Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Coupled Vibration Analysis For Pump

Caricato da

ilmu20 valutazioniIl 0% ha trovato utile questo documento (0 voti)

208 visualizzazioni0 pagineCoupled vibration analysis for pump

Titolo originale

Coupled vibration analysis for pump

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCoupled vibration analysis for pump

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

208 visualizzazioni0 pagineCoupled Vibration Analysis For Pump

Caricato da

ilmu2Coupled vibration analysis for pump

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 0

The coupled vibration analysis

The coupled vibration analysis

for

for

vertical pumps

vertical pumps

and

and

the pump station

the pump station

Michiko SUGIYAMA

EBARA Corporation

Shuji YAMASHITA

NIPPON STEEL Corporation

24

th

INTERNATIONAL PUMP USERS SYMPOSIUM

Abstract

At the engineering stage of pump stations, the evaluation of the

pump vibration is an important consideration.

Finite Element Method (FEM) is an effective method for

prediction of vibration and avoidance of resonance phenomena.

However, if pumps are installed on a low rigidity foundation,

there is a possibility that the following problems occur.

Vibration interaction between pumps

Vibration increase by the resonance of pump excitation

frequencies and foundation natural frequencies.

At large-sized vertical pumps, stiffness of the foundation

structure has a considerable effect on the natural frequencies.

Usually, pumps are installed on a high rigidity foundation.

In such a case, enough accuracy is obtained by a pump unit

model supported by spring elements equivalent to the

foundation stiffness.

Abstract

For these cases, the coupled vibration analysis of the pumps

and the pump foundation structure is effective in obtaining low

vibration levels.

The coupled vibration analysis enables an evaluation

including interaction vibration of several structures by

using the coupled model of these structures.

This presentation shows the case study of

the coupled vibration analysis

for three pumps and a pump station.

For the case study, the vibration levels of pumps were well

below the vibration limits, because the prior review for the

structure of the pump station was performed effectively by

the analysis before the construction of the pump station.

ground

steel pipe piles

pit

existing pit wall

steel framed

reinforced

concrete

Outline

seawater intake pump station for cooling water

Structure of the pump station

The pump station is the

steel framed reinforced

concrete structure.

For the structural reasons

of the pit, the one side of the

pump station is supported by

the ground and the other side

is supported by steel pipe

piles.

It is necessary to confirm

the rigidity to the dynamic load.

vertical cross-sectional view

of the pump station

Prediction by FEM analysis

Outline

seawater intake pump station for cooling water

Pump Specification

Pump type Mixed flow Vertical Pump

Discharge Size 900 mm (35.4 inch)

Capacity

130 m

3

/min

(34342.3 gpm)

Total Head

17 m

(55.8 ft)

Speed

593 min

-1

Output of Motor 500 kW

3 pump units are set on the pump station

Flow of the Case Study

STEP 2 Verification of the FEM model

The transfer function of the pump floor was measured by

the excitation test.

The FEM model was verified by the analytical transfer

function with the measured transfer function.

STEP 3 Measurement of vibration amplitude at the operation

The accuracy of the analysis was verified by comparing

results of the analysis with measurements at the pump

operation.

Measurements were well below the vibration limit.

STEP 1 Prediction of vibration amplitudes by the FEM analysis

For the prior review, vibration amplitudes of the pumps

were calculated by the FEM vibration analysis using the

coupled model of pumps and the pump station.

The pump station structure was decided based on the

analysis.

STEP 1-1 Model for FEM Analysis

900 pumps

steel pipe pile

H-section steel beam

Concrete floor slab

pit

ground level

Concrete wall

Vibration amplitudes were calculated by the model.

STEP 1-2 Dynamic load condition

for the prediction of vibration amplitude

N: rotating frequency

ZN: blade passing frequency

exciting

force

exciting

frequency

Motor unbalanced force

343 N

(77.1 lbf)

9.9Hz(N)

Pump

Impeller

radial force

(hydraulic at shut-off operation &

structural unbalance)

6 860 N

(1542.2 lbf)

9.9Hz(N)

or

39.5Hz(ZN)

Pump

thrust

bearing

thrust force

(10% of static pressure

at shut-off operation)

9 800 N

(2203.1 lbf)

9.9Hz(N)

or

39.5Hz(ZN)

Vibration amplitudes of the motors and the foundation were

calculated by the frequency response analysis

with these load conditions.

STEP 1-3 Results of frequency response analysis

X 45.4 / 1.787

Y 26.6 / 1.047

Z 17.3 / 0.683

X 1.5 / 0.059

Y 1.4 / 0.057

Z 9.9 / 0.390

Motor

foundation

maximum values of

the results of

frequency response

analyses

Unit : mP-P / milsP-P

Analytical vibration amplitudes

of motors were predicted below

vibration limit.

X : pump discharge direction

Y : right angled direction of X in horizontal plane

Z : vertical direction

The foundation structure

of the pump station was

accepted.

Vibration limit : 80 mP-P

(3.15 milsP-P)

To improve the integrity, decrease of motor unbalance was

requested to the motor vender.

Excited point & measurement points

No.2 Pump-floor

pump base

Concrete

floor slab

steel pipe pile

measurement point excited point

H-section

steel beam

pit side

ground side

After the construction of the pump station,

the pump floor was excited by a vibration exciter at frequencies

from 5Hz to 50Hz.

STEP 2-1 Measurement of transfer function

for verification of the FEM model

STEP 2-2 Comparison of transfer function

between analysis and measurement

Transfer Function of No.2 Pump-Floor

0.000

0.005

0.010

0.015

0.020

0.025

0 10 20 30 40 50

Hz

m

m

/

s

e

c

2

/

N

Analysis Measurement

The FEM model was verified.

Analysis agrees with measurement.

Natural frequencies of

Motor & Motor support

Natural frequencies of

the entire pump station

STEP 3-1 Vibration amplitude by the analysis

X 45.4 / 1.787 12.1 / 0.476 16.1 / 0.635 3.6 / 0.140

Y 26.6 / 1.047 12.5 / 0.491 9.6 / 0.380 5.4 / 0.213

Z 17.3 / 0.683 5.9 / 0.233 5.8 / 0.229 3.3 / 0.128

X 1.5 / 0.059 3.2 / 0.124 2.0 / 0.080 0.4 / 0.017

Y 1.4 / 0.057 2.0 / 0.078 1.6 / 0.061 0.6 / 0.024

Z 9.9 / 0.390 2.8 / 0.110 4.8 / 0.190 0.6 / 0.024

Motor

foundation

results of

frequency

response

analyses

measurement

0%Q

(shut-off)

33%Q 100%Q

Unit : mP-P / milsP-P

Motor unbalanced force

Pump

Impeller

radial force

(hydraulic at shut-off

operation & structural

unbalance)

Pump

thrust

bearing

thrust force

(10% of static pressure

at shut-off operation)

Dynamic load condition

Vibration limit : 80 mP-P

(3.15 milsP-P)

X 45.4 / 1.787 12.1 / 0.476 16.1 / 0.635 3.6 / 0.140

Y 26.6 / 1.047 12.5 / 0.491 9.6 / 0.380 5.4 / 0.213

Z 17.3 / 0.683 5.9 / 0.233 5.8 / 0.229 3.3 / 0.128

X 1.5 / 0.059 3.2 / 0.124 2.0 / 0.080 0.4 / 0.017

Y 1.4 / 0.057 2.0 / 0.078 1.6 / 0.061 0.6 / 0.024

Z 9.9 / 0.390 2.8 / 0.110 4.8 / 0.190 0.6 / 0.024

Motor

foundation

results of

frequency

response

analyses

measurement

0%Q

(shut-off)

33%Q 100%Q

STEP 3-2 Comparison of vibration amplitude

between analysis and measurement

Unit : mP-P / milsP-P

Vibration limit : 80 mP-P

(3.15 milsP-P)

Motor vibration amplitudes are less than

results of analysis because the actual motor

unbalance was lower than the analytical

condition.

Results of analyses agree with the measurement amplitude.

Conclusion

The vibration analysis by FEM can examine not only machine

structure units but also large-scale issues between machines

and foundation structures.

A case study of coupled vibration analysis for vertical pumps

and a pump station was presented, and accuracy of the

analysis was verified.

Modeling techniques for units of machine structures and

foundation structures

Definitions of boundary conditions and material properties

such as stiffness and material damping.

For high accuracy of coupled analyses for machines and

foundation structures, the following knowledge is important,

Thank you for your kind attention.

Potrebbero piacerti anche

- Condition Monitoring of Centrifugal Blower Using Vibration Analysis PDFDocumento10 pagineCondition Monitoring of Centrifugal Blower Using Vibration Analysis PDFJose PradoNessuna valutazione finora

- Vibration Analysis For Machinery Health Diagnosis: Emerson SumicoDocumento1 paginaVibration Analysis For Machinery Health Diagnosis: Emerson SumicoTeguh SNessuna valutazione finora

- Pump Vibration AnalysisDocumento12 paginePump Vibration AnalysisSamir Benabdallah100% (1)

- Design of Structures and Foundations For Vibrating Machines PDFDocumento39 pagineDesign of Structures and Foundations For Vibrating Machines PDFsaputrafrandy_958992Nessuna valutazione finora

- Laser Alignment Standards PDFDocumento10 pagineLaser Alignment Standards PDFrohit singh100% (1)

- Condition Monitoring For ElectricalDocumento28 pagineCondition Monitoring For ElectricalArindam SamantaNessuna valutazione finora

- Vibration Acceptance Test ReportDocumento20 pagineVibration Acceptance Test ReportfazzlieNessuna valutazione finora

- Vibration PDFDocumento48 pagineVibration PDFtruva_kissNessuna valutazione finora

- Torsional Natural Frequencies PDFDocumento32 pagineTorsional Natural Frequencies PDFdavih007Nessuna valutazione finora

- Catia Sheet Metal Design PDFDocumento90 pagineCatia Sheet Metal Design PDFNasos MasourasNessuna valutazione finora

- SENT Summary Report TG 500 Run Down 25th JUNE 2010Documento35 pagineSENT Summary Report TG 500 Run Down 25th JUNE 2010jarotNessuna valutazione finora

- Rotor Instability Morton Effects in MachineryDocumento0 pagineRotor Instability Morton Effects in Machineryilmu2Nessuna valutazione finora

- A630 Deephams Sewage Works UpgradeDocumento28 pagineA630 Deephams Sewage Works UpgradedeephamsconsultationNessuna valutazione finora

- Vibration Analysis of Centrifugal FansDocumento18 pagineVibration Analysis of Centrifugal FansMohd Asiren Mohd Sharif100% (4)

- Vibration Analysis Rotating EquipmentDocumento161 pagineVibration Analysis Rotating Equipmentronfrend100% (17)

- Torque Wrench Snap-OnDocumento5 pagineTorque Wrench Snap-Onilmu2100% (1)

- Torque Wrench Snap-OnDocumento5 pagineTorque Wrench Snap-Onilmu2100% (1)

- Torque Wrench Snap-OnDocumento5 pagineTorque Wrench Snap-Onilmu2100% (1)

- Vertical Pump Synchronous Motor VibrationDocumento0 pagineVertical Pump Synchronous Motor Vibrationilmu2Nessuna valutazione finora

- Bearing Vibration Analysis in Labview PDFDocumento11 pagineBearing Vibration Analysis in Labview PDFAli ShanNessuna valutazione finora

- Orbital AnalysisDocumento16 pagineOrbital AnalysisFadooollNessuna valutazione finora

- Reciprocating Compressor Condition Monitoring - GEDocumento6 pagineReciprocating Compressor Condition Monitoring - GEBao-Phuc NguyenNessuna valutazione finora

- Solving Motor Vibration Problems On Vertical PumpsDocumento5 pagineSolving Motor Vibration Problems On Vertical Pumpsjameel babooramNessuna valutazione finora

- Pressure Vessel Exm QuestionsDocumento4 paginePressure Vessel Exm QuestionsJithuJohn100% (1)

- Autocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookDocumento8 pagineAutocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookLe Thanh Hai100% (2)

- Vibration Analysis of Gear Box.5-MilosprokoDocumento3 pagineVibration Analysis of Gear Box.5-MilosprokoRavikiran Hegde100% (2)

- Vibration Analysis Level - 1 FinalDocumento265 pagineVibration Analysis Level - 1 FinalSaadKianiNessuna valutazione finora

- Concrete Terminology PDFDocumento20 pagineConcrete Terminology PDFamirthraj74Nessuna valutazione finora

- Vibration Analysis Measurement ManualDocumento215 pagineVibration Analysis Measurement Manualronfrend100% (1)

- Condition Monitoring of Rotary Equipments by Vibration AnalysisDocumento34 pagineCondition Monitoring of Rotary Equipments by Vibration Analysispradeep.selvarajanNessuna valutazione finora

- ORBIT AnalysisDocumento4 pagineORBIT AnalysisManoj PaneriNessuna valutazione finora

- Pump Vibration-Case StudiesDocumento10 paginePump Vibration-Case StudiesGyogi MitsutaNessuna valutazione finora

- Order Analysis ToolkitDocumento16 pagineOrder Analysis ToolkitManuel Enrique Salas FernándezNessuna valutazione finora

- AMPLITUDE MODULATION Versus BEATSDocumento5 pagineAMPLITUDE MODULATION Versus BEATSHaitham YoussefNessuna valutazione finora

- Bend Shaft Vibration SpectrumDocumento6 pagineBend Shaft Vibration SpectrumAvnish DubeyNessuna valutazione finora

- Vibration NotesDocumento95 pagineVibration NotesHaitham Youssef100% (1)

- Vibration Cause Analysis and Elimination of Reciprocating Compressor Inlet PipelinesDocumento12 pagineVibration Cause Analysis and Elimination of Reciprocating Compressor Inlet PipelinesDaniel GómezNessuna valutazione finora

- Vibration AnalysisDocumento22 pagineVibration Analysisvenkat chakNessuna valutazione finora

- 2 Welding On Rotors Welding On Rotors For Power Plant Turbo Sets Dr.-Ing. Wolfgang Janssen, Siemens AG, Power Generation, GermanyDocumento13 pagine2 Welding On Rotors Welding On Rotors For Power Plant Turbo Sets Dr.-Ing. Wolfgang Janssen, Siemens AG, Power Generation, GermanySumit RaiNessuna valutazione finora

- Bump TestDocumento5 pagineBump Testwsjouri2510Nessuna valutazione finora

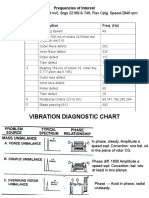

- Vibration Diagnostic Chart1Documento16 pagineVibration Diagnostic Chart1Anand KumarNessuna valutazione finora

- Solving Motor Vibration Problems On Vertical Pumps ResonanceDocumento5 pagineSolving Motor Vibration Problems On Vertical Pumps Resonancejameel babooramNessuna valutazione finora

- Basic Vibration Analysis IIDocumento24 pagineBasic Vibration Analysis IIAshwani Dogra100% (2)

- EngineersGuide2012 UnlockedDocumento192 pagineEngineersGuide2012 UnlockedSanan JalilNessuna valutazione finora

- Motor Vibration AnalysisDocumento61 pagineMotor Vibration Analysiskiki kamuiNessuna valutazione finora

- Vibration BasicsDocumento120 pagineVibration Basicspradeep.selvarajan100% (1)

- Structural Health MonitoringDa EverandStructural Health MonitoringDaniel BalageasNessuna valutazione finora

- Rotating Machinery Reliability for Technicians and EngineersDa EverandRotating Machinery Reliability for Technicians and EngineersNessuna valutazione finora

- Steel and Pipes For Africa Price List PDFDocumento1 paginaSteel and Pipes For Africa Price List PDFBrian67% (12)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionDa EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNessuna valutazione finora

- Rotordynamic Stability Case StudiesDocumento9 pagineRotordynamic Stability Case StudiesYong LiNessuna valutazione finora

- Torsional Vibration Analysis of Synchronous Motor Driven TCDocumento16 pagineTorsional Vibration Analysis of Synchronous Motor Driven TCBharath Chandra ReddyNessuna valutazione finora

- Gearbox Vibration Limits (Dudley) PDFDocumento8 pagineGearbox Vibration Limits (Dudley) PDFilmu2Nessuna valutazione finora

- Gearbox Vibration Limits (Dudley) PDFDocumento8 pagineGearbox Vibration Limits (Dudley) PDFilmu2Nessuna valutazione finora

- Gearbox Vibration Limits (Dudley) PDFDocumento8 pagineGearbox Vibration Limits (Dudley) PDFilmu2Nessuna valutazione finora

- Coupled Vibration Analysis For Vertical PumpsDocumento14 pagineCoupled Vibration Analysis For Vertical PumpsAnwarNessuna valutazione finora

- Diagnosis of Centrifugal Pump Faults Using Vibration MethodsDocumento12 pagineDiagnosis of Centrifugal Pump Faults Using Vibration MethodsHatem ShawkiNessuna valutazione finora

- Transient Speed Vibration AnalysisDocumento34 pagineTransient Speed Vibration AnalysistylerdurdaneNessuna valutazione finora

- Root Cause Analysis On A Multistage Centrifugal Pump in A Power Plant Due To Shaft Crack Based On PDFDocumento42 pagineRoot Cause Analysis On A Multistage Centrifugal Pump in A Power Plant Due To Shaft Crack Based On PDFmariomatoNessuna valutazione finora

- Vibration Analysis Gt6 Generator LibyaDocumento6 pagineVibration Analysis Gt6 Generator LibyaRohit GunerkarNessuna valutazione finora

- Vibration Report 18LAC30AP001 18LAC20AP001Documento37 pagineVibration Report 18LAC30AP001 18LAC20AP001TONNessuna valutazione finora

- Vibration AnalysisDocumento22 pagineVibration Analysistek_surinder100% (1)

- 1 - Boiler Tube FailuresDocumento54 pagine1 - Boiler Tube FailuresMohamad EshraNessuna valutazione finora

- Vibration 2Documento54 pagineVibration 2mister pogiNessuna valutazione finora

- Specifications Standards For Shafts Alignment PDFDocumento18 pagineSpecifications Standards For Shafts Alignment PDFDelfinshNessuna valutazione finora

- EM76 - Modal Testing Part 1 - Introduction & Impact TestingDocumento4 pagineEM76 - Modal Testing Part 1 - Introduction & Impact TestingChad HuntNessuna valutazione finora

- MisalignmentDocumento13 pagineMisalignmentZeeshan Sajid100% (1)

- IIMM ISO 55001 Supplement v1-2014-734Documento36 pagineIIMM ISO 55001 Supplement v1-2014-734ilmu286% (7)

- 01CB1S01Documento5 pagine01CB1S01raobabar21Nessuna valutazione finora

- Maintenance and Reliability: Resolving Vibration Problems in A Crude Booster PumpDocumento5 pagineMaintenance and Reliability: Resolving Vibration Problems in A Crude Booster Pump김형진Nessuna valutazione finora

- Monitoring and Analysis of Machine VibrationDocumento6 pagineMonitoring and Analysis of Machine VibrationAvinashNessuna valutazione finora

- SCHROEDER Automatic Recirculation Check ValveDocumento14 pagineSCHROEDER Automatic Recirculation Check ValveAli Bari100% (1)

- 1 Introduction To VibrationDocumento4 pagine1 Introduction To VibrationMohamed AslamNessuna valutazione finora

- Asset Integrity Management A Complete Guide - 2020 EditionDa EverandAsset Integrity Management A Complete Guide - 2020 EditionNessuna valutazione finora

- Pump Resonance CaseDocumento4 paginePump Resonance CaseLe Thanh HaiNessuna valutazione finora

- Designand Executionofa Test Rigfor Studyingthe Vibrationsofa GearboxDocumento8 pagineDesignand Executionofa Test Rigfor Studyingthe Vibrationsofa GearboxduongnnNessuna valutazione finora

- Controller ExcitationDocumento8 pagineController ExcitationSri SaiNessuna valutazione finora

- Understanding The Concept - Views On News From EquitymasterDocumento11 pagineUnderstanding The Concept - Views On News From Equitymasterilmu2Nessuna valutazione finora

- Common Method For Cost Coal Power PlantDocumento16 pagineCommon Method For Cost Coal Power Plantilmu2Nessuna valutazione finora

- Startup Paralel Turbo CompressorDocumento24 pagineStartup Paralel Turbo Compressorilmu2Nessuna valutazione finora

- Flow Loop Control PumpDocumento0 pagineFlow Loop Control Pumpilmu2Nessuna valutazione finora

- CATIADocumento98 pagineCATIAIvan CatalinNessuna valutazione finora

- Maintenance Gearbox and Online MonitoringDocumento0 pagineMaintenance Gearbox and Online Monitoringilmu2Nessuna valutazione finora

- Dynamic Depressurisation Calculations LNG Regasification UnitDocumento15 pagineDynamic Depressurisation Calculations LNG Regasification Unitilmu2Nessuna valutazione finora

- Case Study 07 PDFDocumento17 pagineCase Study 07 PDFilmu2Nessuna valutazione finora

- Flow Loop Control PumpDocumento0 pagineFlow Loop Control Pumpilmu2Nessuna valutazione finora

- Intermittent Spikes On Vibration and Motor Current Caused by Water CarryDocumento29 pagineIntermittent Spikes On Vibration and Motor Current Caused by Water Carryilmu2Nessuna valutazione finora

- Improving Reliability Through High Speed Energy PumpDocumento0 pagineImproving Reliability Through High Speed Energy Pumpilmu2Nessuna valutazione finora

- Driving Power Pump ReliabilityDocumento0 pagineDriving Power Pump Reliabilityilmu2Nessuna valutazione finora

- Structural Vibration Problem SolvingDocumento0 pagineStructural Vibration Problem Solvingilmu2Nessuna valutazione finora

- Case Study 01Documento19 pagineCase Study 01ilmu2Nessuna valutazione finora

- ANN Heat TransferDocumento5 pagineANN Heat Transferilmu2Nessuna valutazione finora

- A387 Low Alloy BoilerDocumento2 pagineA387 Low Alloy Boilerilmu2Nessuna valutazione finora

- Furnace CodesDocumento40 pagineFurnace Codescheeseheadlen100% (1)

- BITZER Output Data: Created On: 16/05/2017 16:44:22Documento5 pagineBITZER Output Data: Created On: 16/05/2017 16:44:22Hasan Syaiful INessuna valutazione finora

- 1 s2.0 S0048969721053572 MainDocumento15 pagine1 s2.0 S0048969721053572 MainMakhitha MasipaNessuna valutazione finora

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Documento3 pagineBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNessuna valutazione finora

- Draka 2Documento260 pagineDraka 2Sakinah Cik KinoNessuna valutazione finora

- n7k ReplacingDocumento102 paginen7k ReplacingMcyanogen HeshamNessuna valutazione finora

- Sheet Metal Forming PDFDocumento8 pagineSheet Metal Forming PDFAlpha WolfNessuna valutazione finora

- Rating Update - June 2019Documento54 pagineRating Update - June 2019maruf908Nessuna valutazione finora

- Identify The Following: Cien 3090 Construction Materials & Testing Midterm ExamDocumento1 paginaIdentify The Following: Cien 3090 Construction Materials & Testing Midterm Examacurvz2005Nessuna valutazione finora

- STEICO LVL Bonded LVL Sections EN IDocumento2 pagineSTEICO LVL Bonded LVL Sections EN IClaudiu BaditaNessuna valutazione finora

- 1000 Bolted JointsDocumento3 pagine1000 Bolted JointsMahmoud FawzyNessuna valutazione finora

- Astm A 563 14pdf PDFDocumento18 pagineAstm A 563 14pdf PDFSathish KumarNessuna valutazione finora

- Pipeline Risk Management Basic ManualDocumento6 paginePipeline Risk Management Basic ManualhemnNessuna valutazione finora

- Extra High Voltage XLPE Cables: LntrodllctiollDocumento3 pagineExtra High Voltage XLPE Cables: LntrodllctiollNika ThaiNessuna valutazione finora

- Simulation of Draping, Infiltration and Curing of CompositesDocumento49 pagineSimulation of Draping, Infiltration and Curing of CompositesPeti Kovács100% (1)

- Cleanroom CablesDocumento12 pagineCleanroom CablesluisRuben medinaNessuna valutazione finora

- DaihatsuDocumento10 pagineDaihatsuMANIU RADU-GEORGIANNessuna valutazione finora

- EZ Clean 1500Documento4 pagineEZ Clean 1500sebasalinashjNessuna valutazione finora

- Gravity Fed Main Industrial Training ReportDocumento37 pagineGravity Fed Main Industrial Training ReportKoushikSarkar0% (1)

- RS-540SH-7520|MABUCHI MOTOR CO., LTD. Product SearchDocumento2 pagineRS-540SH-7520|MABUCHI MOTOR CO., LTD. Product Searchjoroma58Nessuna valutazione finora

- Materials and Design: Ping Duan, Chunjie Yan, Wei Zhou, Wenjun Luo, Chunhua ShenDocumento13 pagineMaterials and Design: Ping Duan, Chunjie Yan, Wei Zhou, Wenjun Luo, Chunhua ShenJack LinNessuna valutazione finora

- Ahu IqDocumento5 pagineAhu IqAtul SharmaNessuna valutazione finora

- Residual Strength A N D Crack Propagation Tests O N C-130 Airplane Center Wings With Service-Imposed Fatigue DamageDocumento69 pagineResidual Strength A N D Crack Propagation Tests O N C-130 Airplane Center Wings With Service-Imposed Fatigue DamagemilindshettiNessuna valutazione finora

- Rheovis As 1920Documento2 pagineRheovis As 1920Victor LopezNessuna valutazione finora

- Energy Demand in Wood Processing Plants: Jingge Li, Murray Mccurdy, Shusheng PangDocumento9 pagineEnergy Demand in Wood Processing Plants: Jingge Li, Murray Mccurdy, Shusheng PangsabrahimaNessuna valutazione finora