Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Saep 306

Caricato da

imrankhan22Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Saep 306

Caricato da

imrankhan22Copyright:

Formati disponibili

Engineering Procedure

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes Piping Standards Committee Members

Nasri, Nadhir Ibrahim, Chairman Dib, Tony George., Vice Chairman Balhareth, Nasser Mohammad Khashab, Jaafar M. Mullen, Marshall Anson Bannai, Nabeel Saad Qahtani, Khalid Daifallah Rumaih, Abdullah Mohammad Kim, Steve Un Holland, Brad John Dossary, Mohammad Battal Fadley, Gary Lowell Otaibi, Bander Abdulaziz Ramadan, Mousa Sadiq Teraiki, Abdullah Mohammad Phan, Howard Cong Lewis, Trevor Mahmoud, Khalid Ahmed

29 June 2005

Saudi Aramco DeskTop Standards

Table of Contents 1 2 3 4 5 6 7 8 Scope............................................................. 2 Conflicts and Deviations................................ 2 Applicable Documents................................... 2 Definitions...................................................... 3 General........................................................... 4 Data Required................................................ 5 Defect Assessment Levels............................. 5 Pipeline Repair Decision................................ 8

Appendix-A: Chart-1: Corroded Pipelines Defects Assessment Flowchart................... 10 Appendix-B: Schematic Illustrations for Defects Measurements and Grouping.... 11

Previous Issue: 29 March 2000 Next Planned Update: 1 July 2010 Revised paragraphs are indicated in the right margin Primary contact: Nasri, Nadhir Ibrahim on 873-4525

Page 1 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

Scope 1.1 This Saudi Aramco Engineering Procedure (SAEP) provides guidelines for assessing carbon steel pipelines containing corrosion metal-loss defects. Application of the guidance will establish the remaining strength of corroded pipelines and provide the technical basis for determining the acceptability of defects. The assessment methods described in this procedure are intended to be used on corrosion metal-loss defect in pipelines that have been designed to a recognized pipeline design code, including but not limited to ASME B31.4, ASME B31.8. The procedure can be used for in-plant piping designed and constructed in accordance with ASME B31.8 or ASME B31.4 such as bulk plants and pump stations. This procedure should be used by experienced engineers or trained inspectors or who have demonstrated capabilities in understanding and applying this procedure. Also, they should be familiar with SAEP-020 SAEP-310 and SAESL-410.

Commentary: Attending and successfully completing fitness for service courses is highly recommended.

1.2

1.3

1.4

Conflicts and Deviations 2.1 Any conflicts between this standard and other applicable Saudi Aramco Engineering Standards (SAESs), Materials System Specifications (SAMSSs), Standard Drawings (SASDs), or industry standards, codes, and forms shall be resolved in writing by the Company or Buyer Representative through the Manager, Consulting Services Department of Saudi Aramco, Dhahran. Direct all requests to deviate from this standard in writing to the Company or Buyer Representative, who shall follow internal company procedure SAEP-302 and forward such requests to the Manager, Consulting Services Department of Saudi Aramco, Dhahran.

2.2

Applicable Documents 3.1 Saudi Aramco References Saudi Aramco Engineering Procedures SAEP-20 Equipment Inspection Schedule

Page 2 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

SAEP-302

Instructions for Obtaining a Waiver of a Mandatory Saudi Aramco Engineering Requirement Pipeline Repair and Maintenance

SAEP-310

Saudi Aramco Engineering Standards SAES-L-150 SAES-L-310 SAES-L-410 3.2 Industry Codes and Standards American Society of Mechanical Engineers ASME B31G ASME B31.4 ASME B31.8 American Petroleum Institute API RP 570 3.3 Guidance Document PRCI-273-9803 Guidance for Assessing the remaining strength of Corroded Pipeline Piping Inspection Code Manual for Determining the Remaining Strength of Corroded Pipelines Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids Gas Transmission and Distribution Piping Systems Pressure Testing of Plant Piping and Pipelines Design Plant Piping Design of Pipelines

Definitions ERF: Estimated Repair Factor can be established by dividing the maximum allowable operation pressure (MAOP) or design pressure by the predicted failure pressure Pf. ILI: In-Line Inspection of Pipeline LPC: Line Pipe Corrosion equation PRCI: Pipeline Research Council International, Inc.

Page 3 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

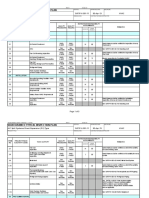

General 5.1 This procedure mandates the use of two assessment levels which are Level-1 and Level-2 as detailed in paragraph 8. Chart-1 of Appendix-A provides schematic diagram of the two levels. 5.1.1 A level-1 assessment only considers the maximum defect dimensions, i.e., the maximum depth(s), maximum length(s) and separating distance(s) of an isolated defect, and uses one of the simple failure equations. The level-1 assessment method is used for assessing multiple or large number of corrosion metal-loss defect so that severe or critical defects can be identified. A level-2 assessment considers not only the maximum defect dimensions but also the shape of the metal-loss area(s) of the defect. The level-2 assessment method is more complex and less conservative than a level-1 assessment method, and requires more information about the defect shape, support of computer software and knowledge of specialists. It gives results with higher accuracy when compared with a level-1 assessment.

5.1.2

5.2

For defects, which fail to pass the level-1 assessment, a level-2 assessment shall then be considered if the defect shape is considerably variable and detailed measurements are available. Numerical stress analysis techniques, such as the non-linear finite element (FE) can be used for assessing corrosion defects which fail to pass level-2. The use of such assessment shall be approved by the Chairman of the Piping Standards Committee. Limitations 5.4.1 This SAEP is applicable for internal corrosion defects or external corrosion defects in the base material of a straight pipe section and pipe bends. The assessment methods can be empirically applied to corrosion metalloss defects across or immediately close to pipe welds (longitudinal seam welds, spiral seam welds and girth welds). This is subject to the following conditions: a. b. c. There are no significant weld defects present that may interact with the corrosion defects. The weld material is not under-matched. Fracture is not likely to occur.

Page 4 of 13

5.3

5.4

5.4.2

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

Data Required 6.1 Data Required The assessment of the corrosion metal-loss defects in line pipe requires the following information: a. b. c. d. e. 6.2 The outside diameter of the pipe. The specified minimum yield strength (SMYS). The specified minimum tensile strength (SMTS). The nominal wall thickness of the pipe. Longitudinal and circumferential spacing between defects.

Defect shape 6.2.1 For level-1 assessment, the data of corrosion metal-loss defect shall be presented by rectangular boxes that envelop the maximum surface dimensions and maximum through-wall-thickness dimension of the metal-loss area, as shown in Figure-1 and Figure-2 in Appendix-B. For level-2 assessment, a corrosion metal-loss area shall be presented by a projected profile as shown in Figure-4 in Appendix-B. The profile represents a longitudinal cross section through the corroded area. The profile spacing can be taken as a regular or irregular spacing according to the software used.

6.2.2

6.3

Defect Grouping 6.3.1 A single metal-loss defect is a metal-loss area that is longitudinally or circumferentially separated from other metal-loss areas by at least 3 times the nominal wall thickness. A number of metal-loss areas, which are longitudinally or circumferentially separated by less than 3 times the nominal wall thickness shall be considered as a single defect as illustrated in Figure-3 in Appendix-B. A single defect does not interact with any other metal-loss defects.

6.3.2

6.3.3 7

Defect Assessment Levels 7.1 Level-1 Defect Assessment

Page 5 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

7.1.1 7.1.2

For level-1, the Line Pipe Corrosion failure equation method (LPC) shall be used. ASME B31G failure equation can only be used for level-1 if the corrosion defects data obtained by the instrument scraper.

Commentary: The B31G method is the most conservative method. Therefore, it is recommended only to be used for IS data to be able to develop the pipeline maintenance repair plan.

7.1.3

LPC failure equation is defined by:

Pf = Po Rs

Po = 2 D 1 t

(1) (2)

= SMTS

d 1 t Rs = 1 d 1 2 t L 1 + 0.31 Dt

(3)

(4)

d for 0.85 ; all lengths t Where: Pf SMTS D t d L 7.2 Predicted failure pressure for corroded pipe, lb/in Specified minimum tensile strength, lb/in Nominal outside diameter, in Nominal wall thickness, in Maximum depth of a corrosion metal-loss area, in Maximum axial length of corrosion metal-loss area, in

Level-2 Defect Assessment

Page 6 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

7.2.1 The RSTRENG effective-area method shall be used for level-2 assessment. 7.2.2 The RSTRENG effective-area method is defined by a procedure of progressive failure predictions based on the RSTRENG equation but assuming that the equivalent depths of the incremental "defects" are determined by the areas of the sub-sections. 7.2.3 The procedure, as schematically illustrated by Figure-4, can be described by the following steps: 1) for a projected defect profile with the area of the profile, A, its axial length, L, and the maximum depth, d, divide the overall defect length, L, by n incremental sub-sections, Li (i=1,2,3,n and Li contains Li-1), then obtain areas of the sub-sections, Ai (i=1,2,3,n and Ai contains Ai-1); calculate a predicted failure pressure using the following formulae:

2)

Pf = min{Pf 1 , Pf 2 ,..., Pfj ,..., Pfn }

di 1 2 t Pi f = D d i 1 1 t t M i

( i = 1, 2, 3, , n )

(5)

for 0.80

d t

(6)

= SMYS + 10000 (lb/in2)

d =

i

(7) (8)

A L

i

Li Li M i = 1 + 0.6275 0.003375 Dt Dt

Li M i = 3.3 + 0.032 Dt

2

for

Li Dt

7.071

(9)

for

Li Dt

> 7.071

(10)

Where: Pf SMYS D Predicted failure pressure for corroded pipe, lb/in Specified minimum yield strength, lb/in Nominal outside diameter, in

Page 7 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

t d L

8 Pipeline Repair Decision

Nominal wall thickness, in Maximum depth of a corrosion metal-loss area, in Maximum axial length of corrosion metal-loss area, in

8.1

Estimated Repair Factor (ERF) The estimated repair factor for a corrosion defect can be established by dividing the maximum allowable operating pressure (MAOP) or design pressure by the predicted failure pressure, Pf, for the corrosion defect, as below:

ERF = MAOP Pf

(11)

8.2

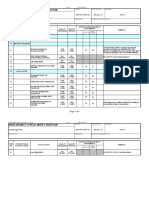

The remedial actions of the assessed pipeline are based on the ERF values for the defects and shall be according to Table-1 below.

Table-1: Corrosion defects remedial action Assessment Level Corrosion Type ERF Values 1 ERF Valves < 1

Level-1

External

Required repair or consider level-2 assessment Required immediate repair

Required coating only to stop corrosion. Required coating only to stop corrosion.

Level-2

External

Level-1

Internal

Required immediate repair

Required periodical corrosion monitoring Required close corrosion monitoring

Level-2

Internal

Required immediate repair

Page 8 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

8.3

Internal corrosion defects, which pass the assessment, shall be monitored on a periodical basis. The inspection period shall be determined by the Engineering of the Operating Organization.

Revision Summary Major revision.

29 June 2005

Page 9 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

Appendix-A: Chart-1: Corroded Pipelines Defects Assessment Flowchart

Assessments start

Report all single defects. Group defects that are less than 3t

Level-1 Calculate predicted failure pressures for all reported single defects using the LPC-1 equation (Paragraph 7.1) Level-2 Are projected profiles of the critical single defect(s) available? Yes Identify critical defect(s) and defect groups. Re-analyze the critical single defect(s) as complex-shaped defect(s) using the RSTRENG effective-area method ERF 1 NO

Calculate the ERF (Paragraph 8.1)

Calculate the ERF (paragraph 8.1)

Check defect(s) acceptance using ERF ERF <1

Check defect(s) acceptance using ERF

ERF <1

ERF 1

Maintain the current operating Condition and recommend defect monitoring actions

Recommend remedial action

Assessments completed

Page 10 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

Appendix-B: Schematic Illustrations for Defects Measurements and Grouping

Longitudinal dimension of the pipe wall

L2

Circumferential dimension of the pipe wall

L1

L3

d1 t

d2

d3

Figure 1. Example of reported corrosion defects

d t

the projected through-wall-thickness profile of a corrosion metal-loss area

Figure 2: Project profile for metal loss

Page 11 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

Figure 3: Defect grouping, defects that are less than 3t should be considered as a single defect.

Page 12 of 13

Document Responsibility: Piping Issue Date: 29 June 2005 Next Planned Update: 1 July 2010

SAEP-306 Assessment of the Remaining Strength of Corroded Pipes

a plan view of four corrosi on pits

(maximum width)

projected defect profile L (overall axial length) A (projected area)

d t

subsection, i

subsection, j

Figure 4: A schematic illustration of level-2 assessment.

Page 13 of 13

Potrebbero piacerti anche

- Design Guidelines for Surface Mount TechnologyDa EverandDesign Guidelines for Surface Mount TechnologyValutazione: 5 su 5 stelle5/5 (1)

- Oil and Gas Pipelines: Integrity and Safety HandbookDa EverandOil and Gas Pipelines: Integrity and Safety HandbookNessuna valutazione finora

- ARAMCO Material SpecificationDocumento21 pagineARAMCO Material Specificationkhorzoo83% (6)

- PIP PLE00012 Piping Exam and Leak Test B31.8 PipelinesDocumento8 paginePIP PLE00012 Piping Exam and Leak Test B31.8 PipelinesCristian RA0% (2)

- Pipe JointDocumento12 paginePipe Jointimrankhan22Nessuna valutazione finora

- Coade Pipe Stress Analysis Seminar Notes PDFDocumento474 pagineCoade Pipe Stress Analysis Seminar Notes PDFAhmad Vawaid Sulthon100% (1)

- Steels Repair IACS REC 47 Pdf193Documento63 pagineSteels Repair IACS REC 47 Pdf193Josep Maria Montoy CanadellNessuna valutazione finora

- 01 Samss 010Documento12 pagine01 Samss 010inatt101Nessuna valutazione finora

- Piping CourseDocumento46 paginePiping Coursemr_heeraNessuna valutazione finora

- PipingDocumento16 paginePipingraja11185100% (1)

- 01 Samss 010Documento12 pagine01 Samss 010aamirtec301Nessuna valutazione finora

- 01 Samss 017Documento13 pagine01 Samss 017Hatem ShawkiNessuna valutazione finora

- SWS Paper FinalA4Documento17 pagineSWS Paper FinalA4faisalmuradNessuna valutazione finora

- Stress Analysis NotesDocumento127 pagineStress Analysis Notesreach_arindomNessuna valutazione finora

- Sabp L 002Documento27 pagineSabp L 002yoonchankim0911100% (1)

- Reliability and Maintainability of In-Service PipelinesDa EverandReliability and Maintainability of In-Service PipelinesNessuna valutazione finora

- M02 Polyethylene Coating Rev6Documento31 pagineM02 Polyethylene Coating Rev6Mohammed Hilal100% (1)

- Saep 306Documento15 pagineSaep 306nadeem shaikh100% (1)

- A State-of-the-Art Guide for Post-Installed ReinforcementDa EverandA State-of-the-Art Guide for Post-Installed ReinforcementNessuna valutazione finora

- Split Tee Specifications and Drawings - 20130906 - 191217Documento17 pagineSplit Tee Specifications and Drawings - 20130906 - 191217Anonymous cuOIjrLINessuna valutazione finora

- Saep 306Documento13 pagineSaep 306brecht1980Nessuna valutazione finora

- Materials System SpecificationDocumento13 pagineMaterials System SpecificationAbdullahNessuna valutazione finora

- T-MCE-STD-001 Rev 0 - Welding and Inspection of Process and Utility Pipework Vessels and EquipmentDocumento59 pagineT-MCE-STD-001 Rev 0 - Welding and Inspection of Process and Utility Pipework Vessels and EquipmentMichael CovillNessuna valutazione finora

- 01 Samss 029Documento15 pagine01 Samss 029inatt101Nessuna valutazione finora

- SATIP K 001 07 Refrigerant - PipingDocumento2 pagineSATIP K 001 07 Refrigerant - Pipingimrankhan22100% (1)

- ASME BPVC Section VIII Division 2: Responsibilities and Duties ParagraphDocumento3 pagineASME BPVC Section VIII Division 2: Responsibilities and Duties ParagraphSubrata PatraNessuna valutazione finora

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDa EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNessuna valutazione finora

- SAUDCO ID/PID FORM REV 1 - 010109 Chilled Water SystemDocumento3 pagineSAUDCO ID/PID FORM REV 1 - 010109 Chilled Water Systemimrankhan220% (1)

- SATIP-K-001-01 Rev 6 Centrifugal FanDocumento3 pagineSATIP-K-001-01 Rev 6 Centrifugal Fanimrankhan22Nessuna valutazione finora

- SATIP-K-001-01 Rev 6 Centrifugal FanDocumento3 pagineSATIP-K-001-01 Rev 6 Centrifugal Fanimrankhan22Nessuna valutazione finora

- SATIP-K-001-01 Rev 6 Centrifugal FanDocumento3 pagineSATIP-K-001-01 Rev 6 Centrifugal Fanimrankhan22Nessuna valutazione finora

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsDa EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNessuna valutazione finora

- Optimizing AHU InspectionsDocumento4 pagineOptimizing AHU Inspectionsimrankhan22Nessuna valutazione finora

- 01-SAMSS-035 2018 API Line PipeDocumento29 pagine01-SAMSS-035 2018 API Line PipeWHWENNessuna valutazione finora

- SAES-L-310 (Design of Plant Piping)Documento30 pagineSAES-L-310 (Design of Plant Piping)Cherukunnon Jubu100% (5)

- Saep 306Documento15 pagineSaep 306Salvatore MasalaNessuna valutazione finora

- SATIP-K-001-08 - Air Filtration Devices and Grease FilterDocumento2 pagineSATIP-K-001-08 - Air Filtration Devices and Grease Filterimrankhan22Nessuna valutazione finora

- Design of Steel Structures: Materials, Connections, and ComponentsDa EverandDesign of Steel Structures: Materials, Connections, and ComponentsNessuna valutazione finora

- IACS June 2013 Shipbuilding and Repair StandardDocumento63 pagineIACS June 2013 Shipbuilding and Repair StandardudaysrpNessuna valutazione finora

- General Requirements For Welding of PipingDocumento8 pagineGeneral Requirements For Welding of PipingMuhammedHafisNessuna valutazione finora

- Saep 306Documento15 pagineSaep 306AbdullahNessuna valutazione finora

- SATIP-K-001-03 - HVAC Metal Duct System - Rev. 6Documento3 pagineSATIP-K-001-03 - HVAC Metal Duct System - Rev. 6imrankhan220% (1)

- Pocket Guide to Preventing Process Plant Materials Mix-upsDa EverandPocket Guide to Preventing Process Plant Materials Mix-upsNessuna valutazione finora

- Engineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee MembersDocumento39 pagineEngineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee Membersbrecht1980100% (4)

- Bioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardDa EverandBioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardNessuna valutazione finora

- Norsok L-004-CR Ror OgDocumento29 pagineNorsok L-004-CR Ror OgWissam Jarmak100% (2)

- Bolt Tightening TorqueDocumento10 pagineBolt Tightening Torquekb7401100% (1)

- Subsea Pipeline Design, Analysis, and InstallationDa EverandSubsea Pipeline Design, Analysis, and InstallationValutazione: 3 su 5 stelle3/5 (1)

- Saep 306Documento13 pagineSaep 306Narvis RinconNessuna valutazione finora

- Assess Strength of Corroded PipesDocumento13 pagineAssess Strength of Corroded PipesDemac SaudNessuna valutazione finora

- Saes L 120Documento11 pagineSaes L 120samsurendran_mech4020Nessuna valutazione finora

- Materials System SpecificationDocumento6 pagineMaterials System SpecificationAwais CheemaNessuna valutazione finora

- 02 Samss 009Documento13 pagine02 Samss 009barouniamineNessuna valutazione finora

- Saes L 131Documento10 pagineSaes L 131samsurendran_mech4020Nessuna valutazione finora

- Materials System SpecificationDocumento23 pagineMaterials System SpecificationGovind JhaNessuna valutazione finora

- Piping Components Spec for Low Temp ServiceDocumento6 paginePiping Components Spec for Low Temp ServiceFlorante NoblezaNessuna valutazione finora

- High Frequency Welded Pipe SpecificationDocumento22 pagineHigh Frequency Welded Pipe SpecificationAwais CheemaNessuna valutazione finora

- 01 Samss 333Documento35 pagine01 Samss 333Jeck MaquitedNessuna valutazione finora

- Materials System SpecificationDocumento6 pagineMaterials System SpecificationAwais CheemaNessuna valutazione finora

- Materials System SpecificationDocumento26 pagineMaterials System SpecificationAwais CheemaNessuna valutazione finora

- Piping Design and Test RequirementsDocumento26 paginePiping Design and Test RequirementsRaj BindasNessuna valutazione finora

- 09 Samss 071Documento6 pagine09 Samss 071inatt101100% (1)

- Saes L 136Documento7 pagineSaes L 136Ahmed KabelNessuna valutazione finora

- Tubing and CasingDocumento10 pagineTubing and CasingEnd LabNessuna valutazione finora

- REC 47 pdf193Documento63 pagineREC 47 pdf193szafakNessuna valutazione finora

- Materials System SpecificationDocumento6 pagineMaterials System SpecificationZubair RaoofNessuna valutazione finora

- Comments Resolution Sheet: Fadhili Sulfur Recovery FacilitiesDocumento1 paginaComments Resolution Sheet: Fadhili Sulfur Recovery Facilitiesimrankhan22Nessuna valutazione finora

- Nabeel-1.jpg (2568×5038)Documento1 paginaNabeel-1.jpg (2568×5038)imrankhan22Nessuna valutazione finora

- SAEP 22asdfasdDocumento15 pagineSAEP 22asdfasdimrankhan22Nessuna valutazione finora

- Concrete moisture and pH testsDocumento3 pagineConcrete moisture and pH testsimrankhan22Nessuna valutazione finora

- Satip-K-001-12 - Tab of Hvac SystemDocumento2 pagineSatip-K-001-12 - Tab of Hvac Systemimrankhan22Nessuna valutazione finora

- SATIP-K-001-09 - Through-The-Wall and Window-Mounted Air Conditioners Rev 6Documento2 pagineSATIP-K-001-09 - Through-The-Wall and Window-Mounted Air Conditioners Rev 6imrankhan22Nessuna valutazione finora

- SATIP-K-001-11 - AC Split Systems - DX TypeDocumento3 pagineSATIP-K-001-11 - AC Split Systems - DX Typeimrankhan22Nessuna valutazione finora

- SCH Q Personnel Calculation SheetDocumento7 pagineSCH Q Personnel Calculation Sheetimrankhan22Nessuna valutazione finora

- Doc9 ASDKJFADSFDocumento1 paginaDoc9 ASDKJFADSFimrankhan22Nessuna valutazione finora

- sdfasdfAS ASKDFJASKLDJF KASLDFJ KPLASDDocumento1 paginasdfasdfAS ASKDFJASKLDJF KASLDFJ KPLASDimrankhan22Nessuna valutazione finora

- Visa Services OverviewDocumento1 paginaVisa Services Overviewimrankhan22Nessuna valutazione finora

- Pearson VUE - Checkout - Step 4 - SummaryDocumento2 paginePearson VUE - Checkout - Step 4 - Summaryimrankhan22Nessuna valutazione finora

- SDFSD - Docx Asfka Sdfkjasdklfj AsdkzflxjaskdlfDocumento1 paginaSDFSD - Docx Asfka Sdfkjasdklfj Asdkzflxjaskdlfimrankhan22Nessuna valutazione finora

- 6811Documento1 pagina6811imrankhan22Nessuna valutazione finora

- Doc10KFJDS ASKDFJASDKDocumento1 paginaDoc10KFJDS ASKDFJASDKimrankhan22Nessuna valutazione finora

- 8Documento1 pagina8imrankhan22Nessuna valutazione finora

- 8Documento1 pagina8imrankhan22Nessuna valutazione finora

- Doc5.docx ASKDFJ APSDKLFJASDKLFJ APSKLDFJADSPKLFZXJ ADSPKLFASJDLKFDocumento1 paginaDoc5.docx ASKDFJ APSDKLFJASDKLFJ APSKLDFJADSPKLFZXJ ADSPKLFASJDLKFimrankhan22Nessuna valutazione finora

- SDFSD - Docx Asfka Sdfkjasdklfj AsdkzflxjaskdlfDocumento1 paginaSDFSD - Docx Asfka Sdfkjasdklfj Asdkzflxjaskdlfimrankhan22Nessuna valutazione finora

- SDFSD - Docx Asfka Sdfkjasdklfj AsdkzflxjaskdlfDocumento1 paginaSDFSD - Docx Asfka Sdfkjasdklfj Asdkzflxjaskdlfimrankhan22Nessuna valutazione finora