE

valve will provide vessel protection 1" 3011/3041 BGR 1/2" 3011/3041 BGR

under control system failure or Supply Pressure psig / barg Supply Pressure psig / barg

external fire conditions. 5– >51 – >101– >151– 5– >51 – >101– >151–

Set Pressure 50 100 150 200 Set Pressure 50 100 150 200

Benefits of storage tank 0.3 – 3.5 – 7.0 – 10.4 – 0.3 – 3.5 – 7.0 – 10.4 –

blanketing are recognized by the 3.4 6.9 10.3 13.8 3.4 6.9 10.3 13.8

following government regulations -2.0" – -8.0" WC -2.0" – -8.0" WC

-5.0 – -20 mbar -5.0 – -20 mbar

and industrial standards: -1.5" – -1.9" WC -1.5" – -1.9" WC

• API Standard 2000 -3.7 – -5.0 mbar 3041H -3.7 – -5.0 mbar

-1.0" – -1.4" WC -1.0" – -1.4" WC 3041H

• EPA Publication AP-42 -2.5 – -3.7 mbar -2.5 – -3.7 mbar

• NFPA 69 - Standard on 3041L

-0.5" – -0.9" WC -0.5" – -0.9" WC

Explosion Prevention Systems -1.2 – -2.5 mbar -1.2 – -2.5 mbar 3041L

• OSHA Part 1910.10 0.5" – 0.9" WC 0.5" – 0.9" WC

1.2 – 2.5 mbar 1.2 – 2.5 mbar 3011L

3011L

1.0" – 1.4" WC 1.0" – 1.4" WC

How to Select a BGR 2.5 – 3.7 mbar 2.5 – 3.7 mbar

1.5" – 1.9" WC 3011H 1.5" – 1.9" WC

3011H

Based on your system require- 3.7 – 5.0 mbar 3.7 – 5.0 mbar

ments, use the information in the 2.0" – 8.0" WC 2.0" – 8.0" WC

5.0 – 20 mbar 5.0 – 20 mbar

following tables to select the proper

2 Groth Corporation, a Continental Disc company, Stafford, TX, USA

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 001-008 Camshaft: InstallDocumento6 pagine001-008 Camshaft: InstallNaing Min HtunNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- MODEL XQ140/20 Hydraulic Power Tong: Parts and Operation ManualDocumento57 pagineMODEL XQ140/20 Hydraulic Power Tong: Parts and Operation ManualCarlos Antonio Fontalvo Carrascal100% (1)

- MM PT6T-3B 72-3Documento24 pagineMM PT6T-3B 72-3Panca Xp100% (1)

- Optimized Skid Design For Compressor PackagesDocumento9 pagineOptimized Skid Design For Compressor Packagesmario_gNessuna valutazione finora

- Universal Alternators Catalog PDFDocumento56 pagineUniversal Alternators Catalog PDFChristopherNessuna valutazione finora

- Screw ConveyorDocumento14 pagineScrew ConveyorMuhammad NuhNessuna valutazione finora

- Internship Report On Suzuki Gujranwala MotorsDocumento108 pagineInternship Report On Suzuki Gujranwala MotorsAbdulrehman Butt87% (15)

- Data Sheet - Rev 01Documento158 pagineData Sheet - Rev 01Martin DanzeNessuna valutazione finora

- GROTH Product Selection GuideDocumento12 pagineGROTH Product Selection GuideccglobalincNessuna valutazione finora

- Model 3011 / 3041: Industrial ProductsDocumento4 pagineModel 3011 / 3041: Industrial ProductsccglobalincNessuna valutazione finora

- Model 3011 / 3041: Industrial ProductsDocumento4 pagineModel 3011 / 3041: Industrial ProductsccglobalincNessuna valutazione finora

- SchematicDocumento1 paginaSchematicccglobalincNessuna valutazione finora

- Fiitjee: Answers, Hints & SolutionsDocumento10 pagineFiitjee: Answers, Hints & SolutionsZayanmalikNessuna valutazione finora

- Domex 355 MC: High Strength Cold Forming SteelDocumento2 pagineDomex 355 MC: High Strength Cold Forming SteelKhantoNessuna valutazione finora

- Scheda Tecnica: IT-T1S Itb-T1SDocumento1 paginaScheda Tecnica: IT-T1S Itb-T1SITALFIL S.p.A.Nessuna valutazione finora

- Civic Turbo DieselDocumento202 pagineCivic Turbo DieselLuciano PereiraNessuna valutazione finora

- Aluminum Crane Systems 1110701Documento32 pagineAluminum Crane Systems 1110701aidixon CAD designNessuna valutazione finora

- Tubo Sin CosturaDocumento4 pagineTubo Sin CosturaJl KaneNessuna valutazione finora

- Mech Dynamics 15.0 L07 Spectrum PDFDocumento69 pagineMech Dynamics 15.0 L07 Spectrum PDFAnonymous P8Bt46mk5INessuna valutazione finora

- 125 Series Diesel: ConvertibleDocumento2 pagine125 Series Diesel: ConvertibleLuis Alberto Serrano MesaNessuna valutazione finora

- Materials and Design: Jun Li, Chengqing Wu, Hong Hao, Yu SuDocumento15 pagineMaterials and Design: Jun Li, Chengqing Wu, Hong Hao, Yu SuAbdulkhaliq AbdulyimahNessuna valutazione finora

- Grundfos CRT 8 5 A P A e AuueDocumento9 pagineGrundfos CRT 8 5 A P A e AuueRajesh KanalaNessuna valutazione finora

- Refractory Equipment GAODETECDocumento9 pagineRefractory Equipment GAODETECorangel anayaNessuna valutazione finora

- Module 2Documento43 pagineModule 2Manchimsetty Sri NidhiNessuna valutazione finora

- Bond Graph Modeling and Computer Simulation of Automotive Torque ConvertersDocumento22 pagineBond Graph Modeling and Computer Simulation of Automotive Torque ConvertersPratik ShahNessuna valutazione finora

- Correlation of Bendability of Materials With Their Tensile Properties Datsko Bab4480.0001.001Documento21 pagineCorrelation of Bendability of Materials With Their Tensile Properties Datsko Bab4480.0001.001lram70Nessuna valutazione finora

- Hydraulics - Civil Engineering Questions and Answers Page 3Documento6 pagineHydraulics - Civil Engineering Questions and Answers Page 3umairNessuna valutazione finora

- Parker 2H CylindersDocumento26 pagineParker 2H CylindersnitinjainmechNessuna valutazione finora

- Filter PartnumberDocumento1.019 pagineFilter PartnumberjaijeyenderNessuna valutazione finora

- 456895431585387343213$5 1refnoapplied MechanicsDocumento1 pagina456895431585387343213$5 1refnoapplied MechanicsKumar SaurabhNessuna valutazione finora

- DDTW Properties For High Strength Line Pipe SteelsDocumento5 pagineDDTW Properties For High Strength Line Pipe SteelsWagner Duarte FloresNessuna valutazione finora

- National Foam ManualDocumento4 pagineNational Foam ManualRiky AyalaNessuna valutazione finora

- Conservation of MomentumDocumento9 pagineConservation of MomentumStraight As StudyNessuna valutazione finora

- Mfe24pi1505 Design of Production Toolingdrill BushingsDocumento14 pagineMfe24pi1505 Design of Production Toolingdrill BushingsSubrat pandaNessuna valutazione finora