Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PDVSA El Tejero Report

Caricato da

Denis JimenezDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PDVSA El Tejero Report

Caricato da

Denis JimenezCopyright:

Formati disponibili

Site Report

PDVSA-Planta El Tejero Dates 10/26-11/01/2005 CSA-R8368 Unit No.4 Mars 100 Package-CT89456 Engine SN- 1741C41

Summary The current operating Mars 100 was recently overhauled and installed by PDVSA in package No.4 however was impacted by low performance that ultimately was affecting the trough put. My overall time on site and the length of stay in Maturin does not reflect the actual work performed due the plant process and of course the Xmas season. The initial issue regarding the engine performance was only a matter of the engine test setup Mars 100 verses the current control setup Mars 90, nothing more. Performance Upon arriving on site the engine was operating at 92.5% Ngp and temp topping T5-1360F with both the LP and IP recycle valves cycling due to the low output power. The T5 delta across the thermocouple was high however not a concern at this junction relative to the way the engine was operating. IGV The as tested guide vane angle stops on the open side were set at 4 max, this was changed to 0 and the speed increased to 97.5% Ngp @ T5-1360, hp-normalized. However within an hour of operation the engine speed had dropped down to 96% Ngp @ T5-1360 and was due to the T5 spread along with losing thermocouple (No.4 and No.10). T5 Performed a few simple tests on the T5 control and found it tracking correctly with zero compensation however the Isothermo Board has a number of terminals were the threads and screws are not making good contact. When using wire terminals the standard screws are not long enough causing them to strip out. Any lose connection on either the thermocouples or the interconnect junction point is going to cause erroneous data within the control system and affect the overall performance of the engine. Was able to make some temporary changes to the T5 connections and isothermo board in order to bring the performance back to normal. However due to the T5 spread the IGVs were adjusted a second time -1 and I clamped down on the T5_Base (1310-1280) in order to limit the overall Hp until the isothermal board is changed. Once the isothermal board has been changed the customer is going to send me the running T5 data points at full load (1-17) and based on that Ill reevaluate the T5_Base. Air Leakage On a secondary note the engine has an air leak located at the GP-PT matting flange that is typically associated with poor fit at the 4th stage support plate. My understanding is the GP and PT were matted on site and it could be that the two sections sagged during the torque process. As listed in highlight Ive asked PDVSA to shutdown the engine and attempt a re-torque of the flange in an attempt to avoid pulling back the PT to refit the joint. If re-torqing does not correct the problem I dont think the issue should be left unresolved for a long period of time since it will affect the performance long term.

EL Tejero Mars 100 No. 4 MC95996 0361M Sr. Matias, This is not my report, only items that PDVSA needs to review regarding engine 0361M. Based on my visit to EL Tejero the Mars engine No.4 has two issues that need to be investigated and resolved. I did not like the T5 profile of the engine during my testing, however adjusted the engine so the plant could use it. 1. 2. The Isothermal plate (190712-1) needs to be replaced (location 4 is 18). I noted a number of air leaks along the lower section of the GP-PT joint that indicates an issue with the 4th stage support plate (PT), possibly during installation. The station personnel told me that the GP and PT were joined together at the station prior to installation? What can happen is if the GP and PT are not aligned and supported properly the two engine assemblies can sage. This is an issue because if the torque procedure does not work then either the PT will have to be moved back or the engine removed in order to correct the problem, regardless a lot of work. So let take it one step at a time i. ii. iii. Shut the engine down and allow to cool so the outer casing is less then 200 deg F Verify the type of bolt used in the engine; tapered (97 ft lbs) or straight (110 ft lbs)? This will determine the torque value. Re-Torque the GP_PT flange in a star pattern but dont loosen all the bolts or the engine could sage. THATS IT, give me a call or send me an e-mail if you have additional questions

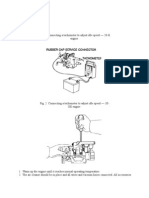

GP - PT FLANGE TORQUE

REDUCED SHANK

97-ft lbs

NORMAL SHANK

110-ft lbs

VERIFY THE TYPE OF BOLT USED IN ENGINE PRIOR TO VERIFYING TORQUE

TORQUE PATTERN

DUE TO AIR LEAKAGE THE GP/PT FLANGE WILL NEED TO BE TORQUE, THIS WILL BE PERFORMED IN A NORMAL STAR PATTERN. DO NOT LOOSEN ALL THE BOLTS OR THE ENGINE COULD SAGE. THE ENGINE WILL NEED TO BE SHUTDOWN AND COOL BEFORE PROCEEDING.

Garry A. Hansen

Enclosure Temperatures Noted that the enclosure temperatures are elevated partly due to the inadequacies of the fan, this can be verified by measuring the motor current relative to the service factor of the motor. However a lot can be done within the package to eliminate most of the heat being dissipated around the engine hot section.

Oil Leaks-Coupling Covers Noted several leaks from the coupling covers and RTV is still being utilized as the preferred sealant by the customer. Theres nothing wrong with using RTV however in my opinion the technicians would be better served using a PTFE product that would offer an enhanced sealing capacity along with easy clean up. For use with the type of coupling covers on the Mars I would recommend using 1/8 or 3/16 rope packing, which is excellent for sealing rough and irregular surfaces.

Conclusion The engine is operational however I would appreciate the customer looking into the two outstanding issues, isothermo board and the air leakage. With respect to the overall performance the steps taken to allow the engine to operate as a Mars 90 was the best course of action. Even prior to implementing any control changes that would allow the engine to operate as a Mars 100 it would have still need to be setup as a Mars 90 for verification purposes. Once the T5 profile can be verified after the isothermo board change out we will schedule a time to implement the Mars 100 control with the current Moog actuators. I appreciated all the support given during my stay on sight and please forward any questions regarding this report to Hansen_garry_a@solarturbines.com or contact me via my cell 0412-3134166. Garry A. Hansen Regional Engineer

Potrebbero piacerti anche

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- 4l30e Pump ConversionDocumento6 pagine4l30e Pump ConversionNuman2100% (1)

- 2nd TA Modification Work List Rev1Documento71 pagine2nd TA Modification Work List Rev1Vy NguyenNessuna valutazione finora

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- Ford Fnr5 TCC SlipDocumento2 pagineFord Fnr5 TCC SlipAlex Maceira Graterol100% (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- Carb Turbo Kit InstructionsDocumento11 pagineCarb Turbo Kit InstructionsKevin ShankleNessuna valutazione finora

- 3092834-Varco Bulletin On TDSDocumento9 pagine3092834-Varco Bulletin On TDSSushil GuptaNessuna valutazione finora

- GM 6t70 UpdatesDocumento45 pagineGM 6t70 UpdatesThePokeOne100% (9)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Barring StallingDocumento6 pagineBarring Stallingnetygen1100% (3)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SDa EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNessuna valutazione finora

- InstructionsDocumento14 pagineInstructionsALEXNessuna valutazione finora

- MPI 5 Port Kit Fitting Instructions Aug 2020Documento3 pagineMPI 5 Port Kit Fitting Instructions Aug 2020Angi RomanoNessuna valutazione finora

- GE Frame 5 Gas Turbine: From The Automation List Department..Documento3 pagineGE Frame 5 Gas Turbine: From The Automation List Department..januaridonNessuna valutazione finora

- Engine Misfire, Runs Rough or Is UnstableDocumento4 pagineEngine Misfire, Runs Rough or Is UnstableAdolfo Dario Saavedra0% (1)

- Testing & CommissioningDocumento46 pagineTesting & CommissioningVuong Viet Cuong100% (1)

- BukuDocumento6 pagineBukuAsep SaefullohNessuna valutazione finora

- AFI Diagnostic Tips Book 3-09Documento36 pagineAFI Diagnostic Tips Book 3-09Ruwan Wevagedara100% (1)

- Handbuch Dellorto VHSH30Documento11 pagineHandbuch Dellorto VHSH30danijel22100% (1)

- Man B&W Serv LTR Sl09-510-Sb-jDocumento43 pagineMan B&W Serv LTR Sl09-510-Sb-jafsal999Nessuna valutazione finora

- ProductionTech Trip HandoverDocumento20 pagineProductionTech Trip HandoverDaniel GrabovskyNessuna valutazione finora

- Sop For HTmotor PDFDocumento4 pagineSop For HTmotor PDFSunny Biswal100% (1)

- Failures of Cylinder Head Valves On G3500C and G3500E Generator Set Engines (1100, 1105, 1121)Documento5 pagineFailures of Cylinder Head Valves On G3500C and G3500E Generator Set Engines (1100, 1105, 1121)Ahmed Nahrawy100% (1)

- Sonnax AW 6-Speed FWDDocumento37 pagineSonnax AW 6-Speed FWDhornet22Nessuna valutazione finora

- Test Transmision 420E CatDocumento8 pagineTest Transmision 420E CatEdin Raul Yalle RafaelNessuna valutazione finora

- Bromyard Pierburg Fitting InstructionsDocumento4 pagineBromyard Pierburg Fitting InstructionsGeorgi GeorgievNessuna valutazione finora

- Service Bulletin Mercarb 97 - 08Documento6 pagineService Bulletin Mercarb 97 - 08hormiganegra431Nessuna valutazione finora

- 9fa ProbsDocumento12 pagine9fa ProbsMarbz Al MonteNessuna valutazione finora

- Atb 1582Documento3 pagineAtb 1582gpearson1002471Nessuna valutazione finora

- 5R55N Seminar InfoDocumento18 pagine5R55N Seminar InfocarlosNessuna valutazione finora

- 1G FUEL SYSTEM (DOHC) - Service Adjustment ProceduresDocumento40 pagine1G FUEL SYSTEM (DOHC) - Service Adjustment ProceduresAgus Prasetyanto100% (1)

- 2006-02 4R70W No ReverseDocumento13 pagine2006-02 4R70W No ReverseAleNessuna valutazione finora

- TCM Torque LimitsDocumento13 pagineTCM Torque Limitsrav100% (1)

- Injection Actuation Pressure - TestDocumento18 pagineInjection Actuation Pressure - TestDanielly GersonNessuna valutazione finora

- FD FanDocumento42 pagineFD FanJAYKUMAR SINGHNessuna valutazione finora

- Trinity & Matrix: Natural To LP Conversion InstructionsDocumento4 pagineTrinity & Matrix: Natural To LP Conversion InstructionsFREDNessuna valutazione finora

- 2008 - 7 - 4 4L30E PumpDocumento4 pagine2008 - 7 - 4 4L30E PumpJon Rodriguez100% (1)

- 6.4L Diesel Talk LIVEDocumento40 pagine6.4L Diesel Talk LIVECHRISTIAN LOZANONessuna valutazione finora

- TSB 2100306Documento13 pagineTSB 2100306ossoskiNessuna valutazione finora

- Pto Tec 116Documento3 paginePto Tec 116Wilber CastilloNessuna valutazione finora

- Maintenance and Tune-Up Idle Speed and Mixture AdjustmentDocumento5 pagineMaintenance and Tune-Up Idle Speed and Mixture AdjustmentFarabi ArdhiantoNessuna valutazione finora

- Torque Converter Stall-TestDocumento3 pagineTorque Converter Stall-TestMiguel Angel Moreno67% (3)

- Tech Tips-PF5 Adaptor For DSG TransmissionDocumento23 pagineTech Tips-PF5 Adaptor For DSG Transmissionsandmike_83100% (1)

- 14 CUX Cold Start UpdateDocumento16 pagine14 CUX Cold Start UpdateAldous Cosmo GitlesNessuna valutazione finora

- Genco IiiDocumento45 pagineGenco IiiRamnadh Mandali100% (1)

- 4L80E Modifications Guide v2Documento36 pagine4L80E Modifications Guide v2sonyaNessuna valutazione finora

- Corvette C4 Conversions - Intake To Carb 1984-1991Documento5 pagineCorvette C4 Conversions - Intake To Carb 1984-1991Corvettecraft100% (1)

- GE Gas Turbine Accessory and Load Gear Compartments Temperature Running HighDocumento20 pagineGE Gas Turbine Accessory and Load Gear Compartments Temperature Running HighShahzad JamesNessuna valutazione finora

- Starting Oil Pump in Service Problem at NTPC, Ttps Unit#5, 110 MW UnitDocumento12 pagineStarting Oil Pump in Service Problem at NTPC, Ttps Unit#5, 110 MW UnitVIBHAVNessuna valutazione finora

- Hvac Boq - R0Documento17 pagineHvac Boq - R0Avik Biswas67% (3)

- GM Drive by Wire Cleaning ProcedureDocumento8 pagineGM Drive by Wire Cleaning ProcedureRaul Villagomez100% (1)

- 93 15Documento4 pagine93 15sharawy12Nessuna valutazione finora

- Toyota101 VSV AdjustmentDocumento11 pagineToyota101 VSV AdjustmentJohn Francis Rosca100% (1)

- Starting Oil Pump in Service Problem at NTPC, Ttps Unit #5, 110 MW UnitDocumento5 pagineStarting Oil Pump in Service Problem at NTPC, Ttps Unit #5, 110 MW UnitVIBHAVNessuna valutazione finora

- SB Exlar Bleed VlaveDocumento5 pagineSB Exlar Bleed VlavemdoNessuna valutazione finora

- StallDocumento3 pagineStallnamduong368Nessuna valutazione finora

- 3612tale Jgd6 DesignDocumento1 pagina3612tale Jgd6 DesignDenis JimenezNessuna valutazione finora

- 460-119 Hoja de Especificaciones.Documento2 pagine460-119 Hoja de Especificaciones.Denis JimenezNessuna valutazione finora

- Hydac SCADocumento6 pagineHydac SCADenis JimenezNessuna valutazione finora

- Fluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDocumento12 pagineFluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDenis JimenezNessuna valutazione finora

- Inline Process FiltersDocumento7 pagineInline Process FiltersDenis JimenezNessuna valutazione finora

- Filter Bound CatalogDocumento248 pagineFilter Bound CatalogDenis JimenezNessuna valutazione finora

- E2000 0 03 11 - SYSTEMTECHNIK - WWWDocumento8 pagineE2000 0 03 11 - SYSTEMTECHNIK - WWWDenis JimenezNessuna valutazione finora

- E831BDocumento4 pagineE831BDenis JimenezNessuna valutazione finora

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDocumento20 pagineBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezNessuna valutazione finora

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDocumento20 pagineBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezNessuna valutazione finora

- Pastillas HSH 1v 1t 5wDocumento1 paginaPastillas HSH 1v 1t 5wDenis JimenezNessuna valutazione finora

- E2902 4 03 13 - Pumpen Uebersicht - LQDocumento20 pagineE2902 4 03 13 - Pumpen Uebersicht - LQDenis Jimenez0% (1)

- PDVSA El Tejero ReportDocumento6 paginePDVSA El Tejero ReportDenis JimenezNessuna valutazione finora

- Transporte de Los Generadores de Gas Rb211 y Avon Rolls Royce 3Documento12 pagineTransporte de Los Generadores de Gas Rb211 y Avon Rolls Royce 3Denis JimenezNessuna valutazione finora

- Lm2500 GearboxDocumento4 pagineLm2500 GearboxDenis JimenezNessuna valutazione finora

- Transporte de Los Generadores de Gas Rb211 y Avon Rolls Royce 2Documento14 pagineTransporte de Los Generadores de Gas Rb211 y Avon Rolls Royce 2Denis JimenezNessuna valutazione finora

- Wheel Install 16x7.5 ET31Documento10 pagineWheel Install 16x7.5 ET31Oleg FedchenkoNessuna valutazione finora

- June July 2016Documento12 pagineJune July 2016Samuel Sneddon-NelmesNessuna valutazione finora

- OLIS COMBI OVEN MANUAL CV CVM CVP Electric Eng MANUALDocumento40 pagineOLIS COMBI OVEN MANUAL CV CVM CVP Electric Eng MANUALMichalisCharalambous33% (3)

- Diamond Infinite Edge ManualDocumento12 pagineDiamond Infinite Edge ManualDaniel MunroNessuna valutazione finora

- SB - 1242a PedalesDocumento7 pagineSB - 1242a PedalesCine Ibagué 19Nessuna valutazione finora

- TRIOCATALDocumento13 pagineTRIOCATALVladimir Illich Pinzon100% (1)

- Man B&W: Fuel Oil High-Pressure PipeDocumento5 pagineMan B&W: Fuel Oil High-Pressure PipeJr Bulog WadayNessuna valutazione finora

- B. P. Tapon MolibleDocumento16 pagineB. P. Tapon Molibleolger nino100% (1)

- Ews-100000-6-Ts-0008 - 1 Torque de Pernos en Flanges PDFDocumento35 pagineEws-100000-6-Ts-0008 - 1 Torque de Pernos en Flanges PDFjoispeNessuna valutazione finora

- Manual - AR2 Robot Arm AssemblyDocumento68 pagineManual - AR2 Robot Arm AssemblyDreyer1416100% (1)

- ANSI ASME B1.5 Acme StandardDocumento123 pagineANSI ASME B1.5 Acme StandardRagesh VVNessuna valutazione finora

- Nissan Truck BB BookDocumento152 pagineNissan Truck BB Booktgvnayagam82% (17)

- PP 180828 Shrink Wrapping ManualDocumento56 paginePP 180828 Shrink Wrapping ManualDavid Anderson100% (1)

- ManualDocumento9 pagineManualbheigh5054100% (1)

- C&P PTFE Slide BearingsDocumento1 paginaC&P PTFE Slide BearingsAchraf BoudayaNessuna valutazione finora

- Instruction Manual - 2240992801 Delta ALDocumento68 pagineInstruction Manual - 2240992801 Delta ALcartarNessuna valutazione finora

- "Toja" Shower Column Set Tx492Stn: Specifications Troubleshooting InstallationDocumento1 pagina"Toja" Shower Column Set Tx492Stn: Specifications Troubleshooting InstallationAndrianus EffendyNessuna valutazione finora

- Ingenieria-Cema 300-Screw Conveyor Standard PDFDocumento33 pagineIngenieria-Cema 300-Screw Conveyor Standard PDFsaulomonNessuna valutazione finora

- Scamec 2000 S 100129425 #FB214 HammerDocumento35 pagineScamec 2000 S 100129425 #FB214 HammerIvan Andres Seguel BristiloNessuna valutazione finora

- ARP - Bolt Catalogue (Bolting Information) - Cat03Documento82 pagineARP - Bolt Catalogue (Bolting Information) - Cat03petermorgan74931Nessuna valutazione finora

- 4 Functional DecompositionDocumento64 pagine4 Functional DecompositionGeac AndreeaNessuna valutazione finora

- Parts: Trailer Mounted Pump Model B20 Illustrated Part ManualDocumento167 pagineParts: Trailer Mounted Pump Model B20 Illustrated Part ManualTimur CakiciNessuna valutazione finora

- 2010-Catalog Rivet PDFDocumento68 pagine2010-Catalog Rivet PDFviettri31Nessuna valutazione finora

- Sect02 Install PDFDocumento38 pagineSect02 Install PDFAngel AdautaNessuna valutazione finora

- Types of Steel Beam Connections and Their DetailsDocumento5 pagineTypes of Steel Beam Connections and Their DetailsARUNNessuna valutazione finora

- Screw Jack 3Documento34 pagineScrew Jack 3Asad HafudhNessuna valutazione finora

- Sve 2510LR PDFDocumento138 pagineSve 2510LR PDFdennis haryanto100% (1)

- Mechanical Properties For Stainless Steel FastenersDocumento3 pagineMechanical Properties For Stainless Steel FastenersGonzalo MazaNessuna valutazione finora

- Magnetic Drive Gear Pump: Installation / Operation ManualDocumento24 pagineMagnetic Drive Gear Pump: Installation / Operation ManualmauricioNessuna valutazione finora

- Engineering Drawings and Spare Parts Lists - Driving Unit F. Carousel - 105473 - R01 - English - KDocumento9 pagineEngineering Drawings and Spare Parts Lists - Driving Unit F. Carousel - 105473 - R01 - English - KZubairNessuna valutazione finora

- Electric Motor Control: DC, AC, and BLDC MotorsDa EverandElectric Motor Control: DC, AC, and BLDC MotorsValutazione: 4.5 su 5 stelle4.5/5 (19)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingDa EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNessuna valutazione finora

- A Practical Handbook for Drilling Fluids ProcessingDa EverandA Practical Handbook for Drilling Fluids ProcessingNessuna valutazione finora

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDa EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsValutazione: 4.5 su 5 stelle4.5/5 (12)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDa EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNessuna valutazione finora

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDa EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentValutazione: 4.5 su 5 stelle4.5/5 (21)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDa EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNessuna valutazione finora

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADa EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANessuna valutazione finora

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDa EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsValutazione: 4.5 su 5 stelle4.5/5 (2)

- Power Electronics Diploma Interview Q&A: Career GuideDa EverandPower Electronics Diploma Interview Q&A: Career GuideNessuna valutazione finora

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Advanced Production Decline Analysis and ApplicationDa EverandAdvanced Production Decline Analysis and ApplicationValutazione: 3.5 su 5 stelle3.5/5 (4)

- Thermal Power Plant: Design and OperationDa EverandThermal Power Plant: Design and OperationValutazione: 4.5 su 5 stelle4.5/5 (23)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesDa EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesValutazione: 4 su 5 stelle4/5 (2)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingDa EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNessuna valutazione finora

- Handbook on Battery Energy Storage SystemDa EverandHandbook on Battery Energy Storage SystemValutazione: 4.5 su 5 stelle4.5/5 (2)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsDa EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNessuna valutazione finora

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDa EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsNessuna valutazione finora