Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

9D15106b Gear Engineering

Caricato da

Muni MuneendranCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

9D15106b Gear Engineering

Caricato da

Muni MuneendranCopyright:

Formati disponibili

www.jntuworld.

com

www.android.jntuworld.com

www.jwjobs.net

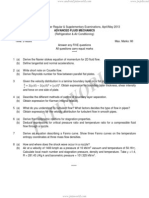

Code: 9D15106b M. Tech I Semester Regular & Supplementary Examinations, April/May 2013 GEAR ENGINEERING (Machine Design) Time: 3 hours Answer any FIVE questions All questions carry equal marks ***** 1 (a) What is backlash in gear teeth? What factors influence the backlash in gear teeth? (b) What are different standard systems for the shape of gear teeth? Explain them. (c) What are different materials used for the manufacture of gears? It is required to design a pair of spur gears with 20 degrees full depth involute teeth consisting of 20 teeth pinion meshing with a 50 teeth gear. The pinion shaft is connected to a 20 KW, 1500 rpm electrical motor. The starting torque of the motor can be taken as 140% of the rated torque. The material for the pinion is plain carbon steel with ultimate strength of 400 N/mm2 and the gear is made of grey cast iron with ultimate strength of 200 N/mm2. The factor of safety is 1.3. Design the gears based on Lewis equation and using velocity factor to account for the dynamic load. (a) Write down the expressions for the three components of resultant tooth force in helical gears. (b) A pair of parallel helical gears consists of a 18 teeth pinion meshing with a 63 teeth gear. The normal module is 3 mm. The helix angle is 23 degrees while the normal pressure angle is 20 degrees. Calculate: (i) the transverse module (ii) the transverse pressure angle (iii) the axial pitch (iv) the pitch circle diameters of the pinion and gear (v) the addendum and deddendum circle diameters of the pinion. Max. Marks: 60

T N

W U

R O

D L

A pair of straight bevel gears is mounted on shafts, which are intersecting at right angles. The number of teeth on the pinion and gear are 21 and 28 respectively. The pressure angle is 20 degrees. The pinion shaft is connected to an electric motor developing 4 K W rated power at 1200 rpm. The service factor can be taken as 1.5. The pinion and gear are made of steel with an ultimate strength of 750 N/mm2 and heat treated to a surface hardness of 400 BHN. The gears are machined by a manufacturing process that limits the error between the meshing teeth to 8 micrometers. The module and face width are 4 mm and 20 mm respectively. Determine the factor of safety for bending as well as pitting. Contd. in Page 2 Page 1 of 2

www.jntuworld.com

www.jntuworld.com

www.android.jntuworld.com

www.jwjobs.net

Code: 9D15106b 5 (a) What is the relationship between number of starts on worm, diametral quotient and lead angle of worm? (b) A pair of worm and worm wheel is designated as 2/52/10/4. 10 KW power at 720 rpm is supplied to the worm shaft. The coefficient of friction is 0.04 and the pressure angle is 20 degrees. Calculate the tangential, axial and radial components of the resultant gear tooth force acting on the worm wheel. (a) What are the basic modes of gear tooth failure? Discuss different types of gear tooth wear. (b) What are the methods of lubrication in gear drives? (a) Describe the function of a pre-selective gear box of an automobile. (b) Explain the procedure to analyze an epicyclic gear train. Formulate an optimization problem for the weight minimization to design a spur gear with the constraints on strength, rigidity and space. Suppose suitable optimization methods to solve the problem. Formulate an optimization problem for the weight minimization to design a spur gear with the constraints on strength, rigidity and space. Suggest suitable optimization methods to solve the problem.

T N

W U

***** Page 2 of 2

R O

D L

www.jntuworld.com

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Plant Management TafskillsDocumento4 paginePlant Management TafskillsTHEOPHILUS ATO FLETCHERNessuna valutazione finora

- Wave and TidalDocumento32 pagineWave and TidalSony WicaksonoNessuna valutazione finora

- Solar Radiation MeasurementsDocumento27 pagineSolar Radiation MeasurementsMuluken TemesgenNessuna valutazione finora

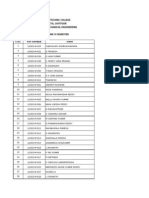

- 9D17105 Advanced Fluid MechanicsDocumento1 pagina9D17105 Advanced Fluid MechanicsMuni MuneendranNessuna valutazione finora

- CL in CK Servicedehdfh LogDocumento8 pagineCL in CK Servicedehdfh LogMuni MuneendranNessuna valutazione finora

- 9D15106b Gear EngineeringDocumento1 pagina9D15106b Gear EngineeringMuni MuneendranNessuna valutazione finora

- SolghjkDocumento2 pagineSolghjkMuni MuneendranNessuna valutazione finora

- 9D17102 Conduction and Rediation Heat TransferDocumento1 pagina9D17102 Conduction and Rediation Heat TransferMuni MuneendranNessuna valutazione finora

- 9D15105 Materials TechnologyDocumento1 pagina9D15105 Materials TechnologyMuni MuneendranNessuna valutazione finora

- 9D15102 Advanced MechanismsDocumento2 pagine9D15102 Advanced MechanismsMuni MuneendranNessuna valutazione finora

- 9D12106b Soil Dynamics and Machine FoundationsDocumento1 pagina9D12106b Soil Dynamics and Machine FoundationsMuni MuneendranNessuna valutazione finora

- 9D15104 Fracture, Fatigue & Creep DeformationDocumento1 pagina9D15104 Fracture, Fatigue & Creep DeformationMuni MuneendranNessuna valutazione finora

- 9D15103 Advanced Mechanics of SolidsDocumento2 pagine9D15103 Advanced Mechanics of SolidsMuni MuneendranNessuna valutazione finora

- Cam Lab ManualDocumento35 pagineCam Lab ManualUma ShankarNessuna valutazione finora

- Aries Polytechnic College B N R Peta, Chittoor Diploma in Mechanical Engineering Class: Dme Vi SemesterDocumento2 pagineAries Polytechnic College B N R Peta, Chittoor Diploma in Mechanical Engineering Class: Dme Vi SemesterMuni MuneendranNessuna valutazione finora

- Solution Combustion Synthesis of Nanoscale Oxides and Their CompositesDocumento4 pagineSolution Combustion Synthesis of Nanoscale Oxides and Their CompositesMuni MuneendranNessuna valutazione finora

- 9D04104 Geometric ModelingDocumento1 pagina9D04104 Geometric ModelingMuni MuneendranNessuna valutazione finora

- Areis Polytechnic College Date Sheet For Admissions 2014 Name of The School: Address: Contact NoDocumento5 pagineAreis Polytechnic College Date Sheet For Admissions 2014 Name of The School: Address: Contact NoMuni MuneendranNessuna valutazione finora

- LS-DYNA Solver Interface 8.0 TutorialsDocumento83 pagineLS-DYNA Solver Interface 8.0 Tutorialsരാകേഷ് നായർNessuna valutazione finora

- DCM LabDocumento3 pagineDCM LabVijay Kshatriya HRNessuna valutazione finora

- Areis Polytechnic College Date Sheet For Admissions 2014 Name of The School: Address: Contact NoDocumento8 pagineAreis Polytechnic College Date Sheet For Admissions 2014 Name of The School: Address: Contact NoMuni MuneendranNessuna valutazione finora

- Fabreeka Thermal Isolation MaterialDocumento2 pagineFabreeka Thermal Isolation MaterialMuni MuneendranNessuna valutazione finora

- GATEFORUM - Online TarGATE Test Paper Discussion PDFDocumento38 pagineGATEFORUM - Online TarGATE Test Paper Discussion PDFMuni MuneendranNessuna valutazione finora

- Star CDDocumento46 pagineStar CDMuni MuneendranNessuna valutazione finora

- I) Short Answer Questions 3X2 6MDocumento1 paginaI) Short Answer Questions 3X2 6MMuni MuneendranNessuna valutazione finora

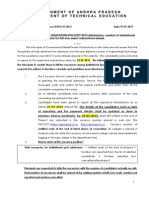

- Spot Admission GuidelinesDocumento8 pagineSpot Admission GuidelinesMuni MuneendranNessuna valutazione finora

- UPSC: Engineering Services Examination 2013Documento7 pagineUPSC: Engineering Services Examination 2013TrcStaffNessuna valutazione finora

- HTML5 3D VisualizacionesDocumento31 pagineHTML5 3D VisualizacionesHENRY ISAAC GONZALEZ CRUZNessuna valutazione finora

- 34-Samss-718 (12-02-2015)Documento14 pagine34-Samss-718 (12-02-2015)Mubin100% (1)

- 17 0000362296Documento1 pagina17 0000362296Ekansh BarsiwalNessuna valutazione finora

- DLL Sci 10 12-09-2022Documento3 pagineDLL Sci 10 12-09-2022Lovely Shiena Cain AragoncilloNessuna valutazione finora

- JKBMS Tutorial SetupDocumento7 pagineJKBMS Tutorial SetupFabricio Varovsky Muñiz ArteagaNessuna valutazione finora

- Asmsc 1119 PDFDocumento9 pagineAsmsc 1119 PDFAstha WadhwaNessuna valutazione finora

- 2-FedEx Vs American Home AssDocumento8 pagine2-FedEx Vs American Home AssJoan Dela CruzNessuna valutazione finora

- Mamba Vs Lara, 608 SCRA 149 (2009) Case DigestsDocumento1 paginaMamba Vs Lara, 608 SCRA 149 (2009) Case DigestsAce Lawrence AntazoNessuna valutazione finora

- Train Details of New DelhiDocumento94 pagineTrain Details of New DelhiSiddharth MohanNessuna valutazione finora

- Welcome To Our Presentation: Submitted byDocumento30 pagineWelcome To Our Presentation: Submitted byShamim MridhaNessuna valutazione finora

- Pk-Kredit Finanzierung-Db International Opening A Bank Account For Foreign StudentsDocumento19 paginePk-Kredit Finanzierung-Db International Opening A Bank Account For Foreign StudentsBoűmřãh FōüĀdNessuna valutazione finora

- Tower BridgeDocumento6 pagineTower BridgeCalvin PratamaNessuna valutazione finora

- Bacnet Today: W W W W WDocumento8 pagineBacnet Today: W W W W Wmary AzevedoNessuna valutazione finora

- Fly The Maddog X User Manual MSFS 2020Documento15 pagineFly The Maddog X User Manual MSFS 2020KING OF NOOBSNessuna valutazione finora

- Elite 08Documento96 pagineElite 08Razza WilliNessuna valutazione finora

- Atex ExplainedDocumento3 pagineAtex ExplainedErica LindseyNessuna valutazione finora

- Advantages, Disadvantages and Applications of Regula Falsi MethodDocumento12 pagineAdvantages, Disadvantages and Applications of Regula Falsi MethodMd Nahid HasanNessuna valutazione finora

- Lesson 2. WHAT IS AGROTECHNOPRENEURSHIPDocumento23 pagineLesson 2. WHAT IS AGROTECHNOPRENEURSHIPRhea Jane DugadugaNessuna valutazione finora

- DS Introduction To TreeDocumento23 pagineDS Introduction To TreePrashant JainNessuna valutazione finora

- Foreclosure Letter - 20 - 26 - 19Documento3 pagineForeclosure Letter - 20 - 26 - 19Santhosh AnantharamanNessuna valutazione finora

- Economics: PAPER 1 Multiple ChoiceDocumento12 pagineEconomics: PAPER 1 Multiple ChoiceigcsepapersNessuna valutazione finora

- However, A Review of The Factual Antecedents of The Case Shows That Respondents' Action For Reconveyance Was Not Even Subject To PrescriptionDocumento7 pagineHowever, A Review of The Factual Antecedents of The Case Shows That Respondents' Action For Reconveyance Was Not Even Subject To Prescriptionkemsue1224Nessuna valutazione finora

- Linux Internet Web Server and Domain Configuration TutorialDocumento59 pagineLinux Internet Web Server and Domain Configuration Tutorialrajnishmishra2488Nessuna valutazione finora

- Report On PesoDocumento10 pagineReport On PesoAerish RioverosNessuna valutazione finora

- C&DS Lab Manual UpdatedDocumento182 pagineC&DS Lab Manual UpdatedJesmin MostafaNessuna valutazione finora

- Types of TrianglesDocumento5 pagineTypes of Trianglesguru198319Nessuna valutazione finora

- Summer 2019 - OSD Exam Paper MS - FINALDocumento13 pagineSummer 2019 - OSD Exam Paper MS - FINALAsifHossainNessuna valutazione finora

- Revenue From LTCCDocumento2 pagineRevenue From LTCCMarife RomeroNessuna valutazione finora

- Appendix: Dhuts-Phase Ii Dhaka Urban Transport Network Development Study-Phase IIDocumento20 pagineAppendix: Dhuts-Phase Ii Dhaka Urban Transport Network Development Study-Phase IIhhbeckNessuna valutazione finora