Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WR01 - Bilaga A - Modelling of Bubble Flows

Caricato da

mlsimhanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WR01 - Bilaga A - Modelling of Bubble Flows

Caricato da

mlsimhanCopyright:

Formati disponibili

Modeling of Bubble Flow in Fluidized Bed

Combustion Units

Master of Science Thesis

JOHANNA OLSSON

Department of Energy and Environment

Division of Energy Technology

CHALMERS UNIVERSITY OF TECHNOLOGY

Gteborg, Sweden, 2008

Report No. T2008-316

Modeling of Bubble Flow in Fluidized Bed Combustion Units

Johanna Olsson

Johanna Olsson, 2008

Examensarbete vid Chalmers Tekniska Hgskola

Department of Energy and Environment

Division of Energy Technology

Chalmers University of Technology

SE-41296 Gteborg (Sweden)

Telephone: +46 (0)31 7721000

Tryckstlle

Gteborg, 2008

Modeling of Bubble Flow in Fluidized Bed Combustion Units

Johanna Olsson

Department of Energy and Environment

Division of Energy technology

Chalmers University of Technology

Abstract

The performance of a fluidized bed combustion (FBC) unit depends on the fuel distribution in

the boiler, which is a complex process. This work includes a survey of previous research and

available models for solids mixing in fluidized beds. The available semi-empirical models

used to describe the solids mixing and the modeling from first principle through

computational fluid dynamics (CFD) both give an unsatisfactory description of the fuel

distribution in large industrial FBC units. To bridge the gap between these two approaches, a

model based on plausible physical mechanisms is needed.

Recognizing the importance of bubbles in a fluidized bed, the aim of this work is the

development and implementation of a dynamic bubble flow model. In this work it is

recognized that the fluidization regime, hence the bubble flow pattern, depends on the ratio of

the pressure drop across the air distributor to that across the bed, not on the individual values.

This ratio determines the relative parts of gas flow in the throughflow phase and the emulsion-

only phase.

The first-step one-dimensional model implemented for the bubble flow in a fluidized bed

under an exploding bubble regime is unique in that it accounts for the influence of the ratio on

the local fluctuations in superficial gas velocity and pressure. It is shown that a high pressure

drop ratio results in severe fluctuations in the system, while a lower ratio results in more

moderate fluctuations, which is in agreement with experimental observations. Moderate

fluctuations indicate that the superficial gas velocities in the respective phases do not differ

much: the bubbles are smaller and the bed is probably not operated in the exploding bubble

regime.

Due to the restriction of the model, it is not possible to perform realistic simulations of cases

in which the pressure drop across the distributor dominates strongly over the pressure drop

across the bed.

Keywords: Fluidized bed combustion units; Modeling; Mixing; Bubble flow pattern

Table of Contents

1. INTRODUCTION .................................................................................................... 1

Scope and aim .................................................................................................................................................... 1

2. BACKGROUND ..................................................................................................... 3

2.1 Fundamentals of fluidization ......................................................................................................................... 3

Minimum fluidization and terminal velocity ...................................................................................................... 3

Pressure drop ...................................................................................................................................................... 4

Geldarts classification of particles .................................................................................................................... 4

The combustion application ............................................................................................................................... 5

2.2 Bubbles in fluidized beds ................................................................................................................................ 6

The two phase theory of fluidized beds .............................................................................................................. 6

Bubble shape, size and rise velocity ................................................................................................................... 7

Davidsons bubble model ................................................................................................................................... 7

Coalescence ........................................................................................................................................................ 8

The dynamic behavior of the gas fluidized bed and fluidization regimes .......................................................... 8

2.3 Solids transport mechanisms ....................................................................................................................... 10

Wake transport and gulf streaming................................................................................................................... 10

Splash zone ....................................................................................................................................................... 11

2.4 Models of gas flow and solids mixing .......................................................................................................... 11

The Counter-Current Back Mixing (CCBM) model ........................................................................................ 12

The Brownian dispersion model ....................................................................................................................... 12

CFD simulations ............................................................................................................................................... 13

3. THEORY ............................................................................................................... 14

3.1 The bubble flow model.................................................................................................................................. 14

3.2 Computational flow scheme ......................................................................................................................... 19

4. RESULTS AND DISCUSSION ............................................................................. 21

4.1 Reference case ............................................................................................................................................... 21

4.2 The influence of the characteristic constant of the air distributor and the bed height ........................... 23

5. CONCLUSIONS ................................................................................................... 28

6. FURTHER WORK ................................................................................................ 29

REFERENCES ......................................................................................................... 30

1

1. Introduction

The use of fluidization technology was first developed for chemical reactors, but its many

beneficial properties have also made it interesting for combustion applications. Although the

process was developed in the 1940s and introduced in combustion systems in the 1960s, the

processes taking place inside the bed are not yet fully understood or explicitly described.

During the past few decades much research was conducted in this area, multiple experimental

studies were made, and in recent years numerical simulations using computational fluid

dynamics (CFD) were also conducted. The findings of these decades have been summarized

in several articles, Lim et al. (1995) being one of them.

However, most of the research on solids mixing and fuel distribution does not have its

experimental basis in conditions corresponding to large-scale fluidized boiler units, as

discussed in Pallars (2005). The boiler dimensions, fluidization gas velocity, bed height-to-

width ratio and the ratio of the pressure drops across the distributor to that of the bed are only

a few of the characteristics that set fluidized bed combustion units for solid fuel apart from

other applications. One of the main features determining the performance of a fluidized boiler

is the fuel distribution in the bed, which is among the more complex phenomena to describe.

In a fluidized bed boiler, fuel makes up only a small percent of the total bed material (Lim and

Agarwal, 1994), which might suggest that if the motion of the bed material and its interaction

with the fuel particles were known, fuel distribution could be determined. However, obtaining

a quantitative description of the fuel distribution, with satisfactory agreement with

experimental data, is more complex than indicated, since solids mixing is coupled to gas

mixing, and vice versa, as schematized in Figure 1. Solids are present in three regions of a

circulating fluidized bed (CFB) riser; the bottom bed, the splash zone and the transport zone,

as shown by Johnsson and Leckner (1995). The movement of solids in all three regions of a

CFB riser is the result of the interaction between particles and gas. This interaction exhibit a

special behavior in the bottom bed, as bubbles and channeling of gas appear under the

operational conditions common to boilers. These phenomena distort the flow fields

throughout the riser, for both bubbling (BFB) and circulating beds (CFB).

Scope and aim

The ultimate goal of this work is to develop a model describing the fuel distribution (marked

with squared background in Figure1) in a gas fluidized bed boiler as a function of operating

conditions that are measurable and controllable. By recognizing the importance of bubbles in

fluidized beds, the aim of this work is to develop, as the first step, a bubble flow model

(marked with dotted background in Figure1). Semi-empirical models for solids mixing

proposed in the literature should be used with care outside of the domain for which they were

developed. A macroscopic model of the fuel mixing, based on plausible underlying physical

mechanisms, describing both the gas and solids flow patterns in freely bubbling beds, would

bridge the existing gap between empirically-fitted models and the under-developed CFD

modeling.

This work begins with a survey of previous research and available models in the literature for

the solids mixing; it then proceeds to present a first-step bubble flow model for large-scale

fluidized bed combustion (FBC) units, both bubbling and circulating. Since the mechanisms

governing the dynamics of a fluidized bed are not yet fully understood, the model will need,

2

at present, to rely on experimental data for the fitting of parameters. Care should be taken so

that the model is subject to empirical fitting as little as possible.

Figure 1: Mapping of the physical mechanisms governing the fuel distribution

Fuel distribution

Gas - Solids flow pattern Fuel properties

Transport zone

(only in CFB)

Bottom bed Splash zone

Particle

motion

Gas

velocity

field

Bubble flow

pattern

Particle

motion

Gas

velocity

field

Particle

motion

Gas

velocity

field

3

2. Background

Fluidization is the operation by which solid particles are transformed into a fluidlike state

through suspension in a gas or a liquid. (Kunii and Levenspiel, 1991.)

2.1 Fundamentals of fluidization

The first large-scaled, commercially significant use of fluidized beds was for the gasification

of powdered coal, invented in 1922. The early use of fluidized beds for catalytic cracking

processes expanded to applications outside of the petroleum industry in the 1940s, at which

point the use and development of the fluidization technology was limited by a lack of

understanding of the processes actually taking place inside the bed. In hope of finding a

combustion system suitable for low grade coal and oil fuels that could not be burnt in

conventional furnaces, fluidized bed combustion (FBC) was developed in the early 1960s, but

it was not commercialized until the early 1980s. At present, fluidization technology is widely

used in a broad range of applications, e.g. chemical and catalytic reactors, combustion and

gasification of solid fuel, and the drying of granular solids; it is now of interest to extend its

operational ranges and areas of application.

Minimum fluidization and terminal velocity

A gas introduced at a low flow rate, as an upward flow from the bottom of a fixed bed,

percolates through the voids in the bed. At a high enough gas flow rate, the gas friction force

developed counterbalances the gravity force of the particles. At this point, called the

minimum fluidization point, particles are suspended in the gas flow and the gas-solid

suspension acquires properties similar to those of a fluid, i.e. the bed becomes fluidized.

Minimum fluidization conditions are characterized by a certain gas velocity, u

mf,

and bed

voidage (gas volume fraction),

mf

.

At gas velocities beyond the minimum fluidization velocity, also known as minimum

bubbling velocity, u

mb

, is reached, at which gas bubbles and channeling of the gas flow

appear, as illustrated in Figure 2. At higher gas velocities, typical for bubbling fluidized beds

(BFB), agitation becomes more violent. As the gas velocity is increased further and bubbles

grow larger, the bed surface becomes strongly fluctuating and difficult to determine. Finally,

at gas velocities exceeding the terminal velocity of the solids, u

t

, bed material is carried out of

the riser by the gas. To ensure a roughly constant solids inventory in the riser, entrained

particles have to be externally recirculated by means of a cyclone or replaced. Under

conditions of significant external recirculation of solids, a circulating fluidized bed (CFB) is

established, as shown in Figure 2.

4

Figure 2: (a) Fixed bed: u < u

mf

; (b) Bubbling fluidized bed: u > u

mb

; and (c) Circulating fluidized bed: u > u

t

Pressure drop

In particulate media, the frictional pressure drop can be described by the Ergun equation:

2

3 2 3

2

) 1 ( 75 . 1 ) 1 ( 150

u

d

u

d L

P

p p

c

c

c

c

+

=

A

. (1)

The pressure drop is described by two terms representing the viscous and the inertial or

kinetic energy losses. According to the Ergun equation a pressure drop depends not only on

the superficial gas velocity but also on particle size and bed voidage. At minimum

fluidization, the pressure drop across the bed equals the static pressure of the bed. Once the

bed is fluidized, the time-averaged pressure drop is nearly independent of the gas flow rate.

This constancy in the pressure drop, as explained by Kunii and Levenspiel (1991), occurs

when the gas-solid phase is well-aerated and can deform easily without appreciable resistance,

thus the viscous pressure drop is rather small.

Geldarts classification of particles

The properties of the particles that make up the bed affect the fluidized bed behavior.

Therefore, particles have been classified by Geldart (1973) into four groups, which are

characterized by solids-gas density difference and mean particle size, as seen in Figure 3.

5

Figure 3: Geldarts classification of particles under ambient conditions (taken from Kunii and Levenspiel, 1991)

Most of the particles in fluidized beds used for commercial scale combustion of solid fuels

belong to group B which contains most of the material of medium-range size and density,

i.e. sand. For beds consisting of group B particles, the minimum bubbling and minimum

fluidization velocities coincide (Geldart, 1973). Most of the literature on the basic properties

of fluidized beds is derived from tall and narrow beds with particles belonging to group A or

small group B particles.

The combustion application

The original aim of developing fluidized bed combustion (FBC) was to obtain a technique

which could efficiently convert low grade coal and oil. In addition, FBC shows high fuel

flexibility, and biomass and waste are becoming the usual fuel in FBC units. Furthermore,

efficient co-combustion of different fuel types is one of the main advantages FBC offers.

Also, the ability to use bed additives to control environmentally hazardous emissions makes

FBC performance relatively insensitive to the quality of the fuel.

The bed is fluidized by primary air supplied through the air distributor at the bottom of the

riser. This primary air represents the main oxygen source for the combustion process. Fuel is

usually fed into the boiler from a chute. As fuel particles enter the furnace they heat up;

moisture and volatiles are released leaving solid char particles. Volatiles are consumed in the

freeboard or the cyclone, while char particles remain mostly in the bed.

The bed material in a fluidized bed combustor acts as a thermal flywheel, providing stability

to the system and making it less sensitive to changes in the fuel heating value. Violent

bubbling and rapid mixing in a fluidized bed leads to a good gas-solids contact, as well as a

rather homogeneous temperature field in the dense bed, which eases the control of the process

(Kunii and Levenspiel, 1991). Only a few percent (typically from 0.1 to 5%) of the bed

material of a fluidized bed for solid fuel combustion consists of fuel (Lim and

Agarwal, 1994).

Since combustion rates of both char and volatiles increase with oxygen concentration, it is of

the utmost importance that good gas-solids contact and gas mixing exist, i.e. that the bed is

well mixed. Fuel mixing is therefore a key phenomenon in the performance of FBC units. In

6

the vertical direction, good fuel mixing is important to ensure sufficient contact time between

fuel and oxygen. In the horizontal direction, a homogeneous fuel distribution is desirable for

both the burnout of the fuel and the optimization of the excess air ratio, thus minimizing the

operational cost. The extent to which the mixing of fuel is sufficient depends on the fuel

conversion time and the characteristic mixing length, as discussed in Pallars (2007).

Bubbles and gas channeling (i.e. gas flowing through the bed without interacting with the gas-

solids emulsion) affect the FBC efficiency negatively. Fuel distribution in the bed depends

mainly on the motion of the bed materials, but the gas flow also influences the distribution.

As commented by Lim and Agarwal (1994), a good understanding of the dynamic behavior of

the bed is therefore crucial for the optimization of the design of the air and fuel feed systems.

The aspect (height-to-width) ratio of the bottom bed in FBC units is often very low, i.e. the

bed is shallow. The bed temperature is often kept close to 850C. Due to operational costs, the

pressure drop over the distributor is often kept as small as possible; the distributor type most

commonly used in commercial large-scale beds is the tuyere or bubble cap type. Boilers are

usually operated at atmospheric or slightly below atmospheric pressure, and the fluidization

gas velocity is often one or two orders of magnitude higher than the minimum fluidization

velocity.

2.2 Bubbles in fluidized beds

Knowledge of the general behavior of a fluidized bed is insufficient for some purposes, e.g.

reaction kinetics and heat transfer depend on details of the gas-solids interaction in the bed.

Hence, a satisfactory treatment of these phenomena requires a reasonable model representing

the gas flow through the bed and its interaction with bed material. As a consequence, the

bubble size, rise velocity, shape, distribution, frequency and flow patterns are of key interest.

In the early stages of fluidization research, the analogy of fluidized bed bubbles with bubbles

in liquids was used. Despite several similarities between these, a major difference is the fact

that no mass transfer with the surrounding exists for bubbles in a liquid, whereas a bubble in a

fluidized bed is a local high-voidage region exchanging gas with its surrounding, as explained

by Davidson (1985). Nevertheless, the above-cited analogy combined with experiments on

single bubbles has been used as basis for several concepts and models developed for bubbling

beds.

The two phase theory of fluidized beds

Toomey and Johnstone (1952) postulated what is known as the simple two-phase theory of

fluidization, which proposes that all gas flow in excess of that required for minimum

fluidization flows through the bed as bubbles. Thus, the bed can be divided into two phases: a

particulate phase (dense or emulsion phase) kept at minimum fluidization conditions and a

solids-free phase (void phase or bubble).

Although this theory has been frequently used, there is substantial evidence that it

overestimates the visible bubble flow. There has been considerable controversy over the

reason for this discrepancy (see Davidson, 1985, and Kunii and Levenspiel, 1991); the lack of

a throughflow term is the most widely accepted reason at present. Throughflow refers to gas

flowing through the bubble at a rate higher than that of the bubble itself. As discussed in Gera

and Gautam (1994), this flow is important in stabilizing the upper surface of bubbles, but is

difficult to measure in three-dimensional beds. A semi-empirical model for the division of the

7

gas flow, which accounts for throughflow, often called the modified two-phase flow theory,

was proposed by Johnsson et al. (1991).

Bubble shape, size and rise velocity

Observation of single bubbles injected into a bed kept at incipient fluidization provides

fundamental qualitative information about the character of the bubble flow. Bubbles in beds

of particles belonging to groups A and B in Geldarts classification are typically spherical

cap-shaped, as shown in Figure 4. As described in Kunii and Levenspiel (1991), this is often

ignored and bubbles are approximated through a sphere. The part of the sphere not included in

the actual bubble is often called the wake. In beds with gas flow rates above that of minimum

fluidization, bubbles are distorted in ways which are hard to predict.

Figure 4: Bubble shape as observed in particles belonging to groups A and B in Geldarts classification (taken

from Kunii & Levenspiel, 1991)

Bubble size is non-uniform throughout the bed and bubbles grow as they raise through the

bed, which makes the determination of the bubble size difficult. Various empirical and semi-

empirical correlations have been proposed to determine the mean bubble size for bubbles in

freely bubbling beds. However, as discussed by Davidson (1985), these correlations are based

on particular data from relatively small beds, which means they do not include all parameters

affecting the variables to model.

Based on experimental bubble observation in fluidized beds, the following correlation was

presented by Clift and Grace (1985) for the bubble rise velocity and is often used for bubbles

in any kind of fluidized bed:

( )

6

1

2

1

79 . 0 711 . 0

b e br

V g gD u = = . (2)

In practice, interactions between adjacent bubbles influence bubble properties such as shape,

size and rise velocity. Grace and Harrison (1969) showed that bubbles in a swarm rise more

rapidly than a single bubble, due to interaction with neighboring bubbles.

Davidsons bubble model

The Davidson model, presented in Davidson (1985), is based on experimental results derived

from observation of single bubbles injected in beds kept at incipient fluidization. The

8

equations constituting the model are based on the assumptions that bubbles in a fluidized bed

follow the same behavior as in an incompressible liquid of low viscosity and that the gas flow

is described by the potential flow theory. The model accounts for the movement of both the

gas and solids as well as the pressure distribution around rising bubbles.

Davidsons bubble model makes a distinction between two types of bubbles.

- Slow or cloudless bubbles (u

br

< u

f

): The emulsion gas rises faster than the bubble,

thus taking a shortcut through the bubble on its way through the bed.

- Fast or clouded bubbles (u

br

> u

f

): The bubble rises faster than the emulsion gas and

the gas leaving the top of the bubble is consequently swept around and returns into the

bubble without mixing with the main stream of fluidizing gas.

However, the assumption made in the Davidson model of potential flow for the gas phase is

only valid for conditions under which the viscous terms govern the pressure field in front of

the inertial terms, i.e. at low gas velocities. At the higher gas velocities typical for operating

fluidized bed units of most types, the model description of the pressure drop is not accurate.

Despite this, the simple approach and correctness of Davidson model under certain conditions

have made it the starting point of many other models for bubbling beds, as discussed in Kunii

and Levenspiel (1991).

Coalescence

As bubbles rise through the bed, they grow partly by means of coalescence (the process by

which two bubbles merges into a larger one). Coalescence occurs typically when a trailing

bubble catches up with a leading bubble. As explained in Davidson (1985), the trailing bubble

accelerates as it reaches the wake of the leading bubble and is drawn into the leading bubble.

As discussed in Kunii and Levenspiel (1991), bubbles in a freely bubbling bed are considered

to be small at the distributor, coalesce rapidly close to the bottom of the bed and grow more

slowly as they rise through the bed.

The general prediction of bubble size as a function of height is one of the ultimate aims of any

investigation of bubble coalescence in a fluidized bed. The various analytical models used to

describe the motion of interacting bubbles are based on the treatment of single bubbles in

liquid, derived by Davies and Taylor (1950). This problem is complex to treat theoretically

and analytically: no adequate general description of the coalescence process has been

developed so far.

The dynamic behavior of the gas fluidized bed and fluidization regimes

Although the bubble flow pattern is strongly dynamic, most research has been devoted to the

gross behavior of the fluidizing bed, i.e. the time averaged behavior. Bubbles give rise to local

differences in gas flow rate, which result in pressure fluctuations, as discussed in Davidson

(1985). Hence, the distribution of gas bubbles in space, time and size is of interest in any

application. The spatial distribution of bubbles formed at the gas distributor is controlled to a

large extent by the distributor. The gas flow through each nozzle or orifice in the gas

distributor depends both on the local pressure difference between the plenum and the bed

bottom and on the flow resistance of the distributor.

The fluidization regimes of a freely bubbling bed have been mapped by Svensson et al.

(1996) in terms of bubble behavior and pressure fluctuations. When operated at velocities

typical for fluidized beds, both bubbling and circulating, the fluidization regimes known as

the single and exploding bubble regime (shown in Figures 5a and 5c) can be observed in the

9

bottom bed. The single bubble regime occurs for low gas velocities; for higher gas velocities

the bed enters the exploding bubble regime. These regimes are characterized by a few large

bubbles which cause severe pressure fluctuations and are typical for beds with low-pressure

drop gas distributors. As shown in Figure 5b, the multiple-bubble regime presents numerous

smaller bubbles, which results in smoother fluidization and damped fluctuations.

Figure 5a: Single bubble regime (taken from Sasic et al. (2005) and Pallars et al. (2006))

Figure 5b: Multiple bubble regime (taken from Sasic et al. (2005) and Pallars et al. (2006))

Figure 5c: Exploding bubble regime (taken from Sasic et al. (2005) and Pallars et al. (2006))

10

2.3 Solids transport mechanisms

Experiments have shown that solids mixing is severely limited at minimum fluidization but

increases notably at slightly higher gas flow rates. Bubbles induce the solids mixing by

stirring the bed material as they are rising through the dense phase. As discussed by Niklasson

et al. (2002) among others, it is now commonly accepted that solids mixing in the bottom

region of a gas fluidized bed is mainly determined by the bubble flow pattern. For large units

with shallow beds, such as fluidized bed combustors, the lateral solids mixing has a major

influence on the performance of the boiler, as explained in Pallars et al. (2007). The main

transport mechanisms identified for the bottom region of fluidized beds, as illustrated in

Figure6, are listed below.

Figure 6: A representative diagram of solids transport taking place in the bottom bed and splash zone (taken

from Pallars, 2005)

Wake transport and gulf streaming

Gas drawn into the wake of the bubble drags solids with it, as schematized in Figure 4. The

solids are lifted with the bubble rise and dispersed along the path of the bubble. As discussed

in Shi and Fan (1984), this is the primary physical mechanism by which solids are mixed

axially in a bubbling bed, with little influence on the horizontal transport of solids. Numerous

experiments have been dedicated to determine the influence of the wake transport and its

contribution to the solids mixing.

It has been observed in large industrial fluidized-bed units that bubbles tend to follow a stable

spatial distribution with preferred bubble paths, as discussed in Werther (1977), determined

by the wall effects in combination with bed and air distributor properties. This bubble flow

pattern leads to a characteristic circulation pattern of solids in which they flow upwards in

regions where bubbles are frequent and downwards in regions where bubbles are less

frequent. The combined effects of gross circulation and small scale local mixing leads to a

notable axial mixing. The rate of lateral mixing is much less pronounced, particularly in

shallow beds where the lateral influence of rising bubbles is weak, as described in Lim et al.

(1995).

11

Splash zone

As bubbles reach the bed surface and erupt, solids from the bubble wake and roof are ejected

into the freeboard. As explained in Niklasson et al. (2002), these ejected solids either can be

entrained by the gas stream and leave the riser or fall back to the bed surface and rejoin the

emulsion. The lateral solids mixing is strongly dependent upon this bubble-induced scattering

of solids at the top of the bed surface. Indeed, the presence of vertically aligned baffle plates

has been shown to significantly decrease the lateral solids mixing, as discussed in Shi and Fan

(1984).

2.4 Models of gas flow and solids mixing

As discussed in Verloop (1968) and later summarized in Lim et al. (1993), various models

have been proposed in the literature to describe the solids mixing in fluidized beds. The

earliest models are of limited use, since they describe the solids mixing by combining

different flow systems (such as perfectly mixed, plug flow, short circuiting), thus neglecting

the physical behavior of the bed. Later, more refined models for solids mixing (and

occasionally also gas flow) are briefly introduced and commented on below.

The K-L bed model or The bubbling bed model

The K-L bed model developed by Kunii and Levenspiel (1991), whose principle is illustrated

in Figure 7, is based on the Davidson bubble model; it gives the gas flow and pressure profile

around the bubble and differentiates between slow cloudless bubbles and fast clouded

bubbles. The model also takes into account the contribution of the wakes to the flow pattern

of both gas and solids.

Figure 7: The bubbling bed model (taken from Kunii and Levenspiel, 1991)

All rising bubbles are assumed to drag behind them a wake with solids which are

continuously exchanged with solids from the emulsion. At the top of the bed, wake particles

rejoin the downflowing emulsion, where the relative gas-solid velocity is assumed to be that

of minimum fluidization. The bubble rise velocity is determined by Eq. 2 given in Section 2.2.

The emulsion phase is assumed to remain at minimum fluidization.

12

While the K-L model does account for the importance of the bubble size under the flow

conditions for both gas and solids in the bed, it is based on the Davidson model; it is therefore

unsuitable for systems operated under conditions far from incipient fluidization.

The Counter-Current Back Mixing (CCBM) model

The counter-current back mixing (CCBM) model proposed by van Deemter (1961) and later

refined by Gwyn et al. (1970) is based on considering the varying flow characteristics for

different bed regions. Van Deemter suggested that the bed could be divided into two phases: a

dense phase consisting of particulate aggregates and a dispersed phase with high vertical gas

velocity. The mass exchange between the two phases is enabled through the break-up and

formation of particulate aggregates, and the exchange between the regions is described by an

empirically-determined exchange coefficient. To account for the horizontal movement of

solids, CCBM models are often combined with a dispersion or diffusive model. Abanades et

al. (2001) included the lateral displacement of solids in a CCBM model structure by

connecting multiple vertical mixing columns.

Since the two-phase division in the CCBM model, there have been models dividing the flow

into more phases, but the development and utilization of the multi-phase CCBM model has

been crippled by the increased need for empirical coefficients which are difficult to measure,

as discussed in Lim et al. (1995). Among the available models at present, CCBM models are

generally believed to give the best description of solids mixing in bubbling beds, despite the

fact that other possible mixing mechanisms, such as solids splashing at the bed surface and

turbulent mixing near the distributor, are not accounted for.

The division of the bed into layers with different flow characteristics is represented by

counter-current back mixing models. The use of CCBM models is inhibited by the lack of

experimental data needed to determine some parameters in the model setup. None of these

models gives a description of the fuel mixing in satisfactory agreement with experimental data

under conditions generally applicable to fluidized bed combustors.

The Brownian dispersion model

As discussed in Kunii and Levenspiel (1991) solid mixing in a fluidized bed occurs as the

sum of two flow mechanisms: a convective and a random (diffusive) one. However, the

convective contribution from the circulatory motion is usually combined with the diffusion,

and both are represented by a dispersion coefficient. Horizontal solids mixing on a

macroscopic scale is often simplified by describing the process in terms of Brownian

diffusion transport:

S C D

t

C

si

s

+ V =

c

c

2

(3)

where C is the solids concentration, and D

si

is the dispersion coefficient which depends on

operational parameters and unit geometry and varies with location, both horizontally and

vertically. All transport processes are embedded in the dispersion coefficient which is

generally averaged over the cross-sectional area and, therefore, denoted as the effective

dispersion coefficient.

Several techniques have been used to determine the rate of solids transport in a fluidized bed.

The results of these investigations are often reported in the form of a dispersion coefficient.

As shown by Niklasson et al. (2002), the high scattering in reported values for the dispersion

13

coefficient is an indication that the affect of the different physical mechanisms underlying the

lateral dispersion vary from study to study. As a consequence, the correlations derived for the

dispersion coefficient found in the literature obviously show a large scatter. This observation

should invoke caution when applying expressions for the dispersion coefficient derived from

a unit operating under conditions other than those modeled.

The original development of the dispersion model, using experimental data from tall, narrow

beds with Geldarts group A and small group B particles, focused on the axial mixing.

However, as explained in Abanades et al. (2001), the dispersion model can not describe the

vertical movement of solids in large-scale fluidized bed units (i.e. combustors) with

satisfactory agreement.

Characterization of the solids mixing as a diffusive process or by a mixing coefficient is an

easy-to-implement method, but its use is questionable since the local dynamics of the bed are

neglected.

CFD simulations

The use of numerical simulations from first principles, computational fluid dynamics (CFD),

is thought to be the future tool for modeling fluidized units, but so far mostly systems of

limited particle numbers and uniform particle size and density have been evaluated due to

limited computational power.

14

3. Theory

The performance of a combustion unit is strongly dependent on the fuel distribution in the

bed, which is why accurate predictions of this through modeling is a key aim in the

understanding and optimization of the combustion process.

The desired model should, for easy implementation, describe the fuel distribution on the basis

of variables that can be measured and/or controlled during operation:

- the properties of the bed material (density and size distribution),

- the bed dimensions,

- the characteristic P-u curve of the air distributor, and

- the operating conditions (fluidization velocity, temperature, etc).

3.1 The bubble flow model

The gas-solid flow in the bottom bed is governed by the presence of bubbles, which gives the

flow picture a dynamic character and strongly affect the pressure profile. Thus, modeling has

to be carried out on a dynamic basis for an accurate description of the bottom bed. The events

to be modeled are: bubble formation, growth, detachment and uprise through the bottom bed.

Once the bed dimensions and bed material properties are established the complete bubble

flow model should properly predict:

- bubble characteristics (position, size, spatial distribution, frequency, density, rise velocity

and direction),

- dynamical pressure field, and

- superficial gas velocity field.

As discussed in Section 2.1, the single and exploding bubble regimes are the most common in

fluidized bed boilers. In the exploding bubble regime the bubble can remain attached to the

distributor until it breaks the bed surface, while in the single bubble regime the bubble often

detaches from the distributor and travels through the bed. Since stable preferred bubble paths

can be readily established under these regimes, a single preferred bubble path and its adjacent

emulsion is considered to be a representative section of the bed in this work.

At present, the bubble is assumed for simplicity to be rectangular and to grow only in the

vertical direction. As schematized in Fig. 8, the region including the bubble is termed the

throughflow phase and the adjacent emulsion is termed the emulsion-only phase.

15

Figure 8: A schematic representation of the modeled bed segment

The bubble flow model presented in this work is based on the following assumptions:

i. Solid particles are spherical and monosized;

ii. The air distributor is of porous type;

iii. The gas has no vertical velocity gradients and flows strictly vertically, i.e. there is no

exchange of mass between the throughflow and the emulsion-only phase;

iv. The emulsion voidage is a local function of the gas velocity;

v. The pressure drop in the emulsion follows the Ergun equation;

vi. The bed is operated in the exploding bubble regime, thus the bubble never detaches

from the air distributor plate;

vii. Bubbles are solids-free voids without properties of their own; and

viii. The bed height is assumed constant and equal to the height at minimum fluidization,

i.e. the increase in volume due to the expansion of the bubble is assumed to be

compensated for by the part of the bed excluded from the section of interest.

Gas flowing through the bubble stabilizes the bubble roof, and is the means by which the

bubble rises through the bed. Gas leaving through the bubble roof exerts a drag force on the

particles contained between the bubble roof and the bottom bed surface. A high enough gas

velocity causes these particles to move, allowing the bubble to ascend through the bed. Thus,

particles are mere passengers dragged along by the gas flow. Since the system is strongly

dynamic, a system of equations has to be solved at each time step to determine the evolution

of the bubble front position and the gas velocity through the two phases involved.

The gas flow through the two phases making up a bed segment is controlled by the pressure

drop across each phase. The impact of a bubble on the balance between the two phases can be

compared with the electrical circuit, schematized in Fig. 9 with the emulsion-only and the

throughflow phases set in parallel.

16

Figure 9: A representation of the flow resistances in a freely bubbling fluidized bed as a power circuit.

In the electrical analogy, gas velocity is likened to current intensity, pressure to voltage, and

mass flow resistance to electric resistance. Hence,

M

gas

E

R

P

U

R

V

I

A

A

= . (4)

As seen from Figure 9, two pressure loss terms exist for each of the phases: one through the

air distributor, R

Dist

, and one through the bed material, R

Bed

. Thus, flows through each one of

the two phases considered are arranged so that a same total pressure loss is obtained for both.

If the pressure drop across the bed is much larger than that across the distributor, that is R

Dist

can be more or less disregarded, the presence of a bubble significantly alters the pressure

balance between the two phases, notably increasing the flow in the throughflow phase.

Conversly, if the pressure drop across the distributor is larger than the drop across the bed, the

presence of a bubble does not alter the pressure balance much, and the division of the gas

between both phases remains relatively unaffected.

When the pressure drop across the bed is dominant, bubbles grow larger since most of the gas

seeks out the low resistance path which bubbles represent. When the pressure drop across the

distributor dominates, smaller and more homogeneously distributed bubbles are formed in the

bed, which does not induce any stable preferred bubble paths:

>>

A

A

1

dist

bed

P

P

Large bubbles forming stable preferred bubble paths

<<

A

A

1

dist

bed

P

P

Small, homogeneously-distributed bubbles

P

ple

P

atm

R

Bed

Eq. 10

R

Bed

Eq. 10

R

Dist

Eq. 9

Throughflow

phase

Emulsion-only

phase

R

Dist

Eq. 9

u

th

u

e

17

A widely used correlation, given by Wen et al. (1966), to determine the particle Reynolds

number at which minimum fluidization occurs is:

1 2

2

1 ,

Re C Ar C C

mf p

+ = (5)

where

( )

2

3

g

g s g p

g d

Ar

= . (6)

Several pairs of the values for C

1

and C

2

have been proposed in the literature. Grace (1986)

suggested the use of C

1

= 27.2 and C

2

= 0.0408. The minimum fluidization velocity, u

mf

, can

be obtained from the Reynolds number expression:

g p

g mf p

mf

d

u

,

Re

= . (7)

The void fraction under minimum fluidization conditions,

mf

, is calculated with the Ergun

equation:

( ) ( )

2

,

3

,

2

Re

1 75 . 1

Re

1 150

mf p

mf

mf

mf p

mf

mf

Ar

c

c

c

c

+

= . (8)

The pressure drop through the distributor plate is generally determined by the characteristic

curve of the distributor:

2

i Dist

ku P = A . (9)

Since the bubble is assumed to be solids free, the gas passes through the bubble without any

pressure drop. The pressure drop across the emulsion is described by the Ergun equation:

( ) ( )

|

|

.

|

\

|

+

= A

2

3 2 3

2

1 75 . 1 1 150

i

p

i

p

Bed

u

d

u

d

L P

c

c

c

c

(10)

where

0 B

h L = for the emulsion-only phase and

x h L

B

=

0

for the throughflow phase.

Unrealistically high pressure drops are obtained at high gas velocities with Eq. 10 if particles

are assumed to be homogeneously distributed. Thus, particles in the emulsion are thought to

have irregular mesoscale structures, i.e. to form clusters, which results in effective larger

particles (see Section 3.3). The clusters are assumed to be spherical and are characterized by a

particle diameter with the same density as a single particle. The excess pressure in the plenum

can then be described by combining Eq. 9 and Eq. 10:

Bed dist ple

P P i P A + A = ) ( . (11)

The pressure inside the bubble exerts a force on the emulsion above the bubble, as shown in

Fig.10. Thus, at a given time step, the displacement of the bubble front can be determined by

18

Newtons second law. Since the gas leaving through the bubble roof flows through the

emulsion above the bubble, the excess pressure in the bubble, P

bub

, can be described by the

Ergun equation (Eq. 10 with L = hb0-x), as show in Eq. iii in the derivation immediately

below.

mg F

g

= (i)

A P F

atm atm

= (ii)

( )A P P A P F

Erg atm Bub Bub

A + = = (iii)

Thus, Newtons second law gives:

ma A P mg F F F F

Erg ple atm g

= A = + = E (12)

Figure 10: Force balance on the emulsion above the bubble in the throughflow phase

A further derivation of Eq. 12 yields:

( ) ( )

( )( ) g a u

d

u

d

s i

p

i

p

+ =

c

c

c

c

c

1

1 75 . 1 1 150

2

3 2 3

2

. (13)

The local emulsion voidage has been studied with optical probes in a cold fluidized bed, as

detailed in Appendix A. Withthe experimental data obtained in this study, a correlation

describing the local voidage in the emulsion as a function of the gas velocity can be derived:

37325 . 0 2104 . 0 + =

i

u c . (14)

The pressure in the plenum is controlled by an air fan regulating system which is modeled

according to:

( ) ( ) ( ) ( ) 1 1 A + = i u u t i P i P

m wanted ple ple

o . (15)

The rate of change in pressure is governed by the fan variable, , and is determined so that the

time-averaged gas velocity corresponds to the value defined as input (see Section 3.3 for

details). Although the rate of change should be restricted by the mechanical capacity of the air

systems to react to changes, this is not accounted for in the model at present time. The phase-

averaged velocity, u

m

, used in Eq. 15, u

m

, is defined as:

( )

B E B B m

i u i u i u + = 1 ) ( ) ( ) ( (16)

where

B

is the fraction of cross-sectional area covered by the bubble.

The horizontal size of the bubble is fitted to predict the average bubble density as calculated

from published experimental data on Chalmers CFB boiler, which is roughly around = 0.27,

as measured by Johnsson and Leckner (1995).

F

g

F

Bub

F

atm

19

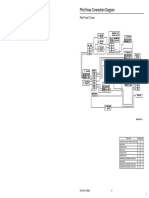

3.2 Computational flow scheme

The model requires the set of input data specified in Table 1 and derives the output data

specified in Table 2:

Table 1: Input data required by the model

Solids density

s

Particle diameter d

p

Operating temperature T

Bed height h

B0

Average operating superficial gas velocity u

wanted

Characteristic constant of air distributor k

Average bubble density

B

The calculation of the bubble rise transient is time-discretized and implemented through an

iteration-based computational structure, which is given in Fig.11a. The dynamic loop

containing the system of equations solved at each time step is depicted by Fig.11b. As seen in

Fig.11a, three self-contained iterations are needed to reach a solution.

Figure 11a: Computational flow scheme Figure 11b: Dynamic loop

gas U

bed P A

B o

Input

(table 1)

Output

(table 2)

gas

wanted

U

u

o o =

mf

bed

cluster cluster

P

P

d d

A

A

=

B

B

B B

o

o

=

Dynamic loop

(fig.11b)

( ) ( ) 1 = i x i x

Eq. 11

and

Eq. 15

u

i

Eq. 13

a

i = i + 1

( ) ( ) t i t i t A + = 1

X

x(i)=X

20

Table 2: Output data from the model

Bubble front position x(t)

Bubble cross-sectional fraction

B

q (see Chapter 4)

Dist

Bed

P

P

A

A

Superficial gas velocity in the through-flow phase U

Th

(t)

Superficial gas velocity in the emulsion-only phase U

E

(t)

Pressure in the plenum P

ple

(t)

Pressure drop across the bed P

ThBed

(t), P

EBed

(t)

Pressure drop across the distributor plate P

ThDist

(t), P

EDist

(t)

Since minimum fluidization conditions have to be fulfilled before the bubbling begins, these

are chosen as initial bed conditions. Initial values and the time step used in the present

calculations are given in Table 3. The computer code used (implemented in Matlab 7.3.0) is

available in Appendix B.

Table 3: Initial parameter values and time step used in the present calculations

Regulating system constant

0

3.5e6 Pa/m

Bubble fraction

B0

0.8

Time step t 0.1e-3 s

21

4. Results and discussion

The present model describes the behavior of a growing bubble in the bottom bed of a

fluidized bed combustion unit, for which all results from the model are given as a function of

time. Once the bubble has reached the bed surface, the bubble structure is assumed to collapse

(as seen from experiments) and the gas velocity in the bed drop drastically, defluidizing the

entire segment, which represents the end of the dynamic cycle. At present, the cycle is

incomplete since the period between short-circuit, when the bubble breaks the bed surface,

and the refluidization of the bed segment is not included in the model. Two parameters

influencing the dynamics in an FBC unit are the bed height, h

B0

, and the characteristic

constant of the air distributor, k. A reference case is chosen as the basis for a later comparison

in which the influence of these two parameters is investigated.

4.1 Reference case

Care should be taken when determining the input data, i.e. the operating conditions, to avoid

exceeding the parameter range in which the model is valid. The conditions for the reference

case, given in Table 4, are therefore chosen to represent typical operational conditions for a

circulating FBC unit.

Table 4: Input data for the reference case

Solids density

s

2600 kg/m

3

Particle diameter d

p

0.4 mm

Temperature T 20C

Average gas velocity u

wanted

3 m/s

Average bubble density

B

0.27

Bed height h

B0

0.5 m

Characteristic constant of air distributor k 300 Pas

2

/m

2

The bubble front propagates through the bed until it reaches the bed surface, as shown in

Figure 12. The rise velocity is low during the initial formation of the bubble, but increases as

the bubble grows larger. As the bubble front approaches the bed surface the rise velocity

levels out and becomes more constant. While analyzing these results, it must be kept in mind

that only the bubble front is taken into account in this model, and that both the rise velocity

and bubble position might be significantly altered if the bubble detaches from the air

distributor.

22

Figure 12: Modeled evolution of the bubble front, h

B0

= 0.5m, k = 300 Pas

2

/m

2

The superficial gas velocity for each phase as well as the weighted average gas velocity is

shown in Figure 13. It is clear that the velocity in the throughflow phase is higher than in the

emulsion-only phase. This is a consequence of the introduction of a region without flow

resistance, i.e. a bubble. The high velocity indicates that a substantial amount of the gas flow

passes through the throughflow phase. As the bubble grows, the flow resistance in the bed

section of the passage is decreased accordingly, and an increasing amount of the gas flow

passes through the throughflow phase. Due to the corresponding decrease in gas flow through

the emulsion-only phase, the gas velocity in the emulsion-only phase decreases as the bubble

propagates through the bed. The velocity even drops below the minimum fluidization

velocity, u

mf

, as the bubble approaches the bed surface. Therefore, in the case studied, the

emulsion-only phase defluidizes before the bubble breaks the bed surface.

Figure 13: Modeled superficial gas velocities in the throughflow (U

TH

) and emulsion only phase (U

E

) and the

weighted average gas velocity (U

M

).

23

Since it is not possible to reach as high fluidizing gas velocities as desired in a FBC unit

without forming bubbles the pressure in the plenum has to overcome the weight of the

incipiently fluidized bed and the flow resistance of the distributor plate. Once the pressure

required to sustain the desired gas velocity is obtained, the pressure in the plenum drops off,

as shown in Figure 14. This explains why the gas velocity appears independent of the bubble

fronts position: A lower flow resistance in the bed section allows for a high gas flow to be

sustained with a lower pressure in the plenum.

Figure 14: Modeled pressure in the plenum, pressure drop across the bed (as expressed by Eq. 17) and time-

averaged pressure drop across the bed.

The pressure drop across the bed is the weighted sum of the pressure drop in both phases

expressed as:

( ) ( )

2 2

1

E B B B Ple Bed

u u k P P + = A . (17)

It can also be seen in the figure that the pressure in the plenum is actually higher than the

minimum requirement for forming a bubble. The rapid increase of pressure in the plenum is a

result of the present formulation of the fan regulating equation, Eq. 15.

The frequency of the pressure and gas velocity fluctuations is determined by the time it takes

for the bubble to break through the surface of the bed and short-circuit the system, while the

amplitude of the pressure fluctuation is the difference between the maximum value (occurring

at bubble formation) and the lowest value (occurring as the bubble approaches the surface).

4.2 The influence of the characteristic constant of the air distributor

and the bed height

The ratio of the pressure drop across the bed to that across the distributor determines the

division of gas flow between the emulsion-only phase and the throughflow phase (see Figure

8). In this work the variable, q, is defined as the ratio of the time-averaged weighted sums of

the pressure drops across the bed to those across the distributor:

24

Dist

Bed

P

P

q

A

A

= . (18)

This ratio, as given by Eq. 18, can be modified by changing the bed height, the characteristic

constant of the air distributor, or both. To investigate the impact of the bed height and the

characteristic constants of the air distributor represented by q, the simulation matrix shown in

Figure 15 was applied.

Figure 15: Simulation matrix; case numbers given in parenthesis.

The fact that, at present stage, the model does not include the detachment of the bubble from

the air distributor imposes the assumption that the bed is operated in the exploding bubble

regime, which is the regime for which this assumption is most realistic. This regime is

observed in systems where q >>1, which implies that the span of the simulation matrix is

limited by the inability of the model to handle cases for which the pressure drop across the

distributor dominates over the pressure drop across the bed, that is q << 1.

In the exploding bubble regime, the pressure drop across the distributor has to be low enough

to allow the flow through the distributor to be non-uniform. Thus, the higher the variable q,

the better the model applies to the simulated conditions. With q < 1, the flow through the

distributor becomes more uniform and a significant rearrangement of the gas flow has to

occur in the bed, which the model at present cannot handle, as discussed above. Both

conditions and results for the cases presented in the simulation matrix are given in Table 5.

Table 5: Conditions and results for the nine cases considered

Parameters Results

Case

h

B0

[m]

k

[kg/m

3

]

B

[-]

q

[-]

10

-6

[Pa/m]

d

cluster

[mm]

Fluctuation

frequency

[Hz]

Ref 0.5 300 0.8234 2.40 4.1 2.4 3.21

2 0.5 100 0.8195 7.02 3.5 2.3 3.38

3 0.5 500 0.8265 1.46 4.9 2.5 3.01

4 0.25 300 0.8245 1.22 3.6 2.5 4.12

5 0.25 100 0.8189 3.57 3.5 2.4 4.67

6 0.25 500 0.8197 0.74 4.7 2.8 3.48

7 1.0 300 0.8210 4.70 4.7 2.4 2.35

8 1.0 100 0.8203 13.99 4.1 2.3 2.42

9 1.0 500 0.8228 2.87 5.4 2.4 2.30

Reference case

k = 300 Pas

2

/m

2

h

B0

= 0.5 m

Constant k

(4) h

B0

= 0.25 m

(7) h

B0

= 1.0 m

Constant h

B0

(2) k = 100 Pas

2

/m

2

(3) k = 500 Pas

2

/m

2

Changing both h and k

(5) h

B0

= 0.25 m, k = 100 Pas

2

/m

2

(6) h

B0

= 0.25 m, k = 500 Pas

2

/m

2

(8) h

B0

= 1.0 m, k = 100 Pas

2

/m

2

(9) h

B0

= 1.0 m, k = 500 Pas

2

/m

2

25

The influence of the bed height on the dynamics of the bubble front position, i.e. the bubble

front velocity, is shown in Figure 16. When the bed height is decreased (compare the

reference case to Case 4), the bubble front propagates more slowly through the bed, i.e. longer

cycle times lower the fluctuation frequency. The same results can be reached by increasing

the characteristic constant for the distributor plate (compare Case 4 to Case 6). On the other

hand, a decrease in the characteristic constant for the distributor as well as a decreased bed

height would then increase the bubble front velocity (compare the reference case to Case 5).

Figure 16: Modeled evolution of bubble front position for the reference case (q = 2.4), Case 4 (q = 1.22), Case 5

(q = 3.57) and Case 6 (q = 0.74).

The effect off a further increase in bed height or decrease of the characteristic constant for air

distributor will where off when q increase far beyond unity. As the relative change in rise

velocity becomes less noticeable, further decreasing the characteristic constant or increasing

the bed height only adds to the operational costs in terms of fan power without further

modifying the gas flow pattern.

These results demonstrate that individual values of the bed height and the characteristic

constant for the air distributor are not important in themselves, but their ratio is. Henceforth,

only the pressure drop ratio, q, will be taken into account, rather than the individual values for

the two parameters investigated. Two systems are therefore expected to exhibit similar

dynamic properties, as long as they have similar values of q, as can be seen in Figure 17.

26

Figure 17: Modeled evolution of the bubble front position for the reference Case (q = 2.4), Case 5 (q = 3.57) and

Case 9 (q = 2.87)

The effect the variable q has on the superficial gas velocity through the throughflow phase is

too small to give a qualitative description of the influence the variable has on the throughflow

phase. Therefore, attention is given to the superficial gas velocity through the emulsion-only

phase, shown in Figure 18, where the influence of the variable q is much clearer.

Figure 18: Modeled superficial gas velocity through the emulsion phase for the reference case (q = 2.4), Case 7

(q = 4.70), Case 8 (q = 13.99) and Case 9 (q = 2.87).

Increasing q, by increasing bed height (compare the reference case to Case 7), decreasing the

characteristic constant of the air distributor compare Case 7 to Case 8), or both, results in a

decrease in superficial gas velocity through the emulsion-only phase. Decreasing q (compare

Case 7 to Case 9) has the opposite effect on the gas velocity. Regardless of the value of q, the

velocity in the emulsion-only phase drops below the minimum fluidization velocity, and the

emulsion-only phase is defluidized. In Figure 18 it can also be noted that the amplitude of the

velocity fluctuations in the emulsion-only phase increases when decreasing q (compare Case

27

8 to Case 9), while the fluctuation frequency is barely altered. Hence, the bed height can be

argued to determine the frequency while the characteristic constant influences the amplitude

of the fluctuations.

As shown in Figure 19, lowering q leads to reduced pressure in the plenum (compare the

reference case to Case 6). It can also be seen that the amplitude of the pressure fluctuations

decreases as q is lowered. This could, according to the discussion in Section 3.1, indicate that

bubbles are smaller, more frequent, and unable to form stable preferred bubble paths through

the bed.

Figure 19: Modeled pressure levels in the plenum position for the reference case (q = 2.4), Case 6 (q = 0.74) and

Case 8 (q = 14)

The tendency observed from the modeled fluctuations (both pressure levels in the plenum and

superficial gas velocity in the emulsion-only phase) seems to indicate that the lower the value

of q, the less severe the fluctuations, which is also in agreement with the observations

discussed in Section 2.2 and shown in Figures 18 and 19. This indicates that the superficial

gas velocities in the phases do not differ much, the bubbles are smaller and the bed is

probably not operated in the exploding bubble regime.

As noted above, since the application mapping of the model is restricted to the exploding

bubble regime, it is not possible to make realistic simulations of cases in which the pressure

drop across the distributor dominates strongly over the pressure drop across the bed.

28

5. Conclusions

A first-step one-dimensional model for the bubble flow in a fluidized bed operated in the

exploding bubble regime has been implemented. From stable preferred bubble paths which

commonly occur, a single such bubble path and its adjacent emulsion is assumed to be a

representative section of the bed. The gas flow is divided into a throughflow phase and

emulsion-only phase. It is found that the fluidization regime depends on the ratio of the

pressure drop across the air distributor plate to that across the bed. The model implemented is

unique in its capability to account for the influence of the air distributor characteristics and the

bed height on the dynamics of both superficial gas velocity and pressure fields.

It was shown that a high pressure drop ratio, q, results in severe fluctuations in the system,

while a lower q results in more moderate fluctuations, which is in agreement with the

observations discussed in Section 2.2 and shown in Figures 18 and 19. Moderate fluctuations

indicate that the superficial gas velocities in the phases do not differ much: the bubbles are

smaller and the bed is probably not operating in the exploding bubble regime. Due to the

restriction of the model, it is not possible to perform realistic simulations of cases in which the

pressure drop across the distributor dominates strongly over the pressure drop across the bed.

29

6. Further work

In the short term, in order to encompass other bottom bed regimes besides the exploding

bubble regime considered here, criteria and descriptions of the processes taking place when

the bubble detaches from the air distributor are needed. This, together with a refined modeling

of the fan inertia can open the way for comparison with experimental data on the bubble flow.

In a longer term, once the description of the bubble is completed, the model of the bubble

flow can be coupled to the movement of the solids (both mixing and segregation) to obtain a

model describing the solids (and thereby, fuel) mixing in the bottom region of a fluidized bed.

30

References

Abanades, J. C., Grasa, G. S., 2001. Modeling the Axial and Lateral Mixing of Solids in

Fluidized Beds. Ind. Eng. Chem. Res., 40, 5656-5665

Clift, R., Grace, J. R., 1985. In: Fluidization, 2

nd

edn., J. F. Davidson et al., eds., pp.79-80,

Academic Press, Inc., Orlando, Florida

Davidson, J. F., 1985, In: Fluidization 2

nd

edn., J. F. Davidson et al. eds., Academic Press,

Inc., Orlando, Florida

Deemter, van, J. J. 1961. Mixing and contacting in gas-solid fluidized beds. Chemical

Engineering Science, 18, pp. 143-154.

Geldart, D., 1973. Types of gas fluidization, Powder technology, 7, 5, 285-292.

Gera, D., Gautam, M., 1994. Variation of throughflow velocity in a 2-D rising bubble.

Powder Technology, 79, 257-263.

Grace, J. R., Harrison, D., 1969. The behaviour of freely bubbling fluidising beds. Chemical

Engineering Science, 24, pp. 497-508.

Grace, J. R., 1986. Contacting modes and behaviour classification of gas-solid and other two-

phase suspensions. Canadian Journal of Chemical Engineering, 64, 353-363.

Gwyn, J. E., Moser, J. H., Parker, W. A., 1970. A three-phase model for gas-fluidized beds.

Chem. Eng. Prog. Symp. Ser., 66, 19-27.

Johnsson, F., Andersson, S., Leckner, B., 1991. Expansion of a freely bubbling fluidized bed.

Powder Technology, 68, 117-123.

Kunii, D., Levenspiel, O., 1991. Fluidization engineering. Butterworth-Heinemann, Newton,

MA.

Lim, K. S., Gururajan, V. S., Agarwal, P. K., 1993. Mixing of homogeneous solids in

bubbling fluidized beds: Theoretical modelling and experimental investigation using

image analysis. Chemical Engineering Science, 48, 12, pp. 251-2265.

Lim, K. S., Agarwal, P. K., 1994. Circulatory motion of a large and lighter sphere in a

bubbling fluidized bed of smaller and heavier particles. Chemical Engineering Science,

49, 3, pp. 421-424.

Lim, K. S., Zhu, J. X., Grace, J. R., 1995. Hydrodynamics of gas-solid fluidization, Int. J.

Multiphase Flow, 21, Suppl. pp. 141-193.

Magnusson, A., Rundqvist, R., Almstedt, A.E., Johnsson, F. 2005. Dual fiber optical probe

measurements of solids volume fraction in a circulating fluidized bed. Powder

Technology, 151, pp. 19-26.

Niklasson, F., Thunman, H., Johnsson, F., Leckner, B., 2002. Estimation of Solids Mixing in

a Fluidized-Bed Combustor. Ind. Eng. Chem. Res., 41, 4663-4673.

Pallars D., 2005. Macroscopic Modeling of Fluid Dynamics in Large-Scale Circulating

Fluidized beds, Licenciate Thesis, Dept. of energy and Enviroment, Chalmers

University of Technology, Gothenburg, Sweden.

Pallars, D., Johansson, A., Johnsson, F. 2006. Interpretation of dynamics of pressure

measurements. Proc. of the 19

th

Int. Conf. on Fluidized Bed Combustion (Vienna,

Austria).

Pallars, D., Dez, P., Johnsson, F., 2007. Experimental Analysis of Fuel Mixing Patterns in

a Fluidized Bed. Proc of the 12

th

International Conference on Fluidization,

(Vancouver, Canada)

Sasic, S., Leckner, B., Johnsson, F., 2005. Parametric modeling of time series of pressure

fluctuations in gassolid fluidized beds. Chem. Eng. Sci., 60, 5069-5077

Shi, Y., Fan, L. T., 1984. Lateral Mixing of Solids in Batch Gas-Solids Fluidized Beds. Ind.

Eng. Chem. Process Des. Dev., 23, 337-341.

31

Svensson, A., Johnsson, F., Leckner, B., 1996. Bottom bed regimes in a circulating fluidized

bed boiler. Int. J. Multiphase Flow, 22, 6, pp. 1187-1204.

Toomey, R.D., Johnstone H.F., 1952. Chemical Engineering Progress, 48, 220

Verloop, J., Nie, L. H., Heertjes, P. M., 1968. The Residence Time of Solids in Gas-Fluidized

Beds. Powder Technology, 2, 1, 32-42.

Wen, C. Y., Yu, Y. H., 1966. A generalized method for predicting the minimum fluidization

velocity. AlChE Journal, 12, 610-612.

Werther, J., 1977. Bubble chains in large diameter gas fluidized beds. International Journal of

Multiphase Flow, 3(4), 367-381.

i

Appendix A

The use of optical probes for experimental

determination of the local bed porosity

ii

The influence of the superficial gas velocity on the local emulsion porosity has been measured

with an optical probe; see Magnusson et al. (2005). The resulting data, given in Table 6, were

correlated through linear regression to give an expression for the porosity as a function of the

gas velocity. The correlation was formulated expressly to ensure the correct prediction of the

point of minimum fluidization, as can be seen in Fig.A.1.

Cold Bed

y = 0,2104x + 0,3733

R

2

= 0,5302

0,35

0,40

0,45

0,50

0,55

0,60

0,65

0,70

0,75

0,10 0,30 0,50 0,70 0,90 1,10 1,30

Superficial gas velocity

E

p

s

i

l

o

n

Figure A.1. Measured porosity values (Epsilon) as a function of the superficial gas velocity. The solid line

indicates the correlation adopted.

Particles used in the experiment were typical silica sand particles used as bed material in FBC

units. As the gas velocity increases the correlation predicts unreliable values for the porosity,

hence the correlation is assumed to be valid only in the range of gas velocities for which the

particles can be assumed to expand homogeneously. When the gas reaches such a high

velocity that the formation of cluster starts, the porosity is assumed to become independent of

the velocity.

Table 6. Data shown in Figure A.1.

Gas velocity

Epsilon

(measured)

Epsilon

(correlated)

0.157 0.40632 0.40632

1.180 0.680 0.6214

0.910 0.700 0.5646

1.017 0.703 0.5871

0.917 0.693 0.5660

0.923 0.657 0.5674

0.900 0.610 0.5625

0.960 0.587 0.5751

0.957 0.590 0.5744

0.997 0.563 0.5829

u

mf

, e

mf

iii

0.867 0.570 0.5555

0.907 0.540 0.5639

0.840 0.553 0.5499

0.913 0.523 0.5653

0.840 0.527 0.5499

0.837 0.527 0.5492

0.787 0.517 0.5387

0.813 0.527 0.5443

0.783 0.513 0.5380

0.780 0.520 0.5373

0.710 0.520 0.5226

0.757 0.517 0.5324

0.747 0.513 0.5303

0.740 0.507 0.5289

0.693 0.503 0.5191

0.680 0.497 0.5163

0.700 0.493 0.5205

0.733 0.490 0.5275

0.767 0.490 0.5345

0.700 0.490 0.5205

0.707 0.490 0.5219

0.637 0.490 0.5071

0.693 0.490 0.5191

0.647 0.483 0.5093

0.637 0.477 0.5071

0.610 0.467 0.5015

0.667 0.463 0.5135

0.743 0.463 0.5296

0.730 0.463 0.5268

i

Appendix B

Computer code

ii

function [ratio,Dp,Alpha,Emax,Xpos,Tid,U,XiB,P,Eps]=bubbleflowmodel;

% The program determine the dynamic superficial gas velocity and the bubble

% front position.

Tic; clear all; close all;

global Repmf Ar i hb0 x k P_ply umf u1 u2 my_air rho_air rho_s dp g e1 e2

emax

%% Constants

g = 9.82; % [N/kg]

rho_s = 2600; % [kg/m3]

dp = 0.4e-3; % [m]

my_air = 1.81e-5; % [Pa*s]

rho_air = 1.189; % [kg/m3]

hb0 = 0.5; % bed height at minimum fluidization [m]

k = 300; % characteristic constant for the air distributor

u_wanted = 3; % operating fluidization gas velocity

deltat = 1e-4; % time step

alpha = 3.5e6; % initial guess for the fan constant

DBgoal = 0.27; % average bubble density

%% Minimum fluidization, Arkimedes and Reynolds number

K1 = 27.2;

K2 = 0.0408;

Ar = dp^3*rho_air*(rho_s-rho_air)*g/my_air^2;

Repmf = sqrt(Ar*K2+K1^2)-K1;

umf = Repmf*my_air/(dp*rho_air);

e_mf = fzero(@sandra,[0.3 0.6]);

P_ply(1) = rho_s*(1-e_mf)*hb0*g + k*umf^2;

Ptarget = hb0*(1-e_mf)*rho_s*g; %Time-average pressure drop across the bed

%% for t>0 %%

XiBub = 0.80; % Bubble fraction

err=1; dp=[dp,dp]; deltaB=DBgoal;

while err > 0.01

XiBub = DBgoal/deltaB*XiBub;

XiEmul = 1-XiBub;

Gast = 1; DP = Ptarget;

while Gast > 0.01

if Gast > 1

dp(1) = dp(1)*2;

else

dp(1) = dp(1)*DP/Ptarget;

end

emax(1) = ptry(my_air,rho_air,dp(1));

emax(2) = ptry(my_air,rho_air,dp(2));

Grind = 1; Umean = u_wanted;

while Grind > 0.01

i=1; t=0; x=0; u1=umf; u2=umf; um=umf; Hast=0;

P_ply=P_ply(1); e1=e_mf; e2=e_mf;

alpha = alpha*u_wanted/Umean;

while x(i)<hb0

i = i+1;

t(i) = t(i-1)+deltat;

x(i) = x(i-1);

P_ply(i) = P_ply(i-1) + alpha*deltat*(u_wanted - um(i-1));

Skillnad = 1;