Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sedimentation Tank Design

Caricato da

yash_btechCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sedimentation Tank Design

Caricato da

yash_btechCopyright:

Formati disponibili

Macquarie Matrix: Vol.2.

2, December 2012

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

Department of Chemical and Biomolecular Engineering, Melbourne School of Engineering, The University of Melbourne

Abstract Mathillo Semrang in rural Nepal relies on stream sources to provide drinking water. Erosion and deforestation of local terrain produces turbid water that requires treatment before distribution. The current round gravity sedimentation technology is large in footprint and cannot handle large water flow-rates and silt concentrations resulting from extreme weather events. In partnership with Nepal Water for Health (NEWAH) and Engineers Without Borders Australia (EWB), the project aim was the design of a small footprint inclined plate settler (IPS) to treat influent flow-rates ranging from 0.25 to 4 L/s. A 76% decrease in footprint was achieved by the IPS design for source flow-rates up to 4 L/s. Laboratory analysis revealed the optimum flow-rate of operation is approximately 10% of the maximum design flow-rate (4 L/s). Further research is needed to establish this finding along with further collaboration with rural Nepalese communities and NEWAH.

Keywords

sedimentation, clarification, Stokes Theory, Inclined Plate Settlers

159

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

Introduction

Drinking Water in Thumi VDC Nepal Nepal ranks among the top nations in terms of fresh water potential Water Resources Management Committee, 2010). The secure provision and distribution of drinking water is crucial in boosting socio-economical development and increasing standards of living, but little has been done thus far at a government level to ensure this outcome. In rural areas, the majority of the inhabitants do not have access to safe drinking water. One such rural village is Mathillo Semrang in the Thumi Village Development Community (VDC) in the Western Region of Nepal. Drinking water in Mathillo Semrang is sourced from hill and mountain springs that are subject to high sediment loads, particularly during monsoon and landslide events. Large concentrations of fine sediment in suspension results in high turbidity water sources. Mountainous terrain deforestation and land degradation are key contributors to high sediment inflows (Julien & Shah, 2005). Nepal Water for Health (NEWAH) is the national Nepalese non-government organisation established in 1992 to address the water and sanitation (WASH) needs of the rural communities of Nepal (Nepal Water for Health, 2011). Many NEWAH WASH programs involve the upgrade or installation of water supply systems from source to tap. In the hilly regions of the Western region of Nepal, where sources are turbid, NEWAH and local workers install sedimentation facilities prior to the distribution of water to villages. Traditionally these sedimentation facilities have consisted of round sedimentation tanks employing gravity sedimentation. However, it has been identified by NEWAH that in many cases there is insufficient space for the existing technology.

160

Macquarie Matrix: Vol.2.2, December 2012

The aim was to design a small footprint, high rate sedimentation system to treat the turbidity issues arising from stream sources in rural hilly regions of Nepal. The new design must meet the following criteria:

1. It must have the potential to produce water of equal or greater quality than that currently produced by the existing technology. 2. It must be low in cost with respect to both construction and operation. 3. It must be easily implemented on steep gradients. 4. It must be stable enough to withstand extreme weather conditions, i.e. monsoonal rainfall and land slides. 5. It must be small enough to suit the Nepalese water supply system. 6. It must require minimal or no machinery to construct and no electricity to operate.

Description of Current Design The current sedimentation system employed in Mathillo Semrang is the round Ferrocement Water Filter tank (Appendix 1). It is a round clarification device with a rectangular valve box attached to the rear of the device. The tank itself is doughnut in shape containing two settling basins. The influent water enters the first central basin where it is allowed to settle. The settled particles collect at the base of the vessel via a sloping floor. The clarified effluent in the central basin then enters the outer basin through a transfer pipe. This water travels in a clockwise direction to settle; the clockwise movement of the water reduces the potential for short-circuiting in the system. The clarified effluent in this outer basin leaves the system through the outlet pipe and travels straight to distribution.

161

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

The settled particles are removed from the system via a washout cycle. This involves entering the valve box via a manhole. The valve servicing the outlet pipe is closed and the washout pipes are opened. The normal operation of the system then allows the accumulated settled particles to be flushed from the system.

Fundamental Design Principles of Sedimentation Units The design of the current system is based on the principle of gravity settling. Gravity settling occurs in tanks of water with large cross-sectional areas where small influent and outward flows create a state of virtual quiescence in the system. Under the influence of gravity, particles with densities higher than that of the surrounding fluid will sink (sedimentation) whilst lighter particles will travel upwards or float (flotation) (Huisman, 1986). The particles present in the system are retained in the sludge layer at the bottom of the tank. This allows the water to leave the system in a clarified state (Huisman, 1986). The rate of rise or fall of the particles depends on the particle size and particle density relative to the fluid. Larger particles descend more rapidly than smaller particles. The size of particle can be changed by aggregation. This segregates the types of clarification experienced in settling into two types (Figure 1): discrete settling and flocculated settling.

162

The size of particle can be changed by the aggregation of particles into one unit. This therefore segregates the types of clarification experienced in settling into two types (Figure 5): discrete settling and flocculated settling. Discrete settling relies on settling by natural forces (i.e. gravity) Matrix: Vol.2.2, December 2012 where the amount of particle aggregation is negligible and where Macquarie during the whole settling period the suspended particles maintain their identity and consequently move down at a constant rate ( 5). Flocculated settling involves the coalescence of particles in an increase in settling rate and Figure 1: Schematic showing difference betweenresulting discrete and flocculated settling is usually achieved by the additions of chemical flocculants.

Figure 5: Schematic describing difference between discrete particle and flocculated settling Discrete settling occurs in systems with small particle concentrations where particle

aggregation is negligible and settling occurs by natural forces (i.e. gravity). In discrete

13

settling, the terminal velocity or settling rate of the particles can be calculated using Stokes law (Equation 1) which assumes the rate depends only on the size of the particle, shape (sphericity) and density as well as the viscosity and density of the surrounding fluid. Stokes law is: ( )

where, d is the particle diameter, g is the gravitational acceleration constant (m2/s), is the fluid viscosity (Ns/m2), is the particle density (kg/m3), f is the fluid density (kg/m3), Ut is the terminal velocity of particle (m/s) and So is the Stokes settling rate of particle (m/s). The overflow parameter is the crucial parameter in the design. It is typically expressed as a rate of flow per unit area (m3/m2 time) (Demir, 1995) and is generally chosen to be half of the value of the Stokes settling rate. For a fixed influent rate, adequate particle removal only depends on the surface area of the tank (Demir, 1995).

163

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

For low removal ratios, a slight increase in tank area results in a large improvement in particle removal, however if large removal ratios are required, large increases in tank cross sectional area are also required (Camp, 1946); this is inconvenient in cases where land

Settling/Sedimentation tanks can be varied in design, they are typically rectangular, square or availability is small. circular, and water flow occurs in a continuous manner either in a horizontal or vertical horizontal direction. The typical design of the a sedimentation tank involves four major parts (Figure 6) (5):

Sedimentation tanks are typically rectangular, square or circular and water flow

1. inThe inlet construction which allows the dispersion of the influent flow into the tank with occurs a continuous manner either in a horizontal or vertical horizontal direction. The the dispersion of the flow uniformly over the entire cross-sectional are of the basin.

typical of thezone a sedimentation tank involves major components (Figure 2. design The settling where the suspended particlesfour subside through the flowing water with a

minimal disturbance caused by fluid displacement.

2)(Huisman, 1986): 3. Sludge zone in which the removal particles accumulate and from which they are withdrawal

for disposal.

Figure Horizontal flow sedimentation showing theuniformly four typical zones in construction. 4.2:Outlet construction which collects ttank he clarified liquid over th e cross-sectional Image source: (Huisman, 1989) area.

Figure 6: Horizontal flow sedimentation tank showing the four typical zones in construction( 5).

1. The inlet zone allows the uniform dispersion of the influent into the tank over the 2.3 Discrete Particle Settling S tokes' Law entire cross-sectional area.

The design of the settling zone of the sedimentation tank is rooted in the understanding of particle 2. The settling zone where the suspended particles subside through the flowing water. settling. Gravity settling allows the the particles from accumulate the fluid medium by gravity which 3. The sludge zone in separation which theof removed particles and from which theyacts are on the particles to drag them through the liquid medium to the bottom where they collect as a layer of sediment leaving a clarified layer above.

removed for disposal.

A particle located in an infinite quiescent medium that is subjected to a force will travel in the 4. Outlet construction that collects liquidsolutions) uniformly direction of that force. Individual particlesthe (i.e clarified dilute particle atover rest the in a crossliquid medium will experience two main forces (Figure 7): a downward force due to gravity and an upward force due tosectional buoyancy. Theof net force arising from the gravitational F g and buoyancy forces F b area the tank. dictates the direction of the particle motion (Equation 7)

164

14

Macquarie Matrix: Vol.2.2, December 2012

Current Tank Design Figure 3 provides the operational range of the five Ferrocement water filter tanks currently in use. These designs vary in cross-sectional area to suit the influent flow rate to the system. The design parameters are calculated using Stokes law on the basis of a 10 micron silt particle. Figure 3: Tank cross-sectional area varying by type for different influent flows.

35 Cross-sectional area (m2) 30 25 20 15 10 5 0 0 0.5 1 1.5 2 2.5 3 3.5 Influent flow-rate (L/s) Type 1 Type 2 Type 3 Type 4 Type 5

The tank types cover flow ranges from 0.25 L/s to 3 L/s. Influent flow-rates greater than 3 L/s require the design of a more complex sedimentation tank. Mathillo Semrang has a maximum stream source flow-rate of 0.32 L/s and employs the use of a Type 2 tank.

Boycott Effect and Inclined Plate Settling The Boycott Effect describes the increase in particle settling rate due to the presence of an inclined surface. This phenomenon was first described by Boycott in 1920 with the discovery

165

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

2.4.4 and Disadvantages of Current Tank Design that Advantages if defribinated blood is put to stand in narrow tubes, the corpuscles sediment a good There are many inherent advantages and disadvantages associated with the current tank design, the deal fasterof if the tube inclined than when it is vertical (Boycott, 1920). most pertinent those areis listed below:

The increase in settling rate can be described by imagining a settling particle within Advantages Disadvantages an infinite quiescent medium in a container with vertical walls. The particle must travel

Proven tank design. Tank footprint particularly for large through the medium until it reaches the bottom surface of the container. the particle flows (in excess of 2 But L/s)ifis unfavourable for implementation in hilly area or area is inside a vessel containing an inclined surface, the particle has the opportunity to make with small land spaces. Proven operation. The current system is poor at handling contact with a surface and slide down to the bottom of the container without having to variations in influent loads, particularly the large loads seen during the monsoon traverse the total height of the container. The increase in particle settling rate can therefore season. Easeas ofa construction, operation a nd (Demir, 1995) Poor robustness: the design is be seen decrease in settling distance and an increase incurrent the surface area maintenance. designed to handle normal (i.e. low) silt particle suspensions and does not treat available for settling (Davis & Acrivos, 1985). effectively in higher silt concentrations. Delivers an acceptable water quality output during normal operation. Inclined Plate Settlers Description and Design No biological treatment or chemical removal is possible in the current design.

Readily scalable and flexible to meet various source water conditions. Inclined plate settlers (Figure 4) are high rate sedimentation devices that consist of a series

2.5

of inclined parallel plates forming channels (plate stack) into which a particle containing

High Rate Gravity Settling

solution be fedissues for separation. The plate is normally installed between a parallel In order to can mitigate encountered with stack the large cross-sectional area required for the traditional round sedimentation units, a high rate system may be employed. One potentially inlet and outlet (Leung & Probstein, 1983). promising system ischannel the inclined plate settler (IPS) (Figure 10) which harnesses the properties of inclined particle settling on a series of thin plates. Figure 4: Cross-section of an inclined plate settler

Figure 10: Cross-section of inclined plate settler (5). 22 166

Macquarie Matrix: Vol.2.2, December 2012

Water enters through the inlet and is forced to flow up through the channels created by the plate stack to the outlet area where the effluent is collected in the outlet chamber (Foellmi & Bryant, n.d.; Leung W-F & Probstein, 1983). As the water flows through the plate stack channels, the particles settle onto the downward facing walls of the inclined plates and slide down to the bottom of the settler where they are collected (Davis, Zhang, & Agarwala, 1989). IPS designs have the capacity to settle out very fine suspended particles at a high rate. The settler capacity per unit volume can be made large without substantial increase in the footprint of the tank (Foellmi & Bryant, n.d.). The ratio of floor area needed for conventional sedimentation basins to the floor area for IPS designs can range from 8:1 to 10:1.

Influence of Plate Dimensions on IPS Design A relationship developed by Huisman (Huisman, 1986) shows the relationship between specific plate parameters and the increase in effective settling rate.

167

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

Figure 5: Schematic of settling particle between two inclined plates.

Figure 5 shows the critical dimensions considered in the design of IPS tanks, where plates of thickness t, angle of inclination to the horizontal , inter-plate distance w and tank height H, the efficiency or removal ratio of the settling tank is given by Equation 2 (Huisman, 1986):

The improved setting rate (Equation 3) is described as a function of the settling rate without the plates and the plate dimensions:

168

Macquarie Matrix: Vol.2.2, December 2012

Full Scale Model Design The general dimensions of the full-scale design are shown in Figure 6. Detailed design drawings are given in Figures 11 and 12 contained in appendices 2 and 3. Figure 6: Cross section of full-scale IPS design

Stokes Analysis Mathillo Semrang spring and stream sources can be considered dilute suspensions with laminar flow; therefore, Stokes analysis was used to determine the theoretical crosssectional area needed for adequate settling.

A minimum particle size of 10 microns was used as the basis for design as it is the smallest expected size of the soil based granitic particles typical of the region. The cross-

169

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

section areas required for the settling of the particle with respect to various influent flowrates were calculated and are shown in Figure 7. Figure 7: Stokes analysis for cross-sectional area of tank required for various influent flows

90 80 Cross-sectional area (m2) 70 60 50 40 30 20 10 0 0.00 1.00 2.00 3.00 4.00 Influent flow-rate (L/s)

A cross-sectional area of 86.26 m2 is necessary to ensure adequate settling of 10 micron particles with an influent flow-rate of 4 L/s; this equates to a diameter of 10.48 m.

Huismans Analysis A summary of the design parameters chosen for the full-scale IPS plate scale design is listed in Table 1: Table 1: Parameters chosen for the full-scale IPS design using the Huisman analysis Parameter Plate stack height (H) Plate length (L) Plate width (W) Plate thickness (t) Plate spacing (w) Angle of inclination () Cross-sectional area of plate stack (A) Value 1.5 m 1.96 m 1.9 m 0.01 m 0.05 m 50o 5.10 m2

170

Macquarie Matrix: Vol.2.2, December 2012

The height of the plate bundle was the crucial element for design and it was necessary for this height to be less than 2 m in to allow a tank height of no greater than 2.5 m to be safely constructed manually. A plate thickness of 0.01 m was chosen to allow structural integrity when manually inserted and removed into grooves constructed in the tank wall. A plate spacing (w) of 0.05 m was chosen for a similar reason. The plate inclination angle of 50o was chosen as it allowed for a small cross-sectional area (5.1 m2) and effective plate cleaning (Culp, Hansen, & Richardson, 1968; Shamim & Wais, 1980).

Inlet Design If the plate bundle is situated in a rectangular tank, there is the loss of a significant amount of area that would otherwise be utilised. Industry mitigates this loss in area by using stabilising structures to construction the clarifier as a tilted piece of equipment without any vertical walls. Although viable, this solution is impractical where ease of construction is necessary. The inlet area was designed to make use of the wasted space associated with the inclination of the plate bundle with adequate positioning of the inlet opening and the lengthening of the first plate in the bundle to create a suitable baffle for momentum dispersion and to reduce short-circuiting.

Outlet Design The outlet design consists of an overflow weir leading to an effluent collection basin containing a submerged outlet. This prevents the carry over of scum into distribution. Due to the length of the tank and the low flow-rate of the influent entering the system, it can be assumed significant settling will occur before the outlet is reached and therefore the use of an overflow with submerged outlet is appropriate.

171

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

Sludge Collection Design The floor of the tank has been constructed with a slope of 2 degrees to allow the collection of sludge to be removed during the washout cycle.

Building Materials and Construction Considerations The current round sedimentation tanks are simple to construct with minimal cost necessary. The tanks exist almost entirely as Ferrocement structures with a stone foundation. The piping, valves and manholes are constructed from more valuable materials. To ensure the full-scale design also remains cost effective, it was decided the construction of the tank would be similar to that of the round sedimentation design. The tank will sit on a foundation of stone and may be dug into the ground if necessary. The outer walls and floors will be Ferrocement with the use of adequate steel reinforcement where appropriate. A corrugated iron roof will protect the system from the weather. The inlet and outlet piping and valves will remain the same specification as is available currently to the Mathillo Semrang community. The plates would ideally be constructed from sheet metal such as stainless steel, plastic (polyethylene, ABS or similar) or even a marine ply (Schultz & Okun, 1984) but these materials are currently unavailable in rural communities. An alternative suggestion would be the use of inclined plastic tubing or an ABS hexagonal matrix instead of a plate design. This would require the redesign of the system and may prove challenging in construction and maintenance, however such systems are common industrially. There is need for further research and liaison with the local community members and NEWAH as to the most appropriate material to be used for the IPS design.

172

Macquarie Matrix: Vol.2.2, December 2012

Laboratory Testing A Perspex model (Figure 8) was built to test the integrity of the full-scale design. A perfect scale model was difficult to achieve, as the scaling of the plate thickness resulted in nonrealistic dimensions. Figure 8: Laboratory IPS model

Figure 15: Solidsworks drawing of the scale model design. Kindly drawn by Otkay Balkis Senior Technical Officer, Technical and EHS Service Unit Melbourne School of Engineering The University of Melbourne. 38

The model does not include an overflow weir or a separate effluent collection chamber with a submerged outlet. The outlet is placed very close to the edge of the plate bundle and the influent opening is placed perpendicular to the outlet opening. There is no sloping floor leading to any washout system. An overflow rate of 2.21 10-4 m/s with a maximum flow-rate of 421 mL/min was calculated using Huisman analysis for the scaled design in Figure 8. A simple laboratory experiment was conducted to test the ability of the scaled model to clarify solutions containing calcium carbonate particles ranging from 15 to 40 microns in size. The influent solution was pre-prepared by settling a small amount of Omycarb 40 (calcium carbonate) in a beaker to collect the 15 micron particles needed for

173

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

experimentation. The sediment was diluted with an appropriate volume of water to provide a solution with a turbidity of 20-25 NTU. A peristaltic pump allowed the calibration of the influent to an initial 55 mL/min, or approximately 13 % of the maximum flow-rate. The model tank was filled with water and a particle solution added. When the inlet chamber solution was recorded as having a turbidity of approximately 25 NTU, the effluent turbidity was measured approximately every 10 minutes to gauge operation of the device. When the effluent turbidity reached the same value as the influent, the process was stopped and the tank was emptied and cleaned. The procedure was repeated at flow rates of 150 and 253 mL/min (36 and 60 % of the maximum flow-rate respectively) and at 421 mL/min (maximum flow-rate).

Results Figure 9: Effluent turbidity of varying influent flow-rates entering the laboratory device.

40

Effluent turbidity (NTU)

35 30 25 20 15

253 mL/min Effluent 55 mL/min Effluent 150 mL/min Effluent

10

421 mL/min Effluent

5 0 0 50 100 Time (mins) 150 200

Figure 9 indicates that an increase in flow-rate from 13 to 60 % of the maximum flow-rate (421 mL/min) resulted in a direct increase in effluent turbidity of 40 %. With the exception of 174

Macquarie Matrix: Vol.2.2, December 2012

the maximum flow-rate, the system produces reasonable effluent less than 5 NTU within the first 60 minutes of operation. After this period, a dense build up of particles was observed in the sludge collection area. This build up of particles resulted in short-circuiting of the system either through the first or last channel for the low and higher flow-rates respectively. This result was noted by an increase in effluent quality after the 60-minute period. This time frame may signal the point at which a washout period is necessary or more likely, that a continuous bleed of this material is required. Calculation indicates that at full scale this washout period must occur every two hours. This timeframe is unfeasible and suggests that washout may need to occur continuously at a low flow-rate to ensure adequate clarification. If the results are indicative of the performance at full-scale operation, it can be seen that the most promising operational flow-rate of the system would be only 10% of the maximum design flow-rate or 0.40 L/s. This is suitable for Mathillo Semrang as the reported stream source flows are on average only 0.32 L/s but the design would not be robust enough to handle large flow and particle loadings, without continuous washout or a better design of the influent area or washout area to prevent short circuiting. Most pertinently, the experimental results revealed the inherent importance of the design of the inlet chamber and sloping floor. An increase in area of the inlet chamber as well as the construction of a steep sludge collection basin leading to a sump would allow an increase in momentum dissipation and an increase in system performance. These changes although crucial, are a challenge for the design as the increase in dimension of the inlet and sludge collection areas results in an increase in footprint and vertical height of the system, proving difficult for safe construction. As the laboratory model was not perfectly representative of the system the above conclusions require validation. Experimental testing with a wider range of feed flow-rates,

175

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

particle concentrations and turbidities would be necessary to fully understand the system performance.

Conclusions and Recommendations A high rate sedimentation device, the inclined plate settler (IPS) was designed to combat the turbidity issues arising from stream sources in the rural hilly community of Mathillo Semrang, Nepal. The footprint of the design is 10.5 m2 with the theoretical capacity to treat a maximum influent flow-rate of approximately 4 L/s. This is a reduction in footprint of up to 76% from the current round sedimentation design (42 m2). The design allows for the construction of a single device to replace the five separate devices currently used. The design is gravity driven and requires no electricity to operate. Its construction is similar to that of the current design and is therefore assumed to be economically viable. Laboratory experimentation revealed the most optimum operating flow-rate is 10 % of the design flow-rate. This conclusion needs further investigation and further experimentation is necessary to determine the system robustness to a range of particle size and loadings. Particle size distributions of the effluent and flow modelling of the system may be useful in revealing the shortcomings of the design. Collaboration with NEWAH and the Mathillo Semrang community is necessary to supplement the design.

Acknowledgements The author would like to express thanks towards the supervisors of this project Prof. Peter Scales (University of Melbourne) and Dani Barrington (EWB Australia).

176

Macquarie Matrix: Vol.2.2, December 2012

References Boycott, A. E. (1920). Sedimentation of blood corpuscles. Nature, 104, 532. Camp, T. R. (1946). Sedimentation and design of settling tanks. American Society of Civil Engineers, 111, 895-936. Culp, G., Hansen, S., & Richardson, G. (1968). High rate sedimentation in water treatment works. Journal of the American Water Works Association, 60(6), 681-936. Davis, R. H., & Acrivos, A. (1985). Sedimentation of noncollodial particles at low Reynold's numbers. Annual Review of Fluid Mechanics, 17, 91-118. Davis, R. H., Zhang, X., & Agarwala, J. P. (1989). Particle classification for dilute suspensions using an inclined settler. Industrial & Engineering Chemistry Research, 28, 785-793. Demir, A. (1995). Determination of settling efficiency and optimum plate angle for plated settling tanks. Water Research, 29(2), 611-616. Foellmi, S. N., & Bryant, H. H. (n.d.). Lamella plate settlers, design and operation: Two case histories. Retrieved from http://www.terrestorm.com/press_research_Foellmi_and_Bryant.pdf Huisman, L. (1986). Discrete settling in continuous horizontal flow basins Flow Basins. Sedimentation and Flotation Mechanical Filtration (pp. 38-96). Delft: Technische Universiteit Delft. Julien, P., & Shah, S. (2005). Sedimentation initiatives in developing countries. Draft report presented to UNESCO-ISI. Colarado State University, USA. Leung W.-F., & Probstein, R. F. (1983). Lamella and tube settlers. 1. Model and operation. Industrial & Engineering Chemistry Process Design and Development, 22(1), 58-67. Nepal Water for Health. (2011). Rural drinking water supply system policy and procedures (3 ed.). Lothsal, Kathmandu, Nepal.

177

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

Nepal Water for Health (NEWAH). (2012). Top view of Ferrocement water filter tank. Lothsal, Kathmandu, Nepal: NEWAH. Schultz, R. C., & Okun, D. A. (1984). Inclined tube and plate settling Surface Water Treatment of Communities in Developing Countries (pp. 139-144). London: Intermediate Technology Publications. Shamim, A., & Wais, M. T. (1980). Potential of tube settlers in removing raw water turbidity prior to coagulant. Aqua, 8, 166-169. Water Resources Management Committee. (2010). Water use master plan Thumi VDC Gorka. Thumi VDC, Nepal.

178

Macquarie Matrix: Vol.2.2, December 2012

Appendix 1 Figure 10: Top view of Ferrocement water filter tank (Nepal Water for Health (NEWAH), 2012)

179

Sedimentation tank design for rural communities in the hilly regions of Nepal

E Wisniewski

Appendix 2 Figure 11: Isometric view of inclined plate settler design showing whole tank

180

Macquarie Matrix: Vol.2.2, December 2012

Appendix 3 Figure 12: Top, front, rear and cross-sectional views of the inclined plate settler design

181

Potrebbero piacerti anche

- Clarifier Design Chap 11Documento71 pagineClarifier Design Chap 11ngoclinh87Nessuna valutazione finora

- Design of Sedimentation TankDocumento9 pagineDesign of Sedimentation TankHans Hans SadzNessuna valutazione finora

- Grit ChambersDocumento28 pagineGrit ChambersmkkNessuna valutazione finora

- Lecture 3 Screening and Grit ChambersDocumento11 pagineLecture 3 Screening and Grit ChambersAs MihNessuna valutazione finora

- Gomez - Payongayong-Filtration-ESE144 - AutosavedDocumento56 pagineGomez - Payongayong-Filtration-ESE144 - AutosavedMaha GomezNessuna valutazione finora

- ClarifierDocumento1 paginaClarifiergroup2sd1314Nessuna valutazione finora

- Cyclic Activated Sludge TechnologyDocumento8 pagineCyclic Activated Sludge TechnologyNavin GuptaNessuna valutazione finora

- Chapter 1 Basic Design ConsiderationDocumento38 pagineChapter 1 Basic Design ConsiderationAce ThunderNessuna valutazione finora

- Cost Analysis of Activated Sludge ProcessDocumento19 pagineCost Analysis of Activated Sludge ProcessDevendra Sharma100% (1)

- MM Aqua Technologies LTD.: TubedekDocumento47 pagineMM Aqua Technologies LTD.: TubedekSourabh Manuja100% (1)

- Gravity - Rapid Sand FiltrationDocumento12 pagineGravity - Rapid Sand FiltrationBrudel_c100% (1)

- Primary TreatmentDocumento22 paginePrimary TreatmentEmil AbdoNessuna valutazione finora

- Grit ChamberDocumento3 pagineGrit Chambergaur_shashikant4432Nessuna valutazione finora

- Design of Water Treatment PlantDocumento85 pagineDesign of Water Treatment Plantjobya_4Nessuna valutazione finora

- 4.introduction To The Design and Process Calculations (542089)Documento35 pagine4.introduction To The Design and Process Calculations (542089)ahmed salamNessuna valutazione finora

- Operator - Book-StpDocumento113 pagineOperator - Book-StpAce Dynamics India100% (1)

- Sedimentation and Sedimentation TanksDocumento43 pagineSedimentation and Sedimentation TanksDevendra Sharma80% (10)

- Grit ChamberDocumento29 pagineGrit Chamberazcomp100% (1)

- Sample WW QuestionsDocumento10 pagineSample WW QuestionsKrishna Kumar MeenaNessuna valutazione finora

- 4 Waste Stabilization PondsDocumento44 pagine4 Waste Stabilization PondsEgana Isaac100% (1)

- Rapid Sand Filter and Tube SettlersDocumento16 pagineRapid Sand Filter and Tube Settlersnp27031990Nessuna valutazione finora

- Daf 2004Documento7 pagineDaf 2004leonardo285Nessuna valutazione finora

- Chapter 17 - MathematicsDocumento13 pagineChapter 17 - MathematicsLivingston JosephNessuna valutazione finora

- MBBR Design StudyDocumento18 pagineMBBR Design StudyVedaraman IyerNessuna valutazione finora

- Tank SizingDocumento2 pagineTank Sizingaike_5Nessuna valutazione finora

- WT - Rapid Sand FiltrationDocumento5 pagineWT - Rapid Sand FiltrationObester Mudazvose ChimhandambaNessuna valutazione finora

- CH 4 Sewage TreatmentDocumento134 pagineCH 4 Sewage TreatmentGetu BogaleNessuna valutazione finora

- Silica Removal During Lime Softening in Water Treatment PlantDocumento10 pagineSilica Removal During Lime Softening in Water Treatment PlantLouay MansourNessuna valutazione finora

- Activated Sludge Calcs With ExcelDocumento22 pagineActivated Sludge Calcs With ExcelsahatNessuna valutazione finora

- Moving Bed Bio Reactor Technology MBBR PDFDocumento3 pagineMoving Bed Bio Reactor Technology MBBR PDFdainguyenlamNessuna valutazione finora

- Lesson Plan: How Do We Clean Polluted Water?Documento15 pagineLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyNessuna valutazione finora

- Lamella ClarifierDocumento6 pagineLamella Clarifiermhossain_mozammel100% (1)

- The F To M RatioDocumento6 pagineThe F To M Ratiojokish100% (2)

- Lec 8 NeutralizationDocumento32 pagineLec 8 Neutralizationhaseeb tahirNessuna valutazione finora

- Physico-Chemical Wastewater Treatment IntroductionDocumento27 paginePhysico-Chemical Wastewater Treatment IntroductionmsinsigneNessuna valutazione finora

- Design of Sedimentation TanksDocumento7 pagineDesign of Sedimentation TanksImtiaz PradhanNessuna valutazione finora

- Activated Sludge Process, Design Criteria, Advantages & DisadvantagesDocumento3 pagineActivated Sludge Process, Design Criteria, Advantages & DisadvantagesThrishnaa BalasupurManiamNessuna valutazione finora

- Tube SettlersDocumento3 pagineTube Settlersmsajidfcc100% (1)

- Plate and Tube SettlersDocumento4 paginePlate and Tube Settlerstrdakshayani100% (3)

- Sediment Tank Design Details - 2Documento6 pagineSediment Tank Design Details - 2Ezdee100% (2)

- Equipment Design - Aeration TankDocumento6 pagineEquipment Design - Aeration TankKENGERALDNessuna valutazione finora

- Concept of Zero DischargeDocumento4 pagineConcept of Zero DischargeShesharam Chouhan67% (3)

- 250mld WTPDocumento6 pagine250mld WTPeepmcjayal2Nessuna valutazione finora

- Water Treatment Part 2 Coagulation PDFDocumento7 pagineWater Treatment Part 2 Coagulation PDFDr-Manoj GargNessuna valutazione finora

- Tube Settler DesignDocumento4 pagineTube Settler DesignKrishna Winx100% (1)

- Inclined Plate ClarifierDocumento2 pagineInclined Plate ClarifierKelvin SiewNessuna valutazione finora

- EE-2 Mini Project ReportDocumento7 pagineEE-2 Mini Project Report63GANESH SINGHCIVILNessuna valutazione finora

- Pre TreatmentDocumento65 paginePre TreatmentSagar SewlaniNessuna valutazione finora

- Yanbu WWTW Process Group PresentationDocumento52 pagineYanbu WWTW Process Group Presentationyxp2237Nessuna valutazione finora

- Design, Estimation and Costing of Sewage Treatment Plant A Case StudyDocumento12 pagineDesign, Estimation and Costing of Sewage Treatment Plant A Case Studyadarsh s100% (1)

- Design of Filtration Tank FINAL FINAL FINALDocumento70 pagineDesign of Filtration Tank FINAL FINAL FINALPeter Nobrega50% (4)

- Optimum Design of Reverse Osmosis System Under Different Feed Concentration and Product SpecificationDocumento11 pagineOptimum Design of Reverse Osmosis System Under Different Feed Concentration and Product SpecificationPatricio LeonardoNessuna valutazione finora

- Wastewater TrainDocumento3 pagineWastewater TrainLester Mercado100% (1)

- Effluent Treatmnt Plant (ETP) : Akash TikheDocumento44 pagineEffluent Treatmnt Plant (ETP) : Akash TikheArvind ShuklaNessuna valutazione finora

- Chapter 6 Pump StationDocumento22 pagineChapter 6 Pump StationAce Thunder100% (2)

- Rapid Sand FiltrationDocumento16 pagineRapid Sand FiltrationNurul ShafinazNessuna valutazione finora

- Design of WTP and STPDocumento14 pagineDesign of WTP and STPVenu Ch100% (1)

- And Filtration: Capacity - htm#ixzz3KLT0AICPDocumento1 paginaAnd Filtration: Capacity - htm#ixzz3KLT0AICPyash_btechNessuna valutazione finora

- Gas Problem in StomachDocumento2 pagineGas Problem in Stomachyash_btechNessuna valutazione finora

- Enzymes in Biological Wastewater TreatmentDocumento9 pagineEnzymes in Biological Wastewater Treatmentyash_btechNessuna valutazione finora

- General Design Data:: Indicative Values For Feed Tap Water at TDS 500 PPMDocumento2 pagineGeneral Design Data:: Indicative Values For Feed Tap Water at TDS 500 PPMyash_btechNessuna valutazione finora

- The Magic Cat Eye1Documento16 pagineThe Magic Cat Eye1Buddhima Atapattu100% (1)

- Anaerobic FilterDocumento23 pagineAnaerobic Filteryash_btechNessuna valutazione finora

- RBCDocumento10 pagineRBCyash_btechNessuna valutazione finora

- Sugar MillDocumento5 pagineSugar Millyash_btechNessuna valutazione finora

- LWR Ex 12 37 PDFDocumento48 pagineLWR Ex 12 37 PDFyash_btechNessuna valutazione finora

- Tolerance Limits For Trade EffluentsDocumento2 pagineTolerance Limits For Trade Effluentsyash_btechNessuna valutazione finora

- Biogas & Wind MillDocumento5 pagineBiogas & Wind Millyash_btechNessuna valutazione finora

- MBR Membrane ComparisionDocumento9 pagineMBR Membrane Comparisionyash_btech100% (1)

- TNPCBDocumento35 pagineTNPCByash_btechNessuna valutazione finora

- 11-Annexure V-Final Spec For Reverse Osmosis - For KumarDocumento24 pagine11-Annexure V-Final Spec For Reverse Osmosis - For Kumaryash_btechNessuna valutazione finora

- Spare Parts Have To For All InstrumentDocumento2 pagineSpare Parts Have To For All Instrumentyash_btechNessuna valutazione finora

- Process Description For Treatment SchemeDocumento2 pagineProcess Description For Treatment Schemeyash_btechNessuna valutazione finora

- Operation and MaintenaneDocumento2 pagineOperation and Maintenaneyash_btechNessuna valutazione finora

- Investing in Granada's Property Market - Gaspar LinoDocumento1 paginaInvesting in Granada's Property Market - Gaspar LinoGaspar LinoNessuna valutazione finora

- Chapter 2Documento69 pagineChapter 2Lizi CasperNessuna valutazione finora

- Ericsson For Sale From Powerstorm 4SA03071242Documento8 pagineEricsson For Sale From Powerstorm 4SA03071242wd3esaNessuna valutazione finora

- Influence of Freezing and Pasteurization of The Physical Condition of The Plastik (PE, PP and HDPE) As Selar Fish Packaging (Selaroides Leptolepis) in Sendang Biru, Malang, East Java. IndonesiaDocumento7 pagineInfluence of Freezing and Pasteurization of The Physical Condition of The Plastik (PE, PP and HDPE) As Selar Fish Packaging (Selaroides Leptolepis) in Sendang Biru, Malang, East Java. IndonesiaInternational Network For Natural SciencesNessuna valutazione finora

- Medical Equipment Quality Assurance For Healthcare FacilitiesDocumento5 pagineMedical Equipment Quality Assurance For Healthcare FacilitiesJorge LopezNessuna valutazione finora

- Invoice ApprovalDocumento54 pagineInvoice ApprovalHamada Asmr AladhamNessuna valutazione finora

- Technical DescriptionDocumento2 pagineTechnical Descriptioncocis_alexandru04995Nessuna valutazione finora

- Mahindra First Choice Wheels LTD: 4-Wheeler Inspection ReportDocumento5 pagineMahindra First Choice Wheels LTD: 4-Wheeler Inspection ReportRavi LoveNessuna valutazione finora

- 16-ELS-Final-Module 16-08082020Documento18 pagine16-ELS-Final-Module 16-08082020jeseca cincoNessuna valutazione finora

- 6 - European Cluster Partnership For Excellence - European Cluster Collaboration PlatformDocumento5 pagine6 - European Cluster Partnership For Excellence - European Cluster Collaboration PlatformDaniela DurducNessuna valutazione finora

- Geopolymer Book Chapter1 PDFDocumento37 pagineGeopolymer Book Chapter1 PDFDick ManNessuna valutazione finora

- Certificate of Attendance: Yosapat NashulahDocumento2 pagineCertificate of Attendance: Yosapat NashulahStrata WebNessuna valutazione finora

- Early Christian ArchitectureDocumento38 pagineEarly Christian ArchitectureInspirations & ArchitectureNessuna valutazione finora

- 0409 Book About Minoru Yamasaki, ReviewDocumento4 pagine0409 Book About Minoru Yamasaki, RevieweviannNessuna valutazione finora

- FM Testbank-Ch18Documento9 pagineFM Testbank-Ch18David LarryNessuna valutazione finora

- Preblending of Raw Materia1Documento26 paginePreblending of Raw Materia1Mohammed Abdo100% (1)

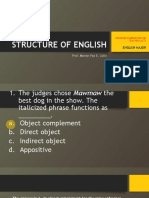

- LET-English-Structure of English-ExamDocumento57 pagineLET-English-Structure of English-ExamMarian Paz E Callo80% (5)

- Market EquilibriumDocumento36 pagineMarket EquilibriumLiraOhNessuna valutazione finora

- List of Bird Sanctuaries in India (State-Wise)Documento6 pagineList of Bird Sanctuaries in India (State-Wise)VISHRUTH.S. GOWDANessuna valutazione finora

- Eddie Struble - Spring Valley Police Report Page 1Documento1 paginaEddie Struble - Spring Valley Police Report Page 1watchkeepNessuna valutazione finora

- H.mohamed Ibrahim Hussain A Study On Technology Updatiing and Its Impact Towards Employee Performance in Orcade Health Care PVT LTD ErodeDocumento108 pagineH.mohamed Ibrahim Hussain A Study On Technology Updatiing and Its Impact Towards Employee Performance in Orcade Health Care PVT LTD ErodeeswariNessuna valutazione finora

- Java Edition Data Values - Official Minecraft WikiDocumento140 pagineJava Edition Data Values - Official Minecraft WikiCristian Rene SuárezNessuna valutazione finora

- Necromunda CatalogDocumento35 pagineNecromunda Catalogzafnequin8494100% (1)

- L5T-112 Manual - 2007 - Issue 1.1 PDFDocumento16 pagineL5T-112 Manual - 2007 - Issue 1.1 PDFfluidaimaginacionNessuna valutazione finora

- Visual Inspection ReportDocumento45 pagineVisual Inspection ReportKhoirul AnamNessuna valutazione finora

- OM Part B - Rev1Documento45 pagineOM Part B - Rev1Redouane BelaassiriNessuna valutazione finora

- Model DPR & Application Form For Integrated RAS PDFDocumento17 pagineModel DPR & Application Form For Integrated RAS PDFAnbu BalaNessuna valutazione finora

- Department of Education: Republic of The PhilippinesDocumento1 paginaDepartment of Education: Republic of The PhilippinesKlaribelle VillaceranNessuna valutazione finora

- Most Probable Number (MPN) Test: Principle, Procedure, ResultsDocumento4 pagineMost Probable Number (MPN) Test: Principle, Procedure, ResultsHammad KingNessuna valutazione finora

- Engine Stalls at Low RPM: Diagnostic CodesDocumento3 pagineEngine Stalls at Low RPM: Diagnostic CodesAmir Bambang YudhoyonoNessuna valutazione finora