Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Acrolon 218 HS

Caricato da

Andres MoralesDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Acrolon 218 HS

Caricato da

Andres MoralesCopyright:

Formati disponibili

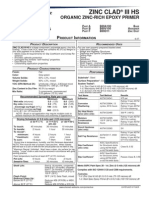

Protective & Marine Coatings

Revised 8/12

ACROLON 218 HS

ACRYLIC POLYURETHANE

PART A PART A PART B B65-600 B65-650 B65V600 GLOSS SERIES SEMI-GLOSS SERIES HARDENER

5.22

PRODUCT DESCRIPTION

ACROLON 218 HS is a low VOC, polyester modied, aliphatic, acrylic polyurethane formulated specically for in-shop applications. Also suitable for industrial applications. A fast drying, urethane that provides color and gloss retention for exterior exposure. Can be used directly over organic zinc rich primers (epoxy zinc primer and moisture cure urethane zinc primer) Color and gloss retention for exterior exposure Fast dry Outstanding application properties

RECOMMENDED USES

Specically formulated for in-shop applications. For use over prepared metal and masonry surfaces in industrial environments such as: Structural steel Tank exteriors Rail cars and locomotives Pipelines Conveyors Ships Bridges Wind Towers - onshore and offshore Offshore platforms - exploration and production Suitable for use in USDA inspected facilities Conforms to AWWA D102 Outside Coating Systems #4 (OCS-4), #5 (OCS-5) & #6 (OCS-6) Acceptable for use in high performance architectural applications Acceptable for use over Stampede 1 and Stampede 1H Caulking A component of INFINITANK Over FIRETEX hydrocarbon systems

PRODUCT CHARACTERISTICS

Finish: Color: Volume Solids: Weight Solids: Gloss or Semi-Gloss Wide range of colors available 65% 2%, mixed, may vary by color 78% 2%, mixed, may vary by color

VOC (EPA Method 24): Unreduced: <300 g/L; 2.5 lb/gal mixed Reduced 10% with R7K15: <340 g/L; 2.8 lb/gal mixed Reduced 9% with MEK, R6K10: <340 g/L; 2.8 lb/gal Mix Ratio: 6:1 by volume, 1 gallon or 5 gallon mixes premeasured components

PERFORMANCE CHARACTERISTICS

Substrate*: Steel Surface Preparation*: SSPC-SP10/NACE 2 System Tested*: 1 ct. Macropoxy 646 @ 6.0 mils (150 microns) dft 1 ct. Acrolon 218 HS Gloss @ 4.0 mils (100 microns) dft

*unless otherwise noted below

Recommended Spreading Rate per coat:

Wet mils (microns) Dry mils (microns) ~Coverage sq ft/gal (m2/L) Minimum 4.5 (112.5) 3.0 (75) 175 (4.3) Maximum 9.0 (225) 6.0 (150) 346 (8.5)

Test Name Abrasion Resistance1 Adhesion Corrosion Weathering2 Direct Impact Resistance1 Dry Heat Resistance1 Flexibility1

Theoretical coverage sq ft/gal 1040 (25.5) (m2/L) @ 1 mil / 25 microns dft NOTE: Brush or roll application may require multiple coats to achieve maximum lm thickness and uniformity of appearance.

Test Method ASTM D4060, CS17 wheel, 1000 cycles, 1 kg load ASTM D4541 ASTM D5894, 9 cycles, 3024 hours ASTM D2794 ASTM D2485, Method A ASTM D522, 180 bend, 1/8" mandrel ASTM D4585, 100F (38C), 1500 hours ASTM D3363 ASTM B117, 7000 hours

Results 43 mg loss 975 psi Rating 10 per ASTM D610, for rusting; Rating 10 per ASTM D714, for blistering 50 in. lb. 200F (93C) Passes Rating 10 per ASTM D610, for rusting; Rating 10 per ASTM D714, for blistering 3H Rating 10 per ASTM D610, for rusting; Rating 9 per ASTM D714, for blistering

Drying Schedule @ 6.0 mils wet (150 microns):

@ 35F/1.7C @ 77F/25C 50% RH @ 120F/49C

To touch: To handle: To recoat: minimum: maximum: To cure: Pot Life: Sweat-in-Time:

4 hours 18 hours 18 hours 3 months 14 days 4 hours

30 minutes 6 hours 8 hours 3 months 7 days 2 hours None

20 minutes 4 hours 6 hours 3 months 5 days 45 minutes

Humidity Resistance2 Pencil Hardness Salt Fog Resistance2

(reduced 5% with Reducer R7K15) If maximum recoat time is exceeded, abrade surface before recoating. Drying time is temperature, humidity, and lm thickness dependent. Paint temperature must be at least 40F (4.5C) minimum.

Shelf Life:

Part A* - 36 months, unopened Part B - 24 months, unopened Store indoors at 40F (4.5C) to 100F (38C). 55F (13C), Seta, mixed

Reducer R7K15, MEK R6K10, or R7K111 Reducer #132, R7K132 or R7K111

Meets the requirements of SSPC Paint No. 36, Level 3 for white and light colors. Dark colors may require a clear coat.

*Aluminum (Part A, Rex # B65SW655) has a shelf life of 24 months.

Complies with ISO 12944-5 C5I and C5M requirements. Footnotes: 1 Finish coat only tested 2 Primer Zinc-Clad II Plus Intermediate Macropoxy 646 Finish Acrolon 218 HS continued on back

Flash Point: Reducer/Clean Up: Spray: Brush / Roll:

www.sherwin-williams.com/protective

Protective & Marine Coatings

RECOMMENDED SYSTEMS

Dry Film Thickness / ct. Mils (Microns)

ACROLON 218 HS

ACRYLIC POLYURETHANE

PART A PART A PART B B65-600 B65-650 B65V600 GLOSS SERIES SEMI-GLOSS SERIES HARDENER

5.22

PRODUCT INFORMATION

SURFACE PREPARATION

Steel: 1 ct. Macropoxy 646 1-2 cts. Acrolon 218 HS Polyurethane Steel: 1 ct. Zinc Clad II Plus 1 ct. Macropoxy 646 1-2 cts. Acrolon 218 HS Polyurethane Steel: 1 ct. Zinc Clad IV 1-2 cts. Acrolon 218 HS Polyurethane

5.0-10.0 (125-250) 3.0-6.0 (75-150) 3.0-5.0 (75-125) 5.0-10.0 (125-250) 3.0-6.0 (75-150) 3.0-5.0 3.0-6.0 (75-125) (75-150) (75-100) (75-150) (150) (75-150) (100-150) (75-150)

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, loose rust, and other foreign material to ensure adequate adhesion. Refer to product Application Bulletin for detailed surface preparation information. Minimum recommended surface preparation: * Iron & Steel: SSPC-SP6/NACE 3, 1-2 mil (25-50 micron) prole * Galvanizing: SSPC-SP1 * Concrete & Masonry: SSPC-SP13/NACE 6, or ICRI No. 310.2, CSP 1-3 * Primer required

Surface Preparation Standards

Condition of Surface White Metal Near White Metal Commercial Blast Brush-Off Blast Hand Tool Cleaning Rusted Pitted & Rusted Power Tool Cleaning Rusted Pitted & Rusted ISO 8501-1 BS7079:A1 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 Swedish Std. SIS055900 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 SSPC SP 5 SP 10 SP 6 SP 7 SP 2 SP 2 SP 3 SP 3 NACE 1 2 3 4 -

Steel: 1 ct. Corothane I-GalvaPac Zinc Primer 3.0-4.0 1-2 cts. Acrolon 218 HS Polyurethane 3.0-6.0 Steel: 1 ct. Epoxy Mastic Aluminum II 1-2 cts. Acrolon 218 HS Polyurethane Steel: 1 ct. Recoatable Epoxy Primer 1-2 cts. Acrolon 218 HS Polyurethane Concrete/Masonry: 1 ct. Kem Cati-Coat HS Epoxy Filler/Sealer 1-2 cts. Acrolon 218 HS Polyurethane Aluminum/Galvanizing: 1 ct. DTM Wash Primer 1-2 cts. Acrolon 218 HS Polyurethane ISO 12944 C5M System: 1 ct. Zinc Clad III HS 1 ct. Tower Guard Epoxy 1 ct. Acrolon 218 HS Polyurethane 6.0 3.0-6.0 4.0-6.0 3.0-6.0

TINTING

Tint Part A with Maxitoner Colorants. Extra white tints at 100% tint strength Ultradeep base tints at 150% tint strength Five minutes minimum mixing on a mechanical shaker is required for complete mixing of color.

10.0-20.0 (250-500) 3.0-6.0 0.7-1.3 3.0-6.0 (75-150) (18-32) (75-150)

APPLICATION CONDITIONS

Temperature: 35F (1.7C) minimum, 120F (49C) maximum (air and surface) 40F (4.5C) minimum, 120F (49C) maximum (material) At least 5F (2.8C) above dew point 85% maximum

Relative humidity:

Refer to product Application Bulletin for detailed application information.

ORDERING INFORMATION

3.0-5.0 (75-125) 5.0-11.5 (125-287.5) 3.0-6.0 (75-150) Packaging: 1 gallon (3.78L) mix: 5 gallon (18.9L) mix: Part A: .86 gal (3.25L) 4.29 gal (16.2L) Part B: .14 gal (0.53L) 0.71 gal (2.7L) (premeasured components) Weight: 11.2 0.2 lb/gal ; 1.3 Kg/L mixed, may vary with color

FIRETEX ONLY: Finish Coat for FIRETEX Hydrocarbon Systems: 1 ct. Acrolon 218 HS Polyurethane*

*Consult FIRETEX PFP Specialist for recommended dft range

SAFETY PRECAUTIONS

Refer to the MSDS sheet before use. Published technical data and instructions are subject to change without notice. Contact your Sherwin-Williams representative for additional technical data and instructions.

The systems listed above are representative of the product's use, other systems may be appropriate.

DISCLAIMER

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommendations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your SherwinWilliams representative to obtain the most recent Product Data Information and Application Bulletin.

WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control procedures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

www.sherwin-williams.com/protective

Protective & Marine Coatings

Revised 8/12

ACROLON 218 HS

ACRYLIC POLYURETHANE

PART A PART A PART B B65-600 B65-650 B65V600 GLOSS SERIES SEMI-GLOSS SERIES HARDENER

5.22

APPLICATION BULLETIN

SURFACE PREPARATIONS APPLICATION CONDITIONS

Temperature:

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, loose rust, and other foreign material to ensure adequate adhesion. Iron & Steel Remove all oil and grease from surface by Solvent Cleaning per SSPC-SP1. Minimum surface preparation is Commercial Blast Cleaning per SSPC-SP6/NACE 3. For better performance, use Near White Metal Blast Cleaning per SSPC-SP10/NACE 2. Blast clean all surfaces using a sharp, angular abrasive for optimum surface prole (1-2 mils / 25-50 microns). Prime any bare steel the same day as it is cleaned or before ash rusting occurs. Aluminum Remove all oil, grease, dirt, oxide and other foreign material by Solvent Cleaning per SSPC-SP1. Primer required. Galvanized Steel Allow to weather a minimum of six months prior to coating. Solvent Clean per SSPC-SP1. When weathering is not possible, or the surface has been treated with chromates or silicates, rst Solvent Clean per SSPC-SP1 and apply a test patch. Allow paint to dry at least one week before testing adhesion. If adhesion is poor, brush blasting per SSPC-SP7 is necessary to remove these treatments. Rusty galvanizing requires a minimum of Hand Tool Cleaning per SSPC-SP2, prime the area the same day as cleaned or before ash rusting occurs. Primer required. Concrete and Masonry For surface preparation, refer to SSPC-SP13/NACE 6, or ICRI No. 310.2, CSP 1-3. Surfaces should be thoroughly clean and dry. Concrete and mortar must be cured at least 28 days @ 75F (24C). Remove all loose mortar and foreign material. Surface must be free of laitance, concrete dust, dirt, form release agents, moisture curing membranes, loose cement and hardeners. Fill bug holes, air pockets and other voids with Steel-Seam FT910. Primer required. Follow the standard methods listed below when applicable: ASTM D4258 Standard Practice for Cleaning Concrete. ASTM D4259 Standard Practice for Abrading Concrete. ASTM D4260 Standard Practice for Etching Concrete. ASTM F1869 Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete. SSPC-SP 13/Nace 6 Surface Preparation of Concrete. ICRI No. 310.2 Concrete Surface Preparation.

35F (1.7C) minimum, 120F (49C) maximum (air and surface) 40F (4.5C) minimum, 120F (49C) maximum (material) At least 5F (2.8C) above dew point 85% maximum

Relative humidity:

APPLICATION EQUIPMENT

The following is a guide. Changes in pressures and tip sizes may be needed for proper spray characteristics. Always purge spray equipment before use with listed reducer. Any reduction must be compliant with existing VOC regulations and compatible with the existing environmental and application conditions. Reducer/Clean Up: Spray..............................Reducer R7K15, MEK R6K10, or R7K111 Brush/Roll ......................Reducer #132, R7K132, or R7K111 If reducer is used, reduce at time of catalyzation. Airless Spray Pressure.........................2500 - 2800 psi Hose...............................3/8" ID Tip ...................................013" - .017" Filter ...............................60 mesh Reduction .......................As needed up to 10% by volume with R7K15 or R7K111, or up to 9% with MEK, R6K10* Conventional Spray Gun ................................Binks 95 Cap ................................63P Atomization Pressure .....50 - 70 psi Fluid Pressure ................20 - 25 psi Reduction .......................As needed up to 10% by volume with R7K15 or R7K111, or up to 9% with MEK, R6K10* Brush Brush..............................Natural Bristle Reduction .......................As needed up to 10% by volume* Roller Cover .............................3/8" woven with solvent resistant core Reduction .......................As needed up to 10% by volume*

Surface Preparation Standards

Condition of Surface White Metal Near White Metal Commercial Blast Brush-Off Blast Hand Tool Cleaning Rusted Pitted & Rusted Power Tool Cleaning Rusted Pitted & Rusted ISO 8501-1 BS7079:A1 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 Swedish Std. SIS055900 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 SSPC SP 5 SP 10 SP 6 SP 7 SP 2 SP 2 SP 3 SP 3 NACE 1 2 3 4 -

If specic application equipment is not listed above, equivalent equipment may be substituted. * Note: Reducing more than maximum recommended level will result in VOC exceeding 340g/L continued on back

www.sherwin-williams.com/protective

Protective & Marine Coatings

APPLICATION PROCEDURES

Surface preparation must be completed as indicated. Mix contents of each component thoroughly with low speed power agitation. Make certain no pigment remains on the bottom of the can. Then combine six parts by volume of Part A with one part by volume of Part B (premeasured components). Thoroughly agitate the mixture with power agitation. Re-stir before using.

ACROLON 218 HS

ACRYLIC POLYURETHANE

PART A PART A PART B B65-600 B65-650 B65V600 GLOSS SERIES SEMI-GLOSS SERIES HARDENER

5.22

APPLICATION BULLETIN

PERFORMANCE TIPS

Stripe coat all crevices, welds, and sharp angles to prevent early failure in these areas. When using spray application, use a 50% overlap with each pass of the gun to avoid holidays, bare areas, and pinholes. If necessary, cross spray at a right angle.

Spreading rates are calculated on volume solids and do not include an application loss factor due to surface prole, roughness or poIf reducer is used, add only after both components have been rosity of the surface, skill and technique of the applicator, method thoroughly mixed. of application, various surface irregularities, material lost during Apply paint at the recommended lm thickness and spreading mixing, spillage, overthinning, climatic conditions, and excessive lm build. rate as indicated below:

Recommended Spreading Rate per coat:

Wet mils (microns) Dry mils (microns) ~Coverage sq ft/gal (m2/L) Minimum 4.5 (112.5) 3.0 (75) 175 (4.3) Maximum 9.0 (225) 6.0 (150) 346 (8.5)

Excessive reduction of material can affect lm build, appearance, and adhesion. Do not apply the material beyond recommended pot life. Do not mix previously catalyzed material with new. In order to avoid blockage of spray equipment, clean equipment before use or before periods of extended downtime with Reducer #15, R7K15 or MEK, R6K10. Mixed coating is sensitive to water. Use water traps in all air lines. Moisture contact can reduce pot life and affect gloss and color. Quick-Thane Urethane Accelerator is acceptable for use. See data page 5.97 for details. E-Z Roll Urethane Defoamer is acceptable for use. See data page 5.99 for details.

Theoretical coverage sq ft/gal 1040 (25.5) (m2/L) @ 1 mil / 25 microns dft NOTE: Brush or roll application may require multiple coats to achieve maximum lm thickness and uniformity of appearance.

Drying Schedule @ 6.0 mils wet (150 microns):

@ 35F/1.7C @ 77F/25C 50% RH @ 120F/49C

To touch: To handle: To recoat: minimum: maximum: To cure: Pot Life: Sweat-in-Time:

4 hours 18 hours 18 hours 3 months 14 days 4 hours

30 minutes 6 hours 8 hours 3 months 7 days 2 hours None

20 minutes 4 hours 6 hours 3 months 5 days 45 minutes

(reduced 5% with Reducer R7K15) If maximum recoat time is exceeded, abrade surface before recoating. Drying time is temperature, humidity, and lm thickness dependent. Paint temperature must be at least 40F (4.5C) minimum.

Refer to Product Information sheet for additional performance characteristics and properties.

Application of coating above maximum or below minimum recommended spreading rate may adversely affect coating performance.

SAFETY PRECAUTIONS

Refer to the MSDS sheet before use. Published technical data and instructions are subject to change without notice. Contact your Sherwin-Williams representative for additional technical data and instructions.

CLEAN UP INSTRUCTIONS

Clean spills and spatters immediately with Reducer #132, R7K132. Clean tools immediately after use with Reducer #132, R7K132. Follow manufacturer's safety recommendations when using any solvent.

WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control procedures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

DISCLAIMER

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommendations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your SherwinWilliams representative to obtain the most recent Product Data Information and Application Bulletin.

www.sherwin-williams.com/protective

Potrebbero piacerti anche

- Zinc Clad IIIDocumento4 pagineZinc Clad IIIScott Van PeltNessuna valutazione finora

- Fast Clad Urethane Spec SheetDocumento4 pagineFast Clad Urethane Spec SheetScott Van PeltNessuna valutazione finora

- Coal Tar PDFDocumento4 pagineCoal Tar PDFMohammadreza AsheghNessuna valutazione finora

- 7) PPG Amercoat 385 - Pds - AiDocumento4 pagine7) PPG Amercoat 385 - Pds - AididbeauNessuna valutazione finora

- Zinc Clad IVDocumento4 pagineZinc Clad IVvitrolaNessuna valutazione finora

- Amercoat 370Documento3 pagineAmercoat 370Victor Hugo Bustos Beltran100% (1)

- en-US_P091Documento8 pagineen-US_P091Cris gomezNessuna valutazione finora

- DP B58W00610Documento4 pagineDP B58W00610tangouzeNessuna valutazione finora

- Carbo Guard 893 SGDocumento2 pagineCarbo Guard 893 SGsuzilamatsallehNessuna valutazione finora

- Om 340Documento3 pagineOm 340RNessuna valutazione finora

- ZRC GALVILITE Galvanizing Repair CompoundDocumento2 pagineZRC GALVILITE Galvanizing Repair CompoundRaymond LalumiereNessuna valutazione finora

- Amerlock 400Documento4 pagineAmerlock 400eternalkhutNessuna valutazione finora

- Devran 224HS Epoxy 4392 P Eng Usa LTRDocumento4 pagineDevran 224HS Epoxy 4392 P Eng Usa LTRAlex Torres CamizanNessuna valutazione finora

- Carbothane+134+HG+PDS+3 11Documento2 pagineCarbothane+134+HG+PDS+3 11James Everett AbdulNessuna valutazione finora

- Carbomastic 15 PDS 2013Documento2 pagineCarbomastic 15 PDS 20134508366279Nessuna valutazione finora

- Carboguard 890 PDSDocumento2 pagineCarboguard 890 PDSLinnie McleodNessuna valutazione finora

- Rex ThaneDocumento4 pagineRex Thanesas999333Nessuna valutazione finora

- Amercoat® 385: Product Data SheetDocumento8 pagineAmercoat® 385: Product Data SheetSampath GaneshNessuna valutazione finora

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetDocumento7 pagineAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasingheNessuna valutazione finora

- ZRC 3 07Documento2 pagineZRC 3 07groelzjNessuna valutazione finora

- Devoe Coatings - Bar Rust 231 - Data SheetDocumento4 pagineDevoe Coatings - Bar Rust 231 - Data SheetAnonymous rKklA4yNessuna valutazione finora

- Amercoat® 385: Product Data SheetDocumento8 pagineAmercoat® 385: Product Data SheetNizar BouchaalaNessuna valutazione finora

- Intergard 251 Tech Data SheetDocumento0 pagineIntergard 251 Tech Data SheetL Mahender ReddyNessuna valutazione finora

- Carboguard 89dfsfs0 PDSDocumento2 pagineCarboguard 89dfsfs0 PDSMayur PatelNessuna valutazione finora

- Pds Psx700 Jan 2008Documento3 paginePds Psx700 Jan 2008mjayhawk28Nessuna valutazione finora

- Acrolon 890 EN 20130206Documento2 pagineAcrolon 890 EN 20130206hainguyenbkvhv0% (1)

- Phenoline 1205 PDS 9-06 PDFDocumento2 paginePhenoline 1205 PDS 9-06 PDFttr_1947Nessuna valutazione finora

- Duraplate Uhs EnglishDocumento4 pagineDuraplate Uhs EnglishLuis JaraNessuna valutazione finora

- Interline 850Documento4 pagineInterline 850shameelNessuna valutazione finora

- Carbomastic 15 PDSDocumento2 pagineCarbomastic 15 PDSAnonymous 4fVUDODNessuna valutazione finora

- Carboguard 635 Thinned 50% - Sealer PDSDocumento5 pagineCarboguard 635 Thinned 50% - Sealer PDSjakeNessuna valutazione finora

- Xylar Data SheetDocumento3 pagineXylar Data Sheetsarath6725Nessuna valutazione finora

- Carboguard 888 PDSDocumento3 pagineCarboguard 888 PDSsalamrefighNessuna valutazione finora

- Interseal 670 HS EN O-FDocumento4 pagineInterseal 670 HS EN O-Fapde06Nessuna valutazione finora

- Description Packaging Product Data SheetDocumento2 pagineDescription Packaging Product Data SheetRonald Fernandez ManubuluNessuna valutazione finora

- 5200 DTM AcrylicDocumento4 pagine5200 DTM AcrylicMarshall BravestarNessuna valutazione finora

- 97 145Documento2 pagine97 145anon_251242493Nessuna valutazione finora

- Sigmaprime 700Documento7 pagineSigmaprime 700Trịnh Minh KhoaNessuna valutazione finora

- SigmaCover 280Documento5 pagineSigmaCover 280ajuhaseenNessuna valutazione finora

- Ceilcote 2000 - Technical Data SheetDocumento4 pagineCeilcote 2000 - Technical Data SheetAlpAccess Alpinism UtilitarNessuna valutazione finora

- Product Data Sheet SP-8888Documento7 pagineProduct Data Sheet SP-8888pablo gonzalezNessuna valutazione finora

- Inspection Check List 2Documento34 pagineInspection Check List 2r.devendranNessuna valutazione finora

- Interplus 1180: Protective CoatingsDocumento4 pagineInterplus 1180: Protective CoatingsAnindya Aulia PratiwiNessuna valutazione finora

- Seven Tank ProcessDocumento4 pagineSeven Tank Processbhaveshbhoi100% (3)

- Devran 224HS PdsDocumento2 pagineDevran 224HS Pdsjopedro96Nessuna valutazione finora

- Carbothane 134 HG PDSDocumento2 pagineCarbothane 134 HG PDSfazeel mohammedNessuna valutazione finora

- Amerlock 400 Sigmacover 400Documento6 pagineAmerlock 400 Sigmacover 400Vijay KumarNessuna valutazione finora

- Carbozinc 11 PDS-MarineDocumento2 pagineCarbozinc 11 PDS-MarineJulie WillisNessuna valutazione finora

- 9546Documento2 pagine9546James DunlapNessuna valutazione finora

- Bitumastic 300MDocumento2 pagineBitumastic 300Mtharman749781Nessuna valutazione finora

- ZRC Zero VocDocumento2 pagineZRC Zero Vochksn77Nessuna valutazione finora

- CISC/CPMA Standard 2-75: A Quick-Drying Primer For Use On Structural SteelDocumento21 pagineCISC/CPMA Standard 2-75: A Quick-Drying Primer For Use On Structural SteelJairo LopezNessuna valutazione finora

- 385 PDS AiDocumento4 pagine385 PDS Ai전상문Nessuna valutazione finora

- Amer Coat 385Documento4 pagineAmer Coat 385Mehman NasibovNessuna valutazione finora

- SigmaPrime 200Documento7 pagineSigmaPrime 200amshivNessuna valutazione finora

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyDa EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNessuna valutazione finora

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingDa EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNessuna valutazione finora

- 75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014Da Everand75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014S. K. SundaramNessuna valutazione finora

- 76th Conference on Glass Problems, Version A: A Collection of Papers Presented at the 76th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 2-5, 2015Da Everand76th Conference on Glass Problems, Version A: A Collection of Papers Presented at the 76th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 2-5, 2015S. K. SundaramNessuna valutazione finora

- Bollhoff Rivkle SFC Inserts For Composite Material Catalog PDFDocumento5 pagineBollhoff Rivkle SFC Inserts For Composite Material Catalog PDFClifford BernardNessuna valutazione finora

- Engineering Science N4 QP April 2020 PDF 1Documento14 pagineEngineering Science N4 QP April 2020 PDF 1Tafadzwa GurazNessuna valutazione finora

- Development and Validation of Bioanalytical Methods For Quantitative Analysis of Gefitinib by Using Uv-Visible SpectrophotometryDocumento13 pagineDevelopment and Validation of Bioanalytical Methods For Quantitative Analysis of Gefitinib by Using Uv-Visible SpectrophotometryPamarthi TejaswiNessuna valutazione finora

- Asme Section Viii Div.1Documento87 pagineAsme Section Viii Div.1balu100% (7)

- Adblue FH4 PDFDocumento45 pagineAdblue FH4 PDFAhmad BaharNessuna valutazione finora

- Prescribed Practicals Lab Manual 2016Documento28 paginePrescribed Practicals Lab Manual 2016rbgrossNessuna valutazione finora

- Alternative Low Temp SteelsDocumento1 paginaAlternative Low Temp SteelsZarna ModiNessuna valutazione finora

- Sequential Extraction ProcedureDocumento1 paginaSequential Extraction ProcedureGangi Reddy UbbaraNessuna valutazione finora

- Me 8301 EtdDocumento3 pagineMe 8301 Etdsrinithims78Nessuna valutazione finora

- Annex4-TRS992 Hold Time Study GuidelineDocumento8 pagineAnnex4-TRS992 Hold Time Study Guidelinensk79in@gmail.com100% (1)

- BIOC 315 - Biochemistry of Food Processing Lecture NotesDocumento55 pagineBIOC 315 - Biochemistry of Food Processing Lecture NotesPerry MasonNessuna valutazione finora

- Additives For Wood Plastic Composites 2009-090420Documento56 pagineAdditives For Wood Plastic Composites 2009-090420Arcangeli24Nessuna valutazione finora

- Polymerppt 140425171028 Phpapp02Documento18 paginePolymerppt 140425171028 Phpapp02zubi0585Nessuna valutazione finora

- UV Air Sterilization System Reduces Airborne Microbes by 99Documento32 pagineUV Air Sterilization System Reduces Airborne Microbes by 99Ali Ben HusseinNessuna valutazione finora

- Drinking Water Treatment Design CalculationsDocumento13 pagineDrinking Water Treatment Design Calculationssalil dubey100% (1)

- ASTU chemistry questionsDocumento68 pagineASTU chemistry questionsFaya MohammadNessuna valutazione finora

- Activity 8 - Analysis and Classification of CoalsDocumento8 pagineActivity 8 - Analysis and Classification of CoalsAnne Maureen MasangcayNessuna valutazione finora

- Phase Diagrams For Metallic SystemsDocumento5 paginePhase Diagrams For Metallic SystemsZesi Villamor Delos SantosNessuna valutazione finora

- Moldex3D R14 FEA Interface IntroductionDocumento46 pagineMoldex3D R14 FEA Interface IntroductionmadhukeshwartNessuna valutazione finora

- Dumas Method LabDocumento5 pagineDumas Method LabJohn JosephNessuna valutazione finora

- Mark Scheme (Results) Summer 2015: GCE Chemistry (6CH05/01)Documento24 pagineMark Scheme (Results) Summer 2015: GCE Chemistry (6CH05/01)Arpan SahaNessuna valutazione finora

- JBC Common Boiler FormulasDocumento12 pagineJBC Common Boiler Formulasnesrine10Nessuna valutazione finora

- MethanizerDocumento1 paginaMethanizerDaniv NguyenNessuna valutazione finora

- ETAG006 2finDocumento66 pagineETAG006 2finSerban RaduNessuna valutazione finora

- ADC3010 AF CGA Selection ChartsDocumento1 paginaADC3010 AF CGA Selection ChartsSasan AbbasiNessuna valutazione finora

- Science X QP Set BDocumento7 pagineScience X QP Set BYogesh KhannaNessuna valutazione finora

- Bore Evacuator Corrosion 155mm SPG 14093humiston PDFDocumento24 pagineBore Evacuator Corrosion 155mm SPG 14093humiston PDFehj choNessuna valutazione finora

- CAIRO INSPECTION COMPANY PT EXAMDocumento16 pagineCAIRO INSPECTION COMPANY PT EXAMAhmedNessuna valutazione finora

- SOP-Calibration and pH MeasurementDocumento2 pagineSOP-Calibration and pH MeasurementrancidNessuna valutazione finora

- Experimental Investigation and Performance Evaluation of Solar Still Using Phase Change MaterialDocumento10 pagineExperimental Investigation and Performance Evaluation of Solar Still Using Phase Change MaterialrassNessuna valutazione finora