Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ergonomics - Observation Form Name: Area

Caricato da

NakkolopDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ergonomics - Observation Form Name: Area

Caricato da

NakkolopCopyright:

Formati disponibili

ERGONOMICS - OBSERVATION FORM NAME:

OBSERVATIONS 1. Employee Size

AREA:

SCORING 1-5 (Very weak = 1, Excelle ! = 5" The workstation is adaptable to employee size (chairs, benches, shelves). When sitting, leg space sho ld be s !!icient. When standing, the spacing !or !eet sho ld be s !!icient. &aterials and tools sho ld be accessible, with minimal h man twisting or body e'tensions( the area !or twisting or t rning sho ld be s !!icient. The operator does not have to make movements above the sho lders, below the waistline or behind. The operator doesn-t have to e'tend.bend an arm or leg !or long periods. /e sho ld not crook his head at e'treme angles. 0or sho ld h stand on one leg. # s pport is available when the operator has to keep his arms or hands e'tended !or a long period. *i!ting and moving ob3ects sho ld be minimal. The operator m st not li!t heavy ob3ects. /e can adopt an appropriate post re when he is li!ting. The weight o! the ob3ect is minimal. The re4 irements !or both precision and strength are avoided when possible, handles are provided to li!t the ob3ect. The workstation is designed to eliminate the motion o! non6essential materials. &echanical assistance is re4 ired (conveyor belt, !orkli!t tr ck, hand tr ck, table or rail between the workbench, tr ck li!t, etc.). The operator does not !re4 ently handle heavy and large ob3ects. Tooling and e4 ipment do not trans!er e'cessive vibrations. Tasks and tools do not create prolonged press re at the base o! the palm or at the !ingertips. Wrists sho ld not be stretched !orward, backward, or sideways. The operator does not have to work with elevated sho lders or elbows. Be#$re Re%&l! (1-5" A#!er Re%&l! (1-5"

". The #ccessibility o! Tools, $ontrols % &aterials

). Static *oad and +i'ed ,ost re

1. *i!ting 2b3ects

5. *oad Transportation

7. +re4 ent #rm, /and and Wrist &otions

File name = 199681098.doc

1 of 3

Date printed = 03/01/14 07:11

ERGONOMICS - OBSERVATION S'EET

OBSERVATIONS 8. $ollision 9isks SCORING 1-5 (Very weak = 1, Excelle ! = 5" +orbidden passages.laneways are closed or appropriately identi!ied. #ccess to passageways are obstacle6!ree( they have good visibility in both directions. *adders and stairs lead onto these protected zones. Service co nters are set back !rom the passages. ,assages that are to be sed are identi!ied. There are no !i'ed or prominent obstacles, nor are there any sharp angles. :! there are some, they are well identi!ied and.or protected. The se o! a working plat!orm is red ced. When being sed, the operator does not have to descend d ring the normal work cycle. 9ailings are provided at hal! meters above the immediate gro nd level or i! the activity warrants it. 2bstacles o! less than hal!6a6metre are marked. There sho ld not be any obstacles across the passageway( i! there are, a gangway is installed. Electrical cables are s spended !rom adapted aerial s pports. &achines and e4 ipment are sealed. 9eceptacles are provided to collect any condensation or accidental spills. ,arts are dried be!ore handling. When necessary the gro nd is covered with anti6slip prod cts. >neven gro nd s r!aces are eliminated. The operator has the appropriate e4 ipment and accessories to li!t heavy or enc mbering loads.ob3ects. The movement o! a hoist sho ld cover the entire work area. ,rotecting !ences are provided when there is a risk o! a !alling ob3ect. The piling o! bo'es, tools, parts, and any other ob3ects located at high levels (on the top o! a machine or a poorly adapted place, is prohibited. Employees sho ld not work nderneath elevated workstations. #ccess to mobile machine parts is protected by railings, g arding, coverings, etc. Work with hand tools on a rotating part is limited. Emergency stop devices are wherever risk demands. 9isks are eliminated thro gh process, machine design, installation, or mechanical operation. ,rotection devices are in place so that the operator is not in the zone o! operation (when the machine is working). Sa!ety switches, railing, motion detectors are some o! these devices. Tools or c tting parts are transported and stored in a special holder. TOTA( O)T OF 1**+ Be#$re Re%&l! (1-5" A#!er Re%&l! (1-5"

;. 9isks o! +alls

<. =ro nd and S r!ace Tra!!ic

1?. 9isks o! +alling 2b3ects

11. 9isk o! @ody or 2b3ects @eing $a ght in &obile &achinery 1". 9isk o! $r shing, $ ts, #mp tation, ,iercing, #brasions

File name = 199681098.doc

2 of 3

Date printed = 03/01/14 07:11

ERGONOMICS - OBSERVATION S'EET

OBSERVATIONS 1). 9isk o! +lying 2b3ects, Splashes, E'plosions SCORING *-5 (Very weak = *, Excelle ! = 5" Tools are appropriate and well designed. Set6 ps, part6positioning controls, and !astening systems sho ld be reliable and resistant. /olding systems, screens or plastic drapes, prevent the !lying o! parts, li4 ids, or piece !ragments. Aac ming, br shing or wiping are sed !or cleaning p rposes (rather than air press re methods). :! necessary, the machine start is related to the closing and locking o! covers. Bepending on the type o! prod ct, sa!ety showers and eyewash !o ntains are installed. ,rod cts are stored based pon their characteristics and their incompatibilities (cons lt with the +ire ,revention Bepartment). &etal masses are gro nded in the !lammable prod cts handling zone. +lammable wastes are stored in containers with special lids. The d cts o! steam or high6temperat re li4 ids are ins lated. ,arts, e4 ipment or high temperat re d cts are isolated and clearly identi!ied. The lighting level sho ld be s !!icient( light so rces sho ld not be harsh or blinding. The operator m st not be e'posed to high levels o! noise. &achines, e4 ipment, and prod ction processes, capable o! emitting dangero s or irritating prod cts, are e4 ipped with s itable ventilation. Re%&l! (*-5" Re%&l! (*-5"

11. 9isk o! +ire, E'plosions, @ rns

15. *ighting, 0oise Aentilation

TOTA( O)T OF

50

T2T#* 2>T 2+ 1??

File name = 199681098.doc

3 of 3

Date printed = 03/01/14 07:11

Potrebbero piacerti anche

- 5S and Safety FormsDocumento4 pagine5S and Safety FormsMadhan KumarNessuna valutazione finora

- Cranes: Hazard: Significant and Serious Injuries May Occur If Cranes Are NotDocumento20 pagineCranes: Hazard: Significant and Serious Injuries May Occur If Cranes Are NotRutuja ShikhareNessuna valutazione finora

- Lathe MachineDocumento18 pagineLathe MachineShreenivas ThakurNessuna valutazione finora

- 04.2.1 SWP 900 - SWP Stepladders, Electric Power-, and Hand Tools, Manual Handling (TCT - OHS Master File 2023)Documento6 pagine04.2.1 SWP 900 - SWP Stepladders, Electric Power-, and Hand Tools, Manual Handling (TCT - OHS Master File 2023)Hibon LodgeNessuna valutazione finora

- Scaffolding-Fixed and MobileDocumento1 paginaScaffolding-Fixed and MobileAsyraf ZainiNessuna valutazione finora

- Workshop Inspection Checklist October 2010Documento11 pagineWorkshop Inspection Checklist October 2010Rajkumar MuthumanickamNessuna valutazione finora

- Fall ProtectionDocumento4 pagineFall ProtectionnainaNessuna valutazione finora

- Machine Guarding: Self-Inspection ChecklistDocumento2 pagineMachine Guarding: Self-Inspection ChecklistMervin VargheseNessuna valutazione finora

- Check List - Machine GuardingDocumento2 pagineCheck List - Machine GuardingSirley Sanmartín RestrepoNessuna valutazione finora

- Toolbox Talk - Ladders: Planning and Assessment of RisksDocumento3 pagineToolbox Talk - Ladders: Planning and Assessment of RisksRedouan Lerhrissi100% (1)

- Craftsman 12-Inch Bandsaw ManualDocumento32 pagineCraftsman 12-Inch Bandsaw Manualottuser100% (1)

- Walking Work SurfacesDocumento8 pagineWalking Work SurfacesSb TeoNessuna valutazione finora

- Fall Protection GRP 4Documento9 pagineFall Protection GRP 4Ruben SibayanNessuna valutazione finora

- Scaffolding ProcedureDocumento3 pagineScaffolding Proceduremd ruman100% (2)

- Job Safety Analysis Construction, EtcDocumento3 pagineJob Safety Analysis Construction, EtcCamilo Salvadora MasbateNessuna valutazione finora

- Hse in Drilling OperationsDocumento13 pagineHse in Drilling OperationsSamad Ali Siddiqui100% (2)

- Durma Press Brake Safety32310Documento5 pagineDurma Press Brake Safety32310Ivan BaraćNessuna valutazione finora

- Ride On Roller ManualDocumento9 pagineRide On Roller ManualRonald AranhaNessuna valutazione finora

- Lathe Wood SopDocumento1 paginaLathe Wood SopLucas BienertNessuna valutazione finora

- Physhaz 0Documento3 paginePhyshaz 0Toka MohamedNessuna valutazione finora

- SWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanDocumento2 pagineSWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanHassan AbdullahNessuna valutazione finora

- ScaffoldingDocumento2 pagineScaffoldingroland magoNessuna valutazione finora

- Construction Site PremisesDocumento52 pagineConstruction Site PremisesAya AlmarioNessuna valutazione finora

- Trades Guidelines - Exterior FinishesDocumento6 pagineTrades Guidelines - Exterior FinishesMohammed AtefNessuna valutazione finora

- Scaffolding Safety TrainingDocumento25 pagineScaffolding Safety Trainingmt_powers100% (1)

- Ac Hd6 Hd11 A B e G ST CL ServiceDocumento80 pagineAc Hd6 Hd11 A B e G ST CL ServiceAntónio AbrunhosaNessuna valutazione finora

- 12 CabinetsFinishing Revised PDFDocumento6 pagine12 CabinetsFinishing Revised PDFMohammed AtefNessuna valutazione finora

- Safety PlanDocumento34 pagineSafety PlanJoeMarieValcarcelNessuna valutazione finora

- 7 Electrical PDFDocumento6 pagine7 Electrical PDFMohammed AtefNessuna valutazione finora

- Manual Craftman 10inch SawDocumento44 pagineManual Craftman 10inch SawGabriel DobrinoiuNessuna valutazione finora

- WeldingDocumento9 pagineWeldingLev ShouyoNessuna valutazione finora

- Topic: Hand & Power Tools, Subpart I: Sample Lesson Plan Construction Training Program (10-Hour)Documento4 pagineTopic: Hand & Power Tools, Subpart I: Sample Lesson Plan Construction Training Program (10-Hour)YeLah BauyonNessuna valutazione finora

- SWP - (LPG System)Documento7 pagineSWP - (LPG System)Md Shahin100% (1)

- EHS ProgramDocumento4 pagineEHS Programadrianalbacete75Nessuna valutazione finora

- Safety While Working at HeightsDocumento57 pagineSafety While Working at HeightsRísês Ãfröz100% (2)

- Use of Full Body Harness With LanyardDocumento3 pagineUse of Full Body Harness With LanyardSn Ahsan100% (1)

- The Full Body HarnessDocumento3 pagineThe Full Body HarnessroelNessuna valutazione finora

- Aerial LiftDocumento1 paginaAerial LiftasknishanNessuna valutazione finora

- SOPDocumento8 pagineSOPAilyn MercadoNessuna valutazione finora

- Working at HeightsDocumento2 pagineWorking at HeightsSusana BarriscoNessuna valutazione finora

- Powrpress Safety 1Documento40 paginePowrpress Safety 1PurveshPatelNessuna valutazione finora

- JHA Lifting-Moving Heavy Objects - ROMODocumento6 pagineJHA Lifting-Moving Heavy Objects - ROMOReza KurniawanNessuna valutazione finora

- ATT400 Operation Maint 241384Documento805 pagineATT400 Operation Maint 241384Hữu Dũng Nguyễn100% (8)

- ATT400 Parts 241384Documento767 pagineATT400 Parts 241384Nguyễn Hữu Dũng86% (7)

- Black and Decker Instruction ManualDocumento5 pagineBlack and Decker Instruction Manualava_lanaNessuna valutazione finora

- Maintenance Safety L3 Pre Ori 1.2Documento14 pagineMaintenance Safety L3 Pre Ori 1.2PROMISE JULIUSNessuna valutazione finora

- Working at Height PDFDocumento30 pagineWorking at Height PDFSibasis ParidaNessuna valutazione finora

- En UK SH410 Bruksanvisning ENGDocumento24 pagineEn UK SH410 Bruksanvisning ENGspaceskipperNessuna valutazione finora

- Aloft Overside Work PDFDocumento5 pagineAloft Overside Work PDFDank100% (1)

- JSA Working at Heights Mobile LadderDocumento3 pagineJSA Working at Heights Mobile LadderCristina RicanNessuna valutazione finora

- Risk Assesment of Tower CraneDocumento7 pagineRisk Assesment of Tower Cranekrmchari100% (1)

- Safety NoteDocumento7 pagineSafety NoteYounis KhanNessuna valutazione finora

- Risk Register: Hazards IdentifiedDocumento5 pagineRisk Register: Hazards IdentifiedthomasNessuna valutazione finora

- Craftsman Table SawDocumento40 pagineCraftsman Table SawdrdaverobertsNessuna valutazione finora

- Angle Grinder SOPDocumento1 paginaAngle Grinder SOPNhypz Marcaida67% (3)

- Preventing Injuries and Deaths From Skid-Steer LoadersDocumento20 paginePreventing Injuries and Deaths From Skid-Steer LoadersElvis Eberth Huanca MachacaNessuna valutazione finora

- Typ SWPDocumento12 pagineTyp SWPZaw Ko Ko OoNessuna valutazione finora

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocumento1 paginaScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilNessuna valutazione finora

- Aeroplane Flight Training: Lesson Plans for Students & Instructors With Questions - Plus a Lot MoreDa EverandAeroplane Flight Training: Lesson Plans for Students & Instructors With Questions - Plus a Lot MoreValutazione: 3 su 5 stelle3/5 (2)

- Revision History Control Valve Sizing WorksheetsDocumento3 pagineRevision History Control Valve Sizing WorksheetsbhuneshwarNessuna valutazione finora

- Appendix A of AC10Documento3 pagineAppendix A of AC10NakkolopNessuna valutazione finora

- DrillingDocumento9 pagineDrillingHakan ÖzkaraNessuna valutazione finora

- Design and Construction of Door Locking Security System Using GSMDocumento24 pagineDesign and Construction of Door Locking Security System Using GSMNakkolopNessuna valutazione finora

- Comparion Water ChillingDocumento1 paginaComparion Water ChillingNakkolopNessuna valutazione finora

- Price Comparison Template 22Documento4 paginePrice Comparison Template 22NakkolopNessuna valutazione finora

- Develve SupportDocumento1 paginaDevelve SupportNakkolopNessuna valutazione finora

- Cosmic Project Asphalt-1Documento1 paginaCosmic Project Asphalt-1NakkolopNessuna valutazione finora

- Estimated Project Cost of 5 MW Solar PV Power PlantDocumento1 paginaEstimated Project Cost of 5 MW Solar PV Power PlantRajeev GargNessuna valutazione finora

- LocationDocumento2 pagineLocationNakkolopNessuna valutazione finora

- Performance Formulas For Power PlantDocumento1 paginaPerformance Formulas For Power Plantmirza_anis100% (1)

- Jha New Format Painting Revision PDFDocumento8 pagineJha New Format Painting Revision PDFNakkolopNessuna valutazione finora

- Slab Punching Shear SpreadsheetDocumento8 pagineSlab Punching Shear SpreadsheetRaju ShresthaNessuna valutazione finora

- Book Wote ClimateDocumento47 pagineBook Wote ClimateNakkolopNessuna valutazione finora

- Jha New Format Painting Revision PDFDocumento8 pagineJha New Format Painting Revision PDFNakkolopNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Foto Condition Road Harian Bulan Februari 2017Documento1 paginaFoto Condition Road Harian Bulan Februari 2017NakkolopNessuna valutazione finora

- Jha New Format Painting Revision PDFDocumento8 pagineJha New Format Painting Revision PDFNakkolopNessuna valutazione finora

- WfbudgetDocumento8 pagineWfbudgetNakkolopNessuna valutazione finora

- Drop Shipment FlowDocumento4 pagineDrop Shipment FlowAmit ChauhanNessuna valutazione finora

- Jha New Format Painting Revision PDFDocumento8 pagineJha New Format Painting Revision PDFNakkolopNessuna valutazione finora

- Jha New Format Painting Revision PDFDocumento8 pagineJha New Format Painting Revision PDFNakkolopNessuna valutazione finora

- PdliceDocumento1 paginaPdliceNakkolopNessuna valutazione finora

- Pdlice SummaryDocumento1 paginaPdlice SummaryNakkolopNessuna valutazione finora

- PdliceDocumento1 paginaPdliceNakkolopNessuna valutazione finora

- Sun Form 5881 - A (6-14-04) PDFDocumento4 pagineSun Form 5881 - A (6-14-04) PDFNakkolopNessuna valutazione finora

- General Flange ChartDocumento4 pagineGeneral Flange ChartNakkolopNessuna valutazione finora

- Sea Water For HydrotestDocumento2 pagineSea Water For HydrotestNakkolopNessuna valutazione finora

- Sun Form 5881 - A (6-14-04) PDFDocumento4 pagineSun Form 5881 - A (6-14-04) PDFNakkolopNessuna valutazione finora

- Computer Name & IDDocumento1 paginaComputer Name & IDNakkolopNessuna valutazione finora

- 100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesDocumento3 pagine100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesPazhamalairajan KaliyaperumalNessuna valutazione finora

- WeldingDocumento27 pagineWeldingankit4565Nessuna valutazione finora

- Um DEDocumento56 pagineUm DEalvaroNessuna valutazione finora

- ANSWER MPSM Johor Kimia Kertas 3 Set 2 2018 PDFDocumento8 pagineANSWER MPSM Johor Kimia Kertas 3 Set 2 2018 PDFSiti Hajar Abd HamidNessuna valutazione finora

- Soil ImprovementDocumento49 pagineSoil Improvementbala rajeeNessuna valutazione finora

- Flowserve Durco CatalogDocumento36 pagineFlowserve Durco CatalogbryandownNessuna valutazione finora

- Partition ManualDocumento42 paginePartition ManualAnonymous SblBDN0Nessuna valutazione finora

- Architectural ConcreteDocumento24 pagineArchitectural ConcreteSaud PathiranaNessuna valutazione finora

- Rock Cycle Crayon LabDocumento4 pagineRock Cycle Crayon Labapi-251355123Nessuna valutazione finora

- Mechanical Designer Resume TemplateDocumento1 paginaMechanical Designer Resume TemplateHubertNessuna valutazione finora

- Samalkot Lab - (16-17 SSR) (Final)Documento161 pagineSamalkot Lab - (16-17 SSR) (Final)Phani PitchikaNessuna valutazione finora

- Product Life Cycle and LifeDocumento3 pagineProduct Life Cycle and LifejoelNessuna valutazione finora

- ARB220CW Tech SheetDocumento2 pagineARB220CW Tech SheetJohn TrippNessuna valutazione finora

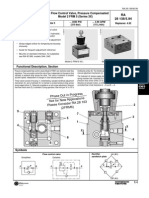

- 2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Documento4 pagine2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Dias EliNessuna valutazione finora

- Research (Edible Cutlery)Documento9 pagineResearch (Edible Cutlery)Reylsea MayNessuna valutazione finora

- Wiring Diagram SectionDocumento76 pagineWiring Diagram Sectiondavydenkoanton5Nessuna valutazione finora

- ST014 Sod - MetasilicateDocumento1 paginaST014 Sod - MetasilicateAreIf Cron BmxStreetNessuna valutazione finora

- UOP 1006-14 Trace Silicon in Petroleum Liquids by ICP-MSDocumento11 pagineUOP 1006-14 Trace Silicon in Petroleum Liquids by ICP-MSMorteza Sepehran100% (1)

- Sae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsDocumento3 pagineSae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsAnonymous 7ZTcBn100% (1)

- Dimethyl Ether SDS E4589Documento7 pagineDimethyl Ether SDS E4589Daniil GhilescuNessuna valutazione finora

- Clear Burn - E - BrochureDocumento21 pagineClear Burn - E - BrochureRamandeep SinghNessuna valutazione finora

- Recycle and Management of Waste Lead Acid BatteriesDocumento9 pagineRecycle and Management of Waste Lead Acid BatteriesJoyce Wm WongNessuna valutazione finora

- Conlit Firestop Systems Installation Method StatementDocumento2 pagineConlit Firestop Systems Installation Method StatementramtsanNessuna valutazione finora

- Pile ReportDocumento14 paginePile ReportChen E LikNessuna valutazione finora

- PW15AHDocumento6 paginePW15AHthiago weniskleyNessuna valutazione finora

- Binder 1Documento6 pagineBinder 1Andy SoxxNessuna valutazione finora

- Fired Heaters - Improving Energy Efficiency in FurnacesDocumento2 pagineFired Heaters - Improving Energy Efficiency in FurnacesReyes SanchezNessuna valutazione finora

- TeflonDocumento1 paginaTeflonSanthosh KumarNessuna valutazione finora

- MBDCDocumento2 pagineMBDCRachel RobinsonNessuna valutazione finora

- Aqua Mats 2005 SDFspecsheet R6Documento1 paginaAqua Mats 2005 SDFspecsheet R6indomie11Nessuna valutazione finora