Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Box of Shapes Toy: Project 18618EZ

Caricato da

BSulliDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Box of Shapes Toy: Project 18618EZ

Caricato da

BSulliCopyright:

Formati disponibili

Project 18618EZ:

Box of Shapes

Toy

The ability to recognize shapes is an important art of a child’s development. This

easy-to-make toy will help kids to learn several of the basic shapes — and have

some fun while they learn. Five different profiles are cut into the box, one in each

of the four sides and one in the top. The child is challenged to get the blocks in the

box, and that can only be done if the shape of the block matches the cutout. A

double ball catch keeps the hinged top shut until the youngster opens it to remove

the blocks.

Ours is made from poplar, a wood that is relatively light, yet durable. Maple,

which has excellent durability, is also a good choice. A piece of stock measuring

1/2" thick x 5-1/2" wide by 20" long will provide enough stock for the four sides

(A), while a piece that’s 1/2" thick x 5-1/2" wide x 11" long will suffice for the top

(C) and bottom (D). The width and length dimensions allow extra stock.

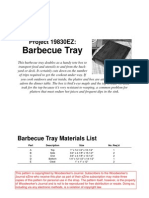

Box of Shapes Toy Materials List

Part Description Size No. Req’d

A Side 1/2" x 5" x 4-1/2" 4

B Spline 1/8" x 3/8" x 4-1/2" 4

C Top 1/2" x 5" x 5" 1

D Bottom 1/2" x 4-3/8" x 4-3/8" 1

E Catch Block 1/2" x 3/4" x 2" 1

F Double Ball Catch 5/16" x 1-11/16" 1

G Hinge 3/4" x 1" 2

H Trapezoid Block See detail. 1

I Triangle Block See detail. 1

J Circle Block See detail. 1

K Diamond Block See detail. 1

L Square Block See detail. 1

Box of Shapes Toy Complete Schematic

Box of Shapes Toy Step-by-Step Instruc-

tions

1. Cut the four sides (A) from the 20" long board.

2. Plane to correct thickness.

3. Set the table saw blade to 45 degrees.

4. Raise it to a height of about 3/4".

5. Set the rip fence to cut the miter along one edge of the 20" length. NOTE:

When setting the fence, keep in mind that it should be located so that,

after the miter is cut, the stock width is not less than 5".

6. Make just one miter cut.

7. Readjust the rip fence to establish the final stock width of 5".

8. Cut the second miter.

9. Lower the saw blade (which should still be set at 45 degrees).

10. Relocate the rip fence.

11. Use scrap stock to check the accuracy of your set-up. NOTE: Most saw

blades make a 1/8" wide cut; however, if your blade makes a slightly

wider or narrower cut, simply adjust the spline (B) thickness as needed.

12. Cut the spline groove. NOTE: Cut the splines a little on the long side so

that after the glue dries, they can be trimmed flush with the ends of the

sides.

13. Crosscut the stock into four pieces, each piece measuring 4-1/2" long.

14. Cut the dado groove along the bottom edge of each side (see bottom detail).

15. Set up the table saw with a 1/4" dado head cutter set to a depth of 1/4".

16. Locate the rip fence 1/4" from the nearest tooth.

17. Hold the stock firmly against the rip fence as you use a push stick to move it

over the cutter, being sure to keep your hands a safe distance from the

blade.

18. Use a push stick to keep hands a safe distance from the blade.

19. Cut the bottom to 4-3/8" square. NOTE: The 1/2" x 5-1/2" x 11" board

that was made earlier will serve as stock for the top and bottom.

20. Cut the 1/4" x 1/4" rabbet all around.

21. Make the top so that it is 5" square.

22. Use a router table and a 1/4" cove bit to cut the 1/4" radius cove on the front

edge.

23. Lay out and mark the five shapes on the four sides and the top.

24. Use a sharp chisel to cut out each one except the circle.

25. Use a Forstner bit or hole saw to make the circle.

26. Assemble the sides and the bottom with glue, then clamp firmly.

27. Use the router table and 1/4" cove bit once again to add a cove, this time

along the top edge of the front.

28. Attach the top to the box with a pair of hinges (G).

29. Add the catch block (E) and the double ball catch (F) to complete the work

on the box.

30. Make the five blocks (H, I, J, K, and L) as shown.

31. Make the circle block (J) so it can be turned to the 1-1/2" diameter.

32. Sand each part, taking care to round over all sharp edges and corners to a

generous (about 3/16") radius.

33. Leave unfinished.

These plans were originally published in Volume 10, Issue 4 of The Woodworker’s

Journal (July/Aug. 1986, pages 46-47).

Potrebbero piacerti anche

- Recipe Box: Project 15193EZDocumento5 pagineRecipe Box: Project 15193EZBSulli100% (1)

- Wireless Stereo Speaker Box: Project PlanDocumento8 pagineWireless Stereo Speaker Box: Project PlancajemarNessuna valutazione finora

- Stacking Desk Tray: Project 19874EZDocumento4 pagineStacking Desk Tray: Project 19874EZBSulliNessuna valutazione finora

- Wood-And-Epoxy Topped Jewelry Cabinet: Project PlanDocumento13 pagineWood-And-Epoxy Topped Jewelry Cabinet: Project Plancajemar100% (1)

- How To Build A CrateDocumento15 pagineHow To Build A CrateMuhammad LukmanNessuna valutazione finora

- Black Panther AmigurumiDocumento11 pagineBlack Panther Amigurumitisaderma100% (4)

- Pine Desk Organizer: Project 13782EZDocumento6 paginePine Desk Organizer: Project 13782EZBSulli100% (1)

- A Collection of Woodwork Patterns for the Making of Children's ToysDa EverandA Collection of Woodwork Patterns for the Making of Children's ToysNessuna valutazione finora

- Chest of Drawers: Project 11819EZDocumento7 pagineChest of Drawers: Project 11819EZBSulli100% (1)

- Ultimate WorkbenchDocumento8 pagineUltimate WorkbenchEric Gruff0% (1)

- Writing Desk: Project 13586EZDocumento7 pagineWriting Desk: Project 13586EZBSulliNessuna valutazione finora

- Writing Desk: Project 13586EZDocumento7 pagineWriting Desk: Project 13586EZBSulliNessuna valutazione finora

- WoodPlans Online - Crown Molding BoxesDocumento9 pagineWoodPlans Online - Crown Molding BoxesЧедомир Арнаут100% (9)

- Router Bit Box: Project 20261EZDocumento6 pagineRouter Bit Box: Project 20261EZBSulliNessuna valutazione finora

- Pine Cabinet: Project 11142EZDocumento5 paginePine Cabinet: Project 11142EZBSulliNessuna valutazione finora

- Pine Cabinet: Project 11142EZDocumento5 paginePine Cabinet: Project 11142EZBSulliNessuna valutazione finora

- Plans: Anel AWDocumento11 paginePlans: Anel AWElysita Macedo SalvadorNessuna valutazione finora

- Tool Steel Grade and Standard DesignationDocumento7 pagineTool Steel Grade and Standard DesignationMustafa SevimliNessuna valutazione finora

- U-Bild: Animal ArkDocumento8 pagineU-Bild: Animal ArkEmilian BalutaNessuna valutazione finora

- Computer WorkstationDocumento8 pagineComputer Workstation- yAy3e -100% (1)

- EZStoolDocumento4 pagineEZStoolBSulliNessuna valutazione finora

- Router Bit Box 2 PartesDocumento11 pagineRouter Bit Box 2 Partesapi-3830394100% (1)

- Workshop Tote Box: Project 20466EZDocumento3 pagineWorkshop Tote Box: Project 20466EZBSulli100% (1)

- Otting Bench: Special Tools and TechniquesDocumento11 pagineOtting Bench: Special Tools and TechniquesFe TusNessuna valutazione finora

- Cerberus Plush Embroidery InstructionsDocumento6 pagineCerberus Plush Embroidery InstructionsRaisa OliveiraNessuna valutazione finora

- Plans Secret Jewelry BoxDocumento7 paginePlans Secret Jewelry Boxkincas100% (2)

- Record and Tape Cabinet: Project 11185EZDocumento8 pagineRecord and Tape Cabinet: Project 11185EZBSulliNessuna valutazione finora

- Record and Tape Cabinet: Project 11185EZDocumento8 pagineRecord and Tape Cabinet: Project 11185EZBSulliNessuna valutazione finora

- BD Guide To Making Jewelry PDFDocumento27 pagineBD Guide To Making Jewelry PDFErick John ElominaNessuna valutazione finora

- CNC Machine DetailsDocumento13 pagineCNC Machine DetailsHariharan VenkatesanNessuna valutazione finora

- Three Tiered Childrens ShelfDocumento5 pagineThree Tiered Childrens ShelfMaricruz Valdivieso de PalaciosNessuna valutazione finora

- Kids Toy ShelfDocumento6 pagineKids Toy ShelfalphyshorNessuna valutazione finora

- Parsons TableDocumento3 pagineParsons Table- yAy3e -100% (1)

- 2019 04 01 Inspirations XXXDocumento98 pagine2019 04 01 Inspirations XXXcuentah12100% (2)

- Shop Workstation: Project 20569EZDocumento3 pagineShop Workstation: Project 20569EZBSulliNessuna valutazione finora

- Shop Workstation: Project 20569EZDocumento3 pagineShop Workstation: Project 20569EZBSulliNessuna valutazione finora

- Ingerie Resser LAN: PlansDocumento10 pagineIngerie Resser LAN: PlansGsmHelpNessuna valutazione finora

- Country Curio Clock: Project 12231EZDocumento7 pagineCountry Curio Clock: Project 12231EZBSulliNessuna valutazione finora

- Wall-Hung Telephone Cabinet: Project 11257EZDocumento6 pagineWall-Hung Telephone Cabinet: Project 11257EZBSulli100% (1)

- Bookcase With Toy StorageDocumento8 pagineBookcase With Toy StorageANTONIO SAENZNessuna valutazione finora

- Wall Hung Magazine and Book Rack: Project 14211EZDocumento3 pagineWall Hung Magazine and Book Rack: Project 14211EZBSulliNessuna valutazione finora

- Porch Swing: Project 16258EZDocumento5 paginePorch Swing: Project 16258EZBSulli100% (1)

- The Pochade and Wet Panel Carrier Do It Yourself PlanDa EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanValutazione: 4 su 5 stelle4/5 (1)

- Trestle Table and Benches: Project 18444EZDocumento5 pagineTrestle Table and Benches: Project 18444EZAndre GaioNessuna valutazione finora

- Early American Step Table: Project 18321EZDocumento4 pagineEarly American Step Table: Project 18321EZBSulliNessuna valutazione finora

- Veneered End Table: Project 17901EZDocumento4 pagineVeneered End Table: Project 17901EZBSulliNessuna valutazione finora

- 4 X 4 Off RoaderDocumento6 pagine4 X 4 Off Roaderhulusi67Nessuna valutazione finora

- Leg Tapering Jig: Project 14585EZDocumento5 pagineLeg Tapering Jig: Project 14585EZBSulliNessuna valutazione finora

- Leg Tapering Jig: Project 14585EZDocumento5 pagineLeg Tapering Jig: Project 14585EZBSulliNessuna valutazione finora

- Ultiple Planter: Special TechniquesDocumento7 pagineUltiple Planter: Special Techniqueskosta vidaliNessuna valutazione finora

- Wooden Coat Hanger: Project 16474EZDocumento3 pagineWooden Coat Hanger: Project 16474EZBSulliNessuna valutazione finora

- DIY Writing DeskDocumento7 pagineDIY Writing DeskStephen MooreNessuna valutazione finora

- Wood Working Plans - Toys - Rocking Horse PDFDocumento6 pagineWood Working Plans - Toys - Rocking Horse PDFBen GerezNessuna valutazione finora

- Rolling Toy: Project 19376EZDocumento3 pagineRolling Toy: Project 19376EZBSulliNessuna valutazione finora

- Country Bench: Project 10307EZDocumento8 pagineCountry Bench: Project 10307EZBSulliNessuna valutazione finora

- Wireless Speaker Box: Project PlanDocumento7 pagineWireless Speaker Box: Project PlancajemarNessuna valutazione finora

- Minnie Mouse Amigurumi: Materials KeyDocumento8 pagineMinnie Mouse Amigurumi: Materials KeyCamiloCruz100% (1)

- Mesa de JardinDocumento5 pagineMesa de JardinDisho1934Nessuna valutazione finora

- Paper Towel HolderDocumento5 paginePaper Towel HoldermchiovettaNessuna valutazione finora

- Chess Table: Project 18732EZDocumento4 pagineChess Table: Project 18732EZfuel4hatredNessuna valutazione finora

- ParquetDocumento4 pagineParquetFernando FrayreNessuna valutazione finora

- Building Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeDa EverandBuilding Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeNessuna valutazione finora

- Woodworking Plans - Chesstable PDFDocumento4 pagineWoodworking Plans - Chesstable PDFInform7105Nessuna valutazione finora

- Screw Less ViseDocumento4 pagineScrew Less ViseAmi JohnstonNessuna valutazione finora

- U-Bild: Three-Piece Bedroom SetDocumento8 pagineU-Bild: Three-Piece Bedroom SetEmilian BalutaNessuna valutazione finora

- Yashica FX-D Se PDFDocumento46 pagineYashica FX-D Se PDFheraasku7194Nessuna valutazione finora

- Build A Toy BoxDocumento10 pagineBuild A Toy BoxkhunchaiyaiNessuna valutazione finora

- NetShape MIM Design GuideDocumento13 pagineNetShape MIM Design Guidegnk68Nessuna valutazione finora

- MPI 2023 - CNC Machining - LatheDocumento15 pagineMPI 2023 - CNC Machining - LatheHisyamRedzuanNessuna valutazione finora

- Amigurumi Cactus Pincushion Pattern - Amigurumi TodayDocumento4 pagineAmigurumi Cactus Pincushion Pattern - Amigurumi TodayFaby Ro75% (4)

- Duck Pull Toy: Project 19247EZDocumento3 pagineDuck Pull Toy: Project 19247EZBSulliNessuna valutazione finora

- Chess Table: Project 18732EZDocumento4 pagineChess Table: Project 18732EZwoodsmithcaNessuna valutazione finora

- Project 18732EZDocumento4 pagineProject 18732EZBSulliNessuna valutazione finora

- Poker Chip BoxDocumento2 paginePoker Chip Box- yAy3e -Nessuna valutazione finora

- Old World Weather Forecaster: Project 14438EZDocumento10 pagineOld World Weather Forecaster: Project 14438EZBSulli100% (1)

- Woodworks - 103-Blanket ChestDocumento10 pagineWoodworks - 103-Blanket ChestzdejotaNessuna valutazione finora

- U-Bild: Curio TableDocumento5 pagineU-Bild: Curio TableEmilian BalutaNessuna valutazione finora

- Flip Top Tool Cart PlansDocumento11 pagineFlip Top Tool Cart PlansMatthew CittaNessuna valutazione finora

- Barbecue Tray: Project 19830EZDocumento4 pagineBarbecue Tray: Project 19830EZRafishfullNessuna valutazione finora

- Barbecue Tray: Project 19830EZDocumento4 pagineBarbecue Tray: Project 19830EZBSulliNessuna valutazione finora

- Barbecue Tray: Project 19830EZDocumento4 pagineBarbecue Tray: Project 19830EZneilradcliffe3618Nessuna valutazione finora

- Kangaroo Pull Toy: Project 19272EZDocumento4 pagineKangaroo Pull Toy: Project 19272EZagustinrubio7946Nessuna valutazione finora

- Drill Press Organizer: Project 20068EZDocumento5 pagineDrill Press Organizer: Project 20068EZBSulli100% (1)

- U-Bild: Hope ChestDocumento6 pagineU-Bild: Hope ChestEmilian BalutaNessuna valutazione finora

- Project 18732EZDocumento4 pagineProject 18732EZBSulliNessuna valutazione finora

- Rope Whipping SheetDocumento6 pagineRope Whipping SheetBSulliNessuna valutazione finora

- Ez Shaker WashstandDocumento7 pagineEz Shaker WashstandBrian-Patty SullivanNessuna valutazione finora

- Workbench Helper: Project 20518EZDocumento3 pagineWorkbench Helper: Project 20518EZBSulliNessuna valutazione finora

- Wooden Combs: Project 16483EZDocumento3 pagineWooden Combs: Project 16483EZBSulliNessuna valutazione finora

- Shaker Single Drop Leaf TableDocumento6 pagineShaker Single Drop Leaf TableLory Dena HeathNessuna valutazione finora

- Carved Walking Stick: Project 16695EZDocumento3 pagineCarved Walking Stick: Project 16695EZBSulli100% (2)

- Valentine Box: Project 10766EZDocumento5 pagineValentine Box: Project 10766EZBSulliNessuna valutazione finora

- Weather Station: Project 14445EZDocumento4 pagineWeather Station: Project 14445EZBSulliNessuna valutazione finora

- EZTowelbar W Glass ShelfDocumento2 pagineEZTowelbar W Glass ShelfBSulliNessuna valutazione finora

- EZVeneer BraceletDocumento3 pagineEZVeneer BraceletBSulliNessuna valutazione finora

- EZTenon JigDocumento3 pagineEZTenon JigBSulliNessuna valutazione finora

- EZSalad TongsDocumento3 pagineEZSalad TongsBSulliNessuna valutazione finora

- Shaker Sewing TableDocumento21 pagineShaker Sewing TableFeng Shu jiNessuna valutazione finora

- EZRouted BookendsDocumento3 pagineEZRouted BookendsBSulliNessuna valutazione finora

- Types of Press Tools: January 2012Documento6 pagineTypes of Press Tools: January 2012Vasanth MNessuna valutazione finora

- ProductionDocumento78 pagineProductionsreerag786Nessuna valutazione finora

- Transferware Collectors Club Bulletin One 2013Documento5 pagineTransferware Collectors Club Bulletin One 2013RichardHallidayNessuna valutazione finora

- Manufacturing TechnologyDocumento37 pagineManufacturing TechnologyHoàng MinhNessuna valutazione finora

- Permanent Residents Photograph Specifications: Take This Specification Sheet With You To The PhotographerDocumento1 paginaPermanent Residents Photograph Specifications: Take This Specification Sheet With You To The PhotographeranusgeorgeNessuna valutazione finora

- Atm-1022 Mechanical Workshop Module 3 PDFDocumento19 pagineAtm-1022 Mechanical Workshop Module 3 PDFMohamed Sayed Abdel GaffarNessuna valutazione finora

- Innovation in Making Mens Suits With Tailor Combination MethodDocumento25 pagineInnovation in Making Mens Suits With Tailor Combination MethodT StyleNessuna valutazione finora

- Lavanya Industries Company Profile - Tools Jigs Fixture - EkkatuthangalDocumento11 pagineLavanya Industries Company Profile - Tools Jigs Fixture - EkkatuthangalpmlmkpNessuna valutazione finora

- K-Faktor-Berechnung: (Nach DIN 6935)Documento4 pagineK-Faktor-Berechnung: (Nach DIN 6935)Laws HackerNessuna valutazione finora

- Series: Ultra High Performance Vertical Machining CenterDocumento20 pagineSeries: Ultra High Performance Vertical Machining Centerwataneta valveNessuna valutazione finora

- Parts ListDocumento18 pagineParts ListRobin Dario Noriega CastañoNessuna valutazione finora

- Data Sheet 159 Hardox 600Documento3 pagineData Sheet 159 Hardox 600Ehab Attia SelimNessuna valutazione finora

- Shop Excercise 6Documento18 pagineShop Excercise 6Athena GrotesqueNessuna valutazione finora

- AccurTool Press Brake Tool CatalogueDocumento66 pagineAccurTool Press Brake Tool CatalogueJiang KatieNessuna valutazione finora

- Analisa Harga MaterialDocumento5 pagineAnalisa Harga MaterialAgungNugrohoNessuna valutazione finora

- Rippled Baby BlanketDocumento2 pagineRippled Baby BlanketCraftsman33100% (6)

- Lee Bench Plate ManualDocumento1 paginaLee Bench Plate Manualbmichelotto2Nessuna valutazione finora

- 1 52Documento52 pagine1 52jl_arvizoNessuna valutazione finora