Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Us 50102

Caricato da

asdfasfCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Us 50102

Caricato da

asdfasfCopyright:

Formati disponibili

UNITED STATES PATENT OFFICE.

JOHN H.DOOLITTLE, 0F ANSONIA, CONNECTICUT.

MODE OF MAKING CLASPS FOR HOOP-SKIRTS.

Specification forming part of Letters Patent No. 50,102, dated September 96, 1865y

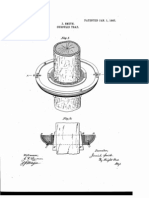

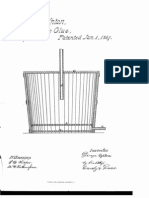

cut to properly leave the die. Fig. 9 is a de Be it known that I, J . H. DooLrrrLE, of tail perspective of the sustaining-plate. Fig. Ansonia, of the county of New Haven, in the l0 is a plan of the continuous strip of blanks. State of Connecticn t, have invented a new Fig. 1l is a perspective view of a clasp formed Method of Making Clasps from Sheet Metal for of one of the blanks seen at Fig. 10; and Fig. Hoop-Skirts, Src.; an d I do hereby declare that 12 is a plan ofthe strip of material from which the following is a full and exact description clasps are'manufactured, illustrating the thereof, reference being had to the accompany the mode ofcutting the strip of blanks from a strip ing drawings, making part of this a-pplication. of stock, as will be presently fully explained. My invention relates to certain new and use In the drawings I have fully shown not only ful improvements in the method of making me the method of working up the stock, but also,

To all whom it may concern :

these ends myinvention consists in cutting from a strip of material (from which the clasps are made) a continuous strip of blanks,which passes on through suitable dies, by which the blanks are separated, formed up complete., and

and has for its objects to manufacture such parts of said machinery have no direct con clasps more rapidly and with less waste stock nection with the invention sought to be covered than they have been heretofore made ; and to in this applica-tion. They will therefore not be

tallic clasps for hoop-skirts and other purposes, in detail, the machinery employed; but many

comprehend my invention and use it, I will H and I are two stands, in which are mount proceed to describe the mode in which I have ed,in suitable bearings, four shafts, 7 8 9 10, most successfully practiced it, referring by let carrying on their front outer ends four rotat ters and figures to the accompanying draw ing circular dies or die-rolls, a b o d, between ings,forming part of this application, and illus the faces of which the metallic sheet is fed, as tratin g the machinery by whichI have worked will be presently explained. The shafts 7 and

my said invention. _

of scrap is discharged from the clasp-forming illustrated in the drawings as carrying out the mechanism and the remaining stock is reeled invention herein claimed. for reuse, as hereinafter more fully explained; A is the bed-plate; B, the supporting-frame and my invention further consists in forming or legs of the machine. A short distance above the continuous strip or the series of united the bed-plate A, and supported by it, is ar blanks in such manner that they may be sepa ranged a work-table, J,which is supported by rated and formed up without the makin got' any four colunms,T, and on which are arranged an scrap in said operation of separating and form adjustable stop and guide plate, Z, and a re ing up, as will be hereinafter more fully ex taining spring-pressure roll, m, for guiding and plained. ~ retaining the strip of metal which may be fed To enable those skilled iu the art to fully into the mechanism for forming the clasps.

discharged, while at the same time the strip the construction and operation of the machine

particularly described here, but will be found more minutely explained in another applica tion led simultaneously with this, in which I claim. the improvements in the said machinery. I will in this specification explain briefly

In the drawings, Figure l is a front eleva tion of an improved machine for making clasps

upon my new method. Fig. 2 is an end eleva tion of the same. Fig. 3 is a horizontal sec

8 are geared together in the manner illustrat ed at Fig. 6, and the shafts 9 and l0 are geared together in like manner, and the two lower shafts, 8 and l0, are driven through the me

for causing the stock from which the blanks are K K, from the work-table J, and carries a reel,

at Fig. 7, together with the sustaining-plate sleeve M, which is sustained by two columns,

dium of gears Q R on their back ends mesh tion at y y, Fig. ]. Fig. 4 is a vert-ical section ing into the driving-pinion P on the main driv at z z, Fig. 2. Fig. 5 is a vertical section at ing-shaft C, said shaft C being provided with new, Fig. 2. Fig. 6 is a detail perspective view, a fast and loose pulley, D andE, on which the showing particularly the device for effecting driving-belt runs. the perfect working of the rotary dies driven l The pulley F is for the purpose of drivinga by gearing. Fig. 7 is a detail sectional view hanger-pulley, from which a belt extends down at the line & St, Fig. 2, increased scale. Fig.8 to the pulley G of the rcel-shaft Z. This reel is a top view of one of the lower dies shown shaft is mounted in suitable bearings in the

50,102

L, on which the strip of stock passed through discharged through chute It, (see Fig. 1,) the part 2 being carried up outside of the chute It, the rotarydies is wound.

and the operation of dividing or cutting it up, is the strip of blanks,) passing through the con

In Figs. l and 2 I have illustrated the strip of metal from which the clasps are foi med,

and between it and the deflector a3, to the reel

L, (see Fig.1,) and the central portion, 1, (which

by red lines, the line numbered l representing ductor 1 , and thence through the dies c d, by

the portion of stock formed into blanks for Whichlatter dies said strip of blanks-is cut up making the clasps, that numbered (two) 2 the at the points through which the red lines pass remaining stock, which is rewound on reel L, at Fig. 10, and formed up into clasps such as and that numbered 3 the strip of scrap, which shown at Fig. 1l. The operation of the dies

discharged.

is discharged from the machine at the e1 dop on the strip of stock is clearly illustrated at posite to that where the iinished clasps are Figs. 7, 1_, and 2. After the whole length of

vot' the bed A,)and a connecting-link, O, in moved to reel N and the end again fed into the such manner that the stand I may be moved machine, when the dies go through a repeti toward or from the stand H by means ot' its tion of the operation just described. cutting adjusting-screws e and f, while at the same ofi' another strip ol' blanks and forming them

time the pinion P will remain always in gearv with the gears l? and Q, whoseshafts are hung separately in the two stands thus moved t0 ward and from each other. The stopping and starting ot' theniachine are

a curved slot, a2, (two slots, one on each side on >the rcel L, the strip of stock on reel L is re

the strip of stock has been passed through the ' The driving-shaft G is hung in bearings in machine,the surplus stock having been Wound

into clasps, discharging another strip of scrap, -

and rewindiug the surplus stock on reel L; and

so ou, the operation is repeated until the whole ofthe stock; has been made into clasps. It will be seen that by the mode of operation

eli'ected, at the pleasure of thc operator, by an described the manufacture of clasps and other ordinary shipper for shifting the driving-belt similar articles (the dies, Sto., being made read from pulley D to E, and vice versa. The bar ily to suit various-shaped articles) from sheet

y dies c b and c d in line in the direction of the simply separated or out apart on aline they are \ in condition to constitute a perfect clasp (such Q . e ofthe stock through them. The object of the adjustment ofthe stand I as shown at Fi g. 11) without any scrap or waste

of this shipper is partially shown in the draw stock by rotary dies is rendered very rapid and ings (at Figs. l and 2) at b3, and its handle at economical; and it will also be observed that n. The stand H is adj ustablc crosswisefot' the the strip of blanks (see Fig. 10) is such (the bed A, for the purpose setting the two sets ot' blanks being connected at their ends) that when

from and toward H, as just before explained, of the strip of blanks; and it will be under

clasps-different kind of work. y is a bridge or conductor, through which

is to vary the distance between the two sets stood that this peculiar feature ot' my inven of dies a. I) and c d for different lengths of tion may be employed in forming a strip of

blanks to' make other shaped clasps than that shown. It will be understood that the invention de the strip of blanks passes from the iirst set of scribed and claimed in this applicationis inde dies to the next. l It is acurved conduit or chute, through which pendent of the peculiar machine described, the strip ot" scrap passes off from the first set and rests in the mode of operation of manufac

of dies.

N is areel, which may be located at any con

turing` the clasps from-a strip' of stock, though

venient distance from the machine in any prop er manner, and from which the stri) of stock is

the machine I have shown and described I am now successfully working, and it turns out

twentytwo hundred and fifty clasps per minute. Having fully explained the nature ot' my in fed to the machine for-making the clasps. l vention and the mode ofcarrying out the same, The general operation of the machine will be understood from a few words ofexplanation. which I have successfully practiced, what I The reelNbeing piled with acontiuuous strip of claim as new, and desire to secure by Letters Patent, is. sheet metal ofany desired width and length 1. Forming the clasps orothersimilar articles sayten to twenty feetlong and sixinches wide thc operator, hayingproperly adjusted the ma by means of asuccession of sets of rotary dies,

chine for the kind ot' work to be done, passes when the strip of stock fed to the dies is di the strip along on the table J with one edge vided into several parts, in the manner sub against the face ofthe adjustable stop or guide stantially as hereinbet'ore described. 2. Forming blanks of sheet metal by one set bar l, (see Fig. 2,) the other edge receiving a pressure from the grooved wheel m, to keep it of rotary dies and close together, substantially against the said bar l, and enters the end of the as described, so that in their subsequent sepa said strip of stock between the first set, a b, of ration and forming up no stock is wasted. In testimony whereof I have hereunto set dies and sets the machine in motion. As the strip of stock is drawn through the diese I) it is my hand and affixed my seal.~ JOHN H. DOOLITTLE. [L.s.] divided into three parts, as illustrated at Fig. 12 In presence of by the portions colored blue and red and that

left white, the red portion or part 3 being the

scrap, which is detlected from the die c and

M. DE LACY, Taos. WALLACE, Jr.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Us 60951Documento2 pagineUs 60951asdfasfNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- H. K. Smith.: No. 60,950. Y. Patented Jan. L, 1867Documento3 pagineH. K. Smith.: No. 60,950. Y. Patented Jan. L, 1867asdfasfNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- @értitrh .. Tstrs Gaunt @ffirn.: Amor Smith, 0F Cincinnati, OhioDocumento1 pagina@értitrh .. Tstrs Gaunt @ffirn.: Amor Smith, 0F Cincinnati, OhioasdfasfNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Patented Jan. 1, I867 V: Z. SperryDocumento3 paginePatented Jan. 1, I867 V: Z. SperryasdfasfNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Us 60945Documento2 pagineUs 60945asdfasfNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Us 60949Documento3 pagineUs 60949asdfasfNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- N. Puckett. - : Centering ToolDocumento2 pagineN. Puckett. - : Centering ToolasdfasfNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Nit2h Giant Gaunt @F?SR.: IMPROVEMENT M Rsrsnsvme BUTTER, MEAT 6mDocumento1 paginaNit2h Giant Gaunt @F?SR.: IMPROVEMENT M Rsrsnsvme BUTTER, MEAT 6masdfasfNessuna valutazione finora

- Gems "Tetra GM": Ffinr.: John '1 . Sohenck, JR, or ' Matteawan, New YorkDocumento1 paginaGems "Tetra GM": Ffinr.: John '1 . Sohenck, JR, or ' Matteawan, New YorkasdfasfNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Making Eyelets'.: L. RichardsDocumento3 pagineMaking Eyelets'.: L. RichardsasdfasfNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Nitrii Tetra Gaunt Ffirr.: Adolphe Roque, of Brire, France, Assignor To Jacques Guedin, ofDocumento1 paginaNitrii Tetra Gaunt Ffirr.: Adolphe Roque, of Brire, France, Assignor To Jacques Guedin, ofasdfasfNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Nitrh Tatte-Lgaunt @ffirt.: Simon Stevens, On New York, N. YDocumento1 paginaNitrh Tatte-Lgaunt @ffirt.: Simon Stevens, On New York, N. YasdfasfNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Refrigerator.: 2 Sheets Sheet 1.' C. F. Pike"Documento5 pagineRefrigerator.: 2 Sheets Sheet 1.' C. F. Pike"asdfasfNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- No. 60,932. - Patented Jan: 1, "1867.: S. J . PEETDocumento2 pagineNo. 60,932. - Patented Jan: 1, "1867.: S. J . PEETasdfasfNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- No. 60,930. Patented Jan. 1, 1867.:: LllliiilitillllllDocumento2 pagineNo. 60,930. Patented Jan. 1, 1867.:: LllliiilitillllllasdfasfNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- F. F. Reynolds.: No. 60,938. ' Patented Jan. Ì, - 867Documento2 pagineF. F. Reynolds.: No. 60,938. ' Patented Jan. Ì, - 867asdfasfNessuna valutazione finora

- Guivt?h Gist" Gamut @F?M: Richard B. Stevenson, F-York Township, OhioDocumento1 paginaGuivt?h Gist" Gamut @F?M: Richard B. Stevenson, F-York Township, OhioasdfasfNessuna valutazione finora

- No. 60,958. Patented Jan. I, 1867.: H. C. Stewart. Glue PotDocumento2 pagineNo. 60,958. Patented Jan. I, 1867.: H. C. Stewart. Glue PotasdfasfNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Guitar Girders Gaunt @ffirr: Frank W. Sterry, of Morrisania, New YorkDocumento1 paginaGuitar Girders Gaunt @ffirr: Frank W. Sterry, of Morrisania, New YorkasdfasfNessuna valutazione finora

- Blanking Box Holder.: .G. W. TaylorDocumento2 pagineBlanking Box Holder.: .G. W. TaylorasdfasfNessuna valutazione finora

- TTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTT A DDocumento2 pagineTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTTT A DasdfasfNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- MSDS - SpaDocumento6 pagineMSDS - SpaChing ching FongNessuna valutazione finora

- Pearson Type IV Characteristic Function 1196285389Documento9 paginePearson Type IV Characteristic Function 1196285389peppas4643Nessuna valutazione finora

- The Power Rule and Other Rules For DifferentiationDocumento23 pagineThe Power Rule and Other Rules For DifferentiationAngel EngbinoNessuna valutazione finora

- UNIT-I Impact of Jet On VanesDocumento8 pagineUNIT-I Impact of Jet On VanesAjeet Kumar75% (4)

- Training Evaluation Form: Seven Seas HotelDocumento2 pagineTraining Evaluation Form: Seven Seas HotelPiyush SevenseasNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Art in Our Life.Documento2 pagineArt in Our Life.hhNessuna valutazione finora

- Breeding Objectives, Selection Criteria and Breeding System of Indigenous Goat Types in Bale Zone, Oromia, EthiopiaDocumento10 pagineBreeding Objectives, Selection Criteria and Breeding System of Indigenous Goat Types in Bale Zone, Oromia, EthiopiareinpolyNessuna valutazione finora

- Bắc NinhDocumento17 pagineBắc Ninhenfa.work.confNessuna valutazione finora

- Layers - of - The - Atmosphere Final Na GrabeDocumento23 pagineLayers - of - The - Atmosphere Final Na GrabeJustine PamaNessuna valutazione finora

- Effect of Coffee Processing Plant Effluent On The Physicochemical Properties of Receiving Water Bodies, Jimma Zone EthiopiaDocumento8 pagineEffect of Coffee Processing Plant Effluent On The Physicochemical Properties of Receiving Water Bodies, Jimma Zone EthiopiaNigist FekedeNessuna valutazione finora

- Ifc 8thconf 4c4papDocumento29 pagineIfc 8thconf 4c4papgauravpassionNessuna valutazione finora

- ISC Class 12 Maths Important QuestionsDocumento2 pagineISC Class 12 Maths Important QuestionsdhinchakclashersNessuna valutazione finora

- Pengaruh Kelas Lereng Dan Tutupan Lahan Terhadap Solum Tanah, Kedalaman Efektif Akar Dan PH TanahDocumento10 paginePengaruh Kelas Lereng Dan Tutupan Lahan Terhadap Solum Tanah, Kedalaman Efektif Akar Dan PH TanahAPRI YANSYAHNessuna valutazione finora

- DESIGN AND ANALYSIS OF HYDRAULIC POWERPACK AND PUMcalculationsDocumento10 pagineDESIGN AND ANALYSIS OF HYDRAULIC POWERPACK AND PUMcalculationssubhasNessuna valutazione finora

- Memory Research Paper ExampleDocumento8 pagineMemory Research Paper Examplexhzscbbkf100% (1)

- Signed PAN: Erwin Panofsky's (1892-1968) "The History of Art As A Humanistic Discipline" (Princeton, 1938)Documento94 pagineSigned PAN: Erwin Panofsky's (1892-1968) "The History of Art As A Humanistic Discipline" (Princeton, 1938)Adrian Anton MarinNessuna valutazione finora

- Diploma in Mechanical Engineering Colleges in NoidaDocumento3 pagineDiploma in Mechanical Engineering Colleges in NoidaGalgotias UniversityNessuna valutazione finora

- Coulombs LawDocumento8 pagineCoulombs LawDaniel Esteban Pinto ChaparroNessuna valutazione finora

- Earth Subsystem: BiosphereDocumento17 pagineEarth Subsystem: BiosphereRhiza Mae LaxNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Logical Reasoning PDFDocumento224 pagineLogical Reasoning PDFBalu Balaji86% (7)

- Popular Horoscopes and The "Barnum Effect" PDFDocumento12 paginePopular Horoscopes and The "Barnum Effect" PDFYilbert Oswaldo Jimenez CanoNessuna valutazione finora

- Creating and Renewing Urban Structures - Tall Buildings, Bridges and InfrastructureDocumento2 pagineCreating and Renewing Urban Structures - Tall Buildings, Bridges and InfrastructureDesign explorer olomizanaNessuna valutazione finora

- Oral Dosage Forms BrochureDocumento20 pagineOral Dosage Forms Brochureselvi aklailia rosaNessuna valutazione finora

- Ultra Mag™ Electromagnetic Flow Meter Submittal PackageDocumento19 pagineUltra Mag™ Electromagnetic Flow Meter Submittal PackageSalvador HernándezNessuna valutazione finora

- Applied Cognitive Psychology - Lecture 1 - Introduction &. Everyday MemoryDocumento69 pagineApplied Cognitive Psychology - Lecture 1 - Introduction &. Everyday MemorybNessuna valutazione finora

- Alt Bar Fri Hun Pat Price Rain Res Type Est Willwait: Example Attributes GoalDocumento19 pagineAlt Bar Fri Hun Pat Price Rain Res Type Est Willwait: Example Attributes GoalSan JongNessuna valutazione finora

- Executive MBA BrochureDocumento36 pagineExecutive MBA BrochureAzad AMİROVNessuna valutazione finora

- BSBSUS601 Ass Task 1 - v2.1Documento4 pagineBSBSUS601 Ass Task 1 - v2.1Nupur VermaNessuna valutazione finora

- CBSE Class 10 Light Reflection and Refraction Study NotesDocumento19 pagineCBSE Class 10 Light Reflection and Refraction Study NotesKanchana SriramuluNessuna valutazione finora

- 2019jahh 22 447GDocumento12 pagine2019jahh 22 447GTomi DwiNessuna valutazione finora

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiDa EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiValutazione: 4 su 5 stelle4/5 (3)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeDa EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeValutazione: 5 su 5 stelle5/5 (2)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsDa EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNessuna valutazione finora

- House Rules: How to Decorate for Every Home, Style, and BudgetDa EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNessuna valutazione finora

- The Martha Manual: How to Do (Almost) EverythingDa EverandThe Martha Manual: How to Do (Almost) EverythingValutazione: 4 su 5 stelle4/5 (11)