Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ANNUAL Maintenance Format

Caricato da

anurag_jay12464Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ANNUAL Maintenance Format

Caricato da

anurag_jay12464Copyright:

Formati disponibili

Winding Tempratuer

LV-Tank

BDV Result

Main Tank S -T

HV-Tank

Tap Changer -S

HV-Winding

HV-Oil TMP

LV-HV

Main Tank S-B

LV -Winding

LV-Oil TMP

Tap-Opration

Cooling System

Through Winding Tempratuer

Manualy

Max Tap

Manualy

Group -1

Min Tap

Group -2

Electricaly

Electricaly

Max Tap

Group -1

Min Tap

Group -2

IR Values

Alarm Value

Oil Tempratuer

Alarm Value

Trip Value

Trip Value

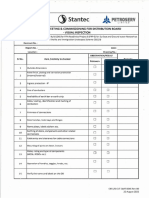

Oman Electricity Transmission Company

Transmission Department

Transformer Testing Sheet (1/2)

Date :_________________

Time:_________________

Area: ________________

Type of Maintenance :

City:________________________

Substation:__________________

Feeder:_____________________

Plan.Prevent. M

Break Down.M

New Installation

Transformer Discription

Manufacuer by: _________________

Capacity: __________________

Vector Group

Year of manufacturing: ____________________

Cooling System :_____________

Sr. No:______________________

LDC Control Eng Name:

01- Record Oil Level in conservation Tank in percentage (%)

02- Check Main Tank, Radiator, for any oil leaks.

03- Check Bucholz Device, Prasure Rlife valves for any oil leaks

04- Check condition of the silica gel, change it if required.

05- Check bushing surface for signs of chipping, dirt, oil, smock.

06- Check Painting.

07- Insure all radiator shut Valve are in open condition

08- Winding Temprature setting test

09- Oil Temprature setting test

LDC Signals

Fan G1

Alarm

W.T ALARM

Fan G2

Trip

W.T TRIP

Alarm Values

Oil Tep Alarm

Trip Values

Oil Tep Alarm

Trip circuit Checked

H.V W.Temp

L.V W.Temp

Oil Temprature

Main Bucholz

OLTC Bucholz

All Alarms Checked

10- IR values

1 Mints Values

5 Mints Values

10 Mints Values

HV-E

HV-E

HV-E

LV-E

LV-E

LV-E

HV-LV

HV-LV

HV-LV

PRV

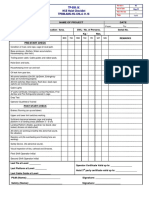

Oman Electricity Transmission Company

Transmission Department

Transformer Testing Sheet (2/2)

11- BDV Values

* Top Tank Sample

* Bottom Tank Sample

* OLTC Sample

Sr

Sr BDV Values

Sr BDV Values

Avr=

Avr=

BDV Values

Avr=

12 - Check Operation of OLTC

12.1) Read Number of Taps

12.2) Operate OLTC Localy & Electricaly for all Tap positions

Tap-1

Any Remark:

.

Tap-2

Tap-3

Tap-4

Tap-5

Tap-6

Tap-7

Tap-8

Tap-9

Tap-10

Tap-11

Tap-12

Tap-13

Tap-14

Tested By:

Tap-15

Tap-16

Tap-17

Tap-18

Checked By:

Tap-19

Local Tap Positions

R. Indication

LDC Indication

12.3) Repeat OLTC Operation Manully by hand & Observe for any abnormal motion or noise.

12.4) Clean control panel by air blower and clean contactors by CRC.

12.5) All moving parts of Tap changer shaft, door to be lubricate with grassie

first virsion 26/09/09 Prepared by Namani

Oman Electricity Transmission Company

Transmission Department

Fire fighting Testing Sheet

Date :_________________

Time:_________________

Area: ________________

City:________________________

Substation:__________________

Feeder:____________________

Type of Maintenance :

Plan. Preventive.M

Break Down.M

New Installation

Fire fighting Discription

Manufacuer by: ___________

Type: __________________

Year of Manufacturing: _______________

Sr. No:______________________

01- Record water level in percentage (%).

02- Record system presure

03- Operate the system to relase the water using Electrical pump.

04- Check water nozels for any blockage

05- Repeat point (03) by Deisal Engine pump.

06- ChecK for any water leake

07- Record water level in percentage (%) after complete all test

08- Check Alarm in control panel & LDC.

* Any Remark/ Upnormalities obsarved:....

.

.

..

* Tested By:

* Checked By:

..

Oman Electricity Transmission Company

Transmission Department

C.T & V.T Testing Sheet

Date :_________________

Time:_________________

Area: ________________

City:________________________

Substation:__________________

Feeder:_____________________

Type of Maintenance :

Plan. Preventive.M

Break Down.M

New Installation

Transformer Discription

Manufacuer by: ___________

Type: __________________

Year of Manufacturing: _______________

Sr. No:______________________

Primary Value:_______________

Secondary Winding :_______________

Voltage Level:___________________________

Current Tranformer

Out door

Voltage Transformer

Indoor

01- Check Insulation surface for signs of chipping, dirt, smock & Clean if required.

02- Check Oil Level In Percentage ( % )

03- Check Painting

04- Check secondary Connection.

05- Clean Around Area

06-Measure insulation Values (IR) earthing to be open before cary out this test.

R-E

Y-E

B-E

07- Normalized earthing Connection.

08- During Commissioning & Un correct Values ( Ratio Test Required )

Special Test Sheet Can be attached

* Any Remark/ Upnormalities obsarved:....

.

.

..

* Tested By:

* Checked By:

..

Oman Electricity Transmission Company

Transmission Department

Lighting Arressted Testing Sheet

Date :_________________

Time:_________________

Area: ________________

City:________________________

Substation:__________________

Feeder:_____________________

Type of Maintenance :

Plan. Preventive.M

Break Down.M

New Installation

Lighting Arressted Discription

Manufacuer by: ___________

Type: __________________

Year of Manufacturing: _______________

Sr. No:______________________

Rated Voltage :_______________

Out door L/A

01- Check Insulation surface for signs of chipping, dirt, smock & Clean if required.

02- Record the Lighting Arressted Counter for Each Pole.

03- Check tightness of nut, bolts, terminal joints of L/A

04- Check earthing connections.

05- Check for any oil leak

06- Check painting

07- Masure insulation value ( IR ) earthing to be open before this test

R-E

Y-E

B-E

08- Earting connection to be returned back

* Any Remark/ Upnormalities obsarved:....

.

.

..

* Tested By:

* Checked By:

..

Oman Electricity Transmission Company

Transmission Department

Circuit Brekar Testing Sheet

Date :_________________

Time:_________________

Area: ________________

City:________________________

Substation:__________________

Feeder:_____________________

Type of Maintenance :

Plan. Preventive.M

Break Down.M

New Installation

C.B Discription

Manufacuer by: ___________

Type: __________________

Year of Manufacturing: _______________

Sr. No:______________________

SF6 Rated presure:___________bar/PSI/kg sqcm

Rated Voltage :_______________

Out door Breaker

Indoor Breaker

01- Check Insulation surface for signs of chipping, dirt, smock & Clean if required.

02- Check operation mechanism, lubricate the sliding parts

03- Check spring charger motor for upnormal sound & movement.

04- Measure insulation resistance of each pole. ( for 33kv C.Bs only)

05- Record the SF6 of gas pressure seen on the gage.

06- ChecK the condition of gas pipe for SF6 C.B

07- Check tightness of nut, bolts, terminal joints of C.B

08- Check earthing connections.

09- Record hydroulic oil Pressure

bar-PSI- Kg/sq cm

10- Check for any oil leak

11- Check painting

Control Panel/ Local Control Panel

01- Check status indication lamps, fuses replaced if it required

02- Check the covers/doors are closing properly.

03- Clean dust by using vacuum cleaner & insulated hand brush.

04- Check condition of all selector, Control, and supply switches.

05- Check remort/Local Operation of the C.B

06- Check Earthing connection.

07- Check the C.B counter & record status values

* Trip circuit Checked

* Close Circuit Checked

* All Alarms Checked

* Any Remark/ Upnormalities obsarved:....

.

.

..

* Tested By:

* Checked By:

..

virsion 26/09/09 Preped by Namani

Potrebbero piacerti anche

- F-030-Diesel Generator Inspection ChecklistDocumento1 paginaF-030-Diesel Generator Inspection ChecklistDedy Rifky SetyawanNessuna valutazione finora

- DG & EB Check ListDocumento43 pagineDG & EB Check ListRamesh MariyappaNessuna valutazione finora

- Diesel Generator Service CardDocumento2 pagineDiesel Generator Service CardJewel RanaNessuna valutazione finora

- Genset - Electrical ChecklistDocumento1 paginaGenset - Electrical ChecklistKarl Jared MasanqueNessuna valutazione finora

- Inspection Checksheet For The Gas TurbineDocumento12 pagineInspection Checksheet For The Gas TurbineMax CuiNessuna valutazione finora

- Site Test Procedure and Report For Bus Duct: Commissioning FormDocumento7 pagineSite Test Procedure and Report For Bus Duct: Commissioning Formimrankhan zNessuna valutazione finora

- 7420p008 Uptimax Ni-CD BatteryDocumento16 pagine7420p008 Uptimax Ni-CD BatteryNazif HawariNessuna valutazione finora

- Solo Run For MotorsDocumento8 pagineSolo Run For MotorsMohamed Haleem100% (1)

- Maintenance Program For EquipmentsDocumento793 pagineMaintenance Program For EquipmentsJoel AlcantaraNessuna valutazione finora

- Certification by Electrical InspectorateDocumento6 pagineCertification by Electrical InspectorateRajdeep KumarNessuna valutazione finora

- Maintenance Instruction V03Documento18 pagineMaintenance Instruction V03Farooq AhmadNessuna valutazione finora

- 14 DG Set InspectionDocumento1 pagina14 DG Set Inspectionabb hseNessuna valutazione finora

- Newsline Generator Inspection ReportDocumento2 pagineNewsline Generator Inspection ReportDevi ChintyaNessuna valutazione finora

- SP-1108 (ESOP-01) Issue of PDO Electrical Safety Rules andDocumento2 pagineSP-1108 (ESOP-01) Issue of PDO Electrical Safety Rules andaslam.ambNessuna valutazione finora

- Fault Diagnostic in MCC Panels PDFDocumento3 pagineFault Diagnostic in MCC Panels PDFkkn1234Nessuna valutazione finora

- Inspection Report of Diesel Engine GeneratorDocumento2 pagineInspection Report of Diesel Engine GeneratorabdulghaforNessuna valutazione finora

- SOP - 6.6 KV Breaker OperationDocumento4 pagineSOP - 6.6 KV Breaker OperationJitendra kumarNessuna valutazione finora

- Maint - Check List - Oil Filled TransforsDocumento2 pagineMaint - Check List - Oil Filled TransforsramNessuna valutazione finora

- Transformer Service ManualDocumento11 pagineTransformer Service ManualshivaramNessuna valutazione finora

- Commissioning Procedure of CURRENT TRANSFORMER - ENDIRADocumento13 pagineCommissioning Procedure of CURRENT TRANSFORMER - ENDIRAYoga SamNessuna valutazione finora

- MDB Specs PDFDocumento9 pagineMDB Specs PDFAbdElrahman AhmedNessuna valutazione finora

- Fault Diagnostic in MDB Panels PDFDocumento2 pagineFault Diagnostic in MDB Panels PDFkkn1234Nessuna valutazione finora

- This Checklist Is To Be Used For The Commissioning of Plant or EquipmentDocumento2 pagineThis Checklist Is To Be Used For The Commissioning of Plant or EquipmentAnonymous v6ybIxZFNessuna valutazione finora

- ChecklistDocumento14 pagineChecklistInstrument SCINessuna valutazione finora

- Periodic Maintenance CuminDocumento3 paginePeriodic Maintenance Cuminali sNessuna valutazione finora

- Power Transformer MaintenanceDocumento5 paginePower Transformer MaintenanceSantoshkumar Gupta100% (1)

- Gen Set Service ReportDocumento1 paginaGen Set Service ReportReman MarykanNessuna valutazione finora

- Testing Earth Leakage DevicesDocumento6 pagineTesting Earth Leakage DevicesMoses MuchakaviriNessuna valutazione finora

- Current TransformerDocumento12 pagineCurrent TransformerSyed AbbasNessuna valutazione finora

- Pre Commissioning Oil Type TransformerDocumento4 paginePre Commissioning Oil Type TransformerKanagaraj Ravi0% (1)

- Electrical Pump & Motor Inspection ChecklistDocumento1 paginaElectrical Pump & Motor Inspection ChecklistJIJESH GOKULDASNessuna valutazione finora

- MCC and Panels Maintenance ProcedureDocumento15 pagineMCC and Panels Maintenance ProcedureEldhose PaulNessuna valutazione finora

- PPM Checklist - Air Circuit Breaker (Acb)Documento1 paginaPPM Checklist - Air Circuit Breaker (Acb)Mohamed Firdaus Bin ZakariaNessuna valutazione finora

- Circuit Breaker Maintenance FormDocumento1 paginaCircuit Breaker Maintenance FormSamuel NdopuNessuna valutazione finora

- HUD Homes Baltimore - 20571 SUMMERSONG LANE, GERMANTOWN MD 20874Documento29 pagineHUD Homes Baltimore - 20571 SUMMERSONG LANE, GERMANTOWN MD 20874Nishika JGNessuna valutazione finora

- DB ChecklistDocumento4 pagineDB ChecklistJabinNessuna valutazione finora

- Inspection of MCC - EEPDocumento3 pagineInspection of MCC - EEPwaseemNessuna valutazione finora

- Condition Assessment Manual: Transformer Inspection Form and ChecklistDocumento9 pagineCondition Assessment Manual: Transformer Inspection Form and ChecklistmuhardionoNessuna valutazione finora

- ELE - Checklist For Sample DBDocumento2 pagineELE - Checklist For Sample DBibrahim680% (1)

- 559 and 1042 Series Operator Interface User GuideDocumento306 pagine559 and 1042 Series Operator Interface User GuideAlcides ZorrillaNessuna valutazione finora

- Title: Maintenance Electrical DOC. No: (ELE-P-01) : ControlledDocumento6 pagineTitle: Maintenance Electrical DOC. No: (ELE-P-01) : ControlledTarek FawzyNessuna valutazione finora

- Maintenance Interval ScheduleDocumento3 pagineMaintenance Interval Scheduleashish_ismdhanbadNessuna valutazione finora

- 250 Kva DG SpecificationsDocumento8 pagine250 Kva DG SpecificationsNiten Gupta0% (1)

- Maintenance of GroundingDocumento7 pagineMaintenance of GroundingBharatiyulamNessuna valutazione finora

- Daily Montly Checklist 04JUN2007Documento9 pagineDaily Montly Checklist 04JUN2007tomiNessuna valutazione finora

- BR Generator Maintenance ChecklistDocumento1 paginaBR Generator Maintenance Checklistahmad fasfousNessuna valutazione finora

- Maintenance PlanDocumento6 pagineMaintenance PlanabdullahqqNessuna valutazione finora

- Hindustan Petroleum Corporation Limited Madurai IRD: Daily Air Compressor ChecklistDocumento1 paginaHindustan Petroleum Corporation Limited Madurai IRD: Daily Air Compressor ChecklistSooraj S BabuNessuna valutazione finora

- How To Use A Megger Insulation TesterDocumento2 pagineHow To Use A Megger Insulation TesterRakesh Babu0% (1)

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Documento201 pagineMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNessuna valutazione finora

- DH3-31MA-T-ITP-0001 ITP For Commissioning of Complete-Set Startup of Steam Turbine REV.0Documento12 pagineDH3-31MA-T-ITP-0001 ITP For Commissioning of Complete-Set Startup of Steam Turbine REV.0Lan RungNessuna valutazione finora

- Power Engineering PM Check ListDocumento11 paginePower Engineering PM Check ListSelvn SubramanianNessuna valutazione finora

- Part 8 Maintenance, Reliability and Failure AnalysisDocumento38 paginePart 8 Maintenance, Reliability and Failure Analysiskeyur1109Nessuna valutazione finora

- 16 Hoist ChecklistDocumento1 pagina16 Hoist ChecklistNavdeep Singh GrewalNessuna valutazione finora

- 1-03-036!04!0 Inspection of Repaired MotorDocumento19 pagine1-03-036!04!0 Inspection of Repaired MotorAhmed AshourNessuna valutazione finora

- Title: Job Description: Ups Technician 8-Skilled ElectricalDocumento4 pagineTitle: Job Description: Ups Technician 8-Skilled ElectricalSundar ThangapandianNessuna valutazione finora

- MotorDocumento165 pagineMotorare_reeNessuna valutazione finora

- Checklist MotorsDocumento1 paginaChecklist Motorsمعين الظفاريNessuna valutazione finora

- Tower Light Inspection ChecklistDocumento1 paginaTower Light Inspection ChecklistHabib ur rahmanNessuna valutazione finora

- Obrazac Za Narucivanje Upravljacke Jedinice-EngDocumento1 paginaObrazac Za Narucivanje Upravljacke Jedinice-EngkizonimeisterNessuna valutazione finora

- Bushings BrochureDocumento14 pagineBushings Brochurebpd21Nessuna valutazione finora

- About Transformer Intelligence: Frequently Asked QuestionsDocumento1 paginaAbout Transformer Intelligence: Frequently Asked Questionsanurag_jay12464Nessuna valutazione finora

- OLTC - Tech. PresentationDocumento57 pagineOLTC - Tech. Presentationanurag_jay12464100% (1)

- Nitrogen Gas - 99 % Pure: Corporate Purchasing Specification AA 544 11 Rev. No. 01 Preface SheetDocumento3 pagineNitrogen Gas - 99 % Pure: Corporate Purchasing Specification AA 544 11 Rev. No. 01 Preface Sheetanurag_jay12464Nessuna valutazione finora

- Dry Type TransformersDocumento49 pagineDry Type Transformersanurag_jay12464Nessuna valutazione finora

- Dry Type TransformersDocumento49 pagineDry Type Transformersanurag_jay12464Nessuna valutazione finora

- 2014 Siegel CMD Korea Comparison Between Electrical and UHF PD PDFDocumento4 pagine2014 Siegel CMD Korea Comparison Between Electrical and UHF PD PDFanurag_jay12464Nessuna valutazione finora

- UK1291if 10023 PDFDocumento2 pagineUK1291if 10023 PDFanurag_jay12464Nessuna valutazione finora

- 01 Micafil Bushings Overview English PDFDocumento6 pagine01 Micafil Bushings Overview English PDFanurag_jay12464100% (1)

- 2003 PCPP Kogelschatz DBD ReviewDocumento46 pagine2003 PCPP Kogelschatz DBD Reviewanurag_jay12464Nessuna valutazione finora

- 2008 Vlach OsDocumento51 pagine2008 Vlach Osanurag_jay12464Nessuna valutazione finora

- Bezborodko. P (Unknown)Documento5 pagineBezborodko. P (Unknown)anurag_jay12464Nessuna valutazione finora

- Belzona Data SheetDocumento4 pagineBelzona Data Sheetanurag_jay12464Nessuna valutazione finora

- 3049 Must ReadDocumento7 pagine3049 Must Readanurag_jay12464Nessuna valutazione finora

- PT100 Detail and Resistance Temperature Chart PDFDocumento4 paginePT100 Detail and Resistance Temperature Chart PDFanurag_jay12464Nessuna valutazione finora

- ALSTOM Relay CatalogueDocumento20 pagineALSTOM Relay CatalogueINZAMAM MUSHTAQNessuna valutazione finora

- P14D TM en 5Documento558 pagineP14D TM en 5anurag_jay12464100% (1)

- Corrosive Sulfur 210x297 enDocumento4 pagineCorrosive Sulfur 210x297 enanurag_jay12464Nessuna valutazione finora

- DSI Sulfur Inhibitor Presentation Doble Clients ConferenceDocumento31 pagineDSI Sulfur Inhibitor Presentation Doble Clients Conferenceanurag_jay12464Nessuna valutazione finora

- Conf09 Ivanka Corrosive SDocumento33 pagineConf09 Ivanka Corrosive Sreza515heiNessuna valutazione finora

- HV CB Condition Assesment Parameters PDFDocumento6 pagineHV CB Condition Assesment Parameters PDFanurag_jay12464Nessuna valutazione finora

- 09 MaschinenfabrikReinhausen on-LoadTap-ChangerDocumento27 pagine09 MaschinenfabrikReinhausen on-LoadTap-ChangerAnna RiNessuna valutazione finora

- Kunhardt. E (1980)Documento5 pagineKunhardt. E (1980)anurag_jay12464Nessuna valutazione finora

- A2 40+Copper+Sulphide+long+term+mitigationDocumento59 pagineA2 40+Copper+Sulphide+long+term+mitigationanurag_jay12464Nessuna valutazione finora

- 11 - Chapter 2Documento46 pagine11 - Chapter 2anurag_jay12464Nessuna valutazione finora

- Kunhardt. E (1980)Documento9 pagineKunhardt. E (1980)anurag_jay12464Nessuna valutazione finora

- Kunhardt. E (1980)Documento9 pagineKunhardt. E (1980)anurag_jay12464Nessuna valutazione finora

- PDCheck User Manual - Rev08Documento59 paginePDCheck User Manual - Rev08anurag_jay12464100% (1)

- Bezborodko. P (Unknown)Documento5 pagineBezborodko. P (Unknown)anurag_jay12464Nessuna valutazione finora

- MN-04 07 105 - Eng - PDProcessingII User Manual - Rev 06Documento64 pagineMN-04 07 105 - Eng - PDProcessingII User Manual - Rev 06anurag_jay12464Nessuna valutazione finora

- Safari - 15 Nov 2019 at 10:13 PMDocumento1 paginaSafari - 15 Nov 2019 at 10:13 PMcrescente galendezNessuna valutazione finora

- Physical Refining Is A Modern Alternative For Processing Crude Palm Oil WhereDocumento2 paginePhysical Refining Is A Modern Alternative For Processing Crude Palm Oil WhereRoi Sachin De MondeNessuna valutazione finora

- 1100 Series VistaDocumento64 pagine1100 Series VistaJesus Neto100% (5)

- HIRADocumento16 pagineHIRASAMEER JAVEDNessuna valutazione finora

- Maleic Anhyride Production MethodDocumento9 pagineMaleic Anhyride Production MethodRıdvan SürmeliNessuna valutazione finora

- Mitsubishi Colt CZT - TuningDocumento7 pagineMitsubishi Colt CZT - Tuningmomo fuciNessuna valutazione finora

- Ksi KRR Operators ManualDocumento69 pagineKsi KRR Operators ManualAeres707Nessuna valutazione finora

- Tarea 19 - Metodo API Rp11lDocumento12 pagineTarea 19 - Metodo API Rp11lMelo GutiérrezNessuna valutazione finora

- Green BookDocumento16 pagineGreen BookYanna AbilaNessuna valutazione finora

- 6.7L DieselDocumento94 pagine6.7L DieselBrendan Brodie100% (15)

- 006-6C CoolPac Air Valve InstallationDocumento7 pagine006-6C CoolPac Air Valve InstallationpdealersNessuna valutazione finora

- E-Trike Presentation For DOE-VFO, 06-19-12Documento37 pagineE-Trike Presentation For DOE-VFO, 06-19-12kapedong100% (2)

- Screening Machines and Process Equipment 01Documento16 pagineScreening Machines and Process Equipment 01tafakorNessuna valutazione finora

- Spec Fire Fighting Vehicle EquipmentDocumento208 pagineSpec Fire Fighting Vehicle Equipmentdas_joydebNessuna valutazione finora

- Sample Dew Point CalculationDocumento3 pagineSample Dew Point Calculationapi-3709413100% (1)

- Power PlantDocumento42 paginePower PlantMuhammad Faizan100% (1)

- Storage Tank DesignDocumento19 pagineStorage Tank DesignSellappan Muthusamy100% (3)

- Bulletin 60 AFQRJOS Issue 27 Feb 2013 PDFDocumento6 pagineBulletin 60 AFQRJOS Issue 27 Feb 2013 PDFpersadanusantaraNessuna valutazione finora

- Steam Boilers Engines Nozzles and TurbinesnewDocumento30 pagineSteam Boilers Engines Nozzles and TurbinesnewAnand AshkNessuna valutazione finora

- Hole Cleaning GuidelinesDocumento26 pagineHole Cleaning GuidelinesEya HentatiNessuna valutazione finora

- Er6n Owner ManualDocumento180 pagineEr6n Owner Manualjuan_guillermo_perez100% (2)

- Lecture2 (Petrochemical)Documento12 pagineLecture2 (Petrochemical)ToniAndiwijaya100% (1)

- WWW Brighthubengineering Com Marine Engines Machinery 24861Documento9 pagineWWW Brighthubengineering Com Marine Engines Machinery 24861Anonymous ITnkbIEFNessuna valutazione finora

- Flushing Oil Flooded Rotary Screw Air Compressors Procedure enDocumento2 pagineFlushing Oil Flooded Rotary Screw Air Compressors Procedure enSergiSerrano100% (1)

- 28638.GM OverviewDocumento2 pagine28638.GM OverviewZenga Harsya PrakarsaNessuna valutazione finora

- Economic ReportDocumento28 pagineEconomic ReportNarrhveein RajasegaranNessuna valutazione finora

- Aits 1718 PT III Jee Adv P 1 PCMDocumento21 pagineAits 1718 PT III Jee Adv P 1 PCMUC SrivastavaNessuna valutazione finora

- Chemical Solutions in Everyday LifeDocumento5 pagineChemical Solutions in Everyday LifeMarcos Oyama100% (1)

- JLG 30 eDocumento104 pagineJLG 30 emink4u0% (1)

- 5606 - 2 - Zoeller 400 Series Owners Manual PDFDocumento8 pagine5606 - 2 - Zoeller 400 Series Owners Manual PDFbugmenot_testNessuna valutazione finora