Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Parametric Study of Rotor Slot Shape On A Cage Induction Motor

Caricato da

vishiwizardTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Parametric Study of Rotor Slot Shape On A Cage Induction Motor

Caricato da

vishiwizardCopyright:

Formati disponibili

PARAMETRIC STUDY OF ROTOR SLOT SHAPE

ON A CAGE INDUCTION MOTOR

Vicente Aucejo Galindo

(1)

, Xose M. Lpez-Fdez

(2)

, J.A. Dias Pinto

(3)

and A. Paulo Coimbra

(4)

(1)

INDIELEC - Ingeniera de Diseo Electrotcnico, Valencia Spain, vaucejo@indielec.es

(2)

Dept. of Electrical Engineering, Vigo University Spain, xmlopez@ieee.org

(3)

ISR/Instituto Superior de Engenheria de Coimbra (ISEC), Coimbra Portugal, j.pinto@ieee.org,

(4)

ISR/Dept. of Electrical Engineering, Coimbra University Portugal, acoimbra@dee.uc.pt

Abstract - In this work the use of the parameterisation in the study of the geometric redesign of the rotor

slots on a cage induction motors is presented. A magnetodynamic model of finite elements was developed

in order to obtain new performance curves. The results are obtained from an industrial 90-kW 4-pole

three-phase double-squirrel cage motor.

Introduction

Usually the rotor slots geometry can be considered as an independent design parameter [1].

Nowadays, with the computing tools based on the numerical analysis, it is possible the redesigning of

the rotor slots to improve the electromagnetic performance of squirrel cage induction motors without

significant cost [2]. Therefore, formal methods can be adequate to modify geometric parameters of the

rotor slots until the optimal performance is achieved.

This work presents the results of a parametric study of the geometry of the rotor slots on an 4-

pole three-phase double-squirrel cage large induction motor. For this purpose a magnetodynamic

model using a finite element software package was developed [3]. In the implementation of the model

it was taken into account both the presence of external circuits supplied by voltage sources as well as

the motor's end-rings resistance and inductance [4].

Description of the problem

The aim of the present work is to improve the performance of a previous motor design at

starting while the nominal performance is maintained. This is accomplished by increasing locked-rotor

torque and lowering locked-rotor current.

In fact, the rotor resistance has the effect of shaping the speed-torque curve, which is largely

independent of stator design [1]. If the cross-section area of the end-rings is limited by mechanical

restrictions, the rotor bar resistance offers the possibility to adjust the rotor tooth width as well as the

rotor depth below the slot [2]. In order to achieve this goal, the numeric approach proposed by the

authors is to seek the improved performance by redesigning the rotor slots. This is performed by

automatically modifying the parameterised geometry within a given rotor bar cross-sectional area.

Strategy to parameterise the rotor slot

Some insights into the possibilities for redesigning rotor slots may be gained by considering

their cross-sectional areas [2]. To explore this, the expression for output power can be examined:

s

r

'

2

2 '

2

out

s

R I 3

P

= (1)

Where R'

2

is the rotor resistance and I

2

is the rotor current, both referred to the stator,

s

is the angular

frequency of the stator supply,

r

is the angular frequency of the rotor and s is the slip.

At nominal load, the rotor resistance is approximately proportional to the inverse of the bar

cross-sectional area, if the end-rings resistance is neglected. Consequently the following expression

will arise:

s out

r

2 '

2

'

2

n

n

b

b

P

I 3

R

s

s

l

A

(2)

Where s

n

is the nominal load slip, l

b

is the length of the bar, is the aluminium conductivity and A

b

is

the total bar cross-sectional area. If the number of the poles, supply frequency, voltage and output

power do not change, then the terms on the right-hand side of equation (2) are practically constant.

Therefore, in order to maintain the performance under nominal load the following is considered:

A

b

constant (3)

Another important consideration with double-cage is the role that the top slot plays on locked-

rotor skin-depth, and consequently on the locked-rotor torque value. With the locked-rotor the torque

is approximately given by equation (4).

s

'

o 2

2

o

o

R I 3

T

(4)

Where R'

2o

is the locked-rotor resistance and I

0

is the locked-rotor current, both referred to the stator.

Neglecting rotor end-rings, R'

2o

is inversely proportional to the locked-rotor skin-depth area A

b

. So it

yields:

constant

I

T A

2 '

o

o b

From the above description, A

b

must be decreased in order to increase the locked rotor torque

and decrease the locked rotor current. Meanwhile, the total cross-sectional area A

b

, must be practically

constant in order to keep the nominal performance.

Parameterisation of the rotor slot

The parameterisation of the rotor slot is based on the previous slot shape shown in Fig.1. The

chosen geometric parameters are: the radius r

1

, r

2

and r

3

, the width w

1

, and the depths d

1

, d

2

and d

3

.

The authors have adopted a compromise between the need to optimise the slot shape and the

time required to perform this study. According with this time constrains, the depths (d

1

,d

2

), the width

(w

1

) and the radius (r

3

) are deemed to be fixed. So, the AREA_3 should be a constant value and there are

three possible variable parameters to redesign the slot (r

1

, r

2

, d

3

). The radius r

1

is chosen as a

parameter dependent on the depth d

3

and on the radius r

2

by means of the AREA_1 value (see Fig.1),

since the total cross-sectional area of the slot A

b

should be a constant value. From the mentioned, a

relationship between cross-sectional areas is obtained:

AREA_1 = Ab (AREA_2 + AREA_3) = Ab ((0.5 (r

2

2

+ r

3

2

) + (r

2

+ r

3

) d

3

) + AREA_3) (5)

Fig.1. Geometric parameterisation.

The depth d

3

and the radius r

2

are finally two independent parameters, which are used in the

following sections.

Model of the motor

Nowadays, the used numerical methods and mainly FEA allow to simulate the influence of the

rotors geometrical parameters on motor's performance characteristics. FEM offers the possibility of

relating the global electrical, mechanical and local electromagnetic quantities, with a particular

geometric shape.

In this work, a 2D finite elements software package (Flux2D) was employed to simulate the

magnetodynamic performance of the motor. The motors voltage supply is modelled by an external

circuit also taking into account the rotor squirrel cage characteristics [3].

Field model of the induction motor

The magnetic field of the induction motor is computed using a 2D FEM and assuming an AC

non-linear problem [4]. This approach enables to study the influence of the rotor bars geometric shape

on the motor`s operating characteristics (torque and current vs. slip). The electromagnetic field model

in the magnetodynamic problems is based on the Maxwell's equations and on the concept of magnetic

vector potential. As known, in 2D problems the diffusion equation (6) provides the means to calculate

the induced bar currents in the rotor cage.

J A s j A

1

s

+ =

(6)

Where A is the magnetic vector potential (unknown), is the electrical conductivity,

s

is the

angular frequency of the stator supply, s is the slip, is the magnetic permeability and J is the

current density supplied by external voltage sources.

The natural excitation for finite element models is usually a current (or current density). In the

real motor the current is normally unknown since it is supplied by an external electric circuit.

Therefore, the external electric circuit which supplies with voltage V must be modelled as coupled to

the 2D FE model [4].

The current i in a stranded coil of the field model can be expressed as follows :

(7)

+ = e S

dt

di

L i R V S

N l

c

2

i

e

t

et

r

3

r

2

1 _ AREA

1

r =

AREA_2

AREA_3

d

3

d

2

d

1

w

1

AREA_1 = A

b

- (AREA_2 + AREA_3)

AREA_1

Where R

et

is the end-turn resistance, L

et

is the end-turn inductance, N is the coil turns, S is the cross-

sectional area where i flows, l

c

is the length of the strand coil and e is the induced e.m.f. on the strand

coil. This induced e.m.f. on a coil (S

+

,S

-

) can be expressed as follows:

(8)

Geometry of the model

In order to reduce the computation time it is necessary to apply Dirichlet and Neumann

conditions taking into account the symmetries of the geometry as well as the field periodicity that

arises in the rotating electrical machines. Fig.2 (a) shows the outline of the problem which corresponds

to one pole pitch.

Fig.2 a) Geometry of the model. b) Electric circuit model.

External electric circuit

The used electromagnetic field model considers a coupling to an external electric circuit in order

to represent the external voltage sources. Fig.2 (b) shows the external electrical connections used for

the induction motors. Each horizontal branch represents the respective active conductors of a coil of a

phase winding. These elements are modelled including winding turns and the resistance to relate with

the region in the domain of finite elements. The inductance which appear in the external circuit

represents the correspondent front and back end-turns of each coil. The related circuit shows one pole

pitch. The symbolic squirrel cage is a macro component that Flux2D model including solid conductors

to represent the rotor bars and the end-rings resistance and end rings inductance.

Practical application

The manufacturers motor characteristics are presented in Table I. Flux2D software package

allows to create parameterised geometry in two dimensions and a finite element mesh in an entirely

interactive way. The finite element mesh used in this study has 12500 nodes and 6800 second order

elements, see Fig.3 (a). This mesh is the result of the combination of triangular and quadrilateral

elements. Fig.3 (b) shows the five slot shapes analysed considering different values for the two

variable geometric parameters (r

2

, d

3

) shown in Table II.

a) b)

=

+

S

t

A

S

t

A

S

l

c

e

S S

Results

Fig.4 shows the magnetic flux lines distribution at locked-rotor starting and under nominal load.

Fig.5 shows the results of the numerical simulation (electromagnetic torque and the rotor bar current

vs. slip characteristics) for different slip values (from 0 up to 1). To evaluate the torque the virtual

work method was used.

Fig.3. a) Mesh of the model. b) Resultant slots with the Table II values.

(0) (+r

2

) (+d

3

) (-r

2

) (-d

3

)

(b)

(a)

Table I. Motor characteristics.

Power (kW) 90

Line voltage (V) 400

Line current (A) 168

Connection type Y

Frequency (Hz) 50

Number of poles 4

Number of stator slots 48

Number of rotor bars 40

Efficiency 95 %

Power factor 0.83

Table II. Values of the variable geometric parameters.

Rotor slot types r

2

d

3

r

1

Original (0) 4.005 mm 29 mm 4 mm

(+) Increment d

3

(+d

3

) 4.005 mm (29+4) mm 2.944 mm

() Decrement d

3

(d

3

) 4.005 mm (294)mm 4.824 mm

(+) Increment r

2

(+r

2

) (4.005+0.5) mm 29 mm 3.721 mm

() Decrement r

2

(r

2

) (4.0050.5) mm 29 mm 4.225 mm

Conclusions

In this paper it has been described a strategy to parameterise geometrically the rotor slot shape.

It has been applied on a large double-squirrel cage induction motor in order to seek to improve

performance of the motor at starting by redesigning the rotor slots shape. The described strategy shows

an easy way to implement the redesign of the rotor slot shape without manufacture additional cost.

The paper has outlined the capability of the actual computing tools based on 2D finite elements

coupled to electrical circuit model taking into account 3D effects, as well as the external supply

voltage sources.

References

[1] R. H. Engelmann and W. H. Middendorft, "Handbook of Electric Motors", New York: Marcel Dekker, 1995.

[2] Stephen Williamson and Catherine I. McClay. "Optimization of the Geometry of Closed Rotor Slots for Cage

Induction Motors, "IEEE Trans. on Industry Applications, vol. 32, no. 3, pp. 560-568, May/J une 1996.

[3] FLUX Users guide. Cedrat, Meylan. France 2001.

[4] K. Hameyer and R. Belmans, "Numerical Modelling and Design of Electrical Machines and Devices",

Boston: WIT Press, 1999.

(a) (b)

Fig.4. Equiflux distribution a) At locked-rotor starting. b) At nominal load.

Fig.5. Numerical results vs. slip. a) Stator current p.u. b) Torque, percent of rated full-load torque.

0

50

100

150

200

0 0,2 0,4 0,6 0,8 1

s

% M/M

n

(-d

3

)

(-r

2

)

(+d

3

) (+r

2

)

(0)

(+d

3

) (+r

2

)

(-r

2

)

(-d

3

)

(0)

0

1

2

3

4

0 0,2 0,4 0,6 0,8 1

s

I/I

n

Potrebbero piacerti anche

- Quantum Energy Generator - Free Energy Device BlueprintsDocumento35 pagineQuantum Energy Generator - Free Energy Device Blueprintsenerchi111181% (16)

- Fault Code 432 Accelerator Pedal or Lever Idle Validation Circuit - Out of CalibrationDocumento10 pagineFault Code 432 Accelerator Pedal or Lever Idle Validation Circuit - Out of CalibrationAhmedmahNessuna valutazione finora

- Generator Relay SettingsDocumento22 pagineGenerator Relay SettingsKuntal Satpathi90% (10)

- Fundamentals of Automotive Electricity & ElectronicsDocumento81 pagineFundamentals of Automotive Electricity & ElectronicsJohnny YmNessuna valutazione finora

- Economic Design of Sleeve Rotor InductioDocumento10 pagineEconomic Design of Sleeve Rotor InductioIraqi stormNessuna valutazione finora

- A Design Method For Cage Induction Motors With Non-Skewed Rotor BarsDocumento2 pagineA Design Method For Cage Induction Motors With Non-Skewed Rotor BarsLava KumarNessuna valutazione finora

- 1 Calculul Parametrilor PM U PDFDocumento11 pagine1 Calculul Parametrilor PM U PDFAnonymous vJbt0ARNessuna valutazione finora

- 1WCE2009 pp435-440Documento6 pagine1WCE2009 pp435-440Noureddine BounaslaNessuna valutazione finora

- G Owacz - V13i2 - 6mathematical Model of DC Motor For Analysis of Commutation ProcesseDocumento4 pagineG Owacz - V13i2 - 6mathematical Model of DC Motor For Analysis of Commutation ProcesseDante GuajardoNessuna valutazione finora

- Extreme Possibilities of Circuital Models of Electric MachinesDocumento10 pagineExtreme Possibilities of Circuital Models of Electric Machinesmherold2Nessuna valutazione finora

- 001 Bien KowskiDocumento5 pagine001 Bien KowskikarnatisharathNessuna valutazione finora

- Submersible Induction Motor Design OptimizationDocumento42 pagineSubmersible Induction Motor Design OptimizationBhargav SuvagiyaNessuna valutazione finora

- Progress in Electromagnetics Research M, Vol. 8, 163-180, 2009Documento18 pagineProgress in Electromagnetics Research M, Vol. 8, 163-180, 2009Carlos NúñezNessuna valutazione finora

- Applied ElectromagneticsDocumento269 pagineApplied ElectromagneticsNur Amiera SyuhadhaNessuna valutazione finora

- Vibration Calculations in A Electric MotorDocumento14 pagineVibration Calculations in A Electric MotorSantiago MolinaNessuna valutazione finora

- Pebn009 Sizing of Electrical Machines PDFDocumento2 paginePebn009 Sizing of Electrical Machines PDFvishiwizardNessuna valutazione finora

- Modeling Induction Motors: Abstract: in This Paper, A Novel Technique For On-Line Estimation of MostDocumento10 pagineModeling Induction Motors: Abstract: in This Paper, A Novel Technique For On-Line Estimation of Mostseshubabu_999Nessuna valutazione finora

- Practical Induction 01Documento5 paginePractical Induction 01sathishNessuna valutazione finora

- Design Methodology of A Permanent MagnetDocumento10 pagineDesign Methodology of A Permanent MagnetJian ZhangNessuna valutazione finora

- Analysis of Brushless Three-Phase Synchronous Generator Without ExciterDocumento10 pagineAnalysis of Brushless Three-Phase Synchronous Generator Without ExciterJuan Andres Rojas SerranoNessuna valutazione finora

- Mathematical Driving Model of Three Phase Induction Motors in Stationary Coordinate FrameDocumento11 pagineMathematical Driving Model of Three Phase Induction Motors in Stationary Coordinate Framegodspower brunoNessuna valutazione finora

- Improved Design For Reduction of Torque Ripple of Brushless DC MotorDocumento4 pagineImproved Design For Reduction of Torque Ripple of Brushless DC MotorPhạm Văn TưởngNessuna valutazione finora

- Ems FNLXM A99 ADocumento13 pagineEms FNLXM A99 AdalbaasNessuna valutazione finora

- Instantaneous Magnetic Field Distribution in Brushless Permanent Magnet DC Motors, Part 111: Effect of Stator SlottingDocumento9 pagineInstantaneous Magnetic Field Distribution in Brushless Permanent Magnet DC Motors, Part 111: Effect of Stator SlottingjececioNessuna valutazione finora

- Development of Axial Flux HTS Induction Motors: International Meeting of Electrical Engineering Research ENIINVIE-2012Documento10 pagineDevelopment of Axial Flux HTS Induction Motors: International Meeting of Electrical Engineering Research ENIINVIE-2012Nilton Ramos EstebanNessuna valutazione finora

- Simulation and Analysis Calculation of PMBLDCM Based On Time-Stepping Finite Element and Matlab MethodsDocumento4 pagineSimulation and Analysis Calculation of PMBLDCM Based On Time-Stepping Finite Element and Matlab Methodsபொன்னியின் செல்வன்Nessuna valutazione finora

- The Analytical Approaches To Calculation of Electric Machines On The Basis of The Annular Domains Boundary Problems Solution by The Method of Fourier Variables SeparationDocumento38 pagineThe Analytical Approaches To Calculation of Electric Machines On The Basis of The Annular Domains Boundary Problems Solution by The Method of Fourier Variables Separationni60Nessuna valutazione finora

- Inductances LD LQ Reluctance: The and MachinesDocumento7 pagineInductances LD LQ Reluctance: The and MachinesHERNAN ALONSO BRAVO URREANessuna valutazione finora

- DC MachineDocumento33 pagineDC MachineJevon WilsonNessuna valutazione finora

- Brushless Permanent Magnet Motor DesignDocumento12 pagineBrushless Permanent Magnet Motor DesignAbi PutraNessuna valutazione finora

- Analysis of Axial Flux MotorDocumento4 pagineAnalysis of Axial Flux MotorAvi GuptaNessuna valutazione finora

- Torque Production in Permanent-MagnetDocumento6 pagineTorque Production in Permanent-MagnetTien Dung TranNessuna valutazione finora

- Geometrija UMDocumento7 pagineGeometrija UMMarina StevanovicNessuna valutazione finora

- Exam 11Documento9 pagineExam 11Bakkari MehdiNessuna valutazione finora

- Traditional Design of Cage Rotor Induction MotorsDocumento35 pagineTraditional Design of Cage Rotor Induction MotorsMohammad Gulam AhamadNessuna valutazione finora

- Design and Analysis of 42-V Permanent-Magnet Generator For Automotive ApplicationsDocumento12 pagineDesign and Analysis of 42-V Permanent-Magnet Generator For Automotive ApplicationsNicholas ValdezNessuna valutazione finora

- Dynamic Modeling of PMSMDocumento10 pagineDynamic Modeling of PMSMHisham Magdi El DeebNessuna valutazione finora

- Modeling and Parameter Identification of A Double-Star Induction MachinesDocumento7 pagineModeling and Parameter Identification of A Double-Star Induction MachineshaimantiNessuna valutazione finora

- 3D MSC/EMAS Simulation of A Three Phase Power Transformer by Means of Anisotropic Material PropertiesDocumento11 pagine3D MSC/EMAS Simulation of A Three Phase Power Transformer by Means of Anisotropic Material PropertiesConstantin DorinelNessuna valutazione finora

- 7 TransformadorDocumento27 pagine7 TransformadorMarkovic Ávila MartínezNessuna valutazione finora

- A Comparison of Torque Capabilities of Axial Flux and Radial Flux Type of Brushless DC BLDC Drives For Wide Speed Range ApplicationsDocumento6 pagineA Comparison of Torque Capabilities of Axial Flux and Radial Flux Type of Brushless DC BLDC Drives For Wide Speed Range ApplicationssosiNessuna valutazione finora

- Constructional Details:: 1. Explain The Construction Details of Synchronous MotorDocumento28 pagineConstructional Details:: 1. Explain The Construction Details of Synchronous MotorrioNessuna valutazione finora

- Matrix Analysis Techniques in Cage Induction Machines: David G. DorrellDocumento7 pagineMatrix Analysis Techniques in Cage Induction Machines: David G. Dorrellni60Nessuna valutazione finora

- An Engineering Approach in Modeling Lightning Effects On Megawatt-Class Onshore Wind Turbines Using EMTP and ModelsDocumento5 pagineAn Engineering Approach in Modeling Lightning Effects On Megawatt-Class Onshore Wind Turbines Using EMTP and ModelsYume YumeNessuna valutazione finora

- Exam Electrical Machines and Drives (ET4117) : Grid Back EMF Time (S)Documento10 pagineExam Electrical Machines and Drives (ET4117) : Grid Back EMF Time (S)chidoNessuna valutazione finora

- Determining Rotor Leakage ReactanceDocumento5 pagineDetermining Rotor Leakage ReactanceGaspar RodríguezNessuna valutazione finora

- Calculation of Power Losses in The Damper Winding Winding of Large Hidrogenerators at Open-Circuit and Load ConditionsDocumento8 pagineCalculation of Power Losses in The Damper Winding Winding of Large Hidrogenerators at Open-Circuit and Load ConditionsWalter SantiNessuna valutazione finora

- Design OptimisationDocumento14 pagineDesign OptimisationAbirami RajagopalNessuna valutazione finora

- IM - Motors To GensDocumento4 pagineIM - Motors To Gensmenilanjan89nLNessuna valutazione finora

- Prediction of Noise Generated by Electromagnetic Forces in Induction MotorsDocumento5 paginePrediction of Noise Generated by Electromagnetic Forces in Induction Motors434lapNessuna valutazione finora

- Design and Simulation of Field Oriented Control of VSI Fed Induction Motor DriveDocumento10 pagineDesign and Simulation of Field Oriented Control of VSI Fed Induction Motor Drivesuhail ahmadNessuna valutazione finora

- Switched Reluctance MotorDocumento52 pagineSwitched Reluctance MotorChandru PrasathNessuna valutazione finora

- Arindam Seminar 11Documento6 pagineArindam Seminar 11Arindam BhattacharjeeNessuna valutazione finora

- Auxiliary Windings, Supplying The AVR of A Brushless Synchronous Generator 2005Documento5 pagineAuxiliary Windings, Supplying The AVR of A Brushless Synchronous Generator 2005Jalil EmadiNessuna valutazione finora

- 02-1 Synchronous MachinesDocumento48 pagine02-1 Synchronous MachinesvenikiranNessuna valutazione finora

- FEM of Induction MotorDocumento6 pagineFEM of Induction MotoromokhafeNessuna valutazione finora

- Simulation of Six Phase Permanent Magnet Synchronous Generator in MATLABDocumento5 pagineSimulation of Six Phase Permanent Magnet Synchronous Generator in MATLABجمال ضيفيNessuna valutazione finora

- Differential Forms on Electromagnetic NetworksDa EverandDifferential Forms on Electromagnetic NetworksValutazione: 4 su 5 stelle4/5 (1)

- Organic Light-Emitting Transistors: Towards the Next Generation Display TechnologyDa EverandOrganic Light-Emitting Transistors: Towards the Next Generation Display TechnologyNessuna valutazione finora

- Characteristic Modes: Theory and Applications in Antenna EngineeringDa EverandCharacteristic Modes: Theory and Applications in Antenna EngineeringNessuna valutazione finora

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkDa EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNessuna valutazione finora

- Resistivity Modeling: Propagation, Laterolog and Micro-Pad AnalysisDa EverandResistivity Modeling: Propagation, Laterolog and Micro-Pad AnalysisNessuna valutazione finora

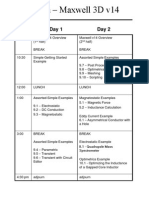

- 852 3D AgendaDocumento1 pagina852 3D AgendavishiwizardNessuna valutazione finora

- ACM2 TAU Datasheet enDocumento5 pagineACM2 TAU Datasheet envishiwizardNessuna valutazione finora

- FAB Resistivity White PaperDocumento8 pagineFAB Resistivity White PapervishiwizardNessuna valutazione finora

- BLDC DesignDocumento13 pagineBLDC DesignvishiwizardNessuna valutazione finora

- Big Energy Series 11.5.2012 Qing-Chang ZhongDocumento1 paginaBig Energy Series 11.5.2012 Qing-Chang ZhongvishiwizardNessuna valutazione finora

- Sensors Used in HEVDocumento4 pagineSensors Used in HEVvishiwizard100% (1)

- Insulating Varnish OverviewDocumento2 pagineInsulating Varnish OverviewvishiwizardNessuna valutazione finora

- How To Check A MOSFET Using A Digital Multimeter - Homemade Circuit Designs Just For YouDocumento2 pagineHow To Check A MOSFET Using A Digital Multimeter - Homemade Circuit Designs Just For YouvishiwizardNessuna valutazione finora

- FTF Aut f0234Documento38 pagineFTF Aut f0234vishiwizardNessuna valutazione finora

- Wittich2011 SonkusaleVanderveldeDocumento1 paginaWittich2011 SonkusaleVanderveldevishiwizardNessuna valutazione finora

- A Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesDocumento1 paginaA Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesvishiwizardNessuna valutazione finora

- Motor Primer1Documento2 pagineMotor Primer1vishiwizardNessuna valutazione finora

- E3632 SerDocumento128 pagineE3632 ServishiwizardNessuna valutazione finora

- Orcad 16 Full - NotepadDocumento2 pagineOrcad 16 Full - NotepadvishiwizardNessuna valutazione finora

- Sona SPEED CatalogueDocumento13 pagineSona SPEED CataloguevishiwizardNessuna valutazione finora

- Wimd32 ParamsDocumento86 pagineWimd32 ParamsvishiwizardNessuna valutazione finora

- Chapter 6. Energy Use CharacterizationDocumento10 pagineChapter 6. Energy Use CharacterizationvishiwizardNessuna valutazione finora

- Selco T Line WebDocumento8 pagineSelco T Line WebMurali SubramaniNessuna valutazione finora

- Mixed Signal Circuit Design ELL 731Documento11 pagineMixed Signal Circuit Design ELL 731Anmol SinhaNessuna valutazione finora

- SCR DatasheetDocumento9 pagineSCR DatasheetSarah DuranNessuna valutazione finora

- Transport ADRDocumento3 pagineTransport ADRZbinca CristianNessuna valutazione finora

- 2) Electromotive Force (Emf)Documento2 pagine2) Electromotive Force (Emf)ZIdanNessuna valutazione finora

- DIGI Keypad - 21Documento15 pagineDIGI Keypad - 21Mahmoud Rob100% (1)

- Standalone Access Control: Packing List WiringDocumento1 paginaStandalone Access Control: Packing List WiringAmine AminouNessuna valutazione finora

- Pakistan Cables Price ListDocumento2 paginePakistan Cables Price ListMudasarS90% (10)

- 7.4 Main Spindle Control With Analog Interface 6SN1121-0BA1!-0AA!Documento7 pagine7.4 Main Spindle Control With Analog Interface 6SN1121-0BA1!-0AA!Edinson ZamoraNessuna valutazione finora

- Advantages & Limitations of Different Energy Storage Systems Electricalvoice 2Documento1 paginaAdvantages & Limitations of Different Energy Storage Systems Electricalvoice 2Slaven IvanovicNessuna valutazione finora

- Efire TCP PsDocumento2 pagineEfire TCP PsAshutoshSharmaNessuna valutazione finora

- Electric Pressure Cookers Training ManualDocumento25 pagineElectric Pressure Cookers Training ManualLa perrritaaaNessuna valutazione finora

- Marshall Class 5 Owner ManualDocumento4 pagineMarshall Class 5 Owner ManualJuan Cruz LeónNessuna valutazione finora

- Installer Pack v3 2Documento50 pagineInstaller Pack v3 2Chris JefferyNessuna valutazione finora

- RRU5301 Technical Specifications: Supported Modes and Frequency BandsDocumento7 pagineRRU5301 Technical Specifications: Supported Modes and Frequency BandsMARCSTARSNessuna valutazione finora

- Iec60598 1 I1 (Ed8.0) BDocumento4 pagineIec60598 1 I1 (Ed8.0) BAnooshdini2002Nessuna valutazione finora

- IEC 60060-2 - High-Voltage Test Techniques - Part 2: Measuring Systems - Edition 3.0Documento19 pagineIEC 60060-2 - High-Voltage Test Techniques - Part 2: Measuring Systems - Edition 3.0ONUR YILMAZNessuna valutazione finora

- Fiat RNS3 Users ManualDocumento8 pagineFiat RNS3 Users ManualMilan ProticNessuna valutazione finora

- 2 V Amp 2nd e Manual ADocumento232 pagine2 V Amp 2nd e Manual Aroymathew2003Nessuna valutazione finora

- Manual Avr Leroy Somer Mod. R 181 - enDocumento8 pagineManual Avr Leroy Somer Mod. R 181 - enMiguel Angel Pavon CarbonellNessuna valutazione finora

- Displays: Specifications FOR LCD Module CGM12864Documento8 pagineDisplays: Specifications FOR LCD Module CGM12864Diego AzevedoNessuna valutazione finora

- 1º Manual Retroescavadeira 416E Julho 2007 (295 345)Documento51 pagine1º Manual Retroescavadeira 416E Julho 2007 (295 345)Cristian SpositoNessuna valutazione finora

- Design StandardDocumento47 pagineDesign StandardWajeeh BitarNessuna valutazione finora

- Engine Electric StstemDocumento51 pagineEngine Electric StstemnahomNessuna valutazione finora

- Power Systems Lab 1.revisedDocumento38 paginePower Systems Lab 1.revisedJerrord ThomasNessuna valutazione finora

- 4 Adc/8 Dac With PLL, 192 KHZ, 24-Bit Codec: Data SheetDocumento33 pagine4 Adc/8 Dac With PLL, 192 KHZ, 24-Bit Codec: Data SheetLAI YEEK HRVENessuna valutazione finora