Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pressure Vessel Shell Design

Caricato da

nitesh1mishraCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pressure Vessel Shell Design

Caricato da

nitesh1mishraCopyright:

Formati disponibili

1

Pressure Vessel Engineering Ltd.

2

3

4

5

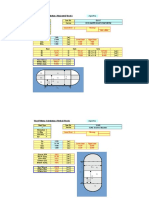

Pipe and Shell Design Tool ver E4.02

Straight Pipe and Shell Description

9

10

11

12

13

14

15

Dimensions:

24.000

0.250

12.000

0.010

0.85

0.70

12.5%

50.0

17

18

19

El - long seam efficiency (circ stress)

Ec - circ seam efficiency (long stress)

UTP [%] - undertolerance allowance

P [psi] - interior pressure

22

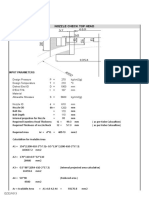

Calculated Properties:

Volume [cuft] = ((Do/2-t)^2)*pi()*L/1728

Weight [lb] = (Do-t)*pi()*L*t*40.84/144

23

Variables:

21

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

Material and Conditions:

SA-240 304 Material

20,000 S [psi] - allowable stress

16

20

Do

Do [in] - outside diameter

t [in] - nominal wall thickness

L [in] -length

Corr [in] - corrosion allowance

Length

Page 1 of 1

Long Seam

((24/2-0.25)^2)*PI()*12/1728 = 3.01

(24-0.25)*PI()*12*0.25*40.84/144 = 63.48

UT [in] = t*UTP

nt [in] = t-Corr-UT

Ri [in] = Do/2-nt

0.25*0.1 = 0.031

0.25-0.01-0.031 = 0.209

24/2-0.209 = 11.791

Required Thickness: UG-27(c)(1,2)

ta [in] = P*Ri/(S*El-0.6*P) ~~ long sem

tb [in] = P*Ri/(2*S*Ec+0.4*P) ~~ circ seam

Treq [in] = MAX(ta,tb) ~~ required minimum thickness

CheckTreq = Treq <= nt

50*11.791/(20000*0.85-0.6*50) =

50*11.791/(2*20000*0.7+0.4*50) =

MAX(0.035,0.021) =

0.035 <= 0.209 =

0.035

0.021

0.035

Acceptable

Maximum Pressure: UG-27(c)(1,2)

Pint1 [psi] = (S*El*nt)/(Ri+0.6*nt)

(20000*0.85*0.209)/(11.791+0.6*0.209) =

Pint2 [psi] = (2*S*Ec*nt)/(Ri-0.4*nt)

(2*20000*0.7*0.209)/(11.791-0.4*0.209) =

PMax [psi] = Min(Pint1,Pint2) ~~ maximum allowed design pressure

MIN(298,499) =

CheckP = PMax >= P

297.8 >= 50 =

298

499

297.8

Acceptable

Treq provides a worst case required thickness for nozzle analysis for a nozzle located on the long seam or circ seam

Check Not a thick walled vessel, calculations are valid

This sheet will not calculate thick walled vessels

The UG-16(b) minimum thickness requirement has not been taken into consideration here.

This sheet cannot be used to check for allowable exterior pressure loads.

Use the Weld Efficiency program to calculate El and Ec

This sheet is for educational use only - use at your own risk.

Pressure Vessel Engineering Ltd.

120 Randall Drive, Suite B

Waterloo, Ontario, Canada, N2V 1C6

www.pveng.com (519) 880-9808

Potrebbero piacerti anche

- Asme Section Viii Div-1,2,3Documento73 pagineAsme Section Viii Div-1,2,3me2437090% (39)

- Horizontal Cylindrical Tank Volume and Level CalculatorDocumento5 pagineHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNessuna valutazione finora

- Memoria ASME-Pressure-Vessel-DesignDocumento143 pagineMemoria ASME-Pressure-Vessel-DesignJuan MendozaNessuna valutazione finora

- Tank Ring Wall Foundation+&+Annular+RaftDocumento12 pagineTank Ring Wall Foundation+&+Annular+Raftasghar750% (2)

- Pressure Vessel Design CalculationsDocumento127 paginePressure Vessel Design Calculationsajayghosh314086% (22)

- Pressure Vessel Design CalculationsDocumento127 paginePressure Vessel Design Calculationsajayghosh314086% (22)

- Vessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDocumento4 pagineVessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDongwon ShinNessuna valutazione finora

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocumento4 pagineUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNessuna valutazione finora

- Design of Pressure Vessel (Int & Ext)Documento394 pagineDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- Design of Pressure Vessel (Int & Ext)Documento394 pagineDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- Sample FLG CalcDocumento6 pagineSample FLG CalcameyyammaiNessuna valutazione finora

- SEISMIC ANALYSIS KazzincDocumento14 pagineSEISMIC ANALYSIS KazzincArees KhambattaNessuna valutazione finora

- Weight Estimation of Vessels AppsDocumento26 pagineWeight Estimation of Vessels Appsdhavalesh1Nessuna valutazione finora

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocumento7 pagineDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocumento7 pagineDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- Pressure vessel design element thickness calculatorDocumento30 paginePressure vessel design element thickness calculatorPeña Eepesa100% (2)

- Cone Design Tool: Pressure Vessel Engineering LTDDocumento1 paginaCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiNessuna valutazione finora

- Xcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseDocumento2 pagineXcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseayushNessuna valutazione finora

- Shell Thickness CalcDocumento1 paginaShell Thickness CalcDidi KurniadiNessuna valutazione finora

- Tank Volume CalculationDocumento9 pagineTank Volume CalculationMangesh MandgeNessuna valutazione finora

- Training ManualDocumento55 pagineTraining ManuallaxmikantNessuna valutazione finora

- Nozzle and ReinforcementDocumento23 pagineNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Nozzle Check Top Head: Input ParametersDocumento2 pagineNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- Engineering Design Guideline Storage Tank Rev 2Documento8 pagineEngineering Design Guideline Storage Tank Rev 2CaptainToniesNessuna valutazione finora

- Half Coil For VersselDocumento1 paginaHalf Coil For VersselhuangjlNessuna valutazione finora

- External Pressure DesignDocumento395 pagineExternal Pressure DesignrsubramaniNessuna valutazione finora

- External Pressure DesignDocumento395 pagineExternal Pressure DesignrsubramaniNessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolSudjono BroNessuna valutazione finora

- Heat Exchanger DesignDocumento7 pagineHeat Exchanger Designsiva sankarNessuna valutazione finora

- Output Summary: SI UnitsDocumento42 pagineOutput Summary: SI UnitsAkhil JoseNessuna valutazione finora

- Vessel Nozzle Load DefinitionsDocumento2 pagineVessel Nozzle Load DefinitionsrsubramaniNessuna valutazione finora

- Skirt Support Analysis Per en 13445Documento13 pagineSkirt Support Analysis Per en 13445karthik1amarNessuna valutazione finora

- Lifting Lug Calculation For Small Horizontal VesselDocumento2 pagineLifting Lug Calculation For Small Horizontal VesselshaishavNessuna valutazione finora

- Large Horizontal Vessel Supported by Two Saddles Stress AnalysisDocumento7 pagineLarge Horizontal Vessel Supported by Two Saddles Stress AnalysisSiva baalanNessuna valutazione finora

- Design Calculations For Pressure ShellDocumento33 pagineDesign Calculations For Pressure ShellGeorge GeorgianNessuna valutazione finora

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocumento12 pagineMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00Nessuna valutazione finora

- Finite Element Analysis and ASME Code Calculations for Pressure VesselsDocumento2 pagineFinite Element Analysis and ASME Code Calculations for Pressure Vesselsnaveen_86Nessuna valutazione finora

- Vessel DatasheetDocumento1 paginaVessel Datasheetsdrtfg100% (1)

- Agitator Vessel Design CostingDocumento20 pagineAgitator Vessel Design CostingneelNessuna valutazione finora

- 8KL FERMENTER DESIGN CALCULATIONSDocumento3 pagine8KL FERMENTER DESIGN CALCULATIONSkirandas_mullasseryNessuna valutazione finora

- Superheated Steam Condensate TankDocumento4 pagineSuperheated Steam Condensate TankGanesh BhardwajNessuna valutazione finora

- Burner specification document summaryDocumento6 pagineBurner specification document summaryHafiz Muhammad AbubakarNessuna valutazione finora

- Hemispherical Head Design ToolDocumento1 paginaHemispherical Head Design ToolBanamali NaskarNessuna valutazione finora

- Saddle Calc PD5500Documento4 pagineSaddle Calc PD5500rsubramaniNessuna valutazione finora

- Pipe Shell Design ToolDocumento1 paginaPipe Shell Design Toolep_alfiNessuna valutazione finora

- Pipe Shell Design ToolDocumento1 paginaPipe Shell Design Toolep_alfiNessuna valutazione finora

- Saddle CalculationDocumento10 pagineSaddle Calculationpharis_chrisNessuna valutazione finora

- Vessel Weight CheckDocumento8 pagineVessel Weight ChecknileshNessuna valutazione finora

- Acum#2 RoladoDocumento1 paginaAcum#2 RoladoJuan PabloNessuna valutazione finora

- TD HE THE v2020.00Documento43 pagineTD HE THE v2020.00Claudia BonocoreNessuna valutazione finora

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocumento30 pagineJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- Vessel Volume CalculationDocumento2 pagineVessel Volume CalculationDhia Slama100% (1)

- Volume Calculation For Pressure Vessel TankDocumento2 pagineVolume Calculation For Pressure Vessel Tanksai srikarNessuna valutazione finora

- Vdocuments - MX Rectangular Tank CalculationDocumento34 pagineVdocuments - MX Rectangular Tank CalculationAtilla TekinNessuna valutazione finora

- TubesheetDocumento8 pagineTubesheetVaibhavNessuna valutazione finora

- 300 - F&D Head Design Tool Ver E4.01Documento1 pagina300 - F&D Head Design Tool Ver E4.01Honey TiwariNessuna valutazione finora

- Elliptical Head DesignDocumento1 paginaElliptical Head Designrodriguez.gaytanNessuna valutazione finora

- Control Valve Sizing - EnggcyclopediaDocumento4 pagineControl Valve Sizing - EnggcyclopediaazitaggNessuna valutazione finora

- Deaera DesignDocumento13 pagineDeaera DesignBhanu K PrakashNessuna valutazione finora

- U-V-673 - Manual Flange and GussetDocumento8 pagineU-V-673 - Manual Flange and GussetDarshan PanchalNessuna valutazione finora

- Branch Reinforcement Pad Requirement CalculationDocumento2 pagineBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Finite Element Analysis and ASME Code CalculationsDocumento1 paginaFinite Element Analysis and ASME Code CalculationsJoshua RiveraNessuna valutazione finora

- Gasket Dimension (ASME B16.5 & B16.47)Documento4 pagineGasket Dimension (ASME B16.5 & B16.47)amaNessuna valutazione finora

- Nozzle ReinforcementDocumento8 pagineNozzle ReinforcementHafizi HZnumismatic0% (1)

- Nozzle ReinforcementDocumento8 pagineNozzle ReinforcementHafizi HZnumismatic0% (1)

- Pump (English) TemplateDocumento1 paginaPump (English) TemplateMichael HaiseNessuna valutazione finora

- Half Pipe Coil AgitatedDocumento1 paginaHalf Pipe Coil AgitatedNITINNessuna valutazione finora

- Asme Viii Uhx Tubesheet CalcsDocumento3 pagineAsme Viii Uhx Tubesheet CalcsjdfdfererNessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolssierroNessuna valutazione finora

- Heat ExchangerDocumento11 pagineHeat ExchangerMangesh MandgeNessuna valutazione finora

- 7 PDFDocumento26 pagine7 PDFargaNessuna valutazione finora

- Cone CalculationDocumento4 pagineCone CalculationAkshat JainNessuna valutazione finora

- 297 - Pipe and Shell Design Tool Ver E4.01Documento1 pagina297 - Pipe and Shell Design Tool Ver E4.01Roshan VardeNessuna valutazione finora

- Finite Element Analysis and ASME Code Calculations for Straight PipeDocumento1 paginaFinite Element Analysis and ASME Code Calculations for Straight PipeLino GabrielNessuna valutazione finora

- Diseño Del Cuerpo de Un RecipienteDocumento1 paginaDiseño Del Cuerpo de Un RecipientepedroluischoqueNessuna valutazione finora

- Cone Design ToolDocumento1 paginaCone Design ToolLuhur PrandikaNessuna valutazione finora

- Cone Design Tool: Pressure Vessel Engineering LTDDocumento1 paginaCone Design Tool: Pressure Vessel Engineering LTDrina2393Nessuna valutazione finora

- 297 - Pipe and Shell Design Tool Ver E4.01 MMDocumento1 pagina297 - Pipe and Shell Design Tool Ver E4.01 MMBAHADIRNessuna valutazione finora

- 191201-140 Calculation of Lengths For HDPE SheathingDocumento9 pagine191201-140 Calculation of Lengths For HDPE Sheathingmonu yadavNessuna valutazione finora

- Hemispherical Head Design ToolDocumento1 paginaHemispherical Head Design Toolzota_alex01Nessuna valutazione finora

- 11 Mat Sel SoftwareDocumento22 pagine11 Mat Sel Softwareep_alfiNessuna valutazione finora

- 298 - Cone Design Tool Ver E4.01Documento1 pagina298 - Cone Design Tool Ver E4.01namasralNessuna valutazione finora

- ASME B31 3 Calculator V2Documento9 pagineASME B31 3 Calculator V2ep_alfiNessuna valutazione finora

- Piping List - OrdinaryDocumento1 paginaPiping List - Ordinaryep_alfiNessuna valutazione finora

- Storage Tank Design GuidelinesDocumento6 pagineStorage Tank Design GuidelinespaaryNessuna valutazione finora

- Piping List - ExtraordinaryDocumento6 paginePiping List - Extraordinaryep_alfiNessuna valutazione finora

- Storage Tank Design GuidelinesDocumento6 pagineStorage Tank Design GuidelinespaaryNessuna valutazione finora

- Mechanical List RFP OI 438Documento2 pagineMechanical List RFP OI 438ep_alfiNessuna valutazione finora